| |

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

| BREAKING

NEWS

|

Now

you can upgrade some 1999-2004 1500-series trucks, with dealer-installed

20-inch wheels and tires. Ten wheel styles available from GMSPO. Some

restrictions apply. Factory warranty. Requires VCI recalibration. See

bulletin 03-03-10-006 and January TechLink for more details. |

| return

to Table of Contents |

|

|

Attention:

GM Dealership Users of the Service Information (SI) Web Site |

United States

Only

During the first quarter of 2004, GM Service and Parts Operations will

migrate users of the http://service.gm.com web site to a more secure

log-in procedure and eliminate common IDs and passwords for GM Service

Information (SI) (fig. 1). GM dealership

users located in the United States will be affected first, with other

customers to follow at a later date.

Access for U.S. Service Managers and Technicians

To prepare for phase one of the transition, U.S. service managers and

technicians are urged to obtain a DealerWorld ID and password from your

Partner Security Coordinator (PSC) located at your dealership (fig.

2 and 3). In order to maintain appropriate security, each technician

should have an individual ID and password for DealerWorld.

During the transition, users who access the service.gm.com

web site will be prompted to enter their DealerWorld ID and password

at the “Enter Network Password” dialog box.

TIP: If your

ID presently looks like this -- si2kncr, si2kwwr, si2kscr, si2kser or

si2kner -- you will now be asked to enter your DealerWorld ID. The old

ID will be deleted.

How to Purchase Access

If you are not a U.S. General Motors service manager or technician,

but have used one of the IDs above, you will be able to purchase access

to GM Service Information (SI) from http://www.gmtechinfo.com.

-

Thanks toBob Savo and Lisa Scott |

figure

1 |

figure

2-3 |

| return

to Table of Contents |

|

|

| Transitioning

from Windows 98 To Windows 2000/XP |

GM Service Operations will end testing support for the following PC

operating systems:

- Windows 98 Second Edition

- Windows Millennium

- Windows NT 4.0

End of support will be effective January 15, 2004. This end of support

follows the GM ACCESS end of support announcement for Windows 98SE in

the GM Messenger announcement VSG20030967.

What End Of Support Means. GM Service Operations discontinues

validation testing of current and future software releases on these

operating systems. Also, Techline Customer Support Center (TCSC) 1.888.337.1010

prompt 3 will provide only limited troubleshooting support on issues

that may be operating system related.

Microsoft Ends Support. With Microsoft no longer supporting

these operating systems, updates for virus protection, fixes and enhancements

will no longer be available.

GM ACCESS Network Administration / Management. With

the GMA 2 servers deployed to all NAO dealerships, network administration

for Techline clients will become more complex, as individual user identification

/ password (ID / PW) credentials must be issued rather than the previous

'generic' Techuser account. (See the accompanying article for more information

on individual ID / PWs.) Supporting this administratively at the dealership

and GM ACCESS levels on Windows 98SE clients is cumbersome and not endorsed

by GM ACCESS.

Technology Lifecycle. PCs that are running Windows

98SE and Millennium are commonly Pentium II and Pentium III systems

in their 3rd and 4th year of effective life cycle. Many of these systems

will not have adequate processor speed or memory to run Windows XP or

Windows 2000 efficiently. In addition, Techline applications function

more efficiently on Windows XP and Windows 2000.

The following specification is the minimum PC configuration:

- Intel Pentium III 600 MHz

- 128 MB SDRAM

- 16 MB DRAM Video Memory

- 16x CDROM

- Windows 2000 Professional/Internet Explorer 6.0

- Windows XP Professional/Internet Explorer 6.0

Systems that do not meet or exceed this minimum specification should

NOT be considered for upgrade but rather replaced.

TIP: It is recommended

to use a full operating system installation rather than an upgrade.

Use of an upgrade may affect proper functionality of SI.

Refer to http://service.gm.com for

current Techline hardware specifications or contact the Techline Customer

Support Center (TCSC) for assistance in selecting the correct Techline

PC.

TIP: If you attend

NADA 2004, stop by the GMSO exhibit for more details.

-

Thanks to Bob Savo and Mike Waszczenko |

|

|

|

| Labor

Operation for Reprogramming |

When

you program a module under warranty, bulletin 02-06-04-057C reminds

you to use the labor operation that most accurately reflects the module

that is being programmed.

GM uses warranty information to make decisions on which components require

engineering changes to assure that customer needs are being met.

Refer to the bulletin for details, including labor times. The bulletin

also explains how to determine the correct code for exceptions. The

accompanying table is a summary.

- Thanks to Marty Case

Module

Being Reprogrammed |

Labor

Operation Number |

Engine

Control Module |

J6354 |

Body

Control Module |

N4808 |

Transmission

Control Module |

K5364 |

Transfer

Case Control Module |

N8521* |

HVAC

Module |

D4707* |

Driver

or Passenger Door Module |

N8520* |

Instrument

Panel Cluster Module |

N4199 |

* Do not apply to

C4500-C8500 vehicles |

| |

return to Table of Contents |

| |

| GMLAN

Update |

This

is an update on the GMLAN (Local Area Network) article which first appeared

in the March 2003 TechLink. Since then, more GM vehicles have begun

utilizing GMLAN data communication systems. These vehicles require the

use of a CANdi (Controller Area Network diagnostic interface) module

for Tech 2 communications (fig. 4). At

present, the 2004 Cadillac XLR and CTS, Chevrolet Malibu, Saturn ION,

and Buick Rendezvous with LY7 engine all use GMLAN for a portion of

their data communications. These vehicles continue to use Class 2 communications

along with GMLAN.

During Tech 2 communications with a GMLAN equipped vehicle, the CANdi

module must be installed in the data cable between the Tech 2 and the

DLC. Class 2 data will pass through the CANdi module, so it can stay

in place when communicating with GMLAN or Class 2 data. Failure to install

the CANdi module can result in communication errors with the Tech 2.

These errors may lead to misdiagnosis, or unnecessary calls to the Technical

Assistance Center.

TIP: Perform

the Tech 2 functionality test before using the CANdi module for the

first time. This will assure all of the circuits used by the CANdi module

are functioning properly. The March 2003 issue of TechLink explains

this funtionality test. For further support, call the Techline Customer

Support Center at 1.800.828.6860 (1.800.503.3222 in French).

-

Thanks to Russ Gilbert |

figure

4

|

| |

| return

to Table of Contents |

|

| ABS

or TCS Light On |

If

the ABS or TCS light is on intermittently in a 2003-04 Buick Regal,

check the electronic brake module harness (EBTCM). If it is positioned

wrong, it may rub on the transaxle rib (fig. 5).

Make the necessary repairs to the wiring, and reroute the harness away

from the rib.

-

Thanks to Wayne Zigler |

figure

5 |

| return

to Table of Contents |

|

| Tire

Rotation Additional Information |

An

article in the October TechLink referred to tire rotation on the 2004

Cadillac SRX. It pointed out that, because of dissimilar sizes, tires

cannot be rotated between front and rear.

TIP: Side to

side rotation, while technically possible, is not needed. |

| |

| return

to Table of Contents |

|

| Vehicle

Data Recorder |

A

completely redesigned version of the J-42598 Vehicle Data Recorder (VDR)

has just been released (fig. 6).

The most important reason for revising the VDR is that GM has introduced

the GMLAN communication system (see TechLink March 2003). The earlier

VDR, which was Class 2 based, could not communicate with the new GMLAN

vehicles. So a redesign was necessary. The new VDR will communicate

with both Class 2 and GMLAN vehicles without need for any adapters.

Do not discard your current VDR. It will still be supported by the same

software release as the new VDR CAN+. The old VDR will be supported

as long as Class 2 vehicles are available.

As before, the VDR has the same snapshot recording capabilities as the

Tech 2. It’s designed to capture data during an intermittent driveability

condition, while the customer drives the vehicle. The VDR can be programmed

to be triggered by specific conditions, or it can be triggered by the

driver pressing the lighted button on the tool.

The VDR has the capacity to receive and record four 30-second snapshots.

If a fifth recording is attempted, the oldest one is overwritten.

The VDR is now shaped like a beverage container, so it fits into the

cupholder included in most new vehicles. When not in use, the data cable

can be wrapped around the VDR for convenient storage.

The VDR is rugged and able to withstand contact with engine and transmission

oil, coolant, brake fluid, and degreasers found in service areas.

As before, you will be able to program the VDR using your Techline terminal,

which must have the latest program installed from the CD Revision 9.0

which comes with the tool. You will also use your Techline terminal

to download, display, store and print the data recorded by the VDR.

And finally, the new VDR is capable of recording data from not only

the powertrain and transmission modules but also from chassis modules

as well. Additional chassis coverage will be available in future software

releases.

-

Thanks to Mike Banar |

figure

6 |

| |

|

return

to Table of Contents |

|

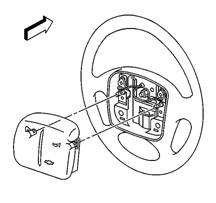

| Steering

Wheel SIR Inflator Module (Air Bag) Replacement Clarification |

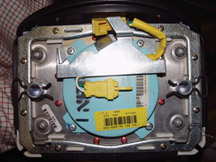

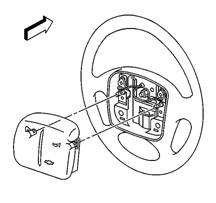

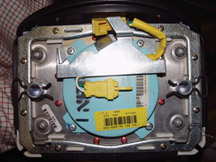

This

information applies to the Chevrolet Venture (U van) from 1997 through

2001. For these model years, the air bag is retained to the steering

wheel with Torx bolts.

To remove the air bag, remove the bolts from the back side of the steering

wheel (fig. 7). Temporarily remove the

clips from the back of the air bag, to free the pins from the air bag.

Install the clips on the air bag, where they came from (fig.

8).

To install the air bag, first install the pins to the steering wheel

with the Torx bolts. After the pins are installed to the steering wheel,

simply push the air bag onto the wheel until the clips snap into place

on the pins (fig. 9).

TIP: For 2002

and later, the Chevrolet Venture uses an air bag retained by clips,

the same as Oldsmobile and Pontiac models. This type of air bag requires

special tool J-44298 to release the clips, following SI procedures.

- Thanks to Bill Trainor and Tom Gahl |

figure

7 |

figure

8 |

figure

9 |

| return

to Table of Contents |

|

| Chevrolet

SSR Pre-Delivery |

Refer

to bulletin 03-00-89-035 for the complete pre-delivery story on the

new Chevrolet SSR (fig. 10 and 11). Performing

a quality pre-delivery inspection is one of the most important functions

your dealership can do for the customer. A quality PDI is essential

to improving a customer’s perception of your dealership and increasing

satisfaction with the new vehicle. Here are highlights from the bulletin

as well as service tips to help understand some of this vehicle’s

unique features.

Wheels and Tires

Set the tire pressure to 30psi (207 kPa) to achieve the intended vehicle

ride and handling characteristics for normal driving.

TIP: The Owner’s

Manual states that if the vehicle is driven at high speeds of 100 mph

(160 km/h) or higher, where it is legal, set the cold inflation pressure

to the maximum inflation pressure shown on the tire sidewall, or to

35 psi (244 kPa), whichever is lower.

To avoid damage to the silver-painted flangeless aluminum wheels, hand

wash the vehicle or use a rail-free car wash.

TIP: Also be

careful not to damage the wheels on the side rails of a flat-bed hauler

when transporting the SSR.

Because the wheels are different sizes (19 inches in front and 20 inches

in rear) the tires should not be rotated. Each tire and wheel should

be used only in the position it is in.

TIP: The SSR

has a tire inflation kit; no spare tire is included.

Miscellaneous Prep Tips

Cycle the retractable hard top to ensure proper operation (fig.

12). The cargo cover must be closed before the top will operate.

Check SI for diagnosis and repair if the top does not operate properly.

Driver Information Center messages and DTCs are useful in diagnosing

improper operation.

In the Driver’s Information Center, reset the average fuel economy,

range, and trip odometer.

Center the exhaust tips if necessary.

Install loose-shipped parts and RPAs.

- Floor mats

- Spare keys

- Owner’s manual and Getting to Know guide

- Top release tool in the pen holder loop of the owner’s manual

portfolio

- Front license plate option VK3 if necessary

TIP: You must

use tool J-45999 to remove the cupholder or the coinholder. Using any

other tool will result in damage to the right knee bolster trim.

Remote Keyless Entry

The Tech 2 must be used for this procedure. When “building”

the vehicle, specify 2003 Pontiac Grand Am. Then follow SI procedures

to complete the process.

HVAC

When the mode knob is turned all the way clockwise to the full defrost

position (yellow), the fan runs at the highest speed and the temperature

is at max. This is regardless of where the other knobs are set. When

the mode knob is moved from max defrost, operation returns to normal.

The fan speed can be changed manually in the max defrost mode as well.

Tailgate and Cargo Cover Operation

To open the tailgate, open the cargo cover using the remote keyless

entry transmitter or the cargo cover release button in the glovebox.

Pull up on the handle inside and lower the tailgate.

To close the tailgate, close the cargo cover before closing the tailgate.

Push the tailgate upward to return it to its upright, latched position.

Push and pull on the tailgate to make sure it is secure.

-

Thanks to Dan Oden

|

figure

10 |

figure

11 |

figure

12

|

|

return

to Table of Contents |

|

| Sit-N-Lift™

Power Seat Now Available |

With the Sit-N-Lift power seat, GM becomes the only automotive manufacturer

in the U.S. to offer a fully motorized, rotating lift-and-lower passenger

seat (fig. 13).

The innovative Sit-N-Lift power seat is available on extended wheelbase

Chevrolet Venture, Pontiac Montana and Oldsmobile Silhouette minivans

with second row captain’s chairs. It’s a regular production

accessory (RPA), installed at the dealership.

TIP: The equipment

is shipped from the factory separately from the vehicle. It is identified

with the vehicle’s VIN. Installation instructions are shipped

with the equipment, along with an owner's manual supplement that covers

operation of the Sit-N-Lift Power Seat.

TIP: Service

information for the Sit-N-Lift components is available in SI under Body

- Seats.

More information on Sit-N-Lift and GM Mobility is available at http://www.gmmobility.com.

- Thanks to Bill Trainor and Bob Jubenville |

figure

13

figure

13 |

|

return

to Table of Contents |

|

| Fuel

Gauge Conditions |

Bulletin

03-08-49-014A contains revised information for fuel gauge conditions

on 2001-03 Blazers and Jimmys, and 2001 Envoys. The conditions are model

year related.

TIP: For 2001-02

models, the information applies to 4-door models only.

A new service calibration was released on TIS2000, version 9.0 or later.

Use this calibration to reprogram the PCM.

TIP: If the cluster

part number is required, you can obtain it using the Tech 2. DO NOT

remove the cluster.

- Thanks to Dan Oden |

| |

return

to Table of Contents |

|

| Quadrasteer™

Service Update |

Here

are some service tips for the Quadrasteer system (fig.

14). For complete information, refer to the appropriate sections

of SI.

Understanding the Features of Normal Quadrasteer Operation

- Rear steering angle is limited to 5° in Park (with no vehicle

speed). Once the vehicle attains forward speed, the system is capable

of 12°.

- Rear steering angle is limited to 5° when driving in Reverse

- The system defaults to 2WS if in Neutral for more than 4 seconds.

The 2WS mode light will illuminate and the light for the previously

selected mode will flash. When shifted out of Neutral, the system will

automatically return to the previously selected mode.

- Quadrasteer will change modes only when the steering wheel passes

through center. Until that occurs, the indicator for the requested mode

will flash. (2003 and newer models will switch modes immediately if

speed is 0).

Vehicle Requirements for Quadrasteer to Operate

- Engine must be running

- Generator / Charging system must be functional. If a fault is detected

by the Generator / Charging system, the Quadrasteer system will become

inoperable to minimize battery drain.

- System voltage must be within a 9 – 16 volt range.

- System voltage is supplied by one high-current connection, one low-current

connection, and one ignition line.

- Valid vehicle speed information from the PCM (hard-wired and Class

2 message) and ABS (Class 2 message) must all correlate.

- Valid hand wheel steering shaft position information must be received.

Analog information from the Truck Body Controller (TBC) Body Control

Module (BCM) via Class 2 and digital information is obtained from phase

A, phase B, and Marker pulse of the position sensor wired directly to

the Quadrasteer control module.

- Valid signals from rear position sensor.

Most Common Mis-Diagnosed Quadrasteer Issues

- Quadrasteer does not operate and all three mode lights illuminated

solidly

Control module needs to be programmed (‘03 model year and above)

and/or needs Tech 2 alignment to be performed. No Class 2 information

is available until the module is programmed.

- Quadrasteer does not operate and mode lights are blinking.

The vehicle may be in Neutral. Quadrasteer will return to normal operation

when shifted out of Neutral and steered through straight ahead.

- C0550 DTC -- internal controller fault

May be caused by a loose 125 amp Mega-fuse, shorted Lat / Yaw combo

sensor, or water intrusion into rear position sensor.

- C0522 DTC and/or C0532 DTC – Rear Wheel Sensor and Rear

Sensor to Hall Comparison

May be caused by shorted Lat / Yaw combo sensor, or water intrusion

into rear position sensor.

- C0455 DTC – Handwheel Position Sensor (HWPS)

May be caused by improper terminal tension at HWPS connector, loose

or damaged ground at circuit G203 (‘03 model year and above),

or damaged harness between C201 and HWPS connector.

- Quadrasteer inoperable with no DTCs present

May be caused by missing required vehicle signals such as Ignition (541),

Batt2 (2640), Engine Run message (Class 2) or faulted Charging System.

See Vehicle Requirements for Quadrasteer Operation above.

TIP: Clearing

History DTCs from the controller is NOT required to restore normal operation

during troubleshooting. Please leave codes stored in the module. This

will aid in root cause analysis.

- Thanks to Steve Love |

figure

14 |

| |

| |

| return

to Table of Contents |

|

Damaged

Electrical Terminal |

Some

2001-04 Buick Century and Regal models may have a combination of the following

intermittent conditions:

- Inoperative IP cluster

- Inoperative SES, TCS ABS lights

- Inoperative air bag light

- Inoperative power windows

- Inoperative sunroof

- Inoperative radio

- Inoperative turn signals

- No crank

- Security light on

- BTSI stuck in PARK (2003-04 only)

- DTCs: U1000, U1016, B1422, B2957, B2958, and possibly others

These may be caused by a damaged terminal in the Underhood Accessory Wiring

Junction Block (also sometimes called the Underhood Bussed Electrical

Center or UBEC). This terminal provides voltage from the IGN 1 30-amp

fuse to nine circuits in the vehicle’s interior.

If the condition is intermittent, and normal diagnosis does not lead to

a conclusive failure mode, perform these steps.

Remove the Underhood Accessory Wiring Junction Block from the bracket

at the right strut tower. Loosen the bolt in the center of connector C2

and pull the connector loose. Check terminal D2 for damage (fig.

15). A good terminal is shown in figure 16

and a damaged one in figure 17.

If the terminal is damaged, obtain a replacement (p/n 12110844) from tray

4 of the J-38125 Terminal Repair Kit. Install it according to proper SI

procedures.

-

Thanks to Wayne Zigler |

figure

15 |

figure

16 |

figure

17 |

return

to Table of Contents |

|

| Product

Feedback Processes |

In

today’s competitive market, vehicle quality is a key factor in

retaining customers and creating customer enthusiasm for our products.

Because dealership personnel are in contact with customers and vehicles

on a daily basis, you’re in an excellent position to be up to

date about current concerns. GM wants to hear what you have to say (fig.

18).

That’s why an important part of GM’s continuous quality

improvement process is collecting information from the field. Engineers

use the data collected to decide how to improve product quality and

modify assembly plant procedures.

Another spin-off is that the information can be distributed to the field

in the form of service bulletins, VME messages, TechLink articles and

the Fix It Right the First Time information (see page 8 of each issue

of TechLink).

When you in the field and engineers at GM are able to work together

to share information, quickly respond to customer concerns and address

product quality issues, everyone wins. Particularly the customers, which

is directly reflected in CSI, and other consumer surveys.

Here’s a brief summary of the various processes presently in use.

These processes were developed with an eye toward creating minimum interference

with workflow in your dealership. We appreciate the effort your dealership

takes to help us in this ongoing quest to maximize the quality of our

products.

General Motors Sentinel Dealers -- These are specific

dealers in key geographic locations across the county who supply Repair

Order information electronically from their dealerships on a daily basis.

Part Restrictions -- In this process, Product Quality

Center and TAC restrict a particular part number or labor operation.

Before proceeding, the dealerships must contact either TAC or PQC, who

collect specific information on the issue. Even if your dealership has

the part in stock, the PQC should be contacted first. These restrictions

can last from a few weeks to 90 days or more -- whatever is required

to permit Engineering to gather enough data to determine the root cause

of the issue.

We are careful not to have too many restrictions going on at one time.

But, the cost and inconvenience of the restriction at both the dealership

level and General Motors is more than offset by the value of improved

product quality. Parts restriction has proven to be one of the most

effective sources of product information we have developed.

Action Centers -- The Action Centers are set up to

gather information for the assembly plant of a new product. The Action

Center takes phone calls from dealers that need help with one of these

new products. The information is then directed to the assembly plant

and improvements are made very rapidly.

Field Engineering Investigation Process -- In this

process, Engineering uses the VIS system to explain what they are looking

for. The Service Advisor prints out the instructions in VIS for the

technician. The technician is requested to contact TAC after following

the directions. A specific labor operation is provided to pay the technician

for this effort in helping the Field Engineering Investigation process.

PQC will process this specific labor operation with prior approval so

the dealership gets paid for the activity.

Warranty Parts Center Process -- All parts of a new

vehicle are returned to the WPC for six months after the vehicle is

launched. In addition, Engineering and Brand Quality can request the

return of a specific part number when the part is replaced on a warranty

claim. Returned parts are analyzed to determine root causes for why

the parts were replaced, and improvements are pursued.

The Field Service VME System -- This provides two-way

voice communication on product issues between GM Service and the dealers.

In the normal course of vehicle repair, if you come across something

that you think will help us improve the repair and quality of our vehicles,

you can use the Field VME Product Feedback system to let us know.

-

Thanks to Jim Colyer, Melissa Suhy, Jack Pantaleo and Ann Briedis |

figure

18 |

| |

| |

|

return

to Table of Contents |

|

| Transaxle

Electrical Connector |

Be

on the lookout for bulletin 02-07-30-022B, which is being re-issued to

include 2004 model year vehicles.

The bulletin applies to numerous carlines which use the 4T65-E, 4T40-E

or 4T45-E transaxles.

Some customers may comment that the SES lamp is illuminated, accompanied

by extremely harsh shifts. The conditions may be caused by an intermittent

connection at the transaxle 20-way connector (fig.

19).

The bulletin lists six potential causes:

- harness stretched tight

- terminals not fully seated

- male terminals bent

- female terminals loose

- terminals insufficiently crimped to wire

- connector not properly seated and locked

Perform an inspection and make the necessary repairs.

-

Thanks to Bob Martin |

figure

19 |

| |

| return

to Table of Contents |

|

| A/C

Compressor Diagnostic Tips |

The information here deals with two conditions that appear to be contradictory.

In the first case, compressors may have been replaced unnecessarily, and

in the second case, compressors may need to be replaced. Here are the

details.

1993-Present Cars and Trucks

Refer to bulletin 01-01-38-013A, which provides information to consider

before replacing an A/C compressor for noise, vibration or insufficient

cooling. Only highlights are given here.

The bulletin lists numerous system conditions (other than the compressor)

that can cause these symptoms. High on the list is the state of refrigerant

charge, either too low or too high. Others include loose attachment hardware,

worn drive belt, grounded refrigerant lines, improper or insufficient

airflow, contamination, and improper oil charge.

TIP: Perform a

thorough visual inspection before performing tests or repairs.

TIP: Use the ACR

2000 Tool to recover and weigh the refrigerant charge to help accurately

diagnose a charge level condition.

If careful diagnosis legitimately leads to compressor replacement, be

sure to follow the bulletin guidelines to determine which of the following

may be appropriate: oil balance, suction screen filter, flushing, addition

of fluorescent dye.

TIP: Bulletin 01-01-38-006B

provides additional information on flushing procedures.

G-Vans and C/K Trucks from January 2002 through April 2003

All of these vehicles use a Denso compressor (fig.

20). Customers with these vehicles may comment on underhood noises

or insufficient cooling.

TIP: If proper

diagnosis pinpoints the compressor as the cause, replacement is the appropriate

repair. Compressors built between the dates listed may be more susceptible

to these conditions.

TIP: A redesign

in April 2003 addressed the reed valve and retainer gasket. Compressors

built after April 2003 are redesigned, revalidated and significantly improved.

These can be easily identified: the serial number begins with 5E.

Part Numbers for Redesigned Compressor

| C/K |

15100337

/ 338 / 339 / 340 |

| G Van |

15106396 /

397 |

The symptoms may be caused by a condition called “liquid slugging.”

In a properly operating A/C system, the refrigerant may be either liquid

or gas, depending on where it is in the system. At the compressor, the

refrigerant is supposed to be gaseous. If liquid refrigerant enters

the compressor, slugging occurs. Because liquid is not compressible,

pressures become extremely high and damage can occur to the reed valves

and retainer gasket.

TIP: The A/C

systems on large vehicles such as vans and utilities contain a larger

amount of refrigerant, and the lines have a greater number of bends,

both of which provide extra opportunities for liquid refrigerant to

return to the compressor. Also, on some of these vehicles, the A/C compressor

is low-mounted, which increases the opportunity for liquid to pool.

-

Thanks to Steve Haar and Saundra Massingille

|

figure

20 |

| return

to Table of Contents |

|

| Loud

Pop or Snap Noise From I/P in Hot Ambient Temperatures |

On

some 2001-03 Chevrolet Impalas and Monte Carlos, a loud popping or snapping

noise may occur at the windshield or I/P pad area. It is often described

as sounding similar to a stone hitting the windshield.

The noise most often occurs shortly into a drive cycle after the A/C begins

cooling the interior, after the vehicle has been sitting in high ambient

temperatures, usually above 90° F (32° C). The noise originates

from the metal plates riveted to the underside of the Upper I/P Pad over

the Instrument Cluster and Passenger Side Airbag.

Once the condition is confirmed, replace the Upper I/P Pad with a new

part from GMSPO. The new pad has eliminated the plate over the Instrument

Cluster and should correct most ocurrences of this condition. Additional

Field Product Reports regarding the successful repair of vehicles using

this procedure would be appreciated.

-

Thanks to Phil Race |

| |

| return

to Table of Contents |

|

| Flywheel

Bolt Holes |

When

replacing the flywheel on a GEN III V-8, you may notice the bolt holes

for the crankshaft in the replacement flywheel are larger than the holes

in the original part.

The original part was superseded. The new flywheel has slightly larger

bolt holes. New bolts with washers have a 22.3 mm conical design and will

provide sufficient clamp load to install the new flywheel. The new bolts

part number 12563533 and flywheel are applicable only on LQ4 engines or

LR4 engines for 1999 and 2000. Install the flywheel using the appropriate

Service Information procedure.

-

Thanks to Sean Garrison |

| |

| return

to Table of Contents |

|

| Tire

Pressure Monitor System Message Displayed On DIC |

On

some 2004 Pontiac Grand Prix models, a customer may comment that there

is a Check Tire Pressure message on the DIC. There may not be any DTCs

or visible defects and no malfunction can be identified in the system.

Inspect the rear wheel speed sensor harnesses 5-10 inches (12-25 cm) inboard

of the suspension knuckles for the presence of either an orange or white

tape label on the left rear harness. If it is on the left harness, the

sensor is installed incorrectly and should be swapped with the right side,

where it belongs. Both rear wheel speed sensors share the same connector

and have harnesses of simliar length.

-

Thanks to Phil Race |

| |

| return

to Table of Contents |

|

| Supplemental

Brake Assist Noisy and May Run Continuously |

On

some 2003 C/K vehicles, the Supplemental Brake Assist (SBA) motor is noisy

and runs when the brake pedal is depressed and may run continuously when

the brake pedal is released.

Use P/N 89040236 to correct this customer concern.

-

Thanks to Dana Evanoff

|

| return

to Table of Contents |

|

| Poor

or No HVAC Heat |

Owners

of some 2004 Cadillac CTS and SRX models may experience poor or no HVAC

heat.

Check the thermostat housing (P/N 12573977) for casting flashing. Remove

the flashing from the thermostat housing. If the material cannot be removed

without damaging the housing, replace the housing.

- Thanks to Duane Raymond

|

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time

Car Issues – Fix It Right The First Time |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2000-2004 |

Cavalier/Sunfire

-- Grinding Noise on Clutch Apply. Very low mileage |

Replace

clutch hydraulic line. |

Don’t

replace clutch/bearing |

02-07-31-003A |

2003-2004 |

Vibe

– Normal Exhaust Odor |

Provide

a copy of the service bulletin to the customer. |

Don’t

replace the catalytic converter |

06-05-006 |

1997-2004 |

Grand

Am / Alero / Malibu – Brake pulsation |

Turn

rotor and use brake align procedure |

Don’t

replace rotors for pulsation |

00-05-23-002

01-05-23-001 Know How 15040.01B) |

2001-2003 |

Venture

/ Montana / Silhouette/Rendezvous/ Aztek – Rattle or Buzz

from Exhaust System |

Install

clamp |

Don’t

replace catalytic converter |

03-06-05-003

dated 01/28/03 |

2004 |

Grand

Prix with Monsoon System -- Speaker Buzz |

Re-Pin

Speaker wires in the IP fuse panel connector |

Don’t

replace the Speaker, Amplifier or Radio |

03-08-44-015 |

2000-2004 |

Impala

/ Monte Carlo -- Condensation in Headlamp |

Normal

when limited to fog or fine mist appearance in high humidity conditions |

Don’t

replace headlamp assembly when no water droplets evident |

01-08-42-001

Sept 2000 TechLink |

2003-2004 |

CTS

– Variable Effort Steering (VES) “Service Steering

Message” DTC C1241 or C0450 |

Replace

VES solenoid only |

Don’t

replace entire steering gear |

03-02-36-001 |

2003 |

All

cars with 4T40/45E, 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM

solenoid and valve asm. |

Don’t

replace transmission or valve body assembly |

02-07-30-039B

(Part numbers in bulletin have been superceded) |

2002-2004 |

All

cars with 4T40/45E and 4T65E with DTC P0716, P0717 and other misc

codes |

Disconnect,

inspect, and reconnect transaxle wiring harness at the transaxle. |

Don’t

replace input speed sensor. |

02-07-30-022B(Oct

2003)

Sept 2003 TechLink |

2004 |

L61

EcoTech 4 Cylinder 2.2L Engine |

Replace

Spark Plug Sets |

Don’t replace PCM or ignition cassettes |

03-042

Recall |

|

| return

to Table of Contents |

|

|

Truck Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

1999-2004 |

Vehicles with HomeLink Universal Transmitter – Programming

Diagnosis |

Use

J41540 HomeLink Tester, follow SI, refer customers to owners manual |

Don’t

replace HomeLink Transceiver without validating internal fault |

01-08-97-001B |

1999-2003 |

Silverado, Sierra, Savana, Express 8600 GVW – ABS lamp on |

TIS

Version 4.0 Re-flash for code C0550 H2504 |

Don’t

replace ABS Module |

03-05-25-003 |

2003-2004 |

FullSize Pickups and Utilities – Door Trim Panel |

Remove

front door panel, then remove switch bezel retaining screw. |

Don’t

pry switch bezel out of door trim panel without first removing

retaining screws |

Service

VME

03-08-64-022 |

2003-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed |

Don’t

replace complete mirror assembly |

03-08-64-028 |

2003 |

Fullsize Pickups and Utilities – Transfer Case Service Light |

Replace

encoder motor sensor and reprogram TCCM |

Don’t

replace module, encoder motor or transfer case |

03-04-21-001B |

2003 |

Fullsize

Pickups – 6.6L Diesel Engine ECM |

Follow

SI and bulletins for proper diagnostics for P0181, refer to the

Owner’s Manual (block heater and front cover) |

Don’t

replace ECM unless diagnostics confirm need to replace |

02-06-04-048,

03-06-04-021, 02-06-04-058 and parts restriction |

2002-2003 |

TrailBlazer,

Envoy, Bravada -- Squeak Rub/Scrub Type Noise in Steering Column |

Lubricate

and remove material per bulletin |

Don’t

replace upper or lower intermediate shaft |

02-02-35-006A |

2002-2004 |

TrailBlazer,

Envoy, Bravada, Rainier – Tail Lamp Socket Circuit Board |

Replace

both tail lamp circuit boards |

Don’t

replace complete assembly |

Service

VME 9/22/03

03-08-42-006A |

2002-2003 |

TrailBlazer,

Envoy, Bravada – Windshield Washer Nozzle |

Replace

windshield washer nozzle |

Don’t

replace complete cowl assembly |

Service

VME 06/25/2002 |

2002-2004 |

TrailBlazer,

TrailBlazer EXT – Wavy Front Fascia |

Repair

fascia with Dual Lock |

Don’t

replace front fascia |

02-08-62-004 |

| 2002-2004 |

TrailBlazer,

Envoy, Bravada – Mirror Erratic Return |

Replace

mirror actuator and reprogram module |

Don’t

replace outside mirror assembly |

02-08-64-008

02-08-64-021 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for January |

| |

|

| Know-How

Broadcasts for January |

| 10280.01D

Emerging Issues |

January

15, 2004 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| 10280.13D

Brakes - Town Hall |

January

29, 2004 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

| |

Car Issues – Fix It Right The First Time

Car Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time