| |

|

|

Note:

Clicking on any picture or illustration will open a larger version

of that art.

|

|

Diesel

Fuel Additives |

This information

pertains to 1994-2003 vehicles with 6.5L or 6.6L Diesel Engine (VINs

F, P, S, Y, 1 -- RPOs L65, L49, L56, L57, LB7). (fig. 1)

TIP: The use of diesel fuel additives is not required or recommended

for the 6.5L diesel or the 6.6L Duramax® Diesel engine under normal

conditions. The filtering system is designed to block water and contaminants

without the use of additives. However, some customers may desire to

use fuel additives to improve the characteristics of available diesel

fuels.

Water Emulsifiers and Demulsifiers

Fuel additives must be selected carefully. There are two common methods

that fuel additives use to cope with water in the fuel.

Demulsification causes water particles to combine together to form

larger particles, which drop out of suspension. This allows the fuel

filter/water separator to separate the water from the fuel as it is

designed to.

Emulsification keeps water particles suspended in the fuel. Alcohol

is frequently used as the emulsifier. Emulsification can allow water

to get past the fuel filter/water separator, in most cases causing

damage to the fuel system.

IMPORTANT: Only alcohol-free water demulsifiers should be used in General

Motors Diesel engines. Both Racor® and Stanadyne® diesel fuel

additives are alcohol-free and utilize water demulsifiers to cope with

water in the fuel. Other brands may be available in different areas.

Before using them, be sure they clearly state that they are alcohol-free

demulsifiers.

(We believe these sources and their products to be reliable. General

Motors does not endorse, indicate any preference for or assume any

responsibility for the products from this firm or for any such items,

which may be available from other sources.)

COMMON DIESEL FUEL CONCERNS

Fuel Waxing/Icing

Fuel distributors blend number 1 and number 2 diesel fuels for seasonal

requirements in a particular region. No other blending of fuels is

recommended. However, a customer may desire to use a winter fuel additive

to prevent fuel waxing or icing during extreme cold snaps. If a winter

fuel additive is used, it should not contain alcohol or other water

emulsifiers that may compromise the water removal effectiveness of

the fuel filtering system.

Bacteria and Fungi Growth

Bacteria and fungi growth can occur in diesel fuel when there is water

present, especially during warmer weather. The best prevention against

bacteria and fungi growth is to use clean fuel that is free of water.

There are diesel fuel biocides available to kill bacterial growth in

the fuel system. However, the dead bacteria can cause blockages throughout

the fuel system. If bacterial growth is found in the fuel system, the

proper method of removal is to flush the fuel system using service

manual procedures, replace the fuel filter element, and refill the

tank with clean diesel fuel. If a customer desires to use a biocide

after flushing the fuel system, it should not contain alcohol or other

water emulsifiers.

Low Cetane Number

The cetane number is one indicator of a diesel fuel's ability to ignite.

There are many indicators of overall fuel quality such as cleanliness,

specific gravity, volatility, viscosity, detergency, corrosion inhibiting

abilities, and lubricity. Increasing the cetane number alone is not

a fix for poor quality fuel. Additionally, increasing the cetane number

beyond the engine's requirements will not increase performance. However,

the cetane number of diesel fuel is not always consistent and some

customers may desire to use a cetane improver to ensure full performance

of their engine. If such an additive is to be used, it must not contain

alcohol or other water emulsifiers.

Poor Lubricity

The 6.5L diesel and the 6.6L Duramax® Diesel engines are designed

to operate on today's low sulfur fuel without the use of additives.

A fuel additive designed to increase lubricity is not a fix for poor

quality or contaminated fuel, but some customers may desire to use

a lubricity additive to aid in the longevity of their fuel system components.

If such an additive is to be used, it must not contain alcohol or other

water emulsifiers.

FUEL SOURCE ISSUES

If a vehicle is properly maintained but has fuel contamination issues,

consider obtaining fuel from a different source. Purchasing fuel from

a high volume fuel retailer increases the likelihood that the fuel

is fresh and of good quality.

-

Thanks to Andy Sutherland |

figure

1 |

|

|

|

|

|

|

| Tech 2 Replacement

-- Fact or Fiction? |

Did you hear the one about the

guy who bought the latest high-tech (you fill in the blank) and it was

obsolete before he opened the box?

Or version 7.0 of a hot computer game being released before version 6.0

went on sale?

So, naturally you’re skeptical about the life expectancy of the

Tech 2, right? Your shop could really use an additional one, but you

don’t want to buy something that’s going to be obsoleted

right away. What to do?

Designed for Expansion

When the Tech 2 came out in 1996, it had 10 times the mass storage capacity

of the Tech 1 it replaced, and four times the display space on the screen.

The processor went from 8 bits to 32 bits, so it was considerably faster.

That was then; this is now. Is the Tech 2 able to keep up?

To put your mind at ease, remember that the Tech 2 was designed to

be changeable and expandable, right from the start. This is evidenced

by

the fact that it contains two memory card slots. And the fact that

the 32 MB card was released in December 2001 to replace the previous

10 MB

card. With that one step alone, the Tech 2’s storage capacity

was tripled.

REMINDER: The 32 MB card is the primary card to be used. If you have

not already done so, remove the 10 MB card from your Tech 2. The 10 MB

card has been the source of some communication errors.

With the onset of GMLAN (TechLink, Mar. 2003), the CANdi module now enables

the Tech 2 to communicate with a whole new data protocol. Other such

communication modules may be developed in the future, to extend the useful

life of the Tech 2 even further.

Some of the components used in the manufacture of early Tech 2s are no

longer available. So, tool engineers have found ways of redesigning circuits

for later Tech 2s to use currently available components. These

Tech 2s work exactly as the original did. This extra development work was done

to ensure that the Tech 2 did not become obsolete, as parts supplies

changed.

This kind of refinement is costly, and would not be undertaken if the

Tech 2 were approaching the end of its life.

What’s Coming

Many of the operating features of the original Tech 2 resulted from surveys

of retail technicians. This is an ongoing process. At present, surveys

are being used to gain insight into where the handheld diagnostsic computer

needs to go in the future. Should it be a laptop? Or a PDA? Have wireless

capabilities? Have handwriting recognition?

At present, the Tech 2 replacement isn’t even in spec form yet.

There is a lot of research and development needed before anything like

a “Tech 3” becomes a reality. This won’t be soon, and

when it does happen, it won’t be a surprise. There will be plenty

of advance information and notice before a new tool becomes essential.

Diagnostic tools can have a very long lifespan. In fact, the Tech 1 is

still being sold after 13 years!

Diagnostic technology certainly doesn’t stand still. There’s

always a need and a desire to diagnose it faster and display it better.

Research and development are ongoing. But a significant milestone such

as a Tech 2 replacement is not on the horizon.

What Should You Do?

Remember, the Tech 2 isn’t going to be replaced until a vehicle

operating system comes along that the Tech 2 can’t be made to

talk to. This is not in the foreseeable future.

So, if you need an additional Tech 2, you can purchase it with confidence

that it will remain useful and current for a long time to come. Contact

GM Dealer Equipment at 1.800.GMTOOLS (1.800.468.6657).

-

Thanks to Mark Palmer, John Cicala, Jeff Flood and Mark Stesney |

| |

|

Know-How

Broadcasts for May |

| |

|

| Know-How

Broadcasts for May |

|

Emerging

Issues

|

May

13, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

|

10270.17D

-- 2004 Chevrolet Passenger Cars New Model Features

|

May

29, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

| -

Thanks to Tracy Timmerman |

|

|

|

|

|

Brake

Pipe Flaring Tool

|

GM

has begun installing vinyl-coated double wall brake pipes on some vehicles.

This will eventually spread to other vehicle lines.

The black coating offers additional protection to the metal pipe. However,

it interferes with the flaring process, so it must be stripped from pipes

before flaring can be done.

Some pre-formed brake pipes are available for service replacement. Others

must be fabricated from bulk pipe. If you must fabricate a pipe, or repair

a pipe on a vehicle, you will have to form flares on the ends of the

pipes.

TIP: When installing any brake pipe to the vehicle, be sure to torque

the nuts to the proper specification. Refer to the appropriate SI section

for details.

The Brake Pipe Flaring Set J-45505 contains all of the tools necessary

to cut, strip and flare brake pipe (fig. 2). These tools have been made

as small as practical, to permit them to be used in cramped areas on

the vehicle.

TIP: This flaring set will work with non-coated brake pipes as well.

Refer to the photographs. Instructions are included on a label attached

to the lid of the storage case.

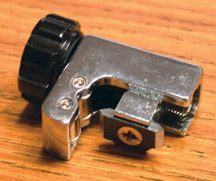

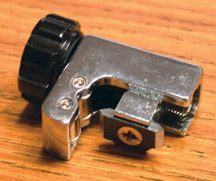

The brake pipe cutter can be adjusted to cut tubing from 1/8-inch to

5/8-inch (3 - 16 mm). (fig. 3)

The stripper is equipped with two guide rollers and an adjustable stripping

blade (fig. 4). Simply insert the pipe between the rollers until it contacts

the stop. This controls the length of coating that is removed. Then snug

the rollers and twist the stripper to remove the vinyl coating (fig.

5).

After cutting, it’s necessary to use the deburring tool to remove

burrs from both the inside and outside of the cut end of the pipe.

Select the appropriate die set and install into the hydraulic hand pump.

Install the proper nut on the pipe. Then insert the pipe into the die

and operate the handle. The hydraulic ram creates the properly shaped

flare with minimal effort.

TIP: Be sure to use the proper die type. Past and present GM vehicles

use either single lap (fig. 6) or double lap flares (fig.

7). Using the

incorrect type can lead to brake system failure.

- Thanks to Rich Staton, Stabilus |

figure

2 |

figure

3 |

figure 4

figure 4 |

figure

5 |

figure

6 |

figure

7 |

| return

to Table of Contents |

| |

| Fuel

Level Sensor |

This

information applies to 2000-2003 Cavalier, Sunfire, Malibu, Alero and

Grand Am with an inaccurate fuel gauge level reading.

If normal diagnostics lead you to replace the fuel level sensor, here

is some late-breaking news.

A new fuel level sensor is manufactured with gold contact surfaces to

provide protection against sulfur and contamination in the fuel.

TIP: The previous sensor/pump module is no longer available.The fuel

level sensor and the fuel pump module are available as separate replacement

parts.

TIP: If you are dealing with an inaccurate gauge condition, install the

sensor. If you are dealing with a fuel system performance condition,

install the fuel pump module.

Details will be given in an upcoming bulletin.

-

Thanks to Steve Oakley

Fuel Level Sensor 22709333 |

Fuel Pump Module (excludes sensor) 88957239 |

|

| |

| |

| return

to Table of Contents |

|

| Blue

Fog Lamps |

The

2003 Limited Edition Grand Prix has special blue fog lamps. The replacement

bulb is different from current Grand Prix lamps (fig.

8). The replacement

bulb has a wire pigtail and is available from GMSPO under AC Delco

part number 11513798.

TIP: It is not necessary to replace the entire fog lamp when the lamp

burns out. Replace only the bulb.

-

Thanks to Fred Tebbets |

figure

8 |

| return

to Table of Contents |

|

| Instrument

Panel Top Pad Gap |

On

2002-03 Impala and Monte Carlo, a gap condition may exist between

the Upper I/P pad to I/P trim plate, which may be objectionable to

a customer (fig.9).

It is possible to correct or improve the appearance of the Upper I/P

pad without replacement. Loosen the attachment screws at or near the

area of the gap and retighten while firmly holding the Upper I/P Pad

down, closing the area of the gap. Repositioning the I/P Upper Pad in

this fashion should eliminate the gap, without requiring the replacement

of the I/P Pad.

-

Thanks to Gary McAdam |

figure

9 |

| |

| |

| return

to Table of Contents |

|

| OnStar

Wake Up Cycle Change |

To create a more streamlined OnStar enrollment process, the vehicle

assembly centers are making a change to the OnStar module wake up

cycle. These will occur according to the schedule in the accompanying

tables.

Remember, in order for OnStar to perform remote functions while the vehicle

is off (door unlock, alerts, theft tracking, etc.) the OnStar module

must wake up at specified intervals and ready itself to receive a call

from the OnStar call center. This wake up cycle is commonly referred

to as DRx (Discontinuous Receive).

Previously, unconfigured OnStar equipped vehicles did not perform this

wake up cycle; the module was always asleep with the ignition off. The

wake up cycle started only after the OnStar system was configured.

Beginning in January of 2003, the following change is being made. Unconfigured

vehicles will wake up every 10 minutes for a period of approximately

1 minute. This wake up cycle starts after each ignition cycle, and ends

after 24 hours. The OnStar module will then return to sleep mode until

the ignition is cycled again. Once the vehicle is configured, the module

will return to the traditional wake up cycle. The vehicle will wake up

1 minute out of every 10 minutes over a 48 hour period following an ignition

cycle.

TIP: Be aware of this change when performing battery parasitic drain

diagnosis.

TIP: The OnStar module can be shut down using the Class 2 Message Monitor

of the Tech 2. This does not affect the DRx cycle; the OnStar module

will still wake up at the scheduled time.

- Thanks to Dale Tripp and Mike Batchik

Models

With Modified Wake-up Cycle beginning Jan. 31, 2003 |

2003 Hummer H2

2003 Saturn ION

2003 Bonneville

2003 Aurora (V8)

2003 Cavalier

2003 Montana

2003 Sunfire

2003 Silhouette

2003 Aztek

2003 Venture

2003 Rendezvous |

2003 LeSabre

2003 Cadillac CTS

2003 Saturn VUE*

2003 Saturn LS/LW*

2003 Monte Carlo*

2003 Impala*

2003 Cadillac DeVille*

2003 Cadillac Seville*

2004 Cadillac SRX*

2004 Cadillac XLR

2004 Grand Prix |

| * Vehicles will be transitioning from Gen 4 OnStar

to Gen 5 OnStar sometime after Jan 31, 2003. The wake up cycle

modification will occur concurrent with this change. |

Models with modified Wake-up Cycle Estimated Dates |

GMC

Savana and Chevrolet Express

Envoy XL, Envoy XUV, Trailblazer EXT

Full-Size Truck (less H2)

Trailblazer, Envoy, Bravada |

Feb.

2003

Feb. 2003

Mar. 2003

Mar. 2003 |

|

| |

| |

|

return

to Table of Contents |

|

| Recent

Essential Tool Shipments |

Several

essential tools were shipped to dealers recently.

J-34730-40 Fuel Pressure Gauge Quick Connect Adapters (fig.

10)

Hummer H1

These adapters are used with the J-29658-D Fuel Pressure Gauge kit and

J-34730-1A Fuel Pressure Gauge and Hose Assembly to test and diagnose

the supply and return fuel systems.

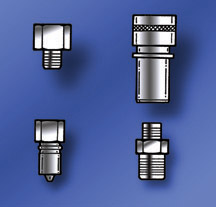

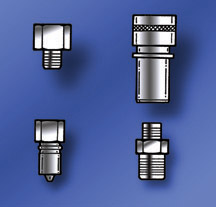

J-45268-115 TXV Adapter (fig. 11)

2004 Grand Prix, Impala, Monte Carlo, SLR, Malibu, Corvette

This adapter is used to replace the TXV when doing an A/C flush with

the ACR2000. The TXV must be removed to allow refrigerant to flow through

the A/C system.

J-46405 Seal Installer (fig. 12)

1997-Current Corvette, XLR

The axle shaft seal has been updated for improved performance. The J-36797

Seal Installer no longer fits. The new installer fits both the new seal

and the first design seal.

- Thanks to Ryan Jankowski |

|

figure

10

|

figure

11 |

figure

12

|

| return

to Table of Contents |

|

| Increased

Steering Effort |

This

condition affects 2003 Chevrolet Cavalier (fig.

13), Pontiac Sunfire,

Grand Am, and Oldsmobile Alero equipped with 2.0 Litre L61 EcoTech

engine (VIN Code F).

A customer may comment on increased steering effort at vehicle start

up on mornings with low ambient temperatures (below 30° F, -2°C).

It may be difficult to confirm this condition, as it may be somewhat

intermittent. Normal testing of the steering system (flow meter, test

drive, etc.) after vehicle warm up may also be inconclusive. The cause

of this condition is a priming issue with the power steering pump. The

problem is not within the steering rack. The correct repair procedure

is to replace the power steering pump.

Delphi Engineering is currently taking steps to identify and resolve

this issue.

- Thanks to Steve Oakley |

|

figure

13 |

| return

to Table of Contents |

|

| Air

Suspension Diagnostic Code |

This

condition may occur on a 2003 Hummer H2 (fig.14) with Electronically

Controlled Air Suspension (ECAS).

While using a Tech 2, if you should encounter a DTC 0660 stored in

history, simply delete the code. This can occur upon a rapid ignition

cycle from ‘accessory’ to ‘crank,’ while

the ECU is performing a self test. A ‘green’ engine causes

a significant voltage drop during initial crank. There is no effect

on the function of the air suspension and will not be cause for concern

for a customer.

TIP: The code will disappear on its own after 100 key cycles and should

not reset.

-

Thanks to Terry Nicholas |

figure

14 |

|

return

to Table of Contents |

|

| Delphi

P04 PCM |

The

Delphi P04 Powertrain Control Module (PCM) may set both 5-volt reference

DTCs simultaneously during a specific failure condition. Depending

on the vehicle platform, these are DTCs P1635/1639 or P0641/0651.

The failure condition resulting in both 5-volt reference codes being

set occurs when the Intake Air Temperature (IAT) sensor signal circuit

is shorted to battery voltage during start-up. The most likely failure

will be an IAT sensor signal circuit that is shorted to a switched ignition

voltage circuit. When the PCM circuitry is exposed to this high voltage,

a miscalculation may occur in the analog-to-digital (A/D) counts, used

in the PCM software. If this miscalculation exceeds a calibrated threshold,

the PCM may set both P1635/1639 or P0641/0651.

To correct this condition, test the IAT sensor signal circuit for a short

to voltage and repair as necessary. Be sure to verify that the IAT sensor

itself has not been damaged. Correct and repair any other DTCs or faults

that may be present. There has not been any reported damage to PCMs as

a result of this failure.

Use the table to determine which vehicle platform/engine combinations

are using the P04 PCM:

-

Thanks to Jim Hanna

|

1998 |

1999 |

2000 |

2001 |

2002 |

2003 |

Park

Avenue |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

LeSabre |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

Firebird |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

Camaro |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

Impala |

–– |

–– |

|

3.4

/ 3.8L |

3.4

/ 3.8L |

|

Monte

Carlo |

3.1

/ 3.8L |

3.1

/ 3.8L |

3.4

/ 3.8L |

3.4

/ 3.8L |

3.4

/ 3.8L |

3.4

/ 3.8L |

Lumina |

3.1

/ 3.8L |

3.1

/ 3.8L |

3.1L |

3.1L |

3.1L |

3.1L |

Grand

Prix |

3.1

/ 3.8L |

3.1

/ 3.8L |

3.1

/ 3.8L |

3.1

/ 3.8L |

3.1

/ 3.8L |

3.1

/ 3.8L |

Grand

Am |

3.1L |

3.4L |

3.4L |

3.4L |

3.4L |

3.4L |

Bonneville |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

Alero |

– |

3.4L |

3.4L |

3.4L |

3.4L |

3.4L |

Malibu |

3.1L |

3.1L |

3.1L |

3.1L |

3.1L |

3.1L |

Regal |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

3.8L |

Century |

3.1L |

3.1L |

3.1L |

3.1L |

3.1L |

3.1L |

Venture |

3.4L |

3.4L |

3.4L |

3.4L |

3.4L |

3.4L |

Silhouette |

3.4L |

3.4L |

3.4L |

3.4L |

3.4L |

3.4L |

Transport |

3.4L |

3.4L |

– |

– |

– |

– |

Montana |

– |

– |

3.4L |

3.4L |

3.4L |

3.4L |

Eighty-Eight/LSS |

3.8L |

3.8L |

– |

– |

– |

– |

Riviera |

3.8L |

3.8L |

– |

– |

– |

– |

Intrigue |

3.8L |

3.5

/ 3.8L |

3.5L |

3.5L |

– |

– |

Rendezvous |

– |

– |

– |

– |

3.4L |

3.4L |

Aztek |

– |

– |

– |

3.4L |

3.4L |

3.4L |

Achieva |

3.1L |

– |

– |

– |

– |

– |

Cutlass |

3.1L |

3.1L |

– |

– |

– |

– |

Skylark |

3.1L |

– |

– |

– |

– |

– |

|

| |

| |

| return

to Table of Contents |

|

| Chemical

Damage To Polycarbonate Headlamp Lenses |

This

information applies to 2003 and prior passenger cars and trucks and

2003 Hummer H2. Refer to bulletin 02-08-42-001.

Most late model vehicles have polycarbonate headlamp lenses. This material

is used because of its temperature and high impact resistance.

A variety of chemicals can cause crazing or cracking of the headlamp

lens. Headlamp lenses are very sensitive. Exercise care to avoid contact

with all exterior headlamp lenses when treating a vehicle with any type

of chemical, such as those recommended for rail dust removal. Rubbing

compound and cleaner waxes may also attribute to this condition. This

could result in the need to replace the entire headlamp housing.

Also, crazing or deformations of the lens may occur if a shop mat or

fender cover is draped over the fender and covers a portion or all of

the headlamp assembly while the DLR or headlamps are on. This action

restricts the amount of heat dissipated by the headlamps.

Once heat buildup is generated by the headlamp, a degradation of the

headlamp lens begins. This degradation of the lens can be unnoticeable

at first and eventually show up as spider cracks. In more extreme cases,

it will begin to melt the lens of the headlamp.

-

Thanks to Bob Broughton and Katie Callahan |

| |

| |

| return

to Table of Contents |

|

| Splice

Corrosion |

Owners

of some 2003 Pontiac Sunfires may comment that the left headlamp is

dim, the high beam indicator is on, and the SVS lamp may be illuminated.

The Tech 2 scan tool may reveal a code B2601. Some customers may also

comment on the left or right fog lamp appearing dim or not illuminating.

The forward electrical harness has splices that may be inadequately sealed

from corrosive elements. Road splash, especially during winter months

may force water into the harness causing increased resistance and eventual

separation of the splices.

Locating the Affected Splices

TIP: You may be able to locate the affected splices visually before removing

the electrical tape wrap. A green mark or spot may have leeched out through

the tape leaving a visual indicator of where to begin removing the tape

(fig. 15). Carefully cut and remove the electrical tape wrapping the

wire harness.

In the case of dim high beam, investigate splice 107 (pink) and splice

108 (dark blue) for corrosion (fig. 16). These splices are located next

to the windshield wiper reservoir and are associated with circuit 593.

High resistance in these splices can cause the driver side headlamp to

dim.

TIP: Splice number 118 (light blue) is located in very close proximity

to the other splices, and is protected in the same manner. This splice

involves the left front turn signal circuit on the vehicle. It is recommended

that it be repaired and protected at the same time.

In the case of dim fog lamps, investigate splice 213 (purple) and splice

113 (orange).

IMPORTANT: In the same area as the orange and purple splices but more

toward the driver’s side, you will find a black wire splice. Inspect

this splice for signs of corrosion. Do not cut into or in any way disturb

this splice unless you see visual signs of corrosion. If evidence of

corrosion is found, re-splice the connection in the same manner as the

other wires.

Repair Procedure

Strip back the wires until clean non-corroded wire is available.

Resplice the wires, using GM crinp and seal connectors P/N 12089189 only.

These connectors are equipped with an internally knurled crimp joint

and heat shrink tubes.

Insert the bare wires fully into the body of the connector. Using the

J-38125-8 crimping tool, fully crimp the body of the connector.

Using the J-38125-5 Ultra Torch from your J-38125-C Terminal Repair Kit,

progressively heat the connector by waving the torch quickly over both

the plastic shrink tube (to activate it) and body of the connector to

get the internal sealant to flow.

Cut a 3M® Electrical Moisture Sealant Patch in half. Apply the patch

to the splice as indicated on the package.

Refer to an upcoming bulletin for further details.

-

Thanks to Steve Oakley |

figure

15 |

figure

16 |

| |

| return

to Table of Contents |

|

| Neutral

Start Backup Switch |

Some

2001-2003 Sierra and Silverado trucks equipped with Allison Series

1000 Automatic Transmission (M74) may have multiple DTCs including

any or all of the following: P0708, P0847, P0872, P0875, P1711, P1713;

partial or no PRNDL display; and no movement.

This condition may be caused by water contamination and corrosion inside

the NSBU (Neutral Start Backup switch) located on the side of the transmission.

Install a new NSBU, P/N 29540479 that has better sealing to resist internal

corrosion (fig. 17). Replacement procedures can be found in SI document

652003. Adjustment procedures can be found in SI document 652060.

When replacing this switch, observe these important points.

First, if the NSBU does not easily slide off the selector shaft, use

a file to remove any burrs or raised metal where the selector lever seats

against the shoulder of the shaft. If the new NSBU is forced over this

raised metal, it may fit the shaft loosely, causing possible repeat DTCs.

Second, be sure to install the splash shield that is included with the

NSBU kit (fig. 18). This shield is installed over the manual shaft before

the shift lever and nut are installed. Failure to install this shield

may result in repeat switch contamination.

Finally, before starting the vehicle, be sure to clear all DTCs.

-

Thanks to Mark Gordon

|

figure

17 |

figure

18 |

| return

to Table of Contents |

|

| Exhaust

Boom or Vibration |

Vehicles

with the 4.2L L6 engine may exhibit a boom or vibration coming from

the exhaust, at or near idle.

The following may help reduce the vibration. Unbolt the downpipe from

the exhaust manifold outlet and replace the donut seal. When you tighten

the downpipe to the manifold, have a second technician hold the rear

end of the downpipe so the two exhaust hangers stay centered in the rubber

bushing holes. Keeping the rods centered in the bushing holes makes a

noticeable improvement.

-

Thanks to GM Technical Assistance |

| |

| return

to Table of Contents |

|

| Vehicle

Customization or Personalization Inoperative |

On

2003 Buick Rendezvous and Pontiac Aztek, the Body Control Module (BCM)

was revised to accommodate vehicle system changes. Because of memory

capacity, on vehicles without Driver Information Center (DIC), certain

customization options had to be deleted.

Vehicles with DIC retained customization of some features controlled

by the BCM, depending on vehicle options.

These decisions were made after final editing of Owner’s Manuals

and Service Manuals, so the Owner’s Manual contains customization

information pertaining to earlier models.

Service replacement BCMs contain the revised programming and supercede

previous BCM part numbers.

IMPORTANT: If the original BCM is

replaced in past model year vehicles, previously available customization

features

will be lost.

-

Thanks to GM Technical Assistance

|

| return

to Table of Contents |

|

| Bulletins – MARCH,

2003

This review

of service bulletins released through mid-March lists the bulletin

number, superseded bulletin number (if applicable), subject and models. |

00 – General

Information

03-00-89-001; Paint Code Corrections; 2003 Chevrolet Suburban, Tahoe,

GMC Yukon, XL

03-00-89-002; New Owner Orientation Clinic Materials Now Available Online;

2003 and Prior Passenger Cars, Trucks, Hummer H2

03-00-89-003; GM Goodwrench Limited Lifetime Service Guarantee; 2003

and Prior Passenger Cars, LD Trucks and Hummer H2

02 – Steering

00-02-35-003B; replaces 00-02-35-003; Clunking Noise Under Hood and Can

Be Felt in Steering Wheel (Lubricate Intermediate Steering Shaft Assembly);

specified 1999-2003 Chevrolet, GMC, Cadillac and Hummer H2 Vehicles with

Recirculating Ball Steering

03-02-35-001; Noise/Clunk from Steering Column (Replace Upper Intermediate

Shaft); 2003 Cadillac CTS

03-02-35-002; Minor Scratches to Wood Stering Wheels (Refinish); 2000-03

Cadillac DeVille, Escalade, Seville, CTS with Wood Steering Wheels

03 – Suspension

99-03-10-009A; replaces 99-03-10-009; Wheel Balance Weight Usage; specified

1999-2003 Chevrolet, GMC, Cadillac and Hummer H2 Vehicles

03-03-09-001; Rear of Vehicle Appears to Sit Low, Low D Trim Height Measurement

(Replace Rear Coil Springs); 2003 Chevrolet Tahoe with Off-Road Chassis

Package (RPO Z71), 3rd Row Seat (RPO AS3), and Off-Road Appearance Package

(RPO BHP)

03-03-10-002; Use of Correct Installation Procedure for Loose Hubcab

Assembly; specified 1998-2003 Chevrolet and GMC Trucks

04 – Driveline Axle

03-04-17-001; Whine Noise from Rear Axle (Diagnose and Replace Rear Shaft

with a Tuned Torsional Damper Rear Propeller Shaft); 2002-03 Cadillac

Escalade EXT, Chevrolet Suburban, Avalanche, GMC Yukon XL, Denali

03-04-20-001; Revised Rear Axle Assemble Procedure and Special Tools;

1997-2003 Chevrolet Corvette

03-04-20-002; Revised Output Shaft Seal Replacement Procedure; 1997-2003

Chevrolet Corvette

05 – Brakes

02-05-26-002A; replaces 02-05-26-002; Scraping Noise from Rear of Vehicle

(Replace Parking Brake Shoe Kit and Clean Drum in Hat Rotor); specified

1999-2003 Cadillac, Chevrolet and GMC Trucks

03-05-23-001; Brake Pulsation/Vibration, Contamination/Corrosion Between

Hub and Rotor and/or Drum and Axle Flange (Clean Rotor and Hub and/or

Drum and Axle Flange Mounting Surface), 1999-2003 Chevrolet Tracker

06 – Engine/Propulsion System

99-06-01-012A; replaces 99-06-01-012; Remanufactured Supercharger Replacement

Units; specified 1992-2003 Vehicles with 3.8L Supercharged V6 Engine

(NIV 1 -- RPO L67)

01-06-01-010B; replaces 01-06-01-010A; Polymer Service Pistons; specified

1996-99 Vehicles with 3.1L Engine (NIV M -- RPO L82)

02-06-03-001; Starter Cranks After Key is Released on Cold Start (Normal

Condition); 2003 Chevrolet Silverado, Suburban, Tahoe, GMC Sierra, Yukon,

XL with 5.3L Engine (NIV Z -- RPO L59)

02-06-04-010; 6.6L LB7 Duramax Diesel Fuel Pressure Regulator Replacement;

2001-03 Chevrolet Silverado, GMC Sierra 2500/3500, Chevrolet Kodiak,

GMC Topkick C4500/C5500 with 6.6L Duramax Diesel Engine (NIV 1 -- RPO

LB7)

02-06-04-054A; replaces 02-06-04-054; Increased Accelerator Pedal Effort

(Clean Throttle Body and Adjust Blade); 1999-2002 Chevrolet Silverado,

Suburban, Tahoe, Avalanche, GMC Sierra, Yukon, XL with 4.8L or 5.3L V8

Engine (NIVs V, T, Z -- RPOs LR4, LM7, L59)

03-06-01-002; New Polymer Coated Piston and Rod Assembly; specified 1997-2003

Vehicles with 3.1L or 3.4L V6 Engine (NIVs E, J -- RPOs LA1, LG8)

03-06-01-003; Flywheel/Flexplate Replacement; 2003 Passenger Cars and

LD Trucks

03-06-04-011; Programming/Re-Programming, Setup, Configuration of Modules

(TBCM, BCM, PCM, VTD, Radio, IPC, DTCs) 2002 Chevrolet TrailBlazer, EXT,

GMC Envoy, XL, Oldsmobile Bravada

03-06-04-012; Inspection of All Related Wiring Hrness Connections When

Diagnosing Miscellaneous DTCs, Intermittent Driveability Concerns, Hard

Start, No Start, Incorrect Gauges, Inoperative A/C Systems, SES Lamp

Illuminated, 4WD Lamp Illuminated, IP Gauges Inoperative, Cruise Inoperative;

2003 and Prior Cars, LD Trucks, Hummer H2

03-06-04-013; SES/CEL and/or ABS Warning Light Illuminated, Erratic Speedomter

and/or Erratic Shifting, Multiple DTCs set (Reposition Surge Tank Hose

Clamp and Repair Wires); 2003 Cadillac DeVille

03-06-05-003; Rattle or Buzz Type Noise from Exhaust System (Install

Clamp); 2001-03 Buick Rendezvous, Chevrolet Venture, Oldsmobile Silhouette,

Pontiac Aztek, Montana with FWD only

07 – Transmission/Transaxle

99-07-30-017A; replaces 99-07-30-017; Automatic Transmission Oil Cooler

Flushing and Flow Check Procedures; 2003 and Prior LD Trucks and Hummer

H2

02-07-30-029B; replaces 02-07-30-029A; Powertrain Quality Center for

Engine and Transmission Assembly and Transfer Case Replacement; 2003

and Prior Passenger Cars, LD Trucks, Hummer H2

03-07-30-001; Transmission Slipping or Torque Converter Clutch (TCC)

Inoperative with No SES Light Displayed and No DTC P1870 (Reprogram PCM

and Diagnose Vehicle Using P1870 Diagnostic Table); 2003 Chevrolet TrailBlazer,

EXT, GMC Envoy, XL, Oldsmobile Bravada

02-07-30-012B; replaces 02-07-30-012A; Hydra-matic 5L40-E Serviceable

Components and Labor Operations; 2003 Cadillac CTS with 2.6L or 3.2L

Engine (NIVs M, N -- RPOs LY9, LA3)

02-07-30-052B; replaces 02-07-30-052A; Automatic Transmission Oil Cooler

Flush and Flow Test Essential Tool J-45096 TransFlow; 2003 and Prior

Passenger Cars and LD Trucks with Automatic Transmission, Hummer H2

03-07-31-001; Low Clutch Pedal Reserve, Poor Clutch Pedal Feel, Transmission

Difficult to Shift (Inspect Clutch Cable and Install Clutch Cable Retention

Block); 2003 Chevrolet Kodiak, GMC Topkick with Manual Transmission

03-07-30-002; Transmission Cooling System Service Tool J-45096, TrnasFlow

Information; 2003 and Prior Passenger Cars and LD Trucks with Automatic Transmission,

Hummer H2

08 – Body and Accessories

99-08-64-016A; replaces 99-08-64-016; Use of Silicone for Weatherstrip

Maintenance; 2003 and Prior Passenger Cars and Trucks, Hummer H2

01-08-51-004A; replaces 01-08-51-004; Premature Aluminum Hood Corrosion/Blistering

(Refinish); specified 1999-2003 Buick, Chevrolet, Oldsmobile, Pontiac

models

01-08-64-012C; replaces 01-08-64-012B; Door Glass Sash Out of Run Channel

(Repair Door Glass Sash Channel); 1999-2003 Oldsmobile Alero, Pontiac

Grand Am

01-08-64-018B; replaces 01-08-64-018A; Front Door Window Glass Won’t

Roll Up or Out of Channel (Replace Guide); 1999-2003 Oldsmobile Alero,

Pontiac Grand Am

02-08-44-020A; replaces 02-08-44-020; No Audio Out of Speakers at Times

(Reprogram Radio and/or Replace Amplifier); 2003 Cadillac Escalade, EXT,

Chevrolet Avalanche, Express, Silverado, Suburban, Tahoe, GMC Savana,

Sierra, Yukon, XL, Hummer H2

03-08-42-001; Dome Lamp Replacement Procedure; 2003 Cadillac CTS

03-08-44-002; Radio and/or HVAC Systems Change While DriNIVg (Reprogram

Driver’s Door Module); 2002 Chevrolet TrailBlazer, EXT, GMC Envoy,

XL, Oldsmobile Bravada

03-08-44-003; Revised Radio Poor Reception Diagnostic Information; 2002

GMC Envoy, Oldsmobile Bravada with RPO U84

03-08-46-001; Information Required by Technical Assistance Center from

Dealers Caling with ONStar and/or XM Radio Concerns; 2000-03 Passenger

Cars and Trucks, Hummer H2

02-08-46-010B; replaces 02-08-46-010A; Programming OnStar Module for

Canadian French Voice Recognition; specified 2003 Vehicles with OnStar

03-08-49-002; I/P Cluster Lens May Craze or Crack (Replace I/P Cluster

Lens Only); 2003 Chevrolet Cavalier

03-08-50-003; Seat Heater and/or Memory Power Seat Inoperative (Replace

Memory Seat Control Module); 2003 Cadillac Escalade, ESV, EXT, Chevrolet

Avalanche, Silverado, Suburban, Tahoe, GMC Sierra, Yukon, XL, Denali,

Denali XL, Hummer H2

03-08-50-004; Power Seat Switch Bezel Pops Out, Trim Comes Off (Install

Retainer to Bezel); 2002 Buick Park Avenue, Ultra

03-08-56-001; Shock Sensor Elimination; 1999-2000 Cadillac Escalade,

GMC Yukon Denali

03-08-64-002; Door Locks and/or Power Windows Inoperative (Re-route Wires);

2001-03 Chevrolet Tracker

03-08-64-003; Outside Rearview Mirror Shake or Vibration (Replace Outside

Rearview Mirrors); 1996-2002 Chevrolet Express Van, GMC Savana Van

03-08-66-002; Wind Noise Heard from Rear of Vehicle (Adjust Primary Seal

Flange); 1999-2003 Oldsmobile Alero, Pontiac Grand Am

03-08-66-003; Deck Lid Pull Down Effort too High (Replace Deck Lid Supports);

2003 Cadillac CTS

03-08-67-001; Proper Positioning of Roof Luggage Carrier Crossrails to

Avoid Windnoise; 2002-03 Chevrolet S-10 and GMC Sonoma Crew Cab Pickup

with Sport Appearance Package (RPO ZR5)

|

| return

to Table of Contents |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|