|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Corvette

Z06 Dry Sump Oiling System |

The

Corvette Z06’s LS7 engine (fig. 1)

has a dry sump oiling system designed to keep the engine fully lubricated

during the high cornering loads the Corvette Z06 is capable of producing.

Ths LS7’s dry sump system was developed and tested on racetracks

in the U.S. and Europe, including Germany’s famed Nürburgring.

And while dry sump oiling is common in racing cars, the Corvette Z06

is one of just a handful of production vehicles -- and the only production

Corvette -- to incorporate such a high-performance oiling system.

What is a Dry Sump Oiling System?

Most automotive engines use a wet sump sytem, in which all of the engine

oil is stored inside the crankcase in the oil pan. In a dry sump oiling

system (fig.2), engine oil is stored in

a reservoir external to the engine, so the crankcase contains only a

minimal amount of oil at all times.

What are the Advantages of a Dry Sump System?

In an engine with a conventional wet sump oil pan, the oil can slosh

away from the oil pump pickup tube during high dynamic maneuvers like

cornering, braking and accelerating. This starves the engine of oil,

causing bearing damage or catastrophic engine failure.

The dry sump system stores engine oil in a tall and narrow oil reservoir

(fig. 3). This shape prevents oil from

sloshing away from, or uncovering, the oil pickup, even under extremely

high dynamic maneuvers. The dry sump system enables increases to the

dynamic capabilities of the vehicle, which is why racing cars and exotic

sports cars use this type of oil system.

Additionally, oil aeration is lower in a dry sump system, because the

oil spends less time in the presence of the crankcase windage. Oil delivered

to the bearings is typically superior to that of a wet sump system.

Finally, without the need for a conventional sump, the engine can be

placed lower in the vehicle, effectively lowering the center of gravity

of the vehicle.

How Does a Dry Sump System Work?

In the LS7 engine, two oil pump sets (scavenge pump and supply pump)

are located in the same housing on the nose of the crankshaft. The location

is common with the oil pump in other small block engines.

The scavenge pump removes engine oil and air from the sump and pumps

both to an external reservoir for conditioning and storage

(fig. 4).

The oil is directed to the top of the reservoir, where it is allowed

to spill onto a spiral-shaped baffle. Crankcase gases and air are separated

from the oil and are returned by the PCV system to the engine, where

they are burned. The deaerated and conditioned oil collects in the bottom

of the reservoir, ready for use.

The supply pump (fig. 5) draws the conditioned

oil from the reservoir, pressurizes it, and feeds it to the engine by

way of the oil filter and oil cooler. After the oil passes through the

engine, it again flows into the sump to be returned by the scavenge

pump to the reservoir once again.

Checking the Oil Level

The engine must be warmed up. Cold oil will not give a correct oil level

reading.

After the engine is warmed up to at least 175°F (80°C), shut

off the engine. Checking the oil with the engine running will result

in an incorrect reading.

Wait for 5 minutes (but not more than 20 minutes), to allow the oil

to drain and settle.

Pull the dipstick with the yellow handle (fig.

6) from the reservoir, and clean it with a lint-free cloth. Then

push it back in all the way until it stops. Remove it again, keeping

the tip down, and note the oil level on the crosshatched area.

An oil level within the crosshatched area is normal. If the level is

below the crosshatched area, add 1 quart (0.96 L) of 5W30 Mobil 1 synthetic

oil through the black oil reservoir fill cap (fig.

6) and take another reading.

TIP: Do not overfill the reservoir, as this may

result in excessive oil consumption. Oil levels above the crosshatched

area may degrade lubrication system performance.

Oil Change Procedure

Remove the two drain plugs from the engine oil pan

(fig. 7). One is located on the left side of the oil pan near

the oil filter. This plug drains the small amount of residual oil from

the engine oil pan, approximately 1 quart (0.96 L). The other drain

plug is located on the front of the oil pan. This plug drains the external

reservoir and hose assembly. Also remove the engine oil filter.

Once the oil has been drained from the engine and reservoir, replace

the engine oil filter with a new PF48 oil filter and tighten to 25 Nm

(18 lb ft).

Replace both oil drain plugs and tighten to 25 Nm (18 lb ft).

Fill the oil through the oil fill cap in the top of the dry sump reservoir.

The total service fill, with a dry filter, is 8 quarts (7.57 L) of 5W30

Mobil 1 synthetic engine oil.

Replace the oil fill cap and start the engine. Let it run at idle for

at least 15 seconds to circulate the fresh engine oil through the lubrication

system. (This is similar to running an engine after a radiator fill,

to purge air from the system.)

Check the oil level according to the instructions above. The oil change

is now complete.

TIP: The owner’s manual may contain a slightly

different procedure, which calls for filling 7 quarts, running the engine

then shutting off, and finally filling 1 additional quart. This procedure

may be used, although it is not necessary.

TIP: There is a cap on the right valve cover under

the decorative cover. Attempting to remove this cap can break the retaining

tabs, requiring removal of the valve cover to retrieve broken pieces.

Under no circumstances should you attempt to fill the engine oil system

through this cap.

-

Thanks to Dan Hommes and Ron Minoletti |

figure

1 |

figure

2 |

figure

3 |

figure

4 |

figure

5

|

figure

6

|

figure

7 |

| return

to Table of Contents |

|

|

| Tech

2 Extended Warranty |

Your Tech 2 automatically comes with a two-year manufacturer’s

Express Exchange Warranty. Did you know that you can ensure the same

reliable service on your Tech 2 by extending the manufacturers warranty?

GM Dealer Equipment (GMDE) is offering a special promotion on extended

warranties during the third quarter of 2005. Purchase a two-year extended

warranty and get the third year free.

|

Warranty

Service

(with Express Exchange Warranty) |

Regular

Repair

(without warranty) |

| Repair Time |

24 hours (replacement

units shipped to arrive the following morning for requests received

before 3:00 pm PST |

4-6 days |

| Administration |

None: One phone

call gets you a replacement unit the next day and return shipping

arrangements |

Delays in getting

repaired unit; i.e., issuing checks, etc. |

Costs --

U.S. |

1 Year $150.00

2 Year $280.00

3 Year $407.00 *

* Purchase during 3rd Quarter 2005 and pay only $280.00 |

Approximately

$785.00 average repair plus return shipping. Dealership service

department losses due to not having Tech 2 for 4-6 days |

| Costs -- Canada |

1 Year $214.00

CD

2 Year $409.00 CD

3 Year $598.00 CD*

* Purchase during 3rd Quarter 2005 and pay only $409.00 |

Approximately

$973.00 CD average repair plus return shipping. Dealership service

department losses due to not having Tech 2 for 4-6 days |

During

the term of your warranty coverage, not only are there no charges for

repairs performed to your Tech 2, you will be guaranteed a 24 hour express

exchange warranty replacement service (warranty does not cover cables,

adapters and the 32 meg card). If you have a problem with your Tech

2, simply call the GM Techline Customer Support Center (TCSC) at 800.828.6860

and you will receive an express exchange replacement unit the next business

day at no additional charge.

Contact 1.800.GM.TOOLS (468-6657, option 1, option 3) for answers to

any questions.

TIP: Please provide

the following promotional code to receive this great offer: DES3RDT2.

- Thanks to Sue Sulewski |

|

|

| |

|

|

Programming Tips |

Technicians

continue to report occasional problems with incomplete programming events

or errors. This leads to damaged controllers and unnecessarily high

warranty. Here are tips that may help prevent some of these problems.

Insufficient Battery Voltage -- The proper battery

voltage is critical to programming. If voltage drops too low at the

end of the programming event, calibration files or VIN data may not

be written, causing problems or failure.

Be sure the battery is fully charged before starting the programming.

If the battery voltage is questionable, you can use a Midtronics PSC

charger during programming (July 2005 TechLink). At this time, GM has

not validated any other charger for this purpose.

Not Turning Accessories Off -- Before programming,

turn off all electrical devices, such as headlights, radio, HVAC, etc.

And during the programming event, do not turn on any electrical devices.

Not Using Current Software -- You must use the most

current Tech 2 software release and the most current TIS software release.

To be sure you are always using the latest data, you must update your

Techline terminal as soon as you receive the new software.

Not Waiting -- Before performing a programming event,

you must turn the ignition key on. Do not begin programming right away.

It’s critical to wait until all modules on the vehicle have “awakened”

before beginning. (This is the same principle as waiting for any computer

to “boot up”. You cannot start to access applications on

your PC until it fully boots up. The same applies for any vehicle systems

with multiple modules.)

If you try too soon, you will get a No Communication message on the

Tech 2. A good rule of thumb is to observe the instrument panel lights

and tones. When everything stops, you can safely proceed. Plug in your

Tech 2 (and CANdi module if required).

Not Cycling Ignition -- When working on a GMLAN system,

you must cycle the ignition off and back on after programming each module.

Do not begin programming a second module without turning the ignition

off and on.

TIP: During the ignition OFF time, avoid opening

and closing the doors for 30 seconds until the controller can write

the new values.

Voltage Held in Components -- Some components contain

capacitors, which can store voltage after being turned off. If stored

voltage is released by a module while you programming another module,

it could cause confusion on the data bus, causing U codes to set. To

prevent this, you may be instructed to disconnect the battery cables

and touch them together. This drains the stored voltage from capacitors.

Using the Wrong Tech 2 Adapter -- There are three 16-pin

adapters that have been used with the Tech 2. At a glance, they all

look the same (fig. 8).

Do not use adapter p/n 71419.

You can use either of the adapters numbered GM 3000098. They have been

manufactured by two different vendors. One of them is coded VTX 02002955,

and the other is coded HP 5063-3255. Either of these will work with

CANdi modules.

-

Thanks to Mark Stesney |

figure

8

|

| return

to Table of Contents |

|

| Radio

Labor Code |

When servicing a radio under warranty, be sure to use the correct labor

code. Do not use the XM radio receiver code when sending a regular or

navigation radio.

-

Thanks to Jim Hughes

Radio

Type |

Labor

Code |

Definition |

Regular

Radio or Navigation Radio |

R0760 |

Remove,

Repair and Replace |

R0762 |

Remove |

R0763 |

Reinstall |

XM

Radio Receiver |

R5600 |

Replace |

|

| |

| return

to Table of Contents |

|

| Remote

Vehicle Start Accessory Kit Followup |

The June 2005 issue of TechLink

introduced you to the Remote Vehicle Start Accessory Kit, which can

be dealer-installed on certain vehicles. Here are some reminders and

some new information to help the installation go well.

During Installation

- Be sure you are using the latest version of Tech 2 and TIS software.

- The vehicle’s battery must be fully charged before programming

the module.

- The kit comes with two additional key fobs (fig.

9) (the vehicle was delivered with two original key fobs). When

programming the fobs using the Tech 2, you should program the new fobs

in slots 1 and 2, to permit diagnosis of the new fobs (Impala, Monte

Carlo, and Lucerne only). You can program the original fobs in slots

3 and 4.

TIP: Remember,

the original fobs can be used only for remote lock and unlock; they

cannot be used for remote start.

After Installing

Here are some points to keep in mind when checking system operation

after installation.

- The hood must be closed for remote start to operate. If you attempt

to check the installation with the hood open, the system will not work.

- Each remote start event times out after 10 minutes of engine operation.

Then the key fob must be pressed again.

- Remote start can be used only twice, then the system must be reset.

Do not interpret this as a malfunction. Turn the ignition on with the

ignition key to reset the system.

-

Thanks to Mark Stesney |

figure

9

|

| return

to Table of Contents |

|

Enhanced

Master Technician Certification Program for 2005

(not applicable in Canada) |

Becoming

a GM Master Certified Technician means you’ve earned the right

as a GM expert in a certification area and have demonstrated you have

the skills and knowledge to “fix it right the first time.”

The GM Service Technical College (STC) is introducing simulations as

part of some 2005 GM Master Technician Certification (MTC) Assessments,

to challenge and evaluate technicians’ diagnostic skills.

GM service technician training is structured around a standard, performance-based

curriculum. The curriculum blends in-dealership training with training

at various off-site locations. In the dealership, the technician acquires

component, systems, and diagnostic knowledge via Web Based Training

(WBT) and Interactive Distance Learning (IDL). The technician can then

practice and demonstrate the application of skills at various training

locations by attending Hands-On courses. The capstone of this standard

curriculum is GM Master Technician Certification (MTC) in each automotive

or body service area.

It is very important that you are adequately prepared for the GM MTC

Assessment. Here are a few tips on preparing for this challenging event:

- If traveling, arrive the day before the assessment.

- Review all WBT courses already taken

- Review all IDL materials received

- Talk to the service manager about any area that could be improved,

including Service Repair documentation

- Review GM MTC Assessment Prep Guide at http://www.gmstc.com/home.asp

- Review the Service Information website, specifically for the Strategy

Based Diagnostics (SBD) process.

- Find an expert at the dealership who can assist in the certification

area

- Investigate and complete ASE certification in the subject matter area

IMPORTANT: If

you have never taken a Hands-On course, or an on-line Hands-On simulation,

you should complete one in the subject matter area before attending

the Certification Assessment. If an on-line Hands-On simulation is not

offered in the subject matter area, familiarize yourself with a simulation

as close to that area as possible.

The following Master Technician Certification categories include a Hands-On

Simulation:

- Brakes

- Gas Engine Performance

- Diesel Engine Performance

- Mechanical / Electrical Body

- Electrical / Electronics

- Steering & Suspension

To access and utilize the GM STC Hands-On simulations, follow these

instructions:

1. Access the GM Training Website at www.gmtraining.com

2. Select Catalog>Catalog Search at the main menu and perform a search

as illustrated below (fig. 10)

3. Select “Course Number” from the drop down menu

4. Select “Ends with”

5. Type in “S” for simulations

6. Select W-Web-Based Training (CBT) from the drop down menu

7. A complied list of results will show at the bottom of the screen.

NOTES:

- The Certification Assessment is similar to the structure of a Hands-On

course, but without the guidance from an instructor, or in the case

of a simulation, a play-by-play coach. Experiencing the Hands-On training

offered today gives the technician a much better idea of what to expect

in Certification Assessment.

- The Master Technician Certification Assessment program has been revised

to include up to seven technicians per session, rather than the previous

five technicians per session.

For more information regarding GM MTC certification, please refer to

the GM Training Website at www.gmtraining.com,

Menu>Resources>Certification.

-

Thanks to Rebecca Farrand |

figure 10

|

| return

to Table of Contents |

|

| Common

Architecture |

Common architecture is a term that is being used to describe the next

level of vehicle data communication in GM cars and trucks.

It starts with a common Body Control Module (BCM) that will be used

on numerous GM vehicle platforms. This is combined with an updated version

of GMLAN (the revisions are transparent to the field, and relate to

serial data message size).

The new BCM is flexible, able to accommodate a wide range of vehicle

content and features. It will work on both car and truck platforms,

with or without door modules, with either standard ignition or EZKey

(i.e., XLR or STS).

Common Architecture Rollout

Common architecture will launch in 2006 with the Chevrolet Impala/Monte

Carlo, the Cadillac DTS and the Buick Lucerne. Application expands in

2007 to include all full-size utilities.

Common Architecture BCM Basics

There will be only two BCM variants in production. These two controllers

will be used in multiple applications, reducing the number of service

parts required.

TIP: Always order

the correct part for the vehicle being serviced.

Here are some of the new BCM’s features:

- Seven connectors with 169 terminals.

- Approximately 100 DTCs, depending on vehicle configuration.

- Over 200 Tech 2 data list parameters.

- Approximately 40 Tech 2 output controls (depending on vehicle configuration).

- I/O (input/output) is reconfigurable. For instance, the DTS park brake

switch input is on a different terminal in a different connector than

in the Impala.

- All configuration is via SPS and “as built” data (much

like Powertrain Controllers).

- All BCMs use the same set of core operational software.

- All configurations are determined by calibration files in flash memory.

Different calibrations account for various options and accessories.

Set-Up Procedures

There are only two Tech 2 set up procedures:

- BPP Sensor Calibration

- Setup SDM Primary Key in SDM

TIP: The service

part is non-functional before SPS programming. It will not communicate

with other on-board devices, and the vehicle will not start.

Benefits of Common Architecture

Designed with flexibility in mind, common architecture will bring consistency

to body control systems. Because functionality will be consistent across

many GM platforms, it will be less likely to drive customer complaints

based on normal operation. Reduced service part numbers are another

benefit. In the future, this hardware and software will be easily transportable

to new platforms.

-

Thanks to Gary Clark |

| |

| return

to Table of Contents |

|

| Parking

Brake Light |

Owners

of some 2004-05 Cadillac DeVilles may comment that the brake light on

the instrument panel (I/P) stays illuminated after releasing the parking

brake. This may be caused by a weak return spring located at the rear

of the parking brake cable.

If this conditon occurs, repleace the rear parking brake cables. Rear

parking brake cables (p/n 15236959) contain a more robust return spring.

Refer to Bulletin 05-05-26-001 for details.

-

Thanks to Bill Denton |

| |

| return

to Table of Contents |

|

| Product

Quality Center |

The

Product Quality Center (PQC) was put in place to help GM improve the

quality of its products.

Before the PQC existed, the assembly return program asked dealerships

to attach information to the returned assembly, explaining the concern

and describing what diagnostics were done. Fewer than 25% of the returned

units had any documentation attached. Most of the information was incomplete.

When PQC was instituted, dealers were required to call before the replacement

of an engine, transmission or transfer case assembly. Now, PQC is able

to collect the necessary information in a database.

All current model engines, transmissions and transfer case assemblies

must be returned 100% (and also a sample of past model units). When

Engineering disassembles these units, they refer to the PQC case file.

This gives them all the information they need to determine the root

cause of the failure. In this way,

Engineering has been able to more quickly identify the causes of assembly

failures. In some cases, Engineering contacts the service technician

directly to further understand the cause of a specific failure.

Engineering then makes improvements in the product to eliminate the

cause of the failures. This process has reduced assembly replacements

in GM products by over 30% in three years.

This process has been so effective that it has been expanded to include

other components, including body and IP wiring harnesses. These restrictions

are usually much shorter in duration.

The PQC will continue to be an important part of the engineering failure

analysis process. This, combined with the outstanding cooperation from

dealers, will help GM reach the goal of manufacturing the highest quality

vehicles available in the market.

-

Thanks to Jim Colyer |

| |

| return

to Table of Contents |

|

| Oil

Capacity Chart |

A new oil capacity chart has been posted on the TechLink website. It

includes GM cars and trucks from 1996 through 2006.

On the website, click on the Reference Guides button, then scroll down

to Oil Capacities for 1996-2006. Click to open the

chart.

TIP: An earlier

Oil Capacities chart is still available in the Reference Guides for

GM cars and trucks from 1988 to 2005.

When the chart opens, scroll down the list to locate the vehicle, then

locate the appropriate engine. The oil capacity is listed in both liters

and quarts.

TIP: Pay attention

to footnotes and other supplemental information.

- Thanks to Jerry Garfield |

| |

|

return

to Table of Contents |

|

| Fuel

Filter Clarification |

External fuel filters were used only on C/K trucks

with an L59 engine (E85). These engines were used on utility models

only, from 2002 to 2004.

-

Thanks to Jerry Garfield |

|

return

to Table of Contents |

|

| Integral

Connector Position Assurance (CPA) |

Many

vehicle systems are using connection systems with an integral connector

position assurance (CPA). In Supplemental Inflatable Restraint (SIR)

applications, these CPAs are used to lift the shorting bars from contacting

the connector terminals. This allows the airbag to be shorted before

the connector is removed, to prevent unwanted deployment. After installation,

if the CPA is not in the firmly locked position, a DTC will set for

low resistance.

The example here shows a connector and CPA on the inflator assembly

of the 2005 midsize trucks. This is an FCI connection system called

ABX4 which will soon appear on other vehicles. If not operated properly,

this CPA can easily be damaged during removal, which can cause DTCs

to set after the CPA is reinstalled. The information provided here is

to aid in the proper installation and removal of this connector and

CPA.

TIP: An article

in the December 2004 TechLink described a similar situation where the

steering wheel coil assembly CPA is integral to the system and causes

the setting of DTCs when damaged or removed.

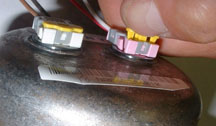

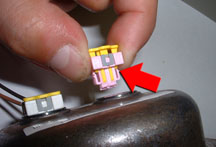

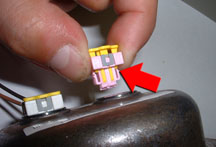

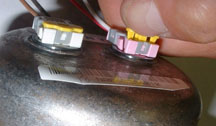

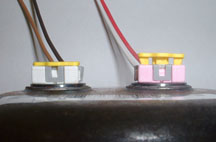

Connector Removal

With your finger or terminal release tool 12094430 from the J-38125

Terminal Repair Kit, apply an upward force on the CPA until the CPA

is in the pre-lock position (approximately 1.7 mm) (fig.

11 and 12).

IMPORTANT: Do

not pull the CPA completely out of the connector. If the CPA

is removed completely from the connector assembly, it will be damaged

and must be replaced with a new one.

TIP: Replacement

CPAs will be available in the SIR tray in the terminal repair kit (J-38125)

later this year. Until available, if the CPA needs to be replaced, order

part number 88988974 RETAINER, INFL RST WRG HARN CONN (CPA AT DRIVER

AIRBAG).

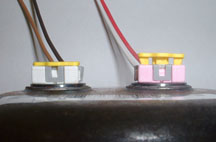

Remove the connector by squeezing the locking tabs while lifting the

connector body (fig. 13 and 14).

TIP: Do not pull

on the harness cable or the yellow CPA as a means of removing the harness

connector. Potential damage could result.

Connector Installation

Align the keyway of the connector to the mating side at the airbag module

initiator (fig. 15).

Press the connector body with your finger to engage the connector (a

tactile feeling or audible click will indicate when it is seated) (fig.

16). Typical mating force is approximately 25 N (5.5 lbs).

TIP:

The CPA must not be moved to the locked position until

the connector is fully mated to the inflator assembly.

Only after the connector is seated, press the CPA with your finger to

engage the CPA (a tactile feeling or audible click will indicate when

it is seated) (fig. 17 and 18).

TIP: To prevent

damage to the connector and CPA, do not exceed 75 N (16.5 lbs) of force.

Important Finishing Steps

After any SIR system repair, remember to follow these steps.

Reconnect all SIR system components.

Verify that all components, connectors and connector position assurances

(CPAs) are properly mounted.

Use the scan tool to clear the DTCs.

Operate the vehicle within the Conditions for Running the DTC as specified

in SI to ensure that the DTC does not reset.

-

Thanks to Chad O’Brien |

|

figure

11

|

figure

12

|

figure

13

|

figure

14

|

figure

15

|

figure

16

|

figure

17

|

figure

18

|

|

return

to Table of Contents |

|

| Loose

Shift Knob |

Some owners of the 2004-06 Chevrolet Malibu and

Malibu Maxx may comment about a loose shift knob.

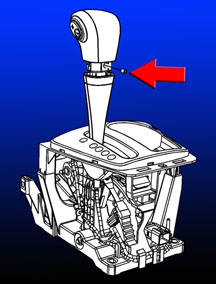

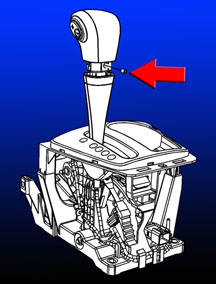

1. Remove the shift control shaft trim by sliding it downward on the

shift control assembly shaft.

2. Remove the shift knob setscrew and raise the shift knob off of the

shift control assembly shaft (fig. 19).

3. Clean the shift knob setscrew with a wire brush, and apply thread

locking compound Loctite® 242 (GM p/n 12345382, 10953489 in Canada)

to the setscrew.

4. Install the shift knob on the shift control shaft and reinstall the

setscrew. Tighten the shift knob setscrew to 2.5 N·m (22 lb in).

5. Install the shift control shaft trim by pushing up until it snaps

onto the lower portion of the shift knob.

-

Thanks to David MacGillis |

figure

19

|

| return

to Table of Contents |

|

| Running

Board End Cap Installation |

On

2004-05 Cadillac Escalades, running boards are assembled to the vehicle

at the time of vehicle assembly without end caps. The end caps are shipped

loose inside the vehicle with an instruction sheet and necessary fasteners.

TIP: End cap

installation is part of the dealer PDI process and is incorporated in

the PDI time for this vehicle.

The adjustment of the main part of the running board must be performed

during end cap installation. The design of the end cap is sensitive

to the position of the main part of the running board relative to the

vehicle.

The 8 fasteners that secure the boards to the vehicle must be loosened

before installing the end caps. Loosening the boards helps install the

end caps without stress on the part and allows for proper alignment

to the vehicle. Failure to properly align the board to the vehicle during

end cap installation will cause the end cap to crack (fig

20).

-

Thanks to David Roland |

figure

20 |

| return

to Table of Contents |

|

| Service

Brake Booster Message |

This information applies to all full-size 2004 Cadillac, Chevrolet and

GMC trucks and utilities with Hydroboost brake system.

The Service Brake Booster message is used to notify the driver of a

Supplemental Brake Assist (SBA) concern on vehicles equipped with a

vacuum boost brake system. There have been reports of the Service Brake

Booster Message being displayed on vehicles equipped with a Hydroboost

brake system.

During normal diagnostics, a DTC C0136 may be present in the IPC. This

DTC will not be in SI for Sport Utility vehicles, because all Sport

Utilities use Hydroboost brake systems starting in 2004.

This message could be caused by the IPC being programmed incorrectly.

If the IPC was replaced on a previous unrelated repair and was not SPS

programmed, this message will be displayed after the IPC does not receive

a valid state of health signal from the SBA for 5 consecutive ignition

cycles.

To correct this concern, SPS program the IPC. To be sure the vehicle

is repaired, cycle the ignition to off and on at least 5 consecutive

times, delaying in each position at least 30 seconds.

-

Thanks to Jim Will |

| |

| return

to Table of Contents |

|

| Heated

Seats Turn Off |

Owners

of some 2003-2005 Silverado and Sierra trucks equipped with the 6.6L

diesel engine may experience the heated seats turning off after 3 to

5 minutes of operation and DTC B3941 sets. This concern will occur only

on the first start in the morning and both the passenger and drivers

heated seats are turned on at start up. After the heated seats inadvertently

turn off, they can be turned back on and will continue to operate normally

the remainder of the drive cycle.

To correct this concern, reprogram the DSM (Driver Seat Module) with

service calibrations available from Techline on TIS2000 version 6.5

or later available June 13, 2005.

-

Thanks to Jim Will |

| |

|

return

to Table of Contents |

|

| Driveline

Vibration at Highway Speed |

Owners

of some 2005 Chevrolet Kodiak and GMC Topkick C4500/C5500 Conventional

4x4 models with 152-inch wheelbase ( RPO EG9) may experience a driveline

vibration when driving at highway speeds.

These models are built with a single rear propshaft. Engineering has

determined that the original rear axle pinion angle is not the optimum

design angle for the 152-inch wheelbase and may result in some driveline

vibration.

Change the rear axle pinion angle from the as-built 8.1° to the

new 6.1° angle by replacing the original rear axle spring seats

with the following spring seats available from GM Service Parts. Refer

to SI document 1202795.

-

Thanks to Jim Will

| DESCRIPTION |

GM

P/N |

QUANTITY |

Rear Axle Spring Seat

(6.1° pinion angle) |

15640807 |

2 |

|

| |

| return

to Table of Contents |

|

| Transfer

Case Stops Shifting |

This

information applies to 1999-2005 trucks and utilities with an RPO NR4,

NP1, or NP8 transfer case.

The electronic transfer case may stop shifting if the driver tries repeated

shifts in a short period of time.

The software in the transfer case control module has a shift abuse lockout

mode to protect the module and encoder motor. This concern will occur

if the module senses repeated shift requests in a short period of time.

If the driver continuously tries to shift in and out of different modes,

the transfer case control module will stop trying to shift for several

seconds to prevent abuse damage to occur.

Cycling the ignition off for 30 seconds or more should allow the transfer

case to resume normal operation.

-

Thanks to Rusty Sampsel |

| |

| return

to Table of Contents |

|

Car Issues

— Fix It Right the First Time (new issues in bold) Car Issues

— Fix It Right the First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) /

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2004-2005 |

Grand

Prix (June 2004, 2005), Allure (2005) – Blower Motor Inoperative

or Intermittent, Blower Speed May Drop or Blower Continues to

Run After Key Off |

Install

330MFD capacitor between LPM circuit and ground. |

Don’t

replace LPM, blower motor or HVAC control head. |

05-01-39-001A |

2002-

2005 |

LeSabre

– Front Door Window Binds/

Inoperative/Moves Slowly |

Adjust glass. |

Don’t replace window regulator. |

05-08-64-011 |

2002-2006 |

Cavalier,

Sunfire, Grand Am, Classic – Vehicle Hesitates, No Start,

Lack of Power, Low Fuel Pressure |

Before

replacing fuel pump module, replace fuel pump strainer using kit,

P/N 88967293. |

Don’t

replace fuel pump module. |

05-06-04-026A |

2001-2003 |

Aztek,

Rendezvous – Window Regulators Separate from Window Motors |

Use window regulator clips and procedure outlined in bulletin. |

Don’t

replace window regulator assemblies that are serviceable and only

have broken clips. |

03-08-64-015 |

2003-2004 |

Cavalier,

Sunfire – Difficult to Adjust HVAC Control Head Mode Dial |

Replace

foam which delaminated from mode door and is causing bind. |

Don’t

replace HVAC control head, module or cables unless damaged. |

03-01-38-005B |

2005 |

Equinox

LT/LS (AWD Only) – Moan, Bind or Growl Coming from Rear

During Low Speed Parking Lot Turns |

Replace

RDM coupling (clutch pack) with proper sealers. Fill with Versatrak

fluid. |

Don’t

replace complete rear drive module. |

04-04-20-004 |

2002-2005 |

Cars

and Trucks – Multiple Driveability Symptoms/ Clogged Fuel

Injectors |

Clean

fuel injectors as described in bulletin |

Don’t

replace fuel injectors. |

03-06-04-030A |

2000-2003 |

Century,

Regal, Lumina, Impala, Monte Carlo, Grand Prix, Intrigue with

3.8L L36 Engine – Coolant Leak |

Replace

upper intake manifold gasket only. |

Don’t

replace upper intake manifold assembly for coolant leak. |

03-06-01-016 |

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

Issue

One: Refinish brake rotor.

Issue Two: Measure for LRO |

Issue

One: Don’t replace brake rotors.

Issue Two: Don’t measure for LRO |

00-05-22-002F |

|

| return

to Table of Contents |

|

|

Truck

Issues — Fix It Right the First Time

(new issues in bold) Truck

Issues — Fix It Right the First Time

(new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2002-2005 |

Escalade, Yukon -- Stains on Rear Bumper Step Pad |

Apply

Armor-Dillo to rear step pad. |

Don’t

replace rear step pad. |

03-08-43-002A |

2004-2005 |

Colorado/Canyon – Side Door Window Glass Clips Fall Off

Glass/Window Inoperative |

Replace

door window glass. |

Don’t

re-attach door window glass clips. |

04-08-64-022 |

2002-2004 |

Silverado, Suburban, Tahoe, Sierra, Yukon/XL, Escalade EXT –

Rough Idle, Misfire, MIL DTC P0300 |

Measure

intake manifold for warpage across two runner ports only. Replace

upper manifold gasket with teal-green color gasket. |

Don’t

measure intake manifold for warpage across all four intake runner

ports. Do not replace upper intake manifold gasket with orange-colored

gaskets. |

05-06-04-029 |

2000-2003 |

Tahoe,

Suburban, Yukon, Yukon XL – DTC P0446 Set SES Illuminated |

Replace

EVAP vent solenoid. |

Don’t

replace EVAP canister. |

04-06-04-055 |

2003-2004 |

SSR – Return of Cooling Fans to WPC -- NTF |

Replace

cooling fan fuse (37) and/or repair cooling fan wiring harness. |

Don’t

replace cooling fan |

04-06-03-004A |

2004-2005 |

Midsize

and Fullsize Pickups and Utilities – CD Issues |

Load new software calibration. |

Don’t

exchange or replace radio |

|

| 2002-2005 |

Tahoe,

Suburban, Yukon, Escalade, Avalanche, H2 – Exhaust Pop/Ping

Noise |

Replace

heat shield. |

Don’t

replace exhaust system |

03-06-05-008B |

| 2004 |

Tahoe,

Suburban, Silverado, Yukon, Yukon XL, Sierra, Escalade, Escalade

EXT, Escalade ESV, H2 – Passenger Door Module and RKE Inoperative |

Re-flash

passenger door module. |

Don’t

replace passenger door module. |

04-08-52-005 |

| 2001-2003 |

Fullsize

Pickups – Injector Replacement for High Flow Rates |

Use

Corporate Bulletin Number 04-06-04-007A for injectors with high

fuel return rates. Use Special Policy 04039 for all 01-02 vehicles. |

Don’t replace 8 injectors for any complaint other than high

fuel return rates. All other injector failures are fix as failed. |

Special

Policy 04039 |

2004-2005 |

All

Cars and Trucks – State-of-Charge Upon Delivery of New Vehicle |

Check

battery’s state-of-charge per revised PDI using J-42000

or J-42000-EU |

Don’t

remove and replace battery. |

02-06-03-009A |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for September |

| |

|

| Know-How

Broadcasts for September |

| 10290.09D

Emerging Issues |

September

8, 2005, 9:30 AM and 12:30 PM Eastern Time |

| New

Model Features |

For

Web NMF courses, log on to the GM Training Website (www.gmtraining.com).

Select Service Know-How from the menu, then choose New Model

Features for a selection of courses. |

| -

Thanks to Tracy Rozman |

|

|

| return

to Table of Contents |

|

Car Issues

— Fix It Right the First Time (new issues in bold)

Car Issues

— Fix It Right the First Time (new issues in bold)

Truck

Issues — Fix It Right the First Time

(new issues in bold)

Truck

Issues — Fix It Right the First Time

(new issues in bold)