|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Wireless

Headphones and Remote Controls |

Because the wireless

headphones and remote controls for GM DVD RSE (Rear Seat Entertainment)

and RSA (Rear Seat Audio) systems are loose

items, it’s possible for them to become separated from the vehicle

they’re intended for, before the vehicle is delivered to the

customer. In many cases, these items are not interchangeable among

vehicles. If the wrong components are provided to the customer, dissatisfaction

will result.

For example, a Chevrolet dealership will have three different remote

controls and they are not compatible (Malibu Maxx, TrailBlazer, and

Uplander). However, the headphones are compatible with all GM DVD systems

except the minivans, which require a 2-channel wireless headphone.

If the 2-channel headphones are used in the wrong vehicle, channel

2 (RSA) will not be audible, but channel 1 (DVD) will be audible.

To help keep these components straight, here’s some information

about the systems in use.

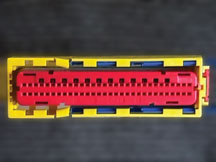

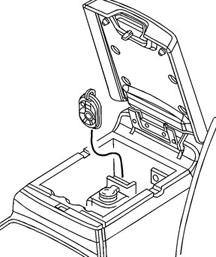

System 1a -- DVD RSE

The following headphone kit (p/n 15140532) is released for the 2005-07

Malibu Maxx only (fig. 1). The remote control will not work with any

other GM vehicles.

15140532 (Visteon) Headphone Package (DVD RSE) |

part number |

quantity |

item |

15762534 |

2 |

Headphone Assembly

(1 Channel Wireless ) |

22698894 |

1 |

Control Assembly - Video Player Remote |

15073730 |

1 Pack |

Battery Package - Headphone

4 - AAA |

15072561 |

1 Pack |

Battery Package - Video T/Player Remote Control

2 - AA |

22727857 |

1 |

Instruction - Video Disc Player Operation |

15140533 |

1 |

Instruction - Video Disc Player |

System

1b -- RSA without DVD RSE

TIP: The Malibu Maxx is the only current GM vehicle that offers an RSA system

with wireless headphones. The other GM vehicles have RSA systems which use wired

headphones (which are not provided to the customer).

The following headphone kit (p/n 10396845) is released for the 2005-07 Malibu

Maxx with RSA option (UK6)..

10396845 (Visteon) Headphone Package (DVD RSA) |

part number |

quantity |

item |

15762534 |

2 |

Headphone Assembly

(1 Channel Wireless ) |

15073730 |

1 Pack |

Battery Package - Headphone

4 - AAA |

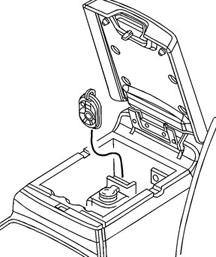

System

2 -- DVD RSE

The following headphone kit (p/n 15072230) (fig. 2) is released for the 2005-06:

- Buick Rendezvous and Rainer

- Cadillac Escalade, EXT, ESV, SRX

- Chevrolet Avalanche, Silverado Crew Cab, Suburban, Tahoe, TrailBlazer

- GMC Envoy, Sierra Crew Cab, Yukon, Denali, XL, XL Denali

- Pontiac Aztek

- Saturn Vue

TIP: The remote control will work only in these GM Vehicles.

15072230 (Panasonic) Headphone Package (DVD RSE) |

part number |

quantity |

item |

01999421 |

2 |

Headphone Assembly

(1 Channel Wireless) |

01999355 |

1 |

Control Assembly - Video Player Remote |

15085989 |

1 Pack |

Battery package - Headphone

4 - AAA |

15085988 |

1 Pack |

Battery Package -Video T/Player Remote Control

2 - AA |

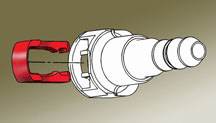

System

3 -- DVD RSE

The following two kits (p/n 15136091 and 15136092) are released for

the 2005-07:

- Buick Terraza

- Chevrolet Uplander

- Pontiac Montana SV6

- Saturn Relay

TIP: The remote control will work only in these GM vehicles. Channel

2 of the wireless headphones will work only in these vehicles (Channel

allows you to listen to DVD and Channel 2 allows you to listen to RSA).

There are two DVD systems available:

- A base system U56 comes with a remote control kit only (no headphones

available).

- An uplevel system U42 comes with a remote control kit and a headphone

kit (fig. 3).

TIP: Headphone kit TX3 can be added to either system.

TIP: Batteries are not included.

15136091 (Hosiden) Headphones Only Package (DVD RSE) |

part number |

quantity |

item |

15185391 |

2 |

Headphone Assembly

(Dual Channel Wireless) |

15136092 (Hosiden) Headphones Only Package (DVD RSE) |

part number |

quantity |

item |

15190411 |

1 |

Control Assembly - Video Player Remote |

TIP:

If a kit is misplaced or was not shipped with the vehicle, follow

established procedures for misplaced/missing components. The service

part numbers for the kits are the same as the OEM part numbers.

- Thanks to Jeri Betts, Dwayne Hall and Matthew Marchiori |

|

figure

1 |

figure 2 |

| |

figure

3 |

| |

| |

| return

to Table of Contents |

|

|

| End

of Support for Windows 98, Millennium and NT 4.0 |

Attention: All Service Department Personnel

Beginning January 1, 2005, GM Service and Parts Operations will discontinue

ALL support for Windows 98 (Second Edition), Millennium and NT 4.0.

An announcement concerning the end of support was distributed to dealers

on October 31, 2003 under administrative message VMG20030999 (In Canada,

dealer communicatiion dated November 27, 2003). During this year, the

Techline Customer Support Center (TCSC) provided “one call limited

support” for the operating systems mentioned above. The one call

limited support will be discontinued on January 1.

For additional detail regarding supported operating systems and PC

hardware, go to http://service.gm.com/techlineinfo/techlinepc.html.

Review this document before making a business grade Techline PC purchase.

Questions regarding the information above can be directed to your local

Techline Consultant (TC) or the Techline Customer Support Center (TCSC).

TC contact information can be found on http://service.gm.com/techlineinfo/techlinepc.html.

TCSC can be reached at 1.888.337.1010, prompt 3. From Canada, 1.800.828.6860

(English) or 1.800.503.3222 (French).

- Thanks to Shawn Sullivan |

| |

| |

|

|

Daytime Running Lights Disable Qualifications and Process |

In

GM Service Operations’ continuous effort to provide the fastest

customer support possible, the following process is in effect for those

select governmental agencies that request and qualify for disabling Daytime

Running Lights (DRL).

TIP: In Canada, disabling of DRLs is not permitted by Transport Canada.

1. Only the following governmental agencies qualify for this disable

request: City/State Government, Police/Sheriff Departments, FBI, CIA,

DEA, and emergency vehicles if government owned.

2. All requests are to be made through the Techline Customer Support

Center (TCSC) at 1.888.337.1010.

3. The dealership will be required to obtain a letter on official agency

letterhead requesting the disable, stating that the agency owns the vehicle,

and stating the reason. The letter must indicate which features are to

be disabled. For example, both AHL and DRL disabled*. The letter must

include the specific VIN(s) of the vehicles which will be disabled and

this statement: “The DRL/Auto Headlamp system will be made fully

operational prior to disposal/sale of the vehicles listed above.” In

addition, the letter needs to be signed by a representative of the official

agency.

The letter must be kept in the service history file at the dealership,

and a copy sent to TCSC before the disable procedures will be released.

In most cases, the vehicles will require a software change that requires

a special VCI override.

* TCSC will make every attempt to honor these requests. In some cases,

it is not possible to disable a feature. Example: AHL disable is not

possible on 1999 and later S/T Trucks. Contact TCSC to see if disabling

the desired feature is possible on your specific vehicle.

-

Thanks to Abby Slagor |

|

return to Table of Contents |

|

| Important

Information About Programming a Replacement Module |

You

must begin by using your Tech 2 to obtain information from the vehicle.

Always follow proper procedures and precautions.

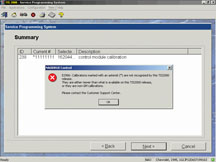

After selecting Service Progarmming Systems in TIS, you have a choice

between:

- Reprogram

- Replace and Reprogram

You now MUST select Replace and Reprogram (fig.

4). Then follow the remainder

of the standard procedure to install the data into the replacement module.

TIP: The default choice is Reprogram, and if you use it, you will receive

an ERROR message (fig. 5). If after following this procedure, you still

get the ERROR message, contact Techline Customer Support Center.

The Reprogram choice is used only to reprogram a module that will continue

to be used in the vehicle (installing the latest calibrations, for instance).

-

Thanks to Abby Slagor and Craig Jones |

figure

4 |

figure

5 |

| return

to Table of Contents |

|

| Top

Tier Gasoline Update |

Shell and Entec Stations

(Montgomery, AL) have been added to the Top Tier list.

These brands have been added to the running list on the TechLink website.

-

Thanks to Jay Dankovich

|

| return

to Table of Contents |

|

| MP3

Radio Software Upgrade |

This

information applies to 2005 Buick Rainier, Chevrolet Colorado, SSR,

TrailBlazer, and TrailBlazer EXT and GMC Canyon, Envoy, and Envoy

XL vehicles with MP3 (RPO US8) Radio CD Player. A software anomaly

within the radio has been found.

Some owners may comment that when playing a CD the radio displays the

last track number for about 5 seconds, but there is no audio. The display

changes to "READING" for about 15 seconds. Then it may play

the CD or eject the CD with a "CHECK CD" message.

TIP: Each

dealership will receive the "2005 US8 MP3 Radio Software

Upgrade" CD through the Dealer World Delivery (DWD Box) process

the week of November 29th, 2004 (fig. 6).

TIP: This disc does not apply to Chevrolet Equinox.

Install the software upgrade CD into MP3 radio. Allow the software files

to transfer completely. This should take 1-2 minutes. This installation

should correct the condition noted above.

-

Thanks to Doug Daugherty

|

figure

6 |

return

to Table of Contents

|

|

| Synthetic

Oil |

The following 2005 engines have synthetic engine oil installed at

the engine plant (fig. 7).

2.0L LSJ

3.6L LY7 Cadillac only

4.6L LH2

6.0L LS2

TIP: When

servicing these engines, use oil that meets the GM4718M specification,

as outlined in the Owners’ Manual. Not all synthetic oils will

meet this GM standard.

-

Thanks to Robert Stockwell |

figure

7

|

| |

|

| Pulse

Wiper Operation |

This

information applies to 2005 Chevrolet Cobalt (Pontiac Pursuit in

Canada) and Pontiac G6.

On these vehicles, there are three wiper modes: Pulse, Low and High.

In the Pulse mode, the wiper timing will fluctuate with the vehicle speed.

If the vehicle speed is below 50 mph (80 km/h), the wipers will take

up to 3 seconds between wipes.

TIP: In certain weather situations, if vehicle speed is below 50 mph

(80 km/h), the customer may find it necessary to switch the wipers to

the Low mode.

-

Thanks to Steve Oakley |

| |

|

|

| return

to Table of Contents |

|

| Tips

for Servicing .64 Terminals |

If

you’ve been following the various stories in TechLink about

electrical terminals over the past few years, you know that numerous

new types of terminal and connector systems have been introduced

(TechLink, Sept. 2002, June 2003, Feb. 2004).

One type of terminal, the .64, is offered by several suppliers, and there

are slight differences between them. The information here is intended

to clarify these differences.

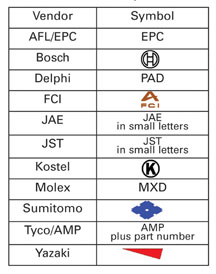

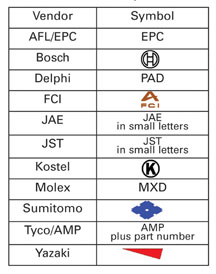

TIP: The

supplier of a system can often be determined by locating and identifying

the manufacturer’s symbol on the connector (fig.

8).

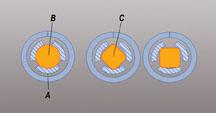

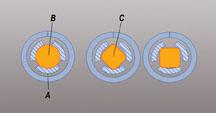

There are two different types or styles of male terminals that will mate

with the .64 female terminal (fig. 9).

A Stationary contact of female terminal

B .80 mm round terminal

C .64 mm square terminal

These are the .80 mm round style (Delphi and Bosch), and the .64 mm square

style (AMP/Tyco, Bosch, JST, Molex and Yazaki). The GM corporate intent

is to use only the Yazaki .64 terminal in the future. So you will see

more of this terminal in the future. A new crimp tool is being developed

that will crimp the Yazaki square and Bosch round .64 terminals.

TIP: It is not recommended to attempt to distinguish between the .64

terminal and the 100 terminal just by looking. The best way to be sure

is to use the .64 test probe (J-35616-64A) initially. If the J-35616-64A

probe seems obviously too small, move to the 100 sized probe.

If a male 100 terminal (or test probe, or anything incorrect) is inserted

into a .64 female, the .64 terminal may split. This destroys the terminal’s

retention capability. When that damaged .64 terminal is reconnected,

tension is too low to ensure proper contact and continuity.

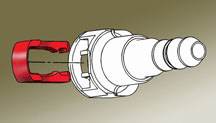

Test Probe

All of these connection systems use the J-35616-64A test probe. There

has been an update to this probe. The latest version has a blue wire

and a more robust silver terminal probe (fig. 10). Use the probe carefully

to avoid damage to the terminal.

TIP: The earlier probe has a white wire and a gold terminal probe (fig.

11).

TIP: The J-35616-64A and J-35616-65 test probes are correctly sized to

substitute for both the round and square male terminals.

Terminal and Connector Systems

The following paragraphs describe various terminal and connector systems

from several suppliers. One type to be aware of is the hybrid type, which

uses both .64 terminals and other sizes of terminals in the same connector.

It is assumed in all of the following that the connector wire cover,

if used, has been removed.

All of the following terminals are in the J-38125 Terminal Repair Kit

and in the tray indicated.

Delphi -- Many different Delphi connector shapes and styles are in use.

All Delphi .64 connection systems use terminal 15359541, which is found

in the Delphi tray 4. A Delphi Hybrid connector is shown in figure

12.

These connectors require the careful removal of the comb style TPA (Terminal

Position Assurance). They will break very easily if extreme care is not

used. Use the 15381651-2 terminal release tool pushed into the small

hole between two terminal cavities.

TIP: Do

not disassemble the Delphi connector body any more than removing the

TPA and in some cases, a nosepiece that covers the small terminal

release holes. It is very difficult to get all the terminals back into

place. If you do disassemble, you’ll have to remove all the terminals

and wires from the connector.

Reassemble the connector and then reinstall

the terminals and wires into the connector.

Watch for an expanded explanation of this in an upcoming issue of TechLink.

Molex -- A new Molex connection system is used on some ECMs. It uses

a square type .64 terminal number 33467-0003 or 33467-0005 depending

on wire size. Both are found in Delphi tray 23.

There is only one style of this connector in use so far (fig.

13). The

TPA surrounds the terminal area, and the color matches the ECM header

color. Lift the TPA up slightly to the preset position. Use the gray

J-38125-213 terminal release tool.

Insert it into the small hole in the

TPA next to the terminal you wish to remove. Once the new terminal has

been pushed back into position, press the TPA back into place.

Sumitomo -- A new Sumitomo connection system is used on some ABS modules.

It uses a square type .64 terminal 8100-3455 in the Sumitomo tray 22.

There is only one style in use so far (fig 14),

but others will follow. At first glance, this connection system looks

like it uses a terminal

larger than a .64. The whiteTPA surrounds the terminal area. Lift it

to remove. This is difficult and feels like it is going to break. Use

the green 12094429 terminal release tool. Insert it next to the terminal

you wish to remove and lift the plastic tang that holds the terminal.

Once the new terminal has been pushed back into position, press the white

TPA back into place.

Tyco -- Several Tyco systems are in use. One of them is used on the Medium

Duty Truck ABS module (fig. 15). It uses a square type .64 terminal 962885-5

in the Yazaki tray 15.

There is only one style of this connector in use so far. Use a small

screwdriver to move the two tabs of the blue TPA out slightly to the

preset position. Use the green 12094429 terminal release tool. Insert

it into the small rectangular hole next to the terminal you wish to remove,

moving the plastic tang that holds the terminal. Once the new terminal

has been pushed back into position, move the blue TPA back into place.

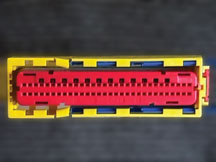

Another Tyco connection system is used on SDM modules (fig.

16). It uses

a square type .64 terminal. The service terminals in this connector are

the terminated leads 1393365-2-SIR in the new SIR tray. There is only

one style in use so far. Lift and remove the red TPA that surrounds the

terminal area. Use the black 15315247 terminal release tool. Insert it

next to the terminal you wish to remove and lift the plastic tang that

holds the terminal. Once the new terminal has been pushed back into position,

press the red TPA back into place.

A Tyco connection system is used on sunroof modules and other small modules

(fig. 17). It uses a square type .64 terminal 1123343-2 in the Lear tray

7.

There are several styles of this connector in use with different terminals.

You must carefully lift the white TPA on the top of the connector. Do

not remove. This TPA actually surrounds the terminal, so you will damage

it if you try to get it completely out. Use the green J-38125-24 terminal

release tool. Insert it next to the terminal you wish to remove and lift

the plastic tang that holds the terminal.

Once the new terminal has been

pushed back into position, press the white TPA back into place.

A Tyco connection system is used on the Transmission Control Modules

(TCM) of the Cadillac SRX, STS and CTS (fig. 18).

This connection system also uses a square type .64 terminal 2-1411578-2

in the Yazaki tray 15. Remove the strain relief (the cover on top of

the connector). Then, depress the lock tab on the side of the connector

and move one of two white TPAs aside to the pre-staged position. Insert

the green 12094429 terminal release tool into the small rectangular hole

next to the terminal you wish to remove. Move the plastic tang that holds

the terminal. Once the new terminal has been pushed back into position,

move the white TPA back into place. This connector is shown in the Wiring

Systems section of SI.

- Thanks to Jack Woodward and Guy Winohradsky |

figure

8

|

figure

9

|

figure

10

|

figure

11

|

figure

12

|

figure

13

|

figure

14

|

figure

15

|

figure

16 |

figure

17

|

figure

18

|

| return

to Table of Contents |

|

| Fuel

Filter Replacement |

Some customers have commented that they have been advised to replace

their vehicle’s fuel filter periodically.

On many vehicles, the fuel filter is non-serviceable (see table). The

filter is an integral part of the fuel pump module and fuel pressure

regulator assembly. The filter can be serviced only by replacement

of the fuel module assembly. This process requires the removal of the

fuel tank (one to two hours of labor, depending on the model), plus

several hundred dollars in unnecessary parts.

The vehicle owner’s manual outlines the periodic maintenance

service required, under the Maintenance 1 and Maintenance 2 guidelines.

Routine fuel filter replacement does not appear on either of these

schedules.

In the future, due to the increased regulation of evaporative emissions,

fuel systems utilizing a non-serviceable filter will become more common

as new models are introduced.

- Thanks to David MacGillis

| Vehicles with Non-Serviceable Fuel Filters |

| Chevrolet |

|

| 2003-05 |

Corvette |

| 2004-05 |

Malibu and MAXX, Silverado*, Tahoe**, Suburban, Avalanche |

| 2005 |

Equinox, Cobalt, Aveo, Trailblazer and EXT, SSR |

| GMC |

|

| 2004-05 |

Sierra*, Yukon** and XL |

| 2005 |

Envoy, XL and XUV |

| Pontiac |

|

| 2003-05 |

Vibe |

| 2005 |

G6, Pursuit ***, Wave*** |

| Buick |

|

| 2005 |

Rainier |

| Cadillac |

|

| 2004-05 |

XLR, Escalade, EXT and ESV |

| Hummer |

|

| 2006 |

H3 |

| Saturn |

|

| 2002-05 |

VUE |

| 2005 |

ION |

| *

2004 V8 only (4.3L uses conventional external filter) |

| **

2004 RPO L59 uses conventional external filter |

| ***

Canada Only |

|

| |

| |

Pontiac Vibe and Wave, and Chevrolet Aveo Fuel Filter

On the Pontiac Vibe, Pontiac Wave (Canada) and Chevrolet Aveo, the

fuel filter is serviced as part of the fuel pump module, as described

in the preceding paragraphs.

TIP: However, on these vehicles, if fuel pump module/fuel filter

replacement is required, it is not necessary to remove the fuel tank.

There is an access panel beneath the rear seat. When it's removed,

the fuel pump module can be removed. Refer to SI for details. |

|

|

return

to Table of Contents |

|

| Cadillac

STS Keyless Access System |

The STS (fig. 19) uses the same basic keyless system as the XLR (TechLink,

Feb. 2004) and Corvette (TechLink, Aug. 2004). The STS operates

at the same frequencies as the XLR and Corvette (315 MHz for

domestic, 433 MHz for Europe).

The STS may be susceptible to RF (radio frequency) interference or

EMI (electromagnetic interference).

This includes not being able to enter the vehicle or start the engine.

The driver can use the mechanical key or call OnStar to open the door.

But once inside, pressing the Start button may not start the engine.

Unnecessary Parts Replacement

These operating conditions are not a fault of the BCM, PCM, or other

control modules or components. Replacing them will not remedy the condition.

To help you understand what normal operation is, refer to the following

paragraphs.

Tips from the STS Owner’s Manual

TIP: The

STS owner’s manual explains the no-start condition under

the heading of NO FOBS DETECTED. Briefly it says the no-start condition

may be caused by equipment the driver has plugged into the accessory

power outlet in the center console. These could include cell phones

and chargers, two-way radios, power inverters, etc.

TIP: PDA devices and remote garage and gate openers may also interfere

with the keyless access transmitter. The owner is advised not to carry

the keyless access transmitter in the same pocket or bag as these devices.

TIP: Locations such as airports, automatic toll booths, and some gas

stations have fields which may interfere with the keyless access transmitter.

TIP: The owner is advised to move the transmitter to different locations

within the vehicle. If this does not help, place the transmitter in

the center console transmitter pocket with the buttons facing forward

(fig. 20) and then press the START button. If the vehicle battery is

sufficiently charged, this action will ALWAYS enable the vehicle to

start.

TIP: If the keyless access transmitter is not detected inside the vehicle

while trying to turn the ignition off, the NO FOB OFF OR RUN message

displays.

The vehicle may be near a strong radio antenna signal, causing the

keyless access system to be jammed. The vehicle will remain in ACCESSORY

until OFF or START has been pressed or 10 minutes has expired.

IMPORTANT: If the ignition is turned off and the keyless access transmitter

cannot be detected, the vehicle will not restart. The keyless access

transmitter needs to be detected inside of the vehicle in order for

the vehicle to start.

Multiple Fobs Present

Under certain circumstances, several people carrying valid keyless access transmitters

(fobs) may approach the vehicle at the same time. This will not affect door opening.

After the driver's door is opened, the driver preferences for the lowest driver

number will be recalled. Depending on which person’s fob is programmed

as Driver 1, the actual driver’s preferences may not be activated.

Battery Replacement

The vehicle will display a message when the fob battery is low. Until this occurs,

there are no effects on the system.

-

Thanks to Tobin Davis

|

figure

19

|

|

figure

20

|

|

return

to Table of Contents |

|

| Fuel

Line Quick Connectors, revisited |

This

updates information originally in the February 2004 issue of TechLink.

Three styles of fuel line quick connects are now in use.

The TI Group© Global Quick Connector is used on C/K trucks, S/T

trucks, Malibu Sedan, Cadillac XLR, Chevrolet Cobalt, Saturn ION, Chevrolet

HHR, and the 2004.5 and 2005 Chevrolet Corvette (fig.

21).

The Legris© (pronounced “la-gree”) QC is used on Aztek,

Rendezvous, Venture, Montana and Silhouette and on the internal line

connection to the sender module on the Malibu Sedan (fig.

22).

The A. Raymond© (pronounced “a ramone”) QC is used on

the Malibu Maxx and on the Pontiac G6 (fig. 23).

Release

TI Group and Legris -- To release the quick connect, push on the retainer

using hand pressure only.

Push first toward the barb on the steel or plastic line, then pull the

quick connector off. Do not attempt to remove the retainer while the

connector is still attached to the mating line.

A. Raymond – To release the quick connect, put finger pressure

on both release buttons simultaneously. Push first toward the barb on

the steel or plastic line, then pull the quick connector off.

Do not use sharp or pointed objects to put pressure on the connector

retainer/release buttons. Using a tool may fracture the retainer, making

it less effective at keeping the connector assembled. It may be easier

to release the connector if it is first pushed toward the barb on the

mating line. If one attempts to release the quick connect while pulling

on the connector, the friction between the barb and the retainer will

make it difficult to release the quick connect feature.

TIP: Attempting to remove the retainer on the TI Group connector with

the line inserted will result in retainer breakage.

TIP: If a quick connect does not release with hand pressure, thoroughly

clean it and blow out grit and dirt with compressed air.

Repair

TI Group -- If the retainer is broken, it is not necessary to replace

the entire fuel line and attached component to repair it (fig.

24). Three

sizes of replacement retainers are available.

5/16-inch |

21992748 |

3/8-inch |

22717568 |

5/8-inch |

21992746 |

Legris

-- Replacement parts are not available for this retainer.

A. Raymond – Replacement parts are not available for this retainer.

- Thanks to David MacGillis |

| |

figure

21, 22, 23

|

| |

figure

24

|

| return

to Table of Contents |

|

| You

Can Review Know-How Videos on GM Training Website |

As

you know, new Emerging Issues and New Model Features programs are

broadcast monthly on the GM satellite network, according to the

schedule published on page 8 of each issue of TechLink. Repeat

programs are also broadcast throughout the month.

Because there’s a lot of information in these broadcasts, GM is

now providing you a way to review the material on the www.gmtraining.com website. At a designated time after Emerging Issues and New Model Features

broadcasts, the videos will be available on the website. You can use

this new web feature as an on-demand tool to recall information right

at the time you need it.

Keyword Search

An important feature of the website is the keyword search capability.

With it, you can pinpoint a specific video segment. You can even search

keywords in the sound track.

Logon Procedure

Here’s how to begin using these videos.

- Log on to the www.gmtraining.com website. You will need your personal

ID and password.

- In the menu, click on TECHAssist.

- Click the Service Know-How logo.

- On the video search page, you can launch a video program, or you can

search for specific content using the search parameters in the left window.

TIP: You can also launch a video from the online course catalog.

- Thanks to Steve Sternicki |

| |

| return

to Table of Contents |

|

| Creaking

or Popping Front Doors |

This

information applies to 2004-05 Chevrolet and GMC Full Size 2500HD

and 3500 trucks with the letter F in VIN position 11, designating

the Flint asembly plant. At this plant, between March and September,

2004, the torque guns used to attach the door check link to the pillar

were set to a low torque level.

Do not replace either check link or the door hinge to address this issue.

Remove the bolt, clean the threads and reapply Loctite® 242, GM p/n

12345382 (GM p/n 10953489 in Canada). Install the bolt and torque to

25 Nm (18 lb ft).

- Thanks to Jim Will |

| |

| return

to Table of Contents |

|

| Roof

Water Leak |

On

some 2005 Chevrolet Equinoxes with RPO CF5 (sunroof) or CE1 (OnStar),

water may leak from the headliner or map light. Here’s what

to look for.

On vehicles with OnStar, be sure the antenna is firmly secured. Run water

over the antenna to confirm it is not leaking.

Next, check the condition of the sunroof drain hoses. Open the sunroof

and release the dual lock fasteners along the front edge. Carefully pull

the front edge of the headliner down to visually inspect the sunroof

drain hoses at the left and right front corners of the sunroof module.

The sunroof drain hoses must be pointing downward from the connection

to the sunroof module to ensure water can quickly drain away and to prevent

stress on the connecting joint. A stressed joint will slowly drip water

onto the headliner and this water can get to the map light. An incorrectly

positioned drain hose is shown in figure 25.

To correct the condition, remove the A-pillar trim on the affected side.

TIP: It

is not necessary to remove the headliner.

Release the hose from the mastic patch on the pillar and from the clip.

Gently pull the hose downward so the edge of the rubber portion can be

seated against the bottom side of the clip when reinstalled. Incorrect

hose installation is shown in figure 26 and correct installation is shown

in figure 27.

Confirm that the hose is pointing downward at the joint to the sunroof.

Then, securely seat the hose into the mastic patch.

Pour a small amount of water into the sunroof module area adjacent to

the drain connection. If leakage is evident, the hose may still be pointing

slightly upward.

TIP: It

may be necessary to remove the visor to give you more freedom of movement

to rotate or position the drain hose downward.

If the leak cannot be stopped, remove the drain hose and seal it to the

module.

TIP: It

may be necessary to remove the B pillar upper trim to get enough movement

in the headliner to access the drain hose for sealing.

-

Thanks to Ron Erman |

figure

25 |

figure

26 |

figure

27 |

| return

to Table of Contents |

|

| Headlamp

Switch |

After

replacing the headlamp switch on a 2003 full size truck or utility

you may notice the following changes.

1. The green and amber LED (light emitting diode) indicators are missing

from the face of the switch.

2. Trouble code B0951 will be set in the BCM after a replacement switch

is installed.

This is a normal condition. No repairs should be attempted.

A running change was implemented starting with the 2004 model year and

the new replacement switch doesn't have the "auto" and "disable" LED

indicators.

The BCM will store a trouble code B0951 when a replacement switch is

installed on a 2003 vehicle. This is due to the deletion of the LEDs

and will not change the operation of the DRLs and headlamps.

- Thanks to Paul Radzwilowicz

|

| |

|

return

to Table of Contents |

|

| Brake

Moan |

Owners

of some 2003-05 Chevrolet, GMC and Cadillac 1500 Utilities may comment

on a brake moan, hoot or fog horn type noise from the brakes.

This concern may be somewhat difficult to duplicate and happens only

after the vehicle is driven for a distance of 20-30 miles (32-48 km).

The noise is most audible when the brakes are applied between 20-40 mph

(32-64 kph) and the brake pedal is lightly released.

TIP: The noise may sound like it is from the front, when in fact it is

from the rear brakes.

Inspect the rear brake rotor surfaces for scoring or a grooving pattern

which may look like a vinyl phonograph record.

To correct this concern, machine the rear rotors and block sand the pads.

-

Thanks to Jim Will |

|

|

| return

to Table of Contents |

|

Car Issues — Fix

It Right the First Time Car Issues — Fix

It Right the First Time |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

1997-2005 |

Buick

Century, Regal – Broken

Armrest Lid Latch |

Replace lid latch

only. |

Don’t

replace console armrest lid (Regal) or front seat center

storage armrest (Century)

when only latch is needed to repair condition. |

03-08-49-018A |

2004-2005 |

Grand

Prix – Outside Rearview

Mirrors |

Replace mirror

glass or motor, whichever is defective. |

Don’t

replace complete mirror assembly. |

04-08-64-009 |

2004 |

Grand

Prix – Steering, Suspension or

Cradle Click Noise |

Re-torque right steering

gear mount. |

Don’t

replace steering gear or cradle. |

03-02-32-048 |

2000-2003 |

Century,

Regal, Lumina, Impala, Monte Carlo, Grand Prix, Intrigue with

3.8L L36 Engine – Coolant Leak |

Replace upper intake manifold

gasket only. |

Don’t

replace upper intake manifold assembly for coolant leak condition. |

03-06-01-016 |

2001-2004 |

Aztek

(01-04), Rendezvous (FWD, 02-04), Venture/Montana/Silhouette

(01-04) – Pop and/or Rattle in Exhaust Down Pipe |

Follow procedure in bulletin

using clamp P/N on down pipe to correct rattle/buzz noise. |

Don’t

replace converter assembly for rattle/buzz noise without completing

instructions in bulletin. |

03-06-05-003 |

2000-2004 |

All

Cars with 4T40/4T45E and 4T65E – Light

On/Various Transmission Codes Stores |

Check transmission 20-way

connector for secure connection (disconnect and reconnect). |

Don’t

replace transmission, TCC PWM, VSS, PCS or valve body. |

02-07-30-022B |

1998-2004 |

Seville – Heated

Seat Inoperative |

Replace only needed heating

element. |

Don’t

replace entire seat cover if heated seat element is inoperative. |

01-08-50-002C |

2000-2004 |

Cavalier/Sunfire/Alero/Grand

Am – Inoperative

Sunroof Module |

Retime module or replace

only motor for inoperative complaints. |

Don’t

replace entire sunroof module assembly. |

03-08-67-009A |

2003-2004 |

Cavalier/Sunfire – Air

Conditioning Compressor Noisy |

Inspect for ground out

conditions that can cause A/C compressor noise complaints. |

Don’t

replace A/C compressor for excessive noise complaint without

inspecting for ground outs. |

03-01-38-012 |

1999-2004 |

All

Cars and Trucks – Brake Warranty,

Service and Procedures |

Issue One: Refinish brake

rotor.

Issue Two: Measure for LRO |

Issue

One: Don’t replace the brake rotors.

Issue Two: Don’t measure for LRO |

00-05-22-002D |

|

| return

to Table of Contents |

|

|

Truck

Issues – Fix It Right The First Time (new

issues in bold) Truck

Issues – Fix It Right The First Time (new

issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2004 |

Tahoe,

Suburban, Silverado, Yukon, Yukon XL, Sierra, Escalade,

Escalade EXT, Escalade ESV, H2 – Passenger Door Module

and RKE Inoperative |

Re-flash

passenger door module. |

Don’t

replace passenger door module. |

04-08-52-005 |

2002-2004 |

Chevrolet

Silverado, GMC Sierra – Accumulator/Accumulator

Bracket |

Replace

accumulator and/or accumulator bracket. |

Don’t

replace compressor. |

02-01-38-007C |

2001-2003 |

Fullsize

Pickups – Injector Replacement for High Flow Rates |

Use

Corporate Bulletin Number 04-06-04-007A for injectors with

high fuel return rates. Use Special Policy 04039 for all 01-02

vehicles. |

Don’t

replace 8 injectors for any complaint other than high fuel

return rates.

All other injector failures are fix as failed. |

Special Policy 04039 |

2004-2005 |

All

Cars and Trucks – State-of-Charge

Upon Delivery of New Vehicle |

Check

battery’s state-of-charge

per revised PDI procedure using Midtronics Conductance Tester. |

Don’t

remove and replace battery. |

02-06-03-009A |

2002-2004 |

Fullsize

and Midsize Pickups and Utilities – Labor Operation

Assignments for Control Module Reprogramming |

When submitting claims

for reprogramming electronic module, use correct labor operation

that reflects module being programmed. |

Do not use K5364, which is for reprogramming

transmission control module (TCM), when reprogramming TCCM. |

02-04-21-006D

02-06-04-057D |

2002-2004 |

Fullsize

and Midsize Pickups and Utilities – Sleepy

New Venture Gear Transfer Case Control Module |

Verify sleepy module as

primary cause, per bulletin. Reprogram TCCM with latest software

released 3/11/04. |

Don’t

replace encoder motor or transfer case. Replace module only

if C0550 DTC shows as current or in

history. |

|

| 2002-2003 |

Chevrolet

Avalanche and Cadillac Escalade EXT – Cargo Covers

and Cladding Faded or Stained |

Thoroughly

clean, dry and treat components with “Armor-dillo.” |

Don’t

replace cargo covers for this condition. |

04-08-111-001A |

| 2002-2004 |

All Passenger

Cars and Trucks – Air Conditioner Compressor

Diagnosis |

Follow SI and bulletin for diagnostic information

before compressor replacement. |

Don’t

replace air conditioning compressor. |

01-01-38-013A

03-01-38-019 |

| 2002-2004 |

All

TrailBlazers, Envoy, Envoy XL, Bravada – Squeak/Rub/Scrub

Type Noise in Steering Column |

Lubricate and remove material,

per bulletin. |

Don’t

replace upper or lower intermediate shaft. |

02-02-35-006A |

2001-2004 |

Fullsize

Pickups and Utilities – Servicing

Wide Load Mirrors (RPO DPF) |

Replace individual parts

as needed. |

Don’t

replace complete mirror assembly. |

03-08-64-028 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for February |

| |

|

| Know-How

Broadcasts for February |

| 10290.02D

Emerging Issues |

February

10, 2005, 9:00 AM, 12:30 PM, and 3:00 PM Eastern Time |

| New

Model Features and Technology Close-Up seminars |

Stay

tuned! These programs will return soon. Check the Service

Know-How section of the GM Training website (www.gmtraining.com)

for more details. |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

Car Issues — Fix

It Right the First Time

Car Issues — Fix

It Right the First Time

Truck

Issues – Fix It Right The First Time (new

issues in bold)

Truck

Issues – Fix It Right The First Time (new

issues in bold)