Table

of Contents – February 2003 |

| |

|

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

Note:

Clicking on any picture or illustration will open a larger version

of that art.

|

|

Cruise

Control with Electronic Throttle Control (ETC) |

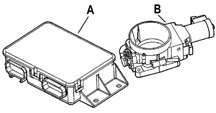

Over the past few

years, a new kind of cruise control has been phased in as engine families

switch over to the Electronic Throttle Control (ETC). In this system,

the position of the throttle blade is controlled by an electric motor,

driven by the Throttle Actuator Control and PCM. This eliminates the

need for a mechanical cable attachment from the accelerator pedal to

the throttle body. The driver’s foot operates an Accelerator Pedal

Position (APP) Sensor. (fig. 1)

TIP: You can quickly tell if the

vehicle has ETC by determining if the throttle pedal connects to a cable

or to the APP.

Because the throttle blade is computer controlled, it’s now possible

to use the same hardware for the cruise control system. A separate cruise

control module, connecting strap, linkage, and associated wiring are

no longer needed. For these reasons, the new system is considerably

more robust.

A great deal of effort went into the design of the new cruise control

system to ensure that it performs as nearly as possible to the way GM

owners’ past vehicles have performed.

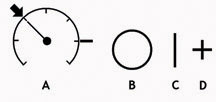

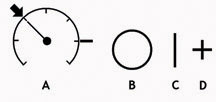

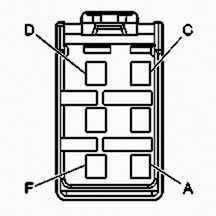

TIP: The appearance of control

buttons or labels (fig. 2) may vary between

models, so the following descriptions are somewhat generic. For specific

details, consult the owner’s manual for the particular vehicle,

found on SI for all 2003 vehicles.

A Set/Coast

B Off

C On

D Resume/Accelerate

With cruise control turned on, once the vehicle has reached the desired

speed, simply press and release the designated SET button and the vehicle

will maintain the chosen speed.

TIP: Cruise control cannot be

engaged until the vehicle has reached a road speed of approximately

25 mph (40.2 km/h) or higher.

If the driver steps on the throttle and reaches a new, higher speed,

pressing and releasing the SET button again will record and maintain

the new, higher speed.

TIP: If the driver uses the throttle

pedal to drive at a speed higher than is set, the cruise control will

disengage after approximately a minute. This is also called drop-out.

It is a new feature, and is not a malfunction. Press the + (RESUME/ACCEL)

button to reengage and continue driving at the previously set speed.

If the brakes are applied, the cruise control disengages. Briefly pressing

the + (RESUME/ACCEL) button causes the cruise control to reengage and

continue at the previously set speed.

TIP: On some versions of the new

system, there is a CANCEL switch, which duplicates the function of stepping

on the brake pedal, without actually applying the brakes.

The driver may override the set speed by pressing and holding the +

or - button until a new higher or lower speed is achieved. The new speed

is recorded when the button is released. These are also referred to

as the ACCEL and COAST buttons.

The driver may also choose a lower or higher speed using the tap-up/tap-down

feature. Tapping the + or - (ACCEL or COAST) button will change the

set speed by approximately 1 mph (1.6 km/h) per tap.

TIP: On the new system, the minimum

speed that can be reached with tap-down is 25 mph (40.2 km/h). The maximum

tap-up increase is 10 mph (16.1 km/h) above the previously set speed.

Diagnostic Tips

Inhibit Function

On the earlier cruise control system, the cruise module and the PCM

were separate components joined by wiring. Under certain circumstances,

it was necessary for the PCM to inhibit (prevent) cruise operation,

so an inhibit circuit ran between the modules.

The status of the inhibit circuit was used in some system diagnostics.

The new system also has occasions when cruise control must be inhibited,

but because the cruise control function is now contained within the

PCM, there is no need for an external inhibit circuit.

TIP: The inhibit circuit in not

mentioned in SI. This is not a mistake. For the reason just given, it

no longer exists in the form you’re familiar with. However, the

inhibit parameter still appears in the Tech 2 display.

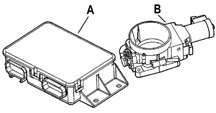

Commonality of Parts

In the cable-controlled system, it was possible for the cruise system

to malfunction without affecting normal throttle operation. In the new

system, because the same components operate the throttle blade for normal

and cruise driving, a failure will affect both at the same time (fig.

3). Put another way, there are no longer any unique cruise components

in the throttle controls to malfunction or to diagnose.

A Module

B Throttle Body

Disengage History Record

On your Tech 2, you can view the last 8 reasons why cruise control was

disengaged. This is a buffered list -- that is, the oldest item drops

off the list as a new one is added.

You may find this list useful when diagnosing customer concerns, such

as drop-out with the throttle depressed above the set speed, discussed

earlier.

TIP: The Disengage History records

all reasons, not just those that involve a DTC. In fact, the most common

reason you will probably see is Brake Applied.

The previous system also had this record, but it’s more comprehensive

in the new system. Depending on model, there are up to 38 items that

can be displayed.

Brake Application Before Engage

During each ignition cycle, the PCM must see one brake application before

the cruise control will engage. On automatic transmission vehicles,

this is satisfied by the brake application necessary to shift out of

PARK (BTSI). On manual transmission vehicles, a switch on the clutch

pedal serves the same function. The clutch must be depressed before

the starter can be engaged.

Clutch Application

On manual transmission vehicles, stepping on the clutch pedal causes

the cruise control to disengage, to prevent engine over-revving. The

RESUME button may be used to engage cruise control again.

-

Thanks to Ken Feliks and Kevin Fondaw |

figure

1 |

|

figure

2 |

|

|

| |

| |

figure 3 |

|

|

|

|

| Know-How Broadcasts

for March |

| |

|

| Know-How

Broadcasts for March |

| Emerging

Issues |

March

13, 2003 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| Technology

Close Up --

Tech 2 Functional Diagnostics and GM-LAN |

March

27, 2003 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| |

|

|

Gas

Springs

|

GM

uses gas springs on rear liftgates in numerous vehicles. The springs perform

several functions:

- assist in raising the liftgate

- hold the liftgate in the raised position

- provide a controlled rate when the liftgate is closed (fig.

4).

Operation

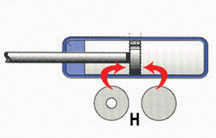

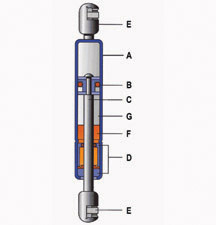

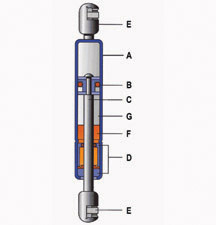

The gas spring looks somewhat like a shock absorber, although it doesn’t

work like one.

It consists of (A) pressure tube, (B) piston, (C) piston rod, (D) seal-guide,

and (E) appropriate connection fittings (fig. 5).

The gas spring is a hydropneumatic device, meaning it contains a liquid

(F - oil) and a gas (G - compressed nitrogen).

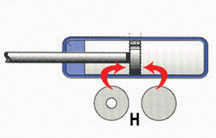

The compressed nitrogen acts with equal pressure on differently dimensioned

cross-sectional areas of the piston (fig. 6).

This produces a force in the extension direction (H). That is, the gas

spring, if left on its own, will extend fully.

The gas spring is designed to operate over a range of - 20°F (-30°C)

to 176°F (80°C). The compressed nitrogen in the gas spring behaves

just like any other gas in a confined space. Pressure moves up or down

along with temperature.

In normal temperatures (warm weather), the gas pressure

is higher. This means that the gas spring may offer sufficient force to

assist in raising the liftgate. It offers enough force to hold the liftgate

in the open position. And when the liftgate is closed, it provides enough

resistance to prevent the liftgate from slamming shut.

When the temperature drops (cold weather), so does the

gas spring’s internal pressure. Under these conditions, the liftgate

may not auto-rise due to the reduced assistance in opening, although it

will still hold the liftgate open. And it may offer reduced resistance

when the liftgate is closed.

TIP: All of these characteristics

are normal and a gas spring should not be replaced if the liftgate performs

as described. Replacing a normal spring (that is cold) with a new spring

(that is warm) will appear to correct the “problem,” but it

will return as soon as the replacement springs are allowed to become cold.

Hydro-Lift-T

The latest version of the gas spring is called the HLT, or hydro-lift

temperature controlled (fig. 7). The name

comes from a temperature sensitive bi-metal poppet valve in the piston

(J). It’s intended to minimize the effects of temperature on the

operation of the spring. At temperatures above 50°F (10°C) the

valve is inactive. Below this temperature, the valve closes and the holding

force increases. The gas must pass through a small orifice (K), against

the pressure of the bi-metal spring. This affects the flow of gas through

the piston when the gas spring rod and piston move into the pressure tube.

The effect is to provide extra holding force in the extended position

to ensure that the liftgate remains open. The HLT does not affect the

lift open effort or the closing resistance.

Replacement

Considering the operation of the gas spring when it is cold, you may wonder

how to tell if the spring should be replaced. Simple. If the springs do

not hold the liftgate up after it is opened.

On vehicles equipped with the new HLT gas spring system, the temperature

valve is contained in the LH spring, indicated by a red label. The RH

spring is indicated by a green label.

TIP: One exception is the Cadillac

Escalade, which uses a yellow label on the LH spring and a white label

on the RH spring.

TIP: When replacing gas springs,

be sure to check the parts book. There should be two numbers, one for

each side.

TIP: If you should install two red-labeled (or yellow-labeled)

gas springs, it will be very difficult to pull the liftgate shut. And

two green-labeled (or white-labeled) springs may not hold the liftgate

up when cold.

Gas springs should be installed with the piston rod pointing down when

the liftgate is open.

Maintenance

For a long service life, gas springs must not be subjected to bending

forces. If the spring or its mounting points are bent, the spring may

bind and not work properly.

Gas springs are designed for long life without maintenance. There is no

need to lubricate the piston rod. You should, however, be sure the rod

does not become contaminated (for instance with masking tape residue or

overspray from a paint repair).

A light film of oil will appear on the rod as the spring extends. This

is normal, and is for lubrication of the guide and seal.

Storage

If spare gas springs are stored in your parts department, be sure they

are placed with the piston rod pointing down. After a maximum storage

time of 6 months, the gas springs should be actuated.

Disposal

IMPORTANT: Wear appropriate eye protection.

When gas springs are no longer needed, they should be disposed of in an

environmentally correct manner. To accomplish this, drill the pressure

tube open, release the compressed nitrogen gas, and drain the oil.

- Thanks to Rich Staton, Stabilus |

figure 4

figure 4 |

figure

5 |

figure

6 |

figure

7 |

| |

| |

| |

| |

| return

to Table of Contents |

| |

| 3

Step Maintenance Fuel Induction Service Kit Followup |

The

December 2002 issue of TechLink introduced a new GM Vehicle Care line

of products called the 3 Step Maintenance Fuel Induction Service Kit.

This followup is to clarify how to obtain the application tool kit and

the cleaner kits.

Tool Kit -- The tool kit includes sprayer tips, adapters,

hoses, gauge, and other items (fig. 8). To

obtain the tool kit, contact the vehicle care specialist at 1.800.955.8591

(1.800.323.4592 in Canada). The maintenance cleaner kits (solvents) can

also be purchased at this number.

TIP: Be sure to inquire about available

incentives when both are purchased together.

Maintenance Kit -- The kit consists of three different

cleaning solvents (fig. 9):

- Fuel System Treatment

- Throttle Body Cleaner

- Induction Cleaner

The GM part number is 12378546. In Canada the AC Delco part number is

88901337. The kits are sold by the case. Each case contains enough materials

to service 12 vehicles. Your parts department can use the computerized

RAPID ordering system or call the TRACS 2000 phone ordering system, 1.800.433.6961

(1.800.866.5832 in Canada).

-

Thanks to Rene Richardson

|

figure

8

|

figure

9 |

| return

to Table of Contents |

|

| Steering

Wheel Mode Button |

Owners

of 2003 Chevrolet Venture vans may be unable to locate information on

the steering wheel radio control 'mode' button in the owner’s

manual or in SI.

Steering wheel radio control information was completely omitted from

the initial owner manual printing. Individual SWRC button operation

is not found in SI. SWRC information may be found in other Chevrolet

Division owner’s manuals such as Monte Carlo or Impala.

For vehicles built with RPO UK3, this is a description of what the 'mode'

button is for. Press this button to choose AM, FM1 OR FM2. If a tape

or compact disc is playing, it will stop and the radio will play. It

will not allow switching back to other sources such as cassette or compact

disc.

-

Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

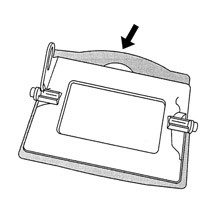

| OnStar

Deactivation Strategy |

This

information affects 1999 through current model year vehicles equipped

with the three-button OnStar system (fig. 10).

OnStar has begun deactivating the OnStar system in vehicles when the

customer has chosen not to renew their OnStar subscription after expiration.

OnStar notifies customers that the OnStar system in their vehicle will

be deactivated unless they renew the account.

After successful deactivation, customers will experience the following

when attempting to contact OnStar from their vehicle:

Blue OnStar key -- the customer will be connected to a dedicated sales

team who can sell an OnStar subscription and reactivate the vehicle.

(On some vehicles, the customer may first hear a message stating there

is no current OnStar subscription for the vehicle, and directing the

customer how to activate services. A second press of the blue button

will connect to a dedicated sales group who can reactivate the vehicle.)

Emergency key -- a message will indicate the service has been deactivated.

On 1999 models, the operation of this key does not change with deactivation.

TIP: When successfully deactivated,

the OnStar system will not attempt to connect to the OnStar center if

the vehicle's front airbags deploy.

The system may not be able to establish a connection to the OnStar Call

Center in certain situations, such as when the VIU is replaced on a

deactivated system. When normal published diagnostic procedures do not

indiate a possible cause for the no-connect concern, the vehicle may

have been deactivated. Further diagnosis and repair is necessary only

if the customer elects to become an active OnStar subscriber.

TIP: On the Tech 2 under the program

phone option, you will notice that the phone number is 011.555.7529

or 123.456.7890 on all units that have been deactivated.

-

Thanks to Dale Tripp |

figure

10

|

| |

| return

to Table of Contents |

|

| Regular

Production Accessories (RPA) |

There are several terms used to describe options and accessories that

can be ordered with a new vehicle.

Regular Production Options (RPO) are installed on the vehicle at the assembly

plant.

IMPORTANT: Some factory equipment is “shipped

loose” with the vehicle for installation at the time of delivery.

These items may be standard equipment or RPOs. Examples include wheel

covers, radio antennas, and roof rack components.

Certain GM accessories can now be ordered at the same time the vehicle

is ordered. These are called Regular Production Accessories (RPA). The

accessory is listed on the vehicle’s window label and SPID label.

An example is the cargo net available with some Buick Rendezvous models

(RPA code AP9).

However, the RPA does not accompany the vehicle when it leaves the assembly

plant. Instead, the item is shipped directly to the dealership for installation

at the time of delivery. The package is identified with the vehicle’s

VIN when it arrives at the dealership.

IMPORTANT: These RPA parts must

not be installed on another vehicle. In fact, it’s

a good idea to store RPAs where they cannot be confused with normal parts

department stock.

RPAs generally fall into the category of items that an owner may otherwise

seek in the aftermarket. Examples may include cargo nets, floor mats,

luggage compartment mats, body kits, running boards, mud flaps, off-road

lights (fig. 11), and many more.

The advantage of ordering a factory RPA is that the item is designed specifically

for the vehicle. Mounting holes, component fit, and colors are perfect

matches for the vehicle, which may not be true of aftermarket items. And

RPAs are covered under the new vehicle warranty.

This ensures that the customer is able to obtain desirable accessories

conveniently, and because the items are considered factory equipment,

they can be included in the vehicle’s financing.

The labor time for installation of an RPA is handled as an add time to

the Pre-Delivery inspection time (labor operation Z7000). Other warranty

labor operations are not to be used for the initial installation of an

RPA.

- Thanks to Russ Gilbert |

| |

figure

11 |

|

return

to Table of Contents |

|

| Regular

Production Option Master List |

A

vehicle consists of standard equipment and in most cases some optional

equipment as well. For organizational purposes, optional equipment is

identified by a Regular Production Option (RPO) code.

Every vehicle contains a Service Parts Identification label (SPID) which

lists every RPO included on that vehicle.

Because there are so many RPOs in use, you will not be able to remember

them all. When you encounter an RPO code that is unfamiliar, there are

several ways to find out what it pertains to.

One way is to go to SI, “build” the vehicle, then look under

General Information. All of the RPOs available on the “built”

vehicle are listed, along with a brief description of each option.

Another way is to go to GM-VIS and input the VIN of a specific vehicle.

You will see a list of the exact RPOs included on that vehicle, again

with a brief description.

Now, there is another way. The current list of RPOs is found on the

TechLink website at http://service.gm.com.

Open the TechLink website and click on a language button. At the top

of the home page, locate the REFERENCE GUIDES tab. This will take you

to a directory of available reference materials.

Click on the RPO Master List. It includes every RPO code in use for

about 20 years, and they’re arranged in alpha-numeric order.

TIP: This list is huge, running

more than 18,000 items. You can scroll the list using your browser’s

scoll bar or up and down arrows.

- Thanks to Kevin Larson |

|

|

|

|

| return

to Table of Contents |

|

| New

Gasket Material |

According

to SPO bulletin IB03-008, a new material is being used for service replacement

transmission pan gaskets.

The previous black fiber material is superceded by UltraCork, comprised

of cork granules embedded in rubber. The advantages of UltraCork include:

- Resists breaking when folded

- Conforms to warped or uneven surfaces

- Improved sealability

- Better torque retention

- Smaller bolt holes, to facilitate installation by holding pan bolts

in place

- Improved thread sealing

The UltraCork transmission pan gasket will be included with the transmission

filter. The transition will occur as inventory of the current black

fiber gaskets is depleted.

- Thanks to GM Parts |

|

|

| return

to Table of Contents |

|

| Trailer

Controller Information |

The

following vehicles are affected:

2002-2003

- Cadillac Escalade, Escalade EXT

- Chevrolet Avalanche

1999-2003

- Chevrolet Silverado

- GMC Sierra

2000-03

- Chevrolet Suburban, Tahoe

- GMC Yukon, Yukon XL

2003

- Hummer H2

Some customers may comment that when the headlamps or park lamps are on,

the brakes on the trailer are always applied, or that the back lighting

for the trailer brake controller illuminates only when the brakes are

applied.

This condition may be due to wiring changes within the vehicle electrical

system for the 2003 model year.

Inspect the brake controller wiring harness jumper that is plugged into

the vehicle relay block body. The relay block body is located under the

left side of the instrument panel near the left kick panel, behind a plastic

cover.

The 1999 through early 2003 wiring harness jumper that plugs into the

relay block will have a reddish/brown 6-way connector and a tag with the

last four digits of the wiring harness part number. Second design 2003

may have a white plastic connector with part number 5418 as well.

- The 1999 jumper is/was PN 12171982 with a pink/purple tag identifier

of 1982. This number has been superseded to 15366255, with a pink/purple

tag identifier of 6255.

- The 2000 jumper harness is PN 15366255. The pink/purple tag identifier

is 6255.

- the 2001-02 jumper is PN 15086884. The orange tag identifier is 6884.

- The 2003 jumper is PN 15085418. The orange tag identifier is 5418.

When transferring the brake controller with the wiring jumper attached

from a 2001-02 vehicle to a 2003 vehicle, a change to the jumper harness

connector must be performed.

The following information is for the 1999-2002 wiring harnesses.

1999-2002

Wiring Harnesses |

| PIN |

WIRE

COLOR |

CIRCUIT

NUMBER |

FUNCTION |

| A |

Lt blue |

1620 |

Stop Lamps |

| B |

Red |

142 |

Brake Controller

12 Volt Source |

| C |

Dk blue |

47 |

Brake Controller

Outpu

(Trailer Brakes) |

| D |

Brown |

2409 |

Brake Controller

Illumination |

| E |

-- |

--

|

-- |

| F |

Black |

1850 |

Ground |

The following information

is for the 2003 wiring harness.

2003

Wiring Harness |

| PIN |

WIRE

COLOR |

CIRCUIT

NUMBER |

FUNCTION |

| A |

Brown |

2409 |

Brake Controller

Illumination |

| B |

Red |

242 |

Brake Controller

12 Volt Source |

| C |

Dk blue |

47 |

Brake Controller

Outpu

(Trailer Brakes) |

| D |

Lt blue |

1620 |

Stop Lamps |

E |

-- |

--

|

-- |

F |

Black |

1850 |

Ground |

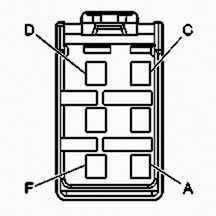

To modify a 12171982,

15366255 or 15086884 harness for use in a 2003 vehicle, switch the wires

in cavities A and D.

To modify a 15085418 harness for use in a 1999-2002 vehicle, switch the

wires in cavities A and D (fig. 12).

-

Thanks to Jim Maddy

|

| |

figure

12

return

to Table of Contents |

|

| Liftgate

Wedge Change |

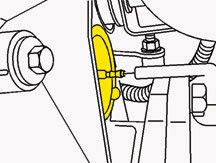

As

a running change to 2003 Ventura, Montana, Silhouette minivans and Aztek,

a different liftgate wedge is being installed. This is the same wedge

used on the Buick Rendezvous.

The liftgate trim panel is being revised to accommodate the shape of

the new wedges. There should be a 6 mm gap between the panel and the

wedges, right and left.

The wedge consists of two parts, the liftgate side and the body side.

Wedge -- Liftgate Side

The liftgate side wedge is attached by a single screw. It is tightened

to 89 lb in (10 N.m). (fig. 13)

Wedge -- Body Side

The body side wedge consists of a spacer and a wedge, and is attached

by a single screw. Before loosening the screw, mark the location of

the wedge on the spacer. Remove the screw and slide the wedge rearward

off the spacer. Pry the spacer off with a flat-blade tool.

(fig. 14)

Install the spacer to the body. Slide the wedge onto the spacer to the

previously marked location. Tighten the screw to 89 lb in (10 N.m).

TIP: There are three different

spacers, one for Rendezvous, one for Aztek, and one for the minivans.

-

Thanks to Mike Muglia |

figure

13 |

figure

14 |

| return

to Table of Contents |

|

| Revised

Windshield Wiper System |

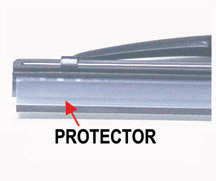

A

revised windshield wiper system will be installed as a running change

on 2003 Chevrolet Cavalier and Pontiac Sunfire beginning in January

(VIN 7 on January 2, VIN S on January 11). The 2003 Pontiac Grand Am,

Chevrolet Malibu and Oldsmobile Alero will be added on February 3.

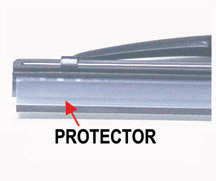

Taking the most obvious first, a protective plastic sleeve is installed

on the wiper blade at the factory (fig. 15).

Gaps in the hook clip and lever of the blade assembly have been reduced

to reduce noise and chatter, and to improve winter performance.

The controller assembly now operates digitally instead of with variable

voltage, providing a more reliable interval wipe.

The manufacturing process for the frame tube and transmission housing

has been simplified, and it is more stable.

And finally, the new assembly weighs about 11 ounces (300 grams) less

(fig. 16).

Service Considerations

TIP: Leave the blade protectors

in place until just before the vehicle is delivered, to prolong blade

life.

TIP: Parts are not interchangeable

between the earlier system and the new one. Consult your parts catalog

for the appropriate numbers.

-

Thanks to Steve Oakley |

figure

15 |

figure

16 |

| return

to Table of Contents |

|

| Synthetic

Front Axle Lubricant |

IMPORTANT:

This information is intended for vehicles sold in very cold weather climates,

especially those in Alaska and certain regions of Canada.

An upcoming bulletin addresses the use of synthetic front axle lubricant

for 4wd C/K trucks with 9.25-inch front axle assemblies sold in cold weather

climates.

TIP: Provide a copy of the bulletin

to the owner when the lubricant is replaced.

The mineral based fluid used in the front axles of these vehicles may

not lubricate properly at -12°F (-24°C) or below. This may contribute

to premature pinion bearing wear if a vehicle is driven extensively in

very low ambient temperatures.

Before delivery to the first retail customer, the front axle fluid should

be drained and refilled with synthetic axle lubricant, following the service

manual procedure (document 673354).

It is not necessary to flush the front axle assembly. Use Synthetic Axle

Lubricant 12378261 (Canadian 10953455). The approximate fluid capacity

is 1.83 qts. (1.73L).

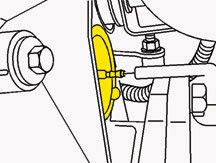

After changing the lubricant, inspect the front axle vent hose connector

(fig. 17). The black type is not compatible

with synthetic lubricants. If necessary, install vent connector 12479296,

following the service manual procedure (document 843184).

TIP: If the vent hose connector

assembly is white, it does not need to be changed.

-

Thanks to Rich Burrell and Ed Laskowski

|

figure

17 |

| return

to Table of Contents |

|

| Air

Vent Flutter |

Owners

of some 2002-03 Chevrolet Venture, Oldsmobile Silhouette and Pontiac Montana

vehicles may comment on a fluttering sound from an I/P air vent when the

fan is set on medium or high.

This may be caused by a dislodged strip of foam gasket on one of the air

shutters.

Repair requires removing the air discharge outlet by pushing in at the

top left corner and pulling out at the lower right. After the outlet pops

out, remove the airflow adjusting wheel.

Pull out the shutter and observe where the gasket is dislodged (fig.

18).

Pull the gasket partially out of the retaining groove and apply hot glue

three places: at the center, and right and left of center. Reseat the

gasket and allow the glue to set.

Repeat with the other edge of the gasket.

Install the shutter, wheel and outlet.

Refer to bulletin 02-01-37-008 for details.

-

Thanks to Tom Geist

|

figure

18 |

| return

to Table of Contents |

|

| Power

Seat Adjuster Inoperative |

Owners

of some 2001-2003 Buick Century and Regal and Chevrolet Impala and Monte

Carlo may comment that the horizontal or vertical power seat adjuster

in the driver or passenger seat is inoperative.

The power seat adjuster cables may have been damaged or disconnected

by objects pushed under the front seat.

Reconnect or replace the power seat adjuster horizontal or vertical

cables. Refer to the Drive Cable Replacement -- Horizontal and Vertical

procedures in the Seats sub-section of the Service Manual (SI Documents

964600 and 964621).

Up to now, it was necessary to replace the entire seat adjuster assembly

because the individual cables were not available separately.

Parts are currently available from GMSPO.

-

Thanks to Mel Spresney and Maurine Miller

|

| |

| return

to Table of Contents |

|

| Bulletins

– January, 2003

This review

of service bulletins released through mid-January lists the bulletin

number, superseded bulletin number (if applicable), subject and models. |

00

– General Information

02-00-89-018; LD Truck Dealers Servicing Chevrolet Kodiak and GMC TopKick

(C4500) Vehicles; 2003 Chevrolet Kodiak and GMC TopKick C4500 Series

01 – HVAC

02-01-37-008; Fluttering Sound From I/P Air Vent (Glue Air-Shutter Sealing

Foam); 2002-03 Chevrolet Venture, Oldsmobile Silhouette, Pontiac Montana

02-01-38-004; Air Conditioning is not Cold Enough (Replace Condenser);

2002 Buick Rendezvous, 2001-02 Chevrolet Venture, Oldsmobile Silhouette,

Pontiac Aztek, Montana

02-01-38-005; Revised Heater/Vent Module Replacement; 1998-2002 Chevrolet

Blazer, S-10, GMC Jimmy, Sonoma, Oldsmobile Bravada

02-01-38-006; Revised Compressor Oil Balancing Procedure; 2002 Chevrolet

TrailBlazer, GMC Envoy, Oldsmobile Bravada

02-01-38-007; Poor A/C Performance -- A/C Will Not Blow Cold Enough

(Perform A/C System Checks); 2003 Chevrolet Silverado, GMC Sierra with

6.6L Diesel Engine (VIN 1 -- RPO LB7)

02-01-39-008; A/C Compressor Inoperative, A/C Cycles too Often, Insufficient

Cooling, DTC P0530 (Replace A/C High Pressure Valve); 2002-03 Buick

Rendezvous, Chevrolet Venture, Oldsmobile Silhouette, Pontiac Aztek,

Montana with Mitsubishi Air Compressor

03 – Suspension

02-03-08-008; Rattle/Creak/Popping Type Noise from Front of Vehicle

When Turning (Replace Both Front Stabilizer Shaft Insulator Brackets);

2002-03 Chevrolet Cavalier, Oldsmobile Alero, Pontiac Grand Am, Sunfire

with FE1 or FE2 Suspension

04 – Driveline Axle

02-04-17-003; Boom Noise or Vibration (Rotate/Reinstall Front Propeller

Shaft to Axle); 2003 Chevrolet Express, GMC Savana 1500/2500 AWD Vans

05 – Brakes

02-05-25-006A; replaces 02-05-25-006; Antilock Brake (ABS) Activation

at Low Speeds (Clean Wheel Speed Sensor Mounting Surface); specified

truck vehicles between 1995-2003

06 – Engine/Propulsion System

00-06-01-023B; replaces 00-06-01-023A; Engine/Balance Shaft “Rattle”

Noise; 1992-2003 Chevrolet and GMC C/K, S/T, M/L, G and P Models, Oldsmobile

Bravada with 4.3L V6 Engine (VINs W, X -- RPOs L35, LF6, LU3)

01-06-01-002A; replaces 01-06-01-002; Revised Piston Pin Removal/Installation

Procedures; specified 1994-99 Vehicles with 3.1L Engine (VIN M -- RPO

L82)

02-06-01-038; Engine Knock or Lifter Noise (Replace O-Ring); 2001-03

Cars and LD Trucks with 4.8L, 5.3L, 5.7L or 6.0L V8 Engine (VINs V,

T, Z, G, S, N, U -- RPOs LR4, LM7, L59, LS1, LS6, LQ9, LQ4)

02-06-02-011A; replaces 02-06-02-011; Engine Overheating and/or Excessive

Noise from Electric Cooling Fan Motor (Install Cooling Fan Shield and

Cooling Fan Module Motor Shroud Assembly, If Necessary); 2000-02 Chevrolet

Impala with specified RPOs

02-06-03-006A; replaces 02-06-03-006; No Start, No Crank, Battery, Batteries,

Generator, Gages, SES, SIR, Brake, Security, Theft, ABS, Hot, DIC Messages,

Lamp, Light, Battery and Generator Diagnostic Testing, and Cadillac

Roadside Service, Warranty Claims Procedure (Proper Diagnostic Procedures);

1997-2003 Passenger Cars and Trucks (except electric vehicle), Hummer

H2

02-06-03-011; Electrical System Diagnostic Work Sheet; 1997-2003 Passenger

Cars and LD Trucks, 2003 Hummer H2

02-06-04-054; Increased Accelerator Pedal Effort (Clean Throttle Body

and Adjust Blade); specified vehicles with 4.8L or 5.3L V8 Engine (VINs

V, T, Z -- RPOs LR4, LM7, L59)

02-06-04-056; Gasoline Auxiliary Generator Will Not Run When Vehicle

is Off (Replace Fuel Sending Unit With Non-RFCV Fuel Sending Unit);

2002 Chevrolet Express, GMC Savana Van with RPOs K50 (Fuel Fitting,

Line Take Off) and/or 7T6 (Fuel Fitting, Line Take Off)

02-06-04-057; Labor Operation Assignments for Vehicle Control Module

Reprogramming; 2003 and Prior Passenger Cars and Trucks, Hummer H2

02-06-04-058; SES Lamp Illuminated, False DTCs P0181 and/or P0116 (Reprogram

ECM); 2001-02 Chevrolet Silverado, GMC Sierra 2500/3500 with 6.6L Duramax

Diesel Engine

02-06-04-060; Automatic Engine Shutdown Feature; 1997-2001 Chevrolet

and GMC F Model MD Tilt Cab with Air Brakes (RPO JE4) and Automatic

Engine Shutdown (RPO KPJ)

07 – Transmission/Transaxle

99-07-30-030B; replaces 99-07-30-030A; Grinding and/or Growling Noise

in Park on Incline; 2003 and Prior FWD Passenger Cars with Hydra-Matic

Front Wheel Drive Automatic Transmission

01-07-30-036B; replaces 01-07-30-036A; Diagnostic Tips for DTC P0756;

2001-03 Passenger Cars and LD Trucks with 4L60E or 4L65E Auto Transmission

(RPO M30 or M32)

02-07-30-039A; replaces 02-07-30-039; Firm Transmission Shifts, Shudder/Chuggle,

Transmission Won’t Downshift On Deceleration, SES Light Illuminated,

DTC P0742 Set (Perform Diagnostics and Replace TCC PWM Solenoid); 2003

Vehicles with 4T65E Transaxle (RPO MN3, MN7, M15, M76) or 4T40E/4T45E

Transaxle (RPO MN4 or MN5)

01-07-30-042A; replaces 01-07-30-042; Information on 2-3 Upshift or

3-2 Downshift Clunk Noise; 2003 and Prior LD Trucks with 4L60E or 4L65E

Auto Transmission (RPOs M30, M32)

02-07-30-046; Newly Designed Transaxle Valve Body and Oil Pump Service

Information; specified 2002-03 vehicles with 4T65E Transaxles, RPOs

MN3, MN7, M15, M76

02-07-30-050; Engineering Changes to Valve Body, Pressure Regulator

Valve, 2-3 Accumulator Valve and Bore; applicable 1995-2003 Chevrolet

Cavalier, Malibu, Oldsmobile Cutlass, Alero, Pontiac Sunfire, Grand

Am with 4T40E or 4T45E Transaxle (RPOs MN4 or MN5)

02-07-30-051; Transmission Shifting In and Out of 4th and 5th Gear (Hunting)

When Pulling/Carrying a Load, Unable to Manually Select 4th Gear (Install

5th Gear Inhibit Switch); 2001-02 Chevrolet Silverado, GMC Sierra with

6.6L Diesel or 8.1L Gas Engine (VINs 1, G -- RPOs LB7, L18) and Allison

Auto Trans (RPO M74)

02-07-30-052A; replaces 02-07-30-052; Essential Tool J-45096 TransFlow;

2003 and Prior Passenger Cars and LD Trucks with Automatic Transmission

(except M74 Allison)

08 – Body and Accessories

02-08-42-006; Relay Omitted for Bodybuilder Connection/Upfitter Provision;

2003 Chevrolet and GMC W3500/4500 MD Tilt Cab Models

02-08-44-016A; replaces 02-08-44-016; Whine, Buzz, Generator Whine,

Whine Type Noise Heard on Acceleration (Repair Vehicle Sound System

Wiring); 2002 Chevrolet TrailBlazer, GMC Envoy, Oldsmobile Bravada

02-08-44-019; Revised Audio System Diagnostic; 1998-2000 Pontiac Firebird,

Chevrolet Camaro

02-08-44-020; No Audio Out of Speakers at Times (No Permanent Repair

Available at this Time); 2003 Cadillac Escalade, Chevrolet Avalanche,

Silverado, Suburban, Tahoe, GMC Sierra, Yukon, Hummer H2

02-08-44-022; Static Noise Heard in Radio Speakers (Install Capacitor

into Rear Differential Clutch Check Valve Circuit); 2002-03 Buick Rendezvous,

Chevrolet Venture, Oldsmobile Silhouette, Pontiac Aztek, Montana with

All Wheel Drive

02-08-50-010; Power Seat Adjuster Inoperative (Reconnect or Replace

Adjuster Cables); 2001-03 Buick Century, Regal, Chevrolet Impala, Monte

Carlo

02-08-62-004; Front Fascia Wavy (Install Dual Lock); 2002-03 Chevrolet

TrailBlazer, EXT

02-08-64-024; Discoloration/Fading of Door Glass Molding; 2002 Chevrolet

TrailBlazer, GMC Envoy, Oldsmobile Bravada

02-08-64-026; Power Sliding Side Door Hard to Open (Replace Lock Rod);

2002-03 Chevrolet Venture, Oldsmobile Silhouette, Pontiac Montana (Long

Wheel Base Only, with Manual or Power Sliding Side Door)

02-08-67-006A; replaces 02-08-67-006; Roof Perforation (Replace Roof);

1997-2003 Chevrolet Venture, Pontiac TransSport/Montana, Oldsmobile

Silhouette

|

| return

to Table of Contents |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|