| |

|

|

Note:

Clicking on any picture or illustration will open a larger version

of that art.

|

|

Attention

Chevrolet Dealers |

Within the next

few weeks, the 2004 Chevrolet Malibu will begin to ship to dealers

(fig 1). This revolutionary new automobile joins the Cadillac XLR

and Saturn Ion in using the GMLAN (local area network) data communication

system1.

TIP: You can review GMLAN principles and purposes in the March 2003

TechLink.

TIP: You can learn more about the GMLAN system in rebroadcasts of the

Know-How 10270.15D – Tech 2 Functional Diagnostics & GMLAN.

The Malibu will use the GMLAN for everything but the ECM, which is

Class 2.

TIP: The Cadillac XLR uses the GMLAN primarily in the powertrain and

brake systems, while a Class 2 data system is used for body and accessory

controllers.

TIP: The 2004 Cadillac SRX uses GMLAN for the ECM and TCM on both 8

cylinder (LH2) and 6 cylinder (LY7) engines. The remaining modules

on the vehicle are on the Class 2 bus.

Your Tech 2 will require an interface called the CANdi module, to communicate

with the GMLAN. CANdi stands for controller area network diagnostic

interface. The CANdi modules and instructions for use will begin arriving

at Chevrolet dealerships shortly.

TIP: It’s strongly recommended that you perform the Tech 2 functionality

test before you connect the CANdi module.

In preparation for this new Tech 2 use, you must perform a functionality

test on your Tech 2 to be sure the circuits used by the CANdi module

are operating properly.

TIP: An explanation of the functionality test is being sent to Chevrolet

and Cadillac dealers along with this August issue of TechLink.

The software necessary to perform these tests should be available the

last week of August (Tech 2 software version 23.005). You must have

this enhanced software loaded to ensure accurate test results.

To perform the functionality test, you will need:

- Tech 2

- Tech 2 cable

- ALDL loopback adapter

- VCI

The instructions will guide you to perform the following routines built

into your Tech 2:

- VCI Automated Test

- VCI Dual Uart Test

- VCI TPU Option F6 Test

- VCI J1708 Test

These routines verify that a Tech 2 and VCI are working according to

specifications and able to work with the CANdi module. These tests

can also be found on your Tech 2 User Guide CD.

You can perform the functionality test quickly. Do it right away. This

will allow sufficient time if your Tech 2 needs repair.

TIP: The August 2002 issue of TechLink contained a thorough explanation

of how to obtain repair for the Tech 2, whether or not it is in warranty

or under a service contract. Guidance is available at the Techline

Customer Support Center (1.800.828.6860 English or 1.800.502.3222 French).

IMPORTANT: Cadillac dealerships received their CANdi modules in March,

along with instructions for the functionality test.

Copies of the functionality test are being sent again to Cadillac dealers

this month as a reminder.

TIP: If you haven’t run the test yet, do so immediately.

-

Thanks to Mark Stesney, Matt Singer, Craig Jones and Richard

St. Pierre |

figure

1 |

|

|

|

|

|

|

| Fuel

System Diagnostic Tips |

Part

I

Recent TechLink articles have covered:

- Changes in Gen III Engine Fuel Injection System (Jan. 2002)

- MFI Systems (Oct. 2002)

- Testing Fuel Injectors – Misfires (Dec. 2002)

- 3 Step Maintenance Fuel Induction Service Kit (Dec. 2002)

With many of the individual components addressed, it’s time to

examine the operation of the entire fuel system and how the components

interact.

Fuel injected engines require fuel under pressure to ensure correct fuel

delivery from the fuel injectors and to maintain driveability.

TIP: Proper fuel system diagnosis requires a fuel pressure gauge that

reads psi and kPa on a scale that is easy to see. Fuel pressure specifications

vary between platforms and engines. Always refer to SI for the current

fuel pressure specs.

Three types of fuel systems can be found on GM vehicles today.

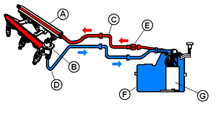

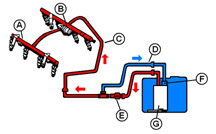

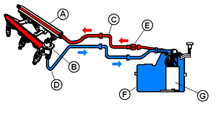

Return System (fig. 2) -- In a return fuel system, fuel travels thought

the entire fuel rail, and unused fuel passes through the regulator and

back to the fuel tank.

A Fuel Rail

B Pressure Regulator

C Pressure Side

D Return Side

E Filter

F Tank

G Pump

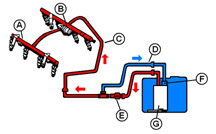

Semi-Returnless System (fig. 3) --

In semi-returnless systems, fuel travels a short distance outside the

fuel tank to an underbody-mounted pressure

regulator/fuel filter assembly. Returned fuel does not travel through

the engine’s fuel rail, decreasing the amount of heat it’s

exposed to.

A Fuel Rail

B Pulsation Damper

C Feed Pipe

D Return Pipe

E Filter

F Regulator

G Pump

Returnless System -- In a returnless system, the regulator is in fuel

tank. Excess fuel returns directly to the fuel tank. The filter may be

in the tank, inside the pump module. Environmental regulations have made

the returnless fuel system necessary. It keeps fuel cooler, reducing

evaporation and excessive hydrocarbon emissions.

The fuel system is divided into two parts, low pressure and high pressure.

In all three types of systems, the high-pressure side begins at the fuel

pump and ends inside the fuel rail. The low pressure side begins at the

regulator fuel bypass port and ends at the fuel reservoir in the tank.

Returnless systems are characterized by a single high-pressure line that

runs to the engine compartment.

The main difference between the three systems is the location of the

fuel pressure regulator. In return systems, the regulator is in the

engine compartment (on or near the fuel rail) and in returnless and

semi-returnless

systems, it’s in or near the fuel tank.

Regardless of location, the fuel pressure regulator regulates system

pressure by bypassing excess fuel back to the tank. In return and semi-returnless

systems, proper diagnosis of pressure concerns requires testing and inspection

of the regulator and verification that the pump or pump module is delivering

adequate fuel. Inadequate fuel flow may be caused by clogged strainers

or filters, rather than pump failure, especially if fuel starvation symptoms

occur only at low fuel levels or during hot weather.

Fuel Pressure Regulator Operation

There are two types of Delphi fuel pressure regulators on GM vehicles,

Universal Pressure Regulator (UPR) and Mini-Cartridge Regulator (MCP).

GM uses regulators from other suppliers, too, but the designs are similar

and operation is identical.

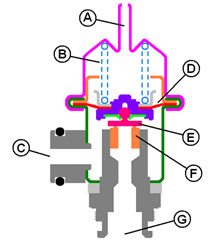

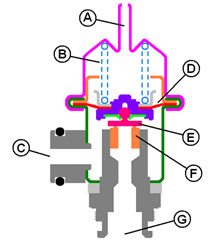

Universal Pressure Regulator (UPR) (fig. 4)

A Vacuum Port

B Spring

C Fuel Out

D Diaphragm

E Valve

F Seat

G Fuel In

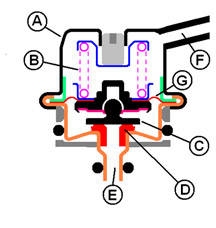

Mini-Cartridge Regulator (MCP) (fig. 5)

A Cover

B Spring

C Valve

D Seat

E Fuel In

F Fuel Out

G Diaphragm

The fuel pump and fuel pressure regulator work in concert to control

fuel pressure supplied to the fuel injectors. At a given voltage, the

fuel pump supplies fuel at a relatively constant rate to the pressure

regulator. Unneeded fuel diverts back to the tank, to match fuel delivery

to engine demand. Fuel flow from the pump varies strongly with voltage.

If system voltage is low, the pump may not receive enough power to fully

pressurize the system or supply the engine at high fuel demand conditions.

Fuel pressure regulators are preset for a particular operating pressure

during assembly, and are not adjustable.

Return System Operation

In most all return systems, the fuel pressure regulator contains a vacuum

chamber that is connected to manifold vacuum and is separated from the

fuel by a diaphragm and valve assembly. The diaphragm has fuel on one

side and engine manifold pressure (vacuum) on the other.

All GM fuel pressure regulators contain a calibrated spring located

in the vaccum chamber side. Fuel pressure in the fuel rail is regulated

by pressurized fuel from the pump acting on the fuel rail side of the

regulator’s diaphragm, pushing against the spring pressure and

manifold pressure (vacuum) on the other side. When the combined force

of vacuum on one side plus pressurized fuel on the diaphragm gets high

enough to overcome spring pressure, the relief valve orifice opens,

reducing rail pressure slightly by bypassing a controlled amount of

fuel to the

fuel tank. When an injector fires, it causes a slight pressure drop

in the rail. In return systems with a vacuum hose connected to the

regulator,

vacuum applied to the regulator keeps the pressure difference (pressure

drop) constant between manifold absolute pressure and supplied fuel

pressure.

Returnless System Operation

Returnless systems operate similarly, but fuel rail pressure decreases

slightly with increasing fuel demand. Fuel pressure does not vary with

manifold vacuum because the regulator is referenced to atmosphere, not

to manifold vacuum. Except for the lack of a vacuum reference, fuel pressure

regulators in returnless systems work just like they do in return fuel

systems. The calibration of the PCM is modified to look at changes in

MAP and vary the pulse width of the fuel injectors to adapt to varying

engine loads.

Fuel Pressure Regulator Common Problems

TIP: These conditions apply to return or semi-return systems.

Leaks -- Regulators can leak internally or externally.

An internal leak is usually caused by a crack in the diaphragm. An

internal leak can be

diagnosed by removing the vacuum hose and checking for fuel seepage

on the outlet tube or the vacuum line. Place a clear piece of vacuum

hose

over the vacuum orifice for a short period of time (15 – 30 minutes).

If fuel rises up in the hose, the regulator is leaking and needs to

be replaced.

Common customer complaints that suggest a leaking regulator are extended

crank and fuel odor. More diagnostic tips will be given later.

Noise -- Regulator related noise may be system oriented or the regulator

itself. Hold a stethoscope on the regulator and listen for the noise

the customer is concerned about. If the regulator is noisy, replace it.

TIP: A noisy regulator may be improperly diagnosed as a noisy alternator.

Disconnecting the alternator is not a good test for isolating noise issues.

System voltage will drop, which causes the fuel pump to create lower

pressure, eliminating the fuel pressure regulator noise.

Temporarily disconnect the vacuum hose from the regulator if it has one,

which slightly raises controlled fuel pressure. If the regulator has

no vacuum hose, connect the fuel shutoff valve special tools listed in

SI and slightly close either valve to alter controlled pressure. DO NOT

fully close either valve when the pump is running, as regulator or pump

damage could occur.

With either procedure, if the noise is gone, the problem is not the alternator.

Be sure to reconnect the vacuum hose if it was disconnected.

TIP: A regulator that is noisy on one vehicle may not be noisy if placed

on another vehicle. And a noisy regulator may be quiet for awhile when

removed and inspected on the same vehicle.

Fuel Injectors

An injector operates on 12 volts and delivers fuel when opened. Voltage

is supplied to the injector when the key is turned on. Some vehicles

have the voltage side of the injector circuit connected to the fuel pump

relay. Therefore the injectors will not receive voltage unless the fuel

pump is energized. The PCM controls the ground circuit to complete the

path for current to flow.

You may suspect an injector is not working if there is a misfire with

a code and a dead skip, and the spark is good. Check for voltage to the

injector and check that the PCM has the ability to pulse the injector

on and off.

TIP: The recommended

test for a complete electrical circuit to the injector utilizes a noid

light. Simply disconnect the wire harness connector,

plug in the noid light, and crank the engine. If the light flashes,

voltage to the injector and the PCM’s ability to turn the injector

on and off are good.

TIP: The noid light does not have the same resistance as the injector

and may not draw the same current. A high resistance circuit may not

affect the noid light as much as it would an injector.

Two causes of intermittent injector operation were covered in past

TechLink articles: ‘fretting corrosion’ in June, 2003 and

injector partially restricted in December, 2002. If you suspect either

of these

conditions, refer to the TechLink article or a bulletin that advises

you on how to test for these conditions.

TIP: If you perform a balance test to find a tricky injector misfire,

be sure to use the kPa scale on your pressure gauge and not the psi scale.

Fuel Pumps

The fuel pump provides fuel flow and pressure to meet engine requirements

under a wide variety of conditions. These functions must be met without

creating undesirable noise, vibration, overpressure, or EMI/RFI in the

vehicle.

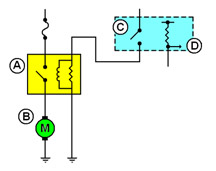

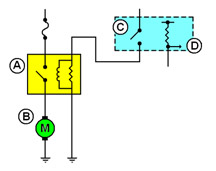

Typical fuel pump schematic (fig. 6)

A Fuel pump relay

B Fuel pump

C Fuel pump relay control

D Fuel level sensor signal

When the ignition key is turned on, the PCM sends voltage to the fuel

pump relay and cycles the fuel pump for 2 seconds. If the PCM does not

see ignition reference pulses, it turns the fuel pump off. Other inputs

may also be involved on some vehicles.

TIP: If you

have concerns about fuel pump operation, go back to the basics, check

the schematic for the vehicle you’re working on, and understand

how the system operates before you start replacing components.

TIP: In the fuel pump circuit, grounds are critical. Ground connections

must be clean and tight.

A fuel pump is designed to operate on numerous fuel compositions in a

global marketplace. The pump must deliver a specific volume and pressure

required for each application. If the pump does not deliver enough volume,

a pressure drop occurs and the vehicle will experience lean combustion

during high fuel demand conditions. If the pump delivers too much flow,

a larger current draw takes place and the fuel that travels through the

system heats up and creates excessive hydrocarbon vapors.

Currently, there are three types of electric fuel pumps used in GM vehicles.

They are the turbine, rollervane and G-rotor types. Although the pumping

section of each of these pumps is different, the main purpose of the

pump is the same -- to provide adequate fuel flow and pressure to the

engine under all operating conditions. For diagnostic purposes, fuel

pressure values are most important for quick and accuate fuel pump diagnosis.

TIP: Current draw readings on the vehicle are not an accurate indicator

of fuel pump condition. There are numerous variables, outside the fuel

pump, which can affect the accuracy of these readings. Electric fuel

pump current values are typically not published for on-vehicle diagnosis.

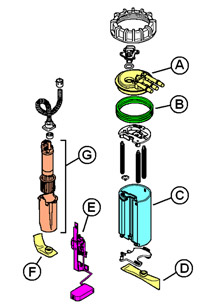

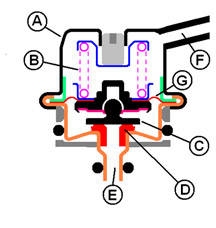

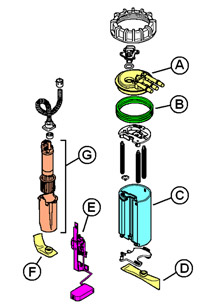

Modular Reservoir Assembly (MRA) (fig. 7)

A Cover

B Seal

C Reservoir

D Strainer

E Fuel level sensor

F Strainer

G Pump

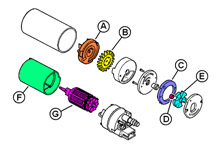

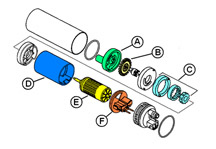

Typical Rollervane Pump (fig. 8)

A Inlet

B Impeller

C Ring (eccentric)

D Roller

E Rotor

F Magnets

G Armature

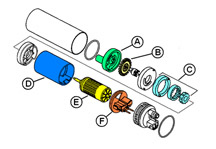

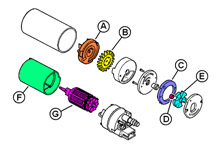

Typical G-Rotor Pump (fig. 9)

A Inlet body

B Impeller

C Gerotor assembly

D Magnet assembly

E Armature

F Brush assembly

Because the fuel pump is located in the fuel tank, quick visual checks

may be difficult. To determine if the fuel pump is working at all, hook

up the Tech 2 and a fuel pressure gauge and cycle the pump on a couple

times. If fuel pressure readings are within specification, you know the

pump is working. If there is no fuel pressure, check for a loss of voltage

to the pump. Wiring can become corroded, loose or broken. Make electrical

repairs according to SI.

If the pump runs when commanded on with the Tech 2 and you still suspect

poor fuel pump performance, look for dirt or rust which could cause the

pump to wear out prematurely.They can also cause the pump check valve

to stick open, leading to hard starting, especially when the engine is

hot. Rust is always caused by water, either from the fuel source, by

condensation or by ingestion of water by the fuel system. If the vehicle

is used under extreme operating conditions (such as off-road), water

and dirt may be ingested through the canister vent system.

Fuel lubricates and cools the pump. Driving the vehicle frequently with

a very low fuel level in the tank can starve the pump of lubrication

and cooling, which can accelerate wear and condensation, two causes of

pump problems.

If you replace a pump that has failed due to dirt or corrosion, clean

out the fuel tank and lines, to avoid the same damage to the new fuel

pump. Also, replace the fuel filter and clean or replace the pickup

screen. Contamination on the screen cannot be seen without magnification.

Newer

vehicles with a pump module usually have two screens, one on the outside

of the module and one on the pump inside the module. Both screens may

block, but the screen on the inside of the module is not serviceable.

So the module must be replaced even if the pump itself is still functional.

Dirt visible inside the module “bucket” is an indication

that both strainers may be blocked. If contamination is in the fuel tank,

it’s most likely to be in other locations in the fuel system. It’s

a good idea to check for contaminants in the fuel rail and fuel lines

also.

Watch for Fuel System Diagnosis, part II, in an upcoming issue.

- Thanks to Dan Wimer and Bob Halsall

|

figure

2

|

figure

3 |

figure

4 |

figure

5

|

figure

6 |

| |

figure 7 |

figure

8

|

figure

9 |

| |

|

|

Floor

Pan Repair Kit

|

This

information applies to various Buick LeSabre and Riviera, Cadillac

Seville and DeVille, Oldsmobile Aurora and Pontiac Bonneville models

between 2000 and present.

For these vehicles, Bulletin 99-06-03-009A contains information for repairing

the floor pan in the area where the battery is located. Damage may result

from weeping of acid from the battery or dislodged vent tube.

To complete this repair, you will need the materials in the table below.

Follow the procedure in the bulletin.

- Thanks to Bill Denton

Part Number |

Description |

12482411 |

Panel Kit -- Floor Pan Repair |

12378567 (US) or 88901675 (Canada) |

GM Metal Bonding Adhesive* |

* or Fusor 108B Metal Bonding Adhesive (Medium Set)

and applicator 103. Contact Fusor at 1.800.234.3876, ext. 3, or

www.fusor.com. |

|

|

|

| return

to Table of Contents |

| |

| Coolant

Loss, Milky Oil |

This

condition can affect some 2000-03 Buick LeSabre, Park Avenue, Regal,

Chevrolet Impala, Monte Carlo, Pontiac Bonneville, Grand Prix with

3.8L V6 Engine (VIN K -- RPO L36).

According to bulletin 03-06-01-016, coolant may leak past the intermediate

intake or throttle body gaskets.

Owners may comment about various symptoms of lost coolant, including

a milky substance on the oil fill cap or dipstick.

The repair kit includes both gaskets. It’s recommended to replace

the thottle body nuts with a new design that improves torque retention.

Medium strength threadlocker is also required.

TIP: Do not replace the upper intake manifold unless a specific driveability

condition and related DTC are noted.

-

Thanks to John Fletcher |

| |

| return

to Table of Contents |

|

| Module

Application and Programming for 2003 |

There

are a number of modules included on cars and trucks that need to

be configured to the vehicle when a replacement is installed. For

your convenience, the accompanying table (click

here) covers all

cars and light duty trucks for the 2003 model year. The table indicates

the type of action required; you must refer to SI for procedures

and details.

The modules listed across the top of the table require configuring to

the vehicle after installation. All of the vehicles are listed in the

left column. Here’s how to interpret the symbols in the table.

- S indicates need for SPS (service programming).

- O indicates set-up required with or without Tech 2

- A indicates actuator set-up is required.

- T indicates an on-vehicle tire pressure monitor programming procedure

is required using special tool J-41760

- # indicates vehicles produced after January 31, 2003 which no longer

require SPS programming

These symbol interpretations are also given in the bottom-left corner

of the table.

The following modules may be installed on certain vehicles, but require

no action, so they are not included in the table:

- Heated Seat Module

- Head Up Display

- Rear Park Assist

- Driver Information Center

- CD Changer

-

Thanks to Lindsey Beauchamp |

| return

to Table of Contents |

|

| New

Monthly Feature Coming |

Beginning

with the September issue, look for the Programming and Setup Corner.

This new feature will discuss a different programming or setup issue

each month.

TIP: This new feature will supplement related supporting information

in SI.

|

| |

| return

to Table of Contents |

|

| GMLAN

Wire Repair |

Beginning this year, a number of GM vehicles will be equipped with a

new serial data system called GMLAN (TechLink, March 2003). Much

new information will be shared about GMLAN and how it functions,

from the GM Technical College and other TechLink articles. Two types

of GMLAN Serial Data Networks can be applied to a vehicle, Low Speed

GMLAN and High Speed GMLAN.

Low Speed GMLAN carries body control serial data messages around the

vehicle. This network is wired with a single wire between modules and

functions at a relatively low speed. For higher priority messages, High

Speed GMLAN may be employed to provide serial data messaging between

different powertrain and chassis controllers. The High Speed GMLAN Network

is wired with two wires in a twisted pair configuration.

TIP: This twisting is critical to protect the network from

outside RF signals and also to prevent radiation of RF interference from

the network.

These problems exist on class 2 serial data networks, but are more critical

on GMLAN Networks, and are extremely critical on the two-wire High Speed

GMLAN network.

A vehicle with GMLAN may have two different serial data networks (the

2004 Chevrolet Malibu). Some vehicles may have only one GMLAN Network

(the 2004 Cadillac XLR, some 2004 Cadillac CTSs and the 2004 Cadillac

SRX).

This article is to remind you that repair of GMLAN wiring must maintain

the integrity of the original network to minimize the risk of outside

RF interference with messaging on the network(s) or having the network

cause noise audible through the radio.

The key things to remember are:

1. Wire repair procedures remain the same as for any other wire repair.

2. The network wire length after repair must be the same length (or very

close to the same) as before the repair.

3. If the network is made up of a twisted pair of wires, the twist must

be maintained or re-created after the repair -- usually one twist per

inch (25 mm).

When making a wire repair such as an open circuit, use the appropriate

crimp and seal splice, and maintain the twist in a High Speed GMLAN circuit

as much as possible.

If splicing a pigtail to a Low Speed GMLAN circuit, use care to maintain

the original length of the circuit. If the circuit is a High Speed GMLAN

twisted pair, then factor that into the amount of wire you use from the

pigtail. Also be sure to offset the crimp and seal splices and position

them to maintain the one twist per inch (25 mm).

A service terminal may be used, as long as you do not untwist any more

than is necessary in a High Speed GMLAN circuit to make the repair.

- Thanks to John Roberts |

| |

|

return

to Table of Contents |

|

| Front

Stabilizer Shaft Installation |

This

condition affects 2003 TrailBlazers, Envoys and Bravadas with the

4.2L L6 engine, with the stabilizer shaft running through the frame.

TIP: On earlier models, the stabilizer is mounted to the front of the

frame.

On these vehicles, it is possible to install the front stabilizer shaft

upside down. If this occurs, the shaft may contact and damage the engine

oil filter (fig. 10).

There is a bend in the shaft for clearance in the area of the oil filter.

When the shaft is installed correctly, it should bend away from the engine.

TIP: There may be a label on the shaft. If so, it should be on the LH

side.

- Thanks to Steve Hathaway |

|

figure

10

|

| return

to Table of Contents |

|

| Diesel

Engine Training |

The

interim 2004 Duramax 6600 diesel engine (RPO LLY) becomes available

January 2004. Though similar to the current production Duramax 6600,

this engine offers some significant differences. The GM Service Technical

College (STC) will offer an updated Diesel Engine Performance course

to reflect the changes. Refreshed and updated CBT, IDL, and Hands-on

course components will be released successively beginning April 2004.

To enable technicians to promptly offer service to customers with the

new LLY Duramax 6600 engine, GM STC will release a supplemental video

course in December of 2003 that focuses on this new engine configuration.

Technicians with credit in any of the current Diesel Engine Performance

2001 course components may take this video course to receive a cross-credit

to the updated course components.

Technicians are encouraged to participate in opportunities to complete

the training components within the Diesel Engine Performance curriculum

path. This curriculum path provides the foundation for December’s

supplemental video. This strategy will not only increase the dealership’s

overall Service Training Standard score, but will help ensure that the

technicians are prepared for LLY Duramax 6600 customer concerns and able

to fix them right the first time. Dealers that complete the current standards

before December will be in an excellent position to address the needs

of the LLY Duramax 6600 customers. Additional communication about the

new courses will be available a few weeks before their release.

- Thanks to Steve Sternicki

Current

Course |

Supplemental

Course

(Released December 2003) |

Updated

Course

(First component released

April 2004) |

Diesel

Engine Performance

2001 (W, D, H) |

Duramax

6600: 04i Engine Performance Updates

(Video and Booklet) |

Duramax

6600: Diesel Engine Performance |

|

|

|

| return

to Table of Contents |

|

| Compass

Erratic or Inaccurate |

According

to upcoming bulletin 03-08-49-008, owners of some 1999-2001 Blazers,

Jimmys and Bravadas may comment that the compass is erratic or inaccurate

while operating the power sunroof. The compass may stay erratic or

inaccurate while the power sunroof is open.

The sunroof module cable may become magnetized with the operation of

the roof, producing a false signal to the compass sensor. Relocate the

compass sensor by replacing the compass sensor bracket with part number

15106819.

TIP: The compass sensor is located to the right side of the original

bracket; it is located forward of the replacement bracket (fig.

11).

TIP: The supply is limited, so do not order parts for stock.

It is necessary to remove the driver information center and lower the

headliner for access to the compass sensor mounting bracket.

While the headliner is lowered, follow the instructions in the bulletin

for notching the headliner to provide clearance for the compass sensor.

Refer to the appropriate SI documents for component removal and installation.

-

Thanks to Dan Oden and TJ Smith |

figure

11 |

return

to Table of Contents

|

|

Car

Issues – Fix It Right The First Time Car

Issues – Fix It Right The First Time |

Model

Year(s)

|

Vehicle

Line(s) --

Condition

|

Do

This

|

Don’t

Do This

|

Reference

Information / Bulletin

|

2001-2003

|

3800

L36 – Coolant Leak at Intake Manifold

|

Replace

the intermediate (upper) intake gasket

|

Replace

the intake manifold assembly

|

Bulletin

in process

VME to field 5/30/03

TechLink article in June

|

1998-2003

|

Seville – Rear

Seat HVAC Controls

|

Replace

the knob only

|

Replace

the entire rear seat blower switch assembly

|

03-01-39-001A

|

2000-2003

|

Cavalier/Sunfire/Grand

Am/Alero/Malibu – Inaccurate Fuel Gauge

|

Replace

sensor card for fuel gauge – accuracy issue

|

Replace

fuel sender/pump assembly

|

01-06-04-008D

|

1999-2003

|

Grand

Am/Alero – Window Disengagement, Broken Clips

|

Replace

sash clip only

|

Replace

door glass assembly

|

01-08-64-018

|

1997-2003

|

Grand

Am/Alero/Malibu – Brake Pulsation

|

Turn

rotor and brake align procedure

|

Replace

brake rotor for pulsation

|

00–05-23-002

01-05-23-001 (Know How Video #15040.01B)

|

1997-2003

|

Venture/Montana/Silhouette –Windshield

Water Leaks

|

Refer

to specific bulletin procedures for diagnosis

|

Assume

that leak came from the windshield sealing

|

01-08-57-006

|

1997-2003

|

Century/Regal – HVAC

Operation, No “Auto” Light

|

Normal

in full heat or cold setting

|

Replace

HVAC control head for “Auto” light

|

99-01-39-007B

|

1999-2002

|

Corvette – Fuel

Gauge Intermittently Goes to Empty

|

Install

revised software

|

Replace

fuel senders or I/P cluster

|

02-06-04-010

(2002 MY)

1999-2001 MY software released – bulletin not yet updated

|

2003

|

All

cars with 4T40/45E, 4T56E and 4T80E – Code P0742

|

Replace

TCC PWM Solenoid

|

Replace

transmission or valve body assembly

|

02-07-30-039B

|

2002-2004

|

L61

EcoTech 4 Cylinder – Engine

|

Replace

Cylinder Bore Liner

|

Replace

Engine

|

03-06-01-018

|

|

| return

to Table of Contents |

|

|

Truck

Issues – Fix It Right The First Time Truck

Issues – Fix It Right The First Time

|

Model

Year(s)

|

Vehicle

Line(s) --

Condition

|

Do

This

|

Don’t

Do This

|

Reference

Information / Bulletin

|

2003

|

Fullsize

Pickups and Utilities – Transfer Case Service Light

|

Replace

encoder motor sensor and reprogram TCCM

|

Replace

the module, encoder motor or transfer case for DTCs C0327,

P0836, P0500

|

03-04-21-001B

|

1999-2002

|

Fullsize

Pickups and Utilities – Throttle Body Sticks

|

Clean

throttle body adjust blade and insert plugs

|

Replace

throttle body

|

02-06-04-054B

and parts restriction

|

2003

|

Fullsize

Pickups – 6.6L Diesel Engine ECM

|

Follow

SI and bulletins for proper diagnostics for P0181. Refer to

the Owner’s Manual (block heater and front cover)

|

Replace

ECM (DTCs P0540 and P0181) unless diagnostics confirm need

to replace

|

02-06-04-048,

03-06-04-021, 02-06-04-058 and parts restriction

|

2003

|

Silverado,

Sierra, Savana, Express > 8600 GVW – ABS Lamp On

|

Reflash

for code C0550

|

Replace

ABS module

|

03-05-25-003

|

2002-2003

|

Envoy,

Envoy XL, Bravada with G67 – Low in Rear

|

Replace

check valve service kit

|

Replace

air suspension compressor

|

02-03-99-001

|

2002-2003

|

All

TrailBlazers, All Envoys, Bravada – Mirror Erratic Return

|

Replace

mirror actuator and reprogram module

|

Replace

outside mirror assembly

|

02-08-64-008

02-08-64-021

|

1999-2003

|

Fullsize

and Midsize Utilities – Sunroof

|

Install

clip or mechanism kits. GMSPO has component parts.

|

Replace

sunroof

|

02-08-67-009

03-08-67-004

|

1999-2003

|

Fullsize

Pickups and Utilities, Midsize Utilities – Noise on Steering

|

Lube

I-Shaft

|

Replace

I-Shaft

|

00-02-35-003B

02-02-35-006A

|

1999-2003

|

TrailBlazer,

Envoy, Bravada without G67 – Moan/Boom

|

Replace

rear coil springs

|

Repurchase

vehicle for rear axle vibration/boom noise

|

02-03-09-002A

|

2002-2003

|

All

TrailBlazers, All Envoys, Bravada – Inoperative Tail

Light

|

Replace

tail lamp circuit board and bulb

|

Replace

rear tail lamp assembly for brake light

|

03-08-42-006

|

|

| return

to Table of Contents |

|

|

|

Know-How

Broadcasts for September

|

| |

|

| Know-How

Broadcasts for September |

|

10270.09D

Emerging Issues

|

September

11, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

|

10270.21D – New

Model Features - 2004 Colorado and Canyon

|

September

25, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

| |

Car

Issues – Fix It Right The First Time

Car

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time