| |

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

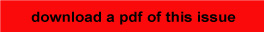

Pro-Cut

Brake Lathe |

GM Dealer Equipment

has begun shipping the new essential Pro-Cut PFM 9.2 Auto-Compensating

On-Vehicle Brake Lathe to all tier 1-4 dealers (franchise sales greater

than 100) who sell Chevrolet Colorado and GMC Canyon trucks (fig.

1).

TIP: Tier 5 dealers

will be required to sublet rotor turning on these vehicles to a facility

equipped with approved equipment.

Refer to bulletin 03-05-23-005 for details.

The Pro-Cut lathe performs brake rotor turning on-vehicle. It can be

used with both hubless and captured rotor configurations.

Explanation of Hubless vs. Captured Rotor

Until now, the typical GM car or truck has used a “hubless”

brake rotor. That is, the rotor is slipped onto the studs on the hub,

followed by the wheel. The wheel nuts clamp the rotor between the hub

and the wheel.

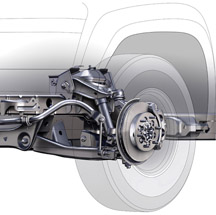

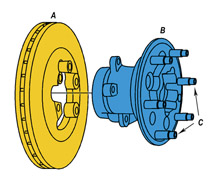

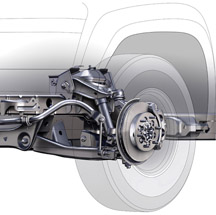

The Colorado/Canyon introduces a new brake design called “captured

rotor” (fig. 2). Here, the wheel

is mounted to the wheel studs on the front side of the hub, the same

as before. But the brake rotor is bolted to the back side of the hub

and is retained by separate fasteners (fig. 3).

A Rotor

B Hub

C Wheel stud

This affects rotor service in several ways.

1. Rotor removal requires removal of not only the wheel, tire, and brake

caliper, but also the hub/bearing assembly, which contains the ABS sensor

and wiring. Then the rotor is removed from the backside of the hub.

2. Once the rotor is removed, it is difficult to chuck onto a lathe

due to the large, irregularly shaped hole in the center (there is no

round center hole, as in hubless rotors). Bench machining may induce

lateral run-out, which requires replacement of the rotor.

3. Brake Align Correction Plates will not work with captured rotors.

For these reasons, captured brake rotors must be turned on-vehicle.

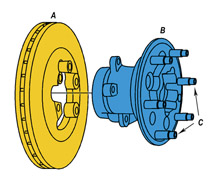

Brake Rotor Lateral Run Out (LRO)

TIP: Refer to

bulletin 01-05-23-001 and TechLink April 2001 for an explanation of

brake rotor lateral run out (fig. 4).

Excessive LRO results in intermittent contact between the brake pads

and rotor. Intermittent contact causes uneven rotor wear (thickness

variation), which causes the piston to pump in and out of caliper when

the brakes are applied. The customer senses this as brake pulsation

through the brake pedal. For this reason, GM has established a total

indicated run-out spec of 0.002-inch (0.050 mm) or less for all vehicles.

Using the Pro-Cut PFM 9.2

TIP: Purchase

of the Pro-Cut lathe includes set-up and training, plus a training CD.

The following is a summary only.

When performing on-car rotor turning, it is essential that the cutting

tools be properly oriented to the wheel hub centerline, to ensure that

LRO of the finished brake rotor is within specifications. The Pro-Cut

PFM 9.2 is auto-compensating, which means that the user does not have

to perform any critical set-up to ensure a high quality job.

Cleaning -- As with any brake job, on-car turning requires

that all mating surfaces be clean and free of corrosion. Use J-42450A

to clean the hub flange around the wheel studs (fig.

5), and use J-41013 to clean the hub/rotor mating surfaces.

Tool Installation -- Select the proper direct-fit adapter

from the four that are included with the Pro-Cut, attach to the vehicle

using the lug nuts, and torque properly (fig.

6). Attach the Pro-Cut to the adapter and tighten the retaining

knob.

TIP: When the

Pro-Cut is attached to the vehicle, it is supported by the vehicle’s

wheel hub. The Pro-Cut carriage is used only to hold the lathe when

not in use, and to assist in positioning the lathe to the wheel hub.

Auto-Compensation -- Run the built-in auto-compensation

routine. This aligns the lathe to the hub centerline, to ensure an accurate

cut. An indicator lamp tells when this has been accomplished (fig.

7).

Rotor Turning -- Take three scratch cuts to determine

the required depth of cut. The Pro-Cut is equipped with micrometer controls

(fig. 8). Once the cutters have been set,

run the Pro-Cut to automatically turn the rotor (fig.

9).

TIP: On vehicles

with rear disc brakes and limited slip differential, consult SI for

special instructions.

TIP: Non-directional

sanding is not required due to lathe performance.

Inspection -- Follow standard GM practices for measuring

LRO, using a dial indicator. The specification is 0.002-inch (0.050

mm) or less for all vehicles.

Wheel Torque -- Improper, uneven wheel lug nut torque

can cause rotor distortion, which undoes the careful work you’ve

done in finishing the brake rotor. (This is not a significant factor

of the captured rotor.) Follow standard GM practices for installing

wheel lug nuts. This requires a torque wrench or an impact wrench equipped

with J-39544 Torque Sockets.

TIP: Be sure

to index-mark the rotor and a wheel stud so the the rotor can be put

back in the same orientation, if it is removed for any reason.

For more information, be sure to watch the 10280.13D Technology Close-Up

-- Brakes Town Hall broadcast on January 29.

-

Thanks to Dave Roland, Jeff Hastings and Derek Trimble |

|

figure

1 |

|

figure 2 |

figure

3 |

figure

4 |

figure

5 |

figure

6 |

figure

7 |

figure

8 |

figure

9 |

| return

to Table of Contents |

|

|

| REMINDER |

DealerWorld ID and Password -- U.S. service managers

and technicians are reminded to obtain individual ID and password from

your Partner Security Coordinator (PSC) for continued access to SI.

End of Support for Windows 98 -- Effective January

15, 2004, GMSO will no longer test TECHLINE software applications on

Windows 98SE, ME and NT. Dealers are strongly recommended to upgrade

with a full version of Windows 2000 Professional or Windows XP Professional.

Review the hardware specifications before buying software to ensure

the TECHLINE PC meets minimum specifications.

Refer to the December TechLink and GM Messenger communication for full

details.

-

Thanks to Mike Waszczenko and Lisa Scott |

|

|

|

| GMLAN

and Class 2 Difficulties |

Here

are some ways to avoid trouble when using the Tech 2 to communicate

with the GMLAN.

1. Be sure you have the current software installed on your Tech 2.

2. Perform the Tech 2 Cable Test before using the Tech 2 with the CANdi

module for the first time. This has been discussed several times in

TechLink (March 2003, August 2003 and December 2003) and also appears

on the TechLink website under the Reference Guide tab. This test permits

you to test the integrity of the Tech 2 and the cables.

TIP: Call TCSC

for help at 800.828.6860.

3. Before using the Tech 2 to communicate with the GMLAN (or Class 2,

for that matter), turn the ignition on and allow all controllers on

the vehicle to wake up (“boot up”). Otherwise, you may get

error messages from the Tech 2 such as “No Communication”

or “CANdi Module Not Detected”.

TIP: You can

be confident that all modules are awake by the time the IP warning lamps

and chimes stabilize.

4. Be sure to use the correct adapters. For instance, with the CANdi

module, you need to use p/n 3000098, which is a 16-pin adapter.

TIP: Do not make

the mistake of using the 71419 adapter from the old T50, T60, etc. Techline

terminals. Although it also has 16 pins, it is incorrect for this application.

5. Most problems experienced with the CANdi module setup result from

the cable or adapter, not the CANdi module itself.

TIP: For further

information on GMLAN, tune in to the IDL broadcast called GMLAN Electrical

Architecture and Functional Diagnostics 16048.20D..

- Thanks to Craig Jones and Mark Stesney |

| |

return to Table of Contents |

| |

| GM

TechLink in Its Sixth Year |

TechLink

began in September, 1998, as an occasional publication of the Service

Technology Group (which eventually became GM Service and Parts Operations).

During the first year, six issues were published. TechLink became a

monthly in October 1999.

TechLink owes much of its technical integrity to a dedicated group known

as the Editorial Advisory Board. At present, there are 14 members; over

the past five years, 20 people have served on the board. We’ve

even welcomed two summer college interns. For a photo of some of the

present members, check the Reference Guide

tab of the TechLink website at http://service.gm.com.

Also too numerous to mention are the many subject matter experts from

all over GM who have contributed story ideas, provided important data,

and reviewed stories for technical accuracy.

Some statistics -- You are reading the 58th issue of TechLink. Each

month, 68,000 copies are distributed to GM retail technicians, some

fleets, and within GM wholesale. And we’ve posted 35 issues on

the website, beginning in March 2001. The website is published in four

languages: English, Spanish, French and German.

Over the past five years, we’ve received numerous unsolicited

comments about TechLink from readers (mostly good!). And we’d

like to hear from you. If you have a comment, suggestion or even a criticism,

send them to:

mark.stesney@gm.com

jim.horner@sandycorp.com

-

Thanks to Bob Savo |

| |

| return

to Table of Contents |

|

| Service

Training Standards Requirements |

Beginning

January 2004, the Emerging Issues seminars become part of the Service

Training Standards requirements. Each dealership will be required to

participate in at least 6 of the 12 Emerging Issues seminars broadcast

in a given year. Dealers can meet this requirement by having either

6 different service technicians participate in distinct seminars, a

single service technician view all 6 seminars, or any combination of

the two. So long as 6 different broadcasts are viewed by service technicians

at a dealership, the dealership will receive a 100% toward meeting the

requirement.

-

Thanks to Tracy Timmerman |

| |

| return

to Table of Contents |

|

| 20-Inch

Accessory Wheels and Tires |

General

Motors has launched its collection of all-new 20-inch wheels, available

in forged or chrome finishes to reflect consumers’ personal styles.

The wheels were designed with a specific tire as part of the GM tire

and wheel system.

The accessory wheels and tires are suitable for installation on certain

1999-2004 Chevrolet Silverado and GMC Sierra pickups (fig.

10). Refer to bulletin 03-03-10-006

for specific details and exceptions. Here are the highlights.

TIP: Initially

the Wheel Launch Kit and required parts will be available in the USA

only. This program will be extended to Canada in 2004. Canadian dealers

must confirm availability of parts before utilizing this bulletin.

Designed with a Specific GM Vehicle in Mind -- Accessory

wheels from GM offer the best fit and function, and most tailored appearance

because they were designed to be an integral part of the vehicle architecture.

The new 20-inch tire and wheel assembly has been tested at GM’s

proving grounds in Michigan and Arizona.

Tires -- GM has created 20-inch wheels based on the

Goodyear Eagle LS P275/55R20 tire. This tire was designed to GM's Tire

Performance Criteria (TPC specification 1235 ms). GM's TPC specifications

meet or exceed all Federal safety guidelines.

Spare Tire -- Use a P265/75R16 or P265/70R17 tire mounted

on the vehicle's original spare wheel as a spare. The spare tire is

not intended for extended driving conditions.

Tire Changers -- Dealers must have the correct level of tire

changing equipment to perform tire changing services. GM requirements

and recommendations for servicing glamour wheels are in the bulletin.

For further information regarding equipment meeting the requirements

for this program, call 1-800-GM-TOOLS.

Balancing -- MC style coated weights are recommended.

If stick-on weights are used, follow the manufacturer's procedure (SI

Document 664222).

The tire and wheel assembly must be balanced on a computerized balancer,

capable of static and dynamic balance modes. Assemblies should be balanced

to within 1/4 ounce on either rim flange.

Center Cap -- Install the center cap onto the wheel after the

tire has been mounted and balanced, but BEFORE the assembly is installed

onto the vehicle. Push the cap in by hand. Alternately, use a nonmetallic

object to push the cap into place. Hammering may result in damage to

the cap.

Tire Pressure Monitoring (TPM) -- If the vehicle was originally

equipped with TPM sensors, transfer the original sensors to the new

wheels. Note the wheel location that the TPM sensor came from. Install

the new tire/wheel/TPM sensor assembly in the same wheel location that

the TPM sensor was originally. If the TPM sensors are not in the original

positions, you must reprogram the sensors.

Air Valve (Valve Stem) -- For vehicles without TPM,

use GM p/n 9593595.

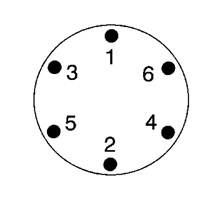

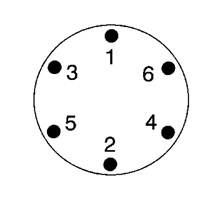

Wheel (Lug) Nuts -- TIP:

Aluminum wheels require special wheel nuts. Use GM p/n 9591772.

Torque each wheel nut in the appropriate sequence (fig.

11) to 190 Nm (140 lb ft). Re-check the torque after the first

160 km (100 mi). A wheel lock kit GM p/n 12497479 is also available.

Wheel Nut Caps -- After tightening the wheel nuts,

install the wheel nut caps finger tight, plus 1/2 turn. Black cap GM

p/n 15646250, bright cap GM p/n 88963146.

Jounce Bumper -- For 2WD vehicles, replace the existing

front suspension spring/jounce bumper with Jounce Bumper kit, GM p/n

12499481. Follow the procedure in the bulletin.

Re-Programming -- Reprogram the PCM for speedometer

accuracy. Contact Techline to obtain a VCI number (1.800.828.6860 English

or 1.800.503.3222 French). Then refer to the table in the bulletin for

the appropriate calibration part number, based on the model year and

axle ratio.

TIP: Because

this is not a warranty repair, dealers will incur a charge to obtain

a VCI number.

Update the tire size value in the ABS module, using the Tech 2. Follow

this path: Diagnostics > Model Year > Vehicle Type > Chassis

> Product Line > GVW > ABS > Special Functions > Tire

Size Calibration > Verify VIN > Select New Tire Size.

TIP: If original

equipment tires/wheels are later reinstalled, it will be necessary to

reset the programming of the PCM and the ABS module to the original

specifications.

Labels -- After installing the recommended P275/55R20

tires, place the provided tire inflation pressure and occupant/cargo

capacities label on the door jamb, near the original tire label. Do

not cover up the original tire label.

Warranty Information -- USA dealers should refer to

GM Warranty Administration Bulletin 00-03-10-003E and GM Parts Process

/ Policy Bulletin IB03-001 for more information.

Canadian dealers should refer to GM Warranty Administration Bulletin

01-03-10-003A.

Important:

Installation of these accessory wheels, tires and additional parts and

related procedures are entirely at customer expense.

-

Thanks to Mikael Hassler, Ann Briedis and Nina Price

|

figure

10 |

figure

11 |

| return

to Table of Contents |

|

| Dinghy

Towing Update |

This

information pertains to 2002-04 Envoy, TrailBlazer and Bravada.

The owner’s manual is being revised regarding dinghy towing (towing

the vehicle with all four wheels on the ground).

Early versions of the owner’s manual said to turn the ignition

to LOCK and remove the Ignition A and Ignition B fuses from the engine

compartment fuse block.

These vehicles do not have a LOCK position. The ignition should be turned

to OFF. There is no need to remove the ignition fuses because there

is no current draw in the OFF position.

Refer to the appropriate owner’s manual for complete procedures.

-

Thanks to Al Ferry |

| |

|

return

to Table of Contents |

|

| Winter

Cover |

This

information applies to trucks with the LB7 and LLY Duramax diesel engine.

A winter cover is included for use in cold weather states (fig.

12).

Installing the winter cover enhances heater performance and reduces

the amount of time it takes to warm the inside of the vehicle when the

temperature is below 0°F (-18°C).

The cover installs over the front bumper and restricts airflow to the

engine compartment.

Overheating Guidelines

The following guidelines apply, to avoid overheating the engine:

- Do not use when temperatures are expected to be above 32°F (0°C).

- Do not use when towing a trailer.

- Do not modify the cover.

Installation Tips

The vinyl cover may appear undersized before being fitted for the first

time. This is normal. It’s best to install for the first time

when the cover is warm.

The cover is retained by push-pins in the grille area, snaps, and black

tabs, which must be bent into a J-shape.

Cut the black stitches provided if a front license plate is required.

More information can be found in the owners manual on SI (document 837330).

Follow this path:

Build vehicle > Features and Controls > Starting and Operating

> Description and Operation > Winter Cover.

- Thanks to Steve Love |

figure 12 |

| return

to Table of Contents |

|

| Evaporator

Case Water Intrusion |

A

potential water leak path from the evaporator case drain provision has

been identified on all 2001-04 Buick Rendezvous and Pontiac Aztek models.

Under certain high humidity and high ambient temperature conditions,

when the vehicle is driven for extended periods with low blower motor

speed, condensation moisture can reach the vehicle interior under the

carpeting. If an owner encounters this condition and water testing shows

no other cause for the water leak, install an extension elbow to reduce

the likelihood of reoccurrences. The part number recommended is 22542866,

which is used on other General Motors products.

The current plan is to utilize this part in production as soon as possible

and a bulletin will contain the breakpoints when the production change

occurs.

-

Thanks to Tom Russell

|

|

|

|

return

to Table of Contents |

|

| Steering

Wheel Controls |

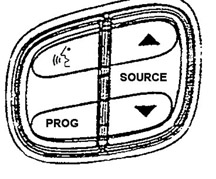

Some 2003 and 2004 GM vehicles equipped with the OnStar system have

Steering Wheel Controls (SWC) that can be used in conjunction with the

OnStar Personal Calling Voice Recognition system.

Here is how the Steering Wheel Controls function on vehicles with OnStar

voice recognition and Steering Wheel Controls.

1. On the following vehicles, the push-to-talk button invokes the voice

recognition feature (fig. 13). A subsequent

press will re-invoke voice recognition for use with a voice mail system,

or other system which may require tones to be transmitted, such as dialing

an extension after reaching an office phone system. Saying the word

“dial” will transmit the tone(s) associated with the digits

entered. Subsequent presses of the button will re-invoke the voice recognition

system and the process repeats. Pressing the white dot button will exit

voice mode if a call has not been placed. To disconnect from the call,

press the white dot button or the "end" button on the steering

wheel.

TIP: If the vehicle

has NAV or the UV8 cell phone, these buttons function differently and/or

are disabled for OnStar functions. Consult the specific vehicle owner

manual for proper operation.

Seville, DeVille, Cadillac CTS, Cadillac XLR,

Cadillac SRX

2. On the following vehicles, the push-to-talk button invokes voice

recognition (fig. 14). A subsequent press

will re-invoke voice recognition for use with a voice mail system, or

other system which may require tones to be transmitted, such as dialing

an extension after reaching an office phone system. Saying the word

“dial” will transmit the tone(s) associated with the digits

entered. Subsequent presses of the button will re-invoke the voice recognition

system and the process repeats. Pressing the white dot button will exit

voice mode if a call has not been placed. The user must use the white

dot button to end a call.

Escalade, Escalade EXT, Escalade ESV, Denali,

Denali XL, Yukon, Yukon XL, Tahoe, Suburban, Avalanche, Sierra Crew,

Sierra Ext, Silverado Crew, Silverado Ext, Hummer H2, TrailBlazer, TrailBlazer

EXT, Envoy, Envoy XL, Bravada, Envoy XUV, Rainier, Ascender

3. For the final group of vehicles, the mute button invokes voice recognition

(fig. 15). A subsequent press will re-invoke

voice recognition for use with a voice mail system, or other system

which may require tones to be transmitted, such as dialing an extension

after reaching an office phone system. Saying the word “dial”

will transmit the tone(s) associated with the digits entered. Subsequent

presses of the button will re-invoke the voice recognition system and

the process repeats. Pressing the white dot button will exit voice mode

if a call has not been placed. The user must use the white dot button

to end a call.

Aztek, Rendezvous, Century, Regal, LeSabre, Bonneville,

Grand Prix, Montana, Venture

4. The following OnStar equipped vehicles do not have steering wheel

controls for use with the voice recognition function. The voice recognition

function used for dialing an OnStar Personal Call is accessed using

the white dot button.

Cavalier, Sunfire, Colorado, Canyon, Venture,

Silhouette, Impala, Monte Carlo, Aurora, Ion, LS/LW, Malibu, Park Avenue,

Express, Savana, VUE

- Thanks to Steve Love and Jim Mikolaizik |

figure

13

figure

13 |

figure

14 |

figure

15 |

|

return

to Table of Contents |

|

| Announcing

the 2004 Chevrolet Aveo |

Chevrolet

has just introduced the entry-level Aveo (T200) subcompact four-door

and five-door sedan (fig. 16). Priced below

the Cavaliler, the Aveo provides Chevrolet dealers with a tremendous

opportunity to attract younger, first-time buyers.

All Aveo models feature Chevrolet's identifiable grille, with trademark

horizontal chrome mid-grille band and gold Chevy bowtie emblem. Additional

brand cues include a silver outlined bowtie on the center caps of the

standard steel wheels and a gold bowtie on the center caps of optional

alloy wheels, offered on LS models. The bowtie is also featured on center

pad of the steering wheel (fig. 17).

The Aveo is equipped with highly distinctive standard aerodynamic halogen

headlamps and amber side turn signal lamps. Fog lamps are also available.

P185/60R14 all-season steel-belted radials are mounted on either steel

or alloy 14-inch wheels.

The Aveo features a 1.6-liter dual overhead cam 16-valve inline 4-cylinder

engine that delivers 105 horsepower at 5800 rpm and 107 lb-ft of torque

at 3600 rpm. It’s teamed with either a manual 5-speed or automatic

4-speed transaxle.

The front suspension consists of McPherson struts with offset coil springs

and a stabilizer bar. The steering gear is mounted on a front suspension

cross member, to improve shock absorption for more precise and stable

handling.

The torsion beam axle mount compound link-type rear suspension is designed

to optimize driving performance when cornering.

All Aveos are equipped with a power-assisted dual diagonal brake system,

with discs in front and drums in the rear. A Delphi four-channel, four-sensor

ABS system (DBC-7) with Electronic Brake force Distribution (EBD) is

available.

Some Service and Pre-Delivery Tips

Aveo PDI service bulletin 03-00-89-040 explains several unique product

features. The information is useful for all technicians, not just the

PDI technician. Here are some highlights.

Coolant -- The Aveo cooling system is factory filled

with blue silicate/hybrid coolant (fig. 18)

and will be serviced with traditional green coolant. This type of coolant

must be drained, flushed and refilled every 30,000 miles (48,000 km).

Use P/N 12378560 (1 gal). In Canada, use P/N 993088 (1L) or P/N 993089

(4L).

Power Steering Fluid -- The power steering system uses

DEXRON® III fluid. Check the fluid level and adjust as necessary.

Use P/N 12378470 (1 qt). In Canada, use P/N 10952621 (500 ml) or P/N

10952622 (1L).

TIP: The use

of conventional power steering fluid in the system may lead to leaks.

Fuse -- The radio/clock fuse is installed in a fuse

holder for shipping (fig. 19). The fuse

holder must be fully depressed toward the fuse panel and the fuse will

slide into place (fig. 20). This must be

done to ensure proper operation of the radio and clock.

Automatic Transmission -- To move the automatic transmission

shift lever out of Park or Neutral, push down on the shifter knob (fig.

21).

When the HOLD button is depressed, the Hold indicator located in the

Secondary Information Center will light. There are two Hold mode features:

Winter Function -- When the vehicle is at a stop, depress

the hold button. The transmission will start off in third gear. This

will reduce the torque to the front wheels and will help the vehicle

maintain traction on slippery road surfaces.

Manually Controlling Shift -- When the vehicle is in

motion, depressing the Hold button will make the transmission operate

like a three speed transmission. You will be able to downshift the transmission

manually. The transmission will not shift into forth gear when the Hold

feature is activated.

The automatic transmission uses T-IV fluid GM P/N 88900925 (1 qt). In

Canada, use P/N 22689186 (1L).

TIP: Do not intermix

DEXRON® III fluid with the T-IV fluid.

Radio Code -- Each radio has a four-digit unlock code that must be entered

before the radio will operate. The code is located on a paper card inside

the glove box. Be sure the owner is aware of this code and remind them

to keep the code is a safe place. Any time the battery is disconnected,

COD will appear in the display, and the code must be entered into the

radio.

License Plates -- Aveos built before December 3, 2003

will not have the license plate fasteners placed in the glove box. Use

p/n 9423101 to fasten the license plate.

TIP: The cost

of the fasteners should be included in the net item column for the PDI

claim.

The Aveo doesn't use a front license plate bracket. There are four dimples

in the front fascia. The inboard dimples are the ones that should be

used to fasten the license plate. The outboard dimples are used for

European countries.

Tire Pressure -- The vehicle’s tires are shipped

inflated to 40 psi (276 kPa) and the pressure must be reduced to30 psi

(207 kPa). The tire pressure label can be found at the bottom of the

driver’s B-pillar.

Key Cutting

The accompanying chart outlines available key cutting equipment. Original

equipment key blanks for the Chevrolet Aveo are steel and are difficult

to accurately cut with hand-held key cutting equipment. Due to the risk

of mis-cutting high-cost Transponder and RKE key blanks with hand-held

key cutters, GM recommends using computerized duplicating/code cutting

equipment.

In addition, RKE and Immobilizer (Transponder) Keys require reprogramming

with Tech 2 after cutting. Refer to SI for detailed procedures.

- Thanks to Jeff Strausser |

figure

16 |

figure

17 |

figure

18 |

figure

19 |

figure

20 |

figure

21 |

| |

| |

GMDAT

Key Cutting Equipment

| Kaba

Ilco Computerized Code Cutting |

| Function |

Standard

Steel Blank |

Standard

Brass Blank |

All

Transponder or RKE Keys |

Part

Number |

Description |

|

|

|

| Computerized

Duplicating and Code Cutting |

Highly Recommended |

Highly Recommended |

Highly Recommended |

74-ULTRACODE

|

Ultracode Code

Cutter & Duplicator |

|

|

|

| |

| Kaba

Ilco Machine Duplicating and Code Cutting |

| Function |

Standard

Steel Blank |

Standard

Brass Blank |

All

Transponder or RKE Keys |

Part

Number |

Description |

Kit

(Required) |

|

|

| Machine Duplicating

and Code Cutting |

Available* |

Available* |

Available* |

74-029A-GM

|

Combo Key Duplicator

& Key Code Cutter |

74-029A-GMDAT |

|

|

| |

| Kaba

Ilco Machine Duplicating |

| Function |

Standard

Steel Blank |

Standard

Brass Blank |

All

Transponder or RKE Keys |

Part

Number |

Description |

|

|

|

| Machine Duplicating

|

Not Recommended |

Available* |

Not Recommended |

74-045-110VAC

|

Heavy Duty

Duplicator |

|

|

|

| |

| Kaba

Ilco Hand Held Code Cutting |

| Function |

Standard

Steel Blank |

Standard

Brass Blank |

All

Transponder or RKE Keys |

Part

Number |

Description |

Kit

(Required) |

|

|

| Hand Operated

Code Cutting |

Available* |

Available* |

Available* |

74-MK1-P26 |

Exacta Cutter

& Case |

74-MK1-GMDAT |

|

|

| |

| Curtis

Computerized Code Cutting |

| Function |

Standard

Steel Blank |

Standard

Brass Blank |

All

Transponder or RKE Keys |

Part

Number |

Description |

|

|

|

Computerized

Duplicating and Code Cutting

All Models |

Highly Recommended |

Highly Recommended |

Highly Recommended |

C9100021 |

PC+ Computerized

Code Cutter |

|

|

|

| |

| Curtis

Hand Held Code Cutting |

| Function |

Standard

Steel Blank |

Standard

Brass Blank |

All

Transponder or RKE Keys |

Part

Number |

Description |

Cam

Set (Required) |

Carriage

(Required) |

Code

Book (Required) |

Chev Aveo

Hand Operated Code Cutting |

Available* |

Available* |

Available* |

C-20791 (15XL-45)

C-20792 (15XL-47) |

45 Degree or

47 Degree Code cutter |

C21222 |

C21223 |

C21403 |

Chev Optra

Hand Operated Code Cutting |

Available* |

Available* |

Available* |

C-20791 (15XL-45)

C-20792 (15XL-47) |

45 Degree or

47 Degree Code cutter |

C21222 |

C21223 |

C21403 |

Chevy Epica

Hand Operated Code Cutting |

Available* |

Available* |

Available* |

C-20791 (15XL-45)

C-20792 (15XL-47) |

45 Degree or

47 Degree Code cutter |

C21222 |

C21223 |

C21403 |

| |

*

Original equipment key blanks for these vehicles are steel and

are difficult to accurately cut with hand held key cutting equipment.

Due to the the risk of "mis-cutting" high cost Transponder

and RKE key blanks with the hand held cutter, computerized

duplicating/code cutting equipment is highly recommended. Current

computerizied equipment will require software updates for GMDAT

vehicles.

Contact 1-800-GM-TOOLS (1-800-468-6657) for Ilco products or Barnes

Distribuiton (Curtis) 1-800-555-2878. |

|

|

| TAC

Corner |

Beginning

with this issue, the Technical Assistance Center (TAC) will be providing

administrative and Technical tips in the TAC Corner.

Access the most current information in SI (http://service.gm.com):

SI on the web is more current than using SI via the CDs. The SI web

is updated weekly on Thursday.

GM ACCESS is updated every second week, and requires the techincian

to process the update, at start up.

The stand-alone CD is updated once a month.

Be Prepared:

We have verified that some recent callers do not represent GM dealerships.

We need your assistance to help us confirm that the caller is a GM Technician

or Shop Foreman using GM supplied Service Information and is thus an

authorized caller. To accomplish this, we are asking that callers be

prepared with an SI document ID number that relates to the primary vehicle

concern of the call. This request applies to all vehicles produced from

1998 to present. This will also help us more quickly assist in diagnosis

and assure that the caller has properly researched the issue before

calling GM TAC.

Please perform all the necessary diagnostics and informational searches

before calling TAC. This allows us to serve you better.

Strategy Based Diagnosis (SBD):

The goal of SBD is to provide guidance when you create a plan of action

for each specific diagnostic situation. By following a similar plan

for each diagnostic situation, you will achieve maximum efficiency when

you diagnose and repair vehicles. Although each of the SBD boxes is

numbered, you are not required to complete every box in order to successfully

diagnose a customer concern. The first step of your diagnostic process

should always be the Verify the Customer Concern box. The final step

of your diagnostic process should be the Repair and Verify the Fix box.

Refer to the Strategy Based Diagnostics chart in SI. Use the keyword

“strategy”.

The guidelines for using Technical Assistance are in the P&P Manual,

Section 5.3.1. The sections cover:

1. Being Prepared -- follow SBD

2. Logging Calls

3. Closing a TAC Case

4. Returning a Survey Request

The forms for Technical Assistance are also available in this section.

- GM-TAF TAC Form

- TAC Case Call Log Sheet

- Diagnostic Worksheet

The worksheets help organize the call.

- Thanks to GM Technical Assistance |

|

|

| return

to Table of Contents |

|

| Waved

Steel Clutch Plate |

This

information applies to 4L60E/4L65E automatic transmissions.

On approximately November 1, 2003, a new heat treating process is used

for some transmission clutches. The Forward Clutch waved steel clutch

plate (648) appears dark in color, as if it were overheated at one time

(fig. 22). The Low/Reverse Clutch waved steel

clutch plate (682A) has a similar appearance on the inner and outer edges

(fig. 23).

Only the appearance has changed; the functionality of the clutches is

no different. These waved clutch plates will be used for both production

and service.

-

Thanks to GM Technical Assistance |

figure

22 |

figure

23 |

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time

Car Issues – Fix It Right The First Time |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2000-2004 |

Cavalier/Sunfire

-- Grinding Noise on Clutch Apply. Very low mileage |

Replace

clutch hydraulic line. |

Don’t

replace clutch/bearing |

03-07-31-005 |

1997-2004 |

Grand

Am / Alero / Malibu – Brake pulsation |

Turn

rotor and use brake align procedure |

Don’t

replace rotors for pulsation |

00-05-23-002

01-05-23-001 Know How #15040.01B) |

2003 |

DeVille

– No Crank / No Start |

Inspect

base of UBEC to ensure wire connectors are fully seated and not

loose. |

Don’t

replace PCM |

03-06-03-009 |

2001-2003 |

Venture

/ Montana / Silhouette/Rendezvous/ Aztek – Rattle or Buzz

from Exhaust System |

Install

clamp |

Don’t

replace Catalytic Converter |

03-06-05-003

dated 01/28/03 |

2004 |

Grand

Prix - Steering, Suspension or Cradle Click Noise. |

Re-torque

the Right Steering Gear Mount |

Don’t

replace the Steering Gear |

03-02-32-048

Dated 10/28/03 |

2000-2004 |

Impala/Monte

Carlo/Grand Prix - Headlamp Replacement for Condensation in Lamp |

Normal

condition when limited to fog or fine mist appearance in high

humidity conditions |

Don’t

replace headlamp assembly when no water droplets are evident |

01-08-42-001A

11/4/2003

Sept 02 TechLink |

2003-2004 |

CTS

– Variable Effort Steering (VES) “Service Steering

Message” DTC C1241 or C0450 |

Replace

VES solenoid only |

Don’t

replace entire steering gear |

03-02-36-001 |

2003 |

All

cars with 4T40/45E, 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM

Solenoid |

Don’t

replace transmission or valve body assembly |

02-07-30-039B |

2002-2004 |

All

cars with 4T40/45E and 4T65E with DTC P0716, P0717 and other misc

codes |

Disconnect,

inspect, and reconnect transaxle wiring harness at the transaxle. |

Don’t

replace input speed sensor. |

02-07-30-022B(Oct

2003)

Sept 2003 Techlink |

2004 |

L61

EcoTech 4 Cylinder 2.2L Engine |

Replace

Spark Plug Sets |

Don’t replace PCM or Ignition Cassettes |

03-042

Recall |

|

| return

to Table of Contents |

|

|

Truck Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

1993-2004 |

All Passenger Cars and Trucks – A/C Compressor |

Follow

SI and Bulletin for diagnostic information before replacing A/C

compressor. |

Don’t

replace A/C compressor. |

Service

VME, 10/31/03

01-01-38-013A |

1999-2003 |

Fullsize Pickups – Rear Spring Slap Noise |

Replace

inserts and rubber washers. |

Don’t

replace leaf spring. |

Service

VME, 11/17/03 |

1999-2004 |

GM Car and Trucks models with HomeLink Universal Transmitter –

Programming Diagnosis |

Use

J-41540 HomeLink Tester. Follow SI and refer customers to Owner’s

Manual. |

Don’t

replace HomeLink Transceiver without validating internal fault

recognized by

J-41540. |

01-08-97-001B |

2002-2003 |

All

TrailBlazers, All Envoys, Bravada – Squeak/Rub/Scrub Type

Noise in Steering Column |

Lubricate

and remove material, per bulletin. |

Don’t

replace upper or lower intermediate shaft. |

02-02-35-006A |

2003-2004 |

All TrailBlazers, All Envoys, Bravada, Rainier – Tail Lamp

Socket Circuit Board |

Replace

both tail lamp circuit boards |

Don’t

replace complete tail lamp assembly. |

Service

VME, 9/22/03

03-08-42-006A |

2003-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed. |

Don’t

replace complete mirror assembly. |

03-08-64-028 |

2003 |

Fullsize

Pickups and Utilities – Transfer Case Service Light |

Replace

encoder motor sensor and reprogram TCCM |

Don’t

replace module, encoder motor or transfer case for DTCs C0327,

P0836, P0500 |

03-04-21-001B |

2003 |

Fullsize

Pickups – 6.6L Diesel Engine ECM |

Follow

SI and bulletins for proper diagnostics for P0181. Refer to the

Owner’s Manual (block heater and front cover) |

Don’t

replace ECM (DTCs P0540 and P0181) unless diagnostics confirm

need to replace |

02-06-04-048,

03-06-04-021, 02-06-04-058 |

2002-2004 |

TrailBlazer,

TrailBlazer EXT – Wavy Front Fascia |

Repair

fascia with Dual Lock |

Don’t

replace front fascia |

02-08-62-004 |

2002-2004 |

All

TrailBlazers, All Envoys, Bravada – Mirror Erratic Return |

Replace

mirror actuator and reprogram module |

Don’t

replace outside mirror assembly |

02-08-64-008

02-08-64-021 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for February |

| |

|

| Know-How

Broadcasts for February |

| 10280.02D

Emerging Issues |

February

12, 2004 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| 10280.14D

2005 Chevrolet Equinox |

February

26, 2004 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

| |

Car Issues – Fix It Right The First Time

Car Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time