| |

|

|

Note:

Clicking on any picture or illustration will open a larger version

of that art.

|

|

Cylinder

Bore Liner Replacement |

A new tool EN-45680-850

has recently been released to replace cylinder bore liners in the

2.2L Ecotec four-cylinder engine (RPO L61 VIN

F or D).

Background

The cylinder block of the Ecotec engine is lost-foam cast aluminum

alloy, with pressed-in centrifugally-cast grey-iron cylinder bore liners.

In production, the liners are pressed into the block, then the deck

of the block and liners are machined all at the same time. The production

specification calls for the liners to be flush with the block, to +

0.02 mm (0.0008 in.) above deck.

The cylinder liner is beveled at the bottom end to help guide the liner

into the block bore. And the top of the liner is slightly flanged,

fitting into a counterbore in the block. This ensures that the liner

is properly seated when it is pressed into place.

Cylinder Damage

A cylinder bore of any engine can be damaged by a broken piston ring,

a loose wrist pin or clip, or piston debris caused by detonation damage.

The Ecotec is susceptible to the same kinds of hazards. In the Ecotec

engine, the liners are thin-wall castings, on the order of 1.5 mm (1/16-inch)

thick, so overboring is not a possibility.

Up until now, if a liner became damaged, it was necessary to replace

the entire engine assembly.

With the introduction of the EN-45680 L61 (L850) Cylinder Bore Liner

R & I Kit, it is now possible to replace a damaged liner. This

procedure can even be done with the engine remaining in the vehicle

on several vehicle product lines.

Although only the damaged liner(s) must be replaced, always inspect

all of the cylinders.

Detailed instructions are included with the tool kit, and are also

available in SI. These are the highlights.

Liner Removal

The cylinder head must be removed, along with the piston and rod from

the affected cylinder(s). Follow SI procedures.

The fixture assembly is attached above the cylinder bore with previously-used

cylinder head bolts (fig. 1).

TIP: Cylinder head bolts must not be reused.

The fixture is installed from above, with the shoe positioned flat

against the bottom of the cylinder liner.

A nut on the puller is turned to pull the liner from the block.

TIP: Do not use any power tools to turn the removal tool nut, to avoid

damage to the block.

Liner Installation

After inserting a replacement liner into the top of the cylinder bore,

position the fixture above the cylinder bore and attach with the four

used cylinder head bolts.

An installation assembly is used to press the liner into place (fig.

2).

TIP: Do not use any power tools to turn the arbor screw, to avoid damage

to the liner.

When the liner is installed to within 1/16-inch (1.6 mm) of the block

deck face, use a torque wrench to tighten the arbor to specification.

When the flange of the liner seats into the counterbore of the block,

a minimal portion of the liner remains above the deck surface.

Liner Trimming

The kit includes debris plugs to be installed in the affected cylinder

and adjacent cylinder(s).

The service liner is very similar to the ones used in production. To

complete the installation, it’s necessary to machine the top

of the liner to production height specification, flush with the block

deck to + 0.02 mm (0.0008 in.) above deck.

It is also necessary to avoid damage to the block deck surface. This

requires proper setup of the cylinder liner trim tool.

TIP: Follow the instructions exactly to set up the cutting blades of

the cylinder liner trim tool, using the set gage ring supplied.

The cylinder liner trim tool is installed to the block over the affected

cylinder (fig. 3). An electric drill motor with specific power rating

and rpm must be used to operate the trimmer. And compressed air operates

the venturi vacuum that catches the metal shavings as the liner is

trimmed.

If multiple cylinder liners are being replaced, move the cylinder liner

trim tool and debris plugs from cylinder to cylinder as required.

Additional Information

The new tool was discussed at an Emerging Issues IDL broadcast on May

30, 2003. If you missed it, check the schedule for future re-broadcasts.

Also refer to bulletin 03-06-01-018 (June 2003).

-

Thanks to Ed Cheung and Joe Sraj |

| |

|

|

figure

1 |

figure

2 |

| |

figure

3

|

|

|

|

| Does

Your Dealership Have Enough Techline PCs? |

Today,

a Techline PC is just as important a service tool as a toolbox. All

Service Information (SI), as well as diagnostic and programming tools

(TIS), is accessed using the Techline PC. A Techline PC must be used

to ensure that all service repairs are fixed right the first time.

Many technicians waste critical time waiting in line or walking a

long distance to use their Techline PC. Imagine if a technician needed

to wait 10 minutes to gain access to his/her toolbox for each job,

every day. This wait time quickly adds up, and results in lost productivity.

The ideal ratio is 1 PC for every 2 technicians (1:2), which provides

the least amount of wait time to complete a job.

Recently, GM Service and Parts Operations teamed up with PC Source to

run a Multiple PC Pilot. Dealerships were provided with enough PCs to

meet the PC to Technician ratio (1:2) for a 90-day trial. These PCs were

new Techline-ready, Business grade machines. Each PC was connected to

the GM ACCESS network with wireless LAN cards, which eliminated the need

to install new hardwire for the network.

The dealerships evaluated the productivity gains from having the proper

equipment accessible to their technicians, and at the end of the 90 days

had a choice to purchase or return the equipment. Every dealership recognized

the initial cost of purchasing the equipment was quickly made up by faster

access to the most current service information. Every dealership purchased

the equipment at the end of the pilot.

A PC that meets the current PC Hardware Specification is now far more

competitive in price than it was 3 years ago. Your Techline consultant

can help with a Return on Investment (ROI) analysis to demonstrate how

quickly the ROI on a Techline PC purchase will be realized.

Fully integrated PCs are available through the PC Source at 1.800.233.0040.

Other PCs are available through GM Dealer Equipment at 1.800.GMTOOLS.

PCs from other vendors may be used, but must meet the PC Hardware Specification

located on http://service.gm.com. PCs that do not meet the Techline specification

may not work properly and will not be supported. Your Techline consultant

can provide additional help in deciding what is needed to maximize the

hardware in your service department.

- Thanks to Sam Hutson

|

| |

|

|

Reprogramming

Passenger Door Module

|

Owners

of some 2003 Chevrolet and GMC full-size pickups and utilities, Cadillac

Escalade models and Hummer H2 may have concerns that the RKE key fob

does not function, the front passenger door power window, lock, mirror

and heated seat are inoperative.

Affected vehicles fall into one of three categories:

- Those built before 01/03 -- refer to Bulletin 03-08-52-001C.

- Those built during 01/03 -- refer to Customer Satisfaction Bulletin

03-011.

- Those built 02/03 or later -- refer to published Service Information

for the symptom experienced by the customer.

TIP: Various names are used to describe the component involved in this

condition. The Door Lock and Side Window Switch contains a microprocessor

called the Passenger Door Module (PDM). The condition and repair procedure

involve the PDM.

Instead of replacing the Door Lock and Side Window Switch, you can now

refresh and reprogram the PDM using your Tech 2.

TIP: Your Tech 2 must contain software 23.001 (CD 3) or newer, released

March 8. If it does not, you must download this software before proceeding.

Depending on the vehicle’s build date, follow the procedure in

the appropriate bulletin to diagnose the conditions and refresh and reprogram

the module.

TIP: You MUST identify the applicable bulletin for the truck you’re

working on. And once you have identified the correct bulletin, you MUST

perform the procedures described in it, in the order given, and do not

skip any steps.

- Thanks to Doug Daugherty |

|

|

|

| return

to Table of Contents |

|

| Fuel

Gauge Erratic or Inaccurate |

This

information applies to 2001 S-10 and Sonoma Crew Cab Pickup models.

Refer to bulletin 03-08-49-003 for details.

On these models, the fuel gauge may be erratic, inaccurate, or go from

1/4 to empty too quickly. The cause may be an improperly calibrated fuel

gauge. The length of the float arm may also affect gauge operation.

The correction is to install a new fuel level sensor 25353298 and reprogram

the PCM with a new calibration. Call TCSC at 1.800.828.6860 (English)

or 1.800.503.3222 (French) for a VCI number to allow installation of

the new calibration.

-

Thanks to Dan Oden |

| |

| return

to Table of Contents |

|

| DTC

Master List |

When

diagnosing a vehicle, it may be helpful to know all of the DTCs that

pertain to the modules on that vehicle.

To obtain this list, go to SI on the web, and follow this path.

- “Build” the vehicle

- Service Manual/Bulletins

- Vehicle Control Systems

- Vehicle DTC Information

- Diagnostic Information and Procedures

- Diagnostic Trouble Code (DTC) List -- Vehicle

This will display a DTC list for that vehicle, including all possible

codes in categories B, C, P and U. Each DTC in the list is followed by

a brief descriptor of the circuit or component.

You can then print out the list for reference in your work area.

-

Thanks to Mark Haning |

| return

to Table of Contents |

|

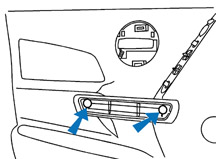

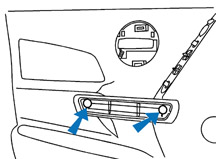

| Switch

Plate Bezel Removal |

This

is a reminder to follow the service procedure when removing the Switch

Plate Bezel from the front doors of 2000-04 full-size Pickups and

Utilities. Several door trims have been damaged by trying to take

out the bezel incorrectly.

TIP: You must first remove the door trim and the screw holding the bezel

in place.

TIP: Do not pry on the bezel from the top in an attempt to remove the

switch. The bezel and/or trim panel could be damaged.

Refer to SI documents 849812 and 849813 for the correct way to remove

the bezel.

1. Remove the front door trim panel.

2. Disconnect the electrical connectors.

3. Remove the screw that retains the switch panel bezel from the front

door panel (fig. 4).

4. Remove the switch panel bezel from the door panel using a flat-bladed

tool.

-

Thanks to Jack Cady and Mark Freigruber |

figure

4

|

| return

to Table of Contents |

|

| Parts

Restriction on PCM

|

The

2004 Pontiac Grand Prix is equipped with a new PCM. To provide feedback

and increased customer satisfaction, a parts restriction is in effect

through August 1, 2003. During this time, the PCM must be ordered

through TAC. When you call TAC, be prepared to provide Dealer Code,

VIN, mileage, RO number and results of diagnosis. Refer to bulletin

03-06-04-027A.

Returned parts will be analyzed by engineering to determine root-causes

of conditions. This information will help improve future products.

- Thanks to John Fletcher

|

| |

|

return

to Table of Contents |

|

| Timing

Tensioner Kit |

Owners

may comment about a noise coming from the engine between 1800 and

2200 rpm on some 1996-2003 Chevrolet and GMC trucks with the 4.3L

V6 engine.

The rattle noise may be caused by torsional vibration of the balance

shaft. A timing chain tensioner kit has been released to deal with this

condition. The tensioner consists of a bracket which holds a nylon blade

against the timing chain.

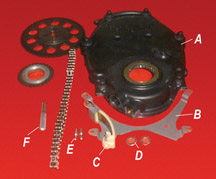

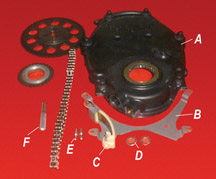

Components are shown in figure 5.

A Front cover

B Tensioner bracket

C Nylon blade

D Washer

E Dowel pin

F J-46165 Pin Driver

TIP: The noise may resemble detonation or spark knock, which must be

ruled out before installing the tensioner kit.

Here are some of the highlights of the procedure. An upcoming bulletin

and an IDL broadcast will provide additional information.

The engine front cover must be removed for access to the crankshaft and

camshaft sprockets and chain. The camshaft chain must be removed. Depending

on model year, either the cam gear or crankshaft sprocket must be removed

to do this. Follow standard SI procedures.

The tensioner bracket fits over four existing holes (fig.

6). The upper

two are the front cover center bolt holes. And the lower two are front

cover alignment holes.

TIP: The nylon blade must be temporarilly removed from the bracket.

With the tensioner bracket in position, use J-46165 Pin Driver to drive

dowel pins into the two bottom holes to retain the bracket.

Follow the bulletin procedure to complete the installation of the chain,

nylon blade and sprockets.

TIP: The kit includes two washers. Place them under the two center cover

bolts, which extend through the tensioner bracket. These are required

to maintain proper crush on the engine front cover seal.

-

Thanks to George Kaganac and Marty Case |

figure

5

|

| |

figure

6

|

|

|

| return

to Table of Contents |

|

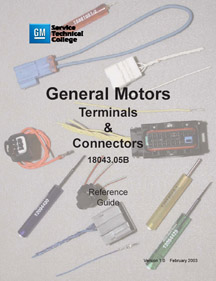

| Terminal

and Connector Reference Guide |

If

you saw the Terminal Repair Kit Update article in the June 2003 issue

of TechLink, you may now have some questions about the proper way

to remove, install, and otherwise service terminals and connectors.

The answer is found on the internet, at the following address (no spaces

except as noted).

https://www.gmcommontraining.com/images/Terminals_and_Connectors_022003.pdf

This will provide you with the General Motors Terminals & Connectors

Reference Guide, 18043.05B. It’s a 56 page manual, offered in PDF

format. There are plans to update this Reference Guide as needed (fig

7).

TIP: If you do not have the necessary software to download a PDF, go

to www.adobe.com for a free version of Adobe Acrobat.

The manual includes several subsections. In Standard Terminal Replacement,

you will find:

- crimp tools

- splice crimp tools

- splice clip application

- visual inspection standards

- and more.

In Terminals and Connectors, you will find Delphi connector identification

and Yazaki connector identification. The information is presented using

full-color illustrations.

Connectors

- photos

- terminal position assurance lock (TPA), if equipped

- location of the entry canal for insertion of the removal tool

Replacement Terminals

- photos

- part number(s)

Removal Tools

- photos

- tool number

- Kent-Moore J-number

Crimper Tools

- photos

- tool number

- Kent-Moore J-number

For convenience and future reference, you may print your own copy of

this manual, using your computer’s Print function.

- Thanks to John Roberts |

|

figure 7

|

| return

to Table of Contents |

|

| Availability of Electrical Terminals |

According

to parts bulletin IB03-044, a select group of terminals are no longer

offered by GM Parts, but are available directly from SPX Kent-Moore.

38 part numbers are affected.

-

Thanks to GMSPO |

| return

to Table of Contents |

|

| TransFlow Heater Blanket |

Kent-Moore

has just released an optional accessory (fig.

8) for the J-45096

Transmission Oil Cooler Flush and Flow Testing Kit (TechLink, Jan.

2003).

To review, the TransFlow equipment has two major functions: (1) to use

Dexron III automatic transmission fluid (ATF) to flush the transmission

oil cooler and lines, and (2) to accurately perform a flow test to identify

restrictions.

The Heater Blanket J-45096-10 fastens around the TransFlow’s internal

supply vessel. When plugged into a 110 v AC supply, the blanket will

heat ATF in the supply vessel to at least 65° F (18° C). This

is the minimum required operating temperature.

TIP: Below 65° F, the TransFlow will shut itself off. Below this

temperature, it is difficult to accurately measure the flow of ATF.

TIP: Allow extra warming time when you replenish fluid in the supply

vessel. Remember, it holds 31 quarts.

A special feature of the blanket is the thermostat, which will maintain

a set temperature.

TIP: Heating blankets without temperature control (typical freon heating

blanket) could affect the electronics in the TransFlow equipment.

To order, call Kent-Moore at 1.800.345.2233.

-

Thanks to Dan Popoff and Rick Mills |

figure

8

|

| return

to Table of Contents |

|

| HomeLink® Test

Kit |

The

Homelink Wireless Control System has been available on numerous GM

passenger cars and light duty trucks since 1995. It provides remote

operation of garage doors, estate gates, home lighting, and other

home automation devices, using a 3-channel transceiver built into

the vehicle.

The J-41540-GM Transmitter Test Kit (fig. 9) is an essential tool which

is useful in diagnosing the system.The kit includes a HomeLink Tester,

a Hand Held Transmitter, and a 120V-to-12V power supply. The Tester may

be operated from the vehicle’s accessory outlet or from the kit’s

power supply.

Complete instructions are supplied with the test kit, and you should

follow them when performing the tests. Proper testing and diagnosis can

help eliminate unnecessary replacement of parts. Here are some highlights.

Functionality Test

The Functionality Test establishes:

- That the Tester (receiver) from the kit is functioning.

- That the Hand Held Transmitter from the kit is capable of transmitting.

- That HomeLink is getting power from the vehicle.

- That HomeLink can be placed in the Default Mode This is a special mode

used only for testing. It is not the same as the Training Mode used by

the customer to program HomeLink to operate different devices.

- That HomeLink is capable of transmitting.

The instructions explain how to perform each of these tests and what

to do in case of a failure.

Range Test

The Range Test establishes:

- That the signal from HomeLink extends from the vehicle for a distance

of 15-30 m (50-100 ft.).

The instructions explain how to perform the test and what to do in case

of a failure.

Training Test

The Training Test establishes:

- That HomeLink is capable of being trained (programmed), in this case

using the Hand Held Transmitter from the kit.

- That the trained HomeLink is capable of operating the appropriate device

(in this case, the Tester from the kit) from a distance of 15-30 m (50-100

ft.).

The instructions explain how to perform each of these tests and what

to do in case of a failure.

TIP: Garage door openers manufactured before 1982 may not be compatible

with the HomeLink system. The fact that HomeLink passes the test procedure

does not guarantee that it will work with an older system. A universal

receiver or fix kit (for some older systems that were not manufactured

before 1982) is available for purchase at www.homelink.com or by calling

1.800.355.3515.

Once you have used the test kit to establish that HomeLink is functioning

properly, be sure the owner understands how to train HomeLink, using

their own hand held transmitter for the device they are programming.

TIP: You may offer to train HomeLink for them, using the customer’s

hand held transmitter, as a special service. If you successfully train

the hand held transmitter to HomeLink, it doesn’t guarantee that

the device will operate when they return home. Some garage door openers

and gates are equipped with rolling codes. The customer will need to

perform additional steps for HomeLink to activate these devices.

To determine if HomeLink has learned a rolling code, press the HomeLink

button. If the LED flashes rapidly for 2 seconds, then turns solid, additional

programming steps are needed.

Owners who require special programming assistance, who want to purchase

HomeLink accessories or learn about compatible products, may call 1.800.355.3515,

or visit the website at www.homelink.com.

TIP: A dealer

specific website is also available at www.dealerlink.homelink.com.

-

Thanks to Kobie Glenn and Marci Brogan |

figure

9

|

| return

to Table of Contents |

|

| Tool

Numbering System Changed |

See

bulletin 03-00-89-005 for details. Here are the highlights.

Effective immediately, all new essential and available tools will be

numbered according to a global numbering scheme.

TIP: Existing J-numbered tools will not be re-numbered.

Each tool will be placed in one of six categories according to function:

|

Category |

GE |

General, including HVAC |

EN |

Engine |

DT |

Transmission, differential |

CH |

Chassis |

EL |

Electrical, including SIR |

BO |

Body, frame, trim |

The two-character

function code will be followed by a five-digit number sequence:

EN-12345

As before, an alpha suffix indicates a revision:

EN-12345-A

A numerical suffix indicates a part of a kit:

EN-12345-1

TIP: Use the first two characters to help you organize your new tools. -

Thanks to Dave Roland and Derek Trimble

|

| return

to Table of Contents |

|

| P-Codes

with Warranty Claims |

The

OBDII (On-Board Diagnostics) system is capable of providing a great

deal of diagnostic information when vehicles are repaired because

the Malfunction Indicator Lamp (MIL) is illuminated. You are requested

to pass along as much of this information as possible.

Technicians -- On the repair order, record the OBDII P-codes, technician

observations, and customer comments. (GM Service Policies and Procedures

Manual, article 1.6.2)

Warranty Claims Administrator -- Enter the same information in the comment

section on the warranty claim for submission. (GM Claims Processing Manual,

Section 4.2.g)

This information is continually analyzed by GM Powertrain Engineering.

This process will provide engineers with accurate, detailed information

on a more timely basis. The idea is to identify and resolve potential

product concerns as early as possible.

If you will provide P-codes, your observations, and customer comments

on every vehicle you repair for an OBDII related code, Engineering can

begin to better understand what is causing the MIL to illuminate.

The inclusion of P-codes on repair orders varies from year to year. In

2002, 36% of repair orders did not include P-codes. So far this year,

it’s dropped slightly to 32%. But there’s still a lot of

room for improvement. Engineering asks for your cooperation.

-

Thanks to Kiet Nguyen |

| return

to Table of Contents |

|

| Proper

Removal of O2 Sensors |

This

reminder applies to all vehicle lines and model years, and is about

proper oxygen sensor removal techniques. Some of the oxygen sensors

returned to the Warranty Parts Center have been damaged during removal,

which means they cannot be analyzed (fig. 10).

There are a variety of special tools and slotted sockets available for oxygen

sensor removal which will not damage the pigtail. If space allows, a crowfoot

wrench is also appropriate. A suitable tool is needed for installation of the

new sensor. Using it for removal as well will eliminate damaging the wires on

the sensor being removed.

The rate of damaged O2 sensors returned for analysis has been cut in half so

far this year. Engineering appreciates your help and asks that you continue to

take care not to damage them during removal.

-

Thanks to Kiet Nguyen |

figure

10 |

| return

to Table of Contents |

|

| Door

Trim Panel Removal |

When

removing the door trim panel on the 2004 Grand Prix, do not use a

standard socket to remove the hexhead screws located in the pull

handle of the front or rear door trim panels. Some of the tubes are

too narrow and the standard socket, when pushed down onto the screw

will split the plastic tubes (fig. 11).

A thin walled 10 mm socket must be used. Early production vehicles use

a screw with a hex head. Later production vehicles have a screw that

has a combination of hex head and Torx head. This screw can be removed

with either a thin walled 10 mm socket or a T30 Torx head driver.

-

Thanks to Mel Spresney |

figure

11

|

| return

to Table of Contents |

|

| Transmission

Shift Conditions |

Owners

of some 2002-2003 LeSabres, Park Avenues and Bonnevilles may experience

no transmission upshifts, erratic shifts, and/or slipping from the

transmission. This condition may be caused by a poor electrical connection

inside of the underhood fuse box or Bussed Electrical Center. The

terminal that feeds the tranmission fuse may be spread too large.

TIP: If you discover a deformed terminal, follow SI procedures to replace

it.

On the LeSabre and Bonneville, the terminal at connector C3 pin E7 is

at fault. On the Park Avenue, connector C2 pin E4 is the faulty terminal.

The DTCs are P0753 and P1860.

-

Thanks to Bill Metoyer |

| return

to Table of Contents |

|

| Electrically

Folding Mirrors |

There

are some misunderstandings about the operation of RPO DL3 mirrors

on 2003 full size pickups and utilities (fig

12).

The mirrors in this option can be folded inboard electrically (when entering

a car wash, or parking in a confined space, for instance) using the same

switches normally used for adjusting the individual mirrors. Place the

L/R toggle switch in neutral. Then use the pad to fold the mirrors in

or out.

These mirrors must always be moved electrically. If a mirror is folded

inward manually, and then moved back outboard manually, the mirror will

not latch into the detent. The result is that the mirror may move and/or

shake.

TIP: If the mirror displays these conditions, simply cycle the mirror

inboard and back outboard using the electric controls. This will cause

the mirrors to click into the proper detents.

New vehicle prep technicians should be made aware of these procedures

and should verify proper operation of the mirrors before delivery.

TIP: Be sure the customer also understands mirror operation.

-

Thanks to Steve Love |

figure

12

|

| return

to Table of Contents

|

|

Grille

Bowtie

|

The

Chevrolet front grille bowtie emblem on 2000-03 Tahoe and Sububurban

(new body style) or 2003 Silverado may peel, delaminate or not properly

adhere. This emblem can be serviced by ordering just the bowtie (fig.

13) and not the entire front grille.

TIP: The upper grille baffle must be removed to replace the emblem. Refer

to SI document 1327886 for the procedure.

The service part number for the 2003 Silverado bowtie emblem is 12335700.

The service part number for the Tahoe and Suburban bowtie emblem is 12335633.

Parts are currently available from GMSPO.

-

Thanks to Doug Daugherty |

figure

13 |

| return

to Table of Contents |

|

| Performance

of XM Radio System with Sunroof |

Owners

of 2003 Chevrolet Monte Carlo and 2004 Pontiac Grand Prix may experience

poor XM signal reception with the sunroof fully opened.

Because the sunroof travels over the XM antenna at the rear of the roof,

the signal may be blocked. This is a characteristic of this antenna and

sunroof system.

This statement is contained in the vehicle owners manual. “Your

XM Satellite Radio antenna is located on the roof of your vehicle. Keep

this antenna clear of snow and ice build-up for clear radio reception.

The performance of your XM system may be affected if your sunroof is

open.”

TIP: Suggest that the customer move the sunroof forward enough to allow

the XM signal a direct line from the satellite/repeater to the antenna.

-

Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

| Wire

Harness Stretched |

Affected

Models:

98-02 Buick Century, Regal, Park Avenue, Le Sabre, Chevrolet Monte Carlo,

Venture, Oldsmobile Intrigue, Aurora, Silhouette, Pontiac Grand Prix,

Bonneville, Montana

98-99 Buick Riviera, Oldsmobile Eighty Eight

98-01 Chevrolet Lumina

01-02 Chevrolet Impala, Pontiac Aztek

02 Buick Rendezvous

On the listed vehicles, the 4T65E Pressure Control Solenoid (PCS) wire

harness may be stretched, or the PCS may not be oriented in the same

position, after installing a service replacement valve body assembly.

TIP: The service valve body casting is different from the original casting.

The casting difference does not affect operation.

There is a small tab on the pintle end of the solenoid windings. Bend

this tab in slightly toward the pintle. DO NOT remove it. Bending the

tab inward will allow the PCS to rotate in the bore and orient the connector

in the same position as the original PCS. This relieves the wire harness

strain.

-

Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

| Water

Leak in Front Floor Carpet Area |

Affects

1998-2003 Chevrolet S-10 and Blazer, 1998-2001 Oldsmobile Bravada,

1998-2003 GMC Sonoma, 1998-2001 GMC Jimmy (US), 1998-2003 GMC Jimmy

(Canada Only), 1998-2001 GMC Envoy

Some of the above vehicles may have a mildew odor or wet carpet in the

front passenger seat area. Here are the most common causes and cures.

- Water backing up at the plenum drain

Too much sealer at the plenum drain area can act as a dam, allowing water

to back up in the plenum and either seep around the air box seal or around

the lower right air box mounting screw. If a plenum drain has a ridge

of sealer higher than 1/4 inch (6.4 mm), use a utility knife to cut the

sealer down to 1/4 inch (6.4 mm) in height.

- Voids in the plenum seam sealer

Use a mirror to examine the inside of the plenum for possible voids in

the seam sealer where water can gain entry to the passenger compartment.

Seal any voids using the procedures listed in the service manual.

- HVAC recirculation door being left open

The HVAC recirculation, or air box, door opens upward when the HVAC conrols

are set to MAX A/C. In extreme conditions, water can pool on top of this

door and spill into the vehicle. This door can remain open if the HVAC

mode is set to MAX A/C when the ignition key is cycled off. Customers

should be informed of this condition and should be advised to turn the

HVAC setting to the regular A/C or OFF position before turning the vehicle

off.

TIP: Water may still leak into the passenger compartment, even with the

recirculation door in the fresh air position. This may occur in extreme

conditions (heavy downpours, etc.). Check for a hole above the air box

(between the two threaded holes that retain the right front fender) for

proper sealing. This hole should be sealed if found not to be sealed

properly.

To prevent water leaking into the passenger compartment(s), even under

heavy downpour conditions, fabricate a small plastic dam, 3/4 inch (19

mm) high x 3 inches (76 mm) long, then glue and seal it to the recirculation

register under the recirculation door. This will allow small amounts

of water (1/4 inch (6.4 mm) to 1/2 inch (12.7 mm)) to puddle in the HVAC

case without entry into the vehicle.

- Door harness boot

Water that is found in either the driver or passenger floor at the A-pillar

may have entered at the door harness boot on the A-pillar side. Make

sure the boot harness if fully seated in the A-pillar.

- Plenum/Cowl/Instrument sub panel (windshield tray)

Water may enter at the three piece Plenum/Cowl/Instrument sub panel.

This area must be sealed from the inside of the vehicle; the dash assembly

must be removed to gain access. This area can be sealed by spraying a

clear sealer (KENT brand) in a gallon commercial sprayer, up under the

Plenum/Cowl/Instrument sub panel.

IMPORTANT: Please follow these diagnosis processes thoroughly and complete

each step. If the condition exhibited is resolved without completing

each step, the remaining steps do not need to be performed. If these

steps do not resolve the condition, please contact GM TAC for further

diagnostic assistance. This diagnostic approach was developed for the

vehicles listed and should not automatically be used for other vehicles

with similar symptoms.

-

Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

| Clunk

Noise Felt Through Floor Pan |

Affected

Models:

1998-2003 Chevrolet S-10, Blazer

1998-2001 GMC Envoy, Sonoma, Jimmy (US), and Oldsmobile Bravada

1998-2003 GMC Jimmy (Canada)

Some owners of the listed vehicles may experience a clunk noise that

can be felt through the floor pan

This condition may be caused by the torsion bar crossmember contacting

the frame rails during left or right turns or on uneven surfaces.

Determine if the clearance between the left frame rail to crossmember

and right frame rail to crossmember are equal. If not, install either

a washer or alignment shim between the upper mount and frame.

Refer to SI document 539243. This document includes a component diagram

of the torsion bar crossmember to frame rail assembly and may provide

assistance in the repair.

-

Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

| Radio

Buzz, Pop, Static, or Whine Noise From Any Speaker |

Vehicles

equipped with non-class 2 amplifier (RPO UQ7, w/o Y91) may have no

volume or speaker buzz, whine, distortion, pop, or static noise coming

from any speaker.

Inspect the center console wire harness, approximately 5 inches (12.7

cm) from connector C306 toward the amplifier connector, for excessive

twisting. If the harness has excessive twisting, the bare drain wire

(ckt 2011 or 2099) may cut into the low level audio signals and cause

this concern. Repair the harness as necessary.

-

Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

Car

Issues – Fix It Right The First Time Car

Issues – Fix It Right The First Time |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2001-2003 |

3800

L36 -- Coolant leak at intake manifold |

Replace

the intermediate (upper) intake gasket |

Replace

the intake manifold assembly |

Bulletin

in process

VME to field 5/30/03

Techlink article |

2003 |

CTS

-- “Service Stability System” DTC C1286 |

Reprogram

EBCM |

Replace

steering wheel position sensor |

02-05-25-004 |

2000-2003 |

Cavalier,

Sunfire, Grand Am, Alero, Malibu – Fuel gage accuracy and

pump concerns |

Replace

sensor card for fuel gauge accuracy issue |

Replace

the fuel sender / pump assembly |

01-06-04-008D |

1999-2003 |

Grand

Am / Alero – Door glass clip breakage |

Replace

sash clip only |

Replace

entire door glass assembly for broken clips |

01-08-64-018 |

1997-2003 |

Grand

Am / Alero / Malibu – Brake pulsation |

Turn

rotor and use brake align procedure |

Replace

rotors for pulsation |

00-05-23-002

01-05-23-001

Know How 15040.01B |

1997-2003 |

Venture

/ Montana / Silhouette – Windshield water leaks |

Use

correct diagnosis procedures described in service bulletin |

Assume

that leak came from the windshield sealing |

01-08-57-006 |

1997-2003 |

Century

/ Regal – HVAC “Auto” light function |

Normal

in full heat or cold setting |

Replace

HVAC control head for "Auto" light |

99-01-39-007B |

1999-2002 |

Corvette

- Fuel gauge goes to empty intermittently |

Install

revised software |

Replace

fuel senders or I/P cluster |

2002

Bulletin

02-06-04-010,

1999-2001 Software released bulletin not yet updated |

2003 |

All

cars with 4T40/45E, 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM Solenoid |

Replace

transmission or valve body assembly |

02-07-30-039B |

2002-2004 |

L61

EcoTech 4 Cylinder Engine |

Replace

Cylinder Bore Liner |

Replace

Engine |

03-06-01-018 |

|

| return

to Table of Contents |

|

|

Truck

Issues – Fix It Right The First Time Truck

Issues – Fix It Right The First Time

|

Model

Year(s)

|

Vehicle

Line(s) --

Condition

|

Do

This

|

Don’t

Do This

|

Reference

Information / Bulletin

|

2003

|

C/K

Fullsize Pickups & Utilities -- Transfer Case Service Light

|

Replace

Encoder Motor Sensor, Reprogram TCCM

|

Replace

Module, Encoder Motor or Transfer Case For DTCs C0327, P0836,

P0500

|

03-04-21-001B

|

1999-2002

|

C/K

Fullsize Pickups & Utilities -- Throttle Body

|

Clean

throttle body adjust blade and insert plugs

|

Replace

throttle body for idle instability or pedal effort

|

02-06-04-054B & Parts

Restriction

|

2003

|

C/K

Fullsize Pickups

6.6L Diesel --Engine ECM

|

Follow

SI & Bulletins for proper Diagnostics; P0181 refer to Owner’s

Manual -- Block Heater and Front Cover

|

Replace

ECM (codes P0540 & P0181) unless Diagnostics confirm need

to replace

|

02-06-04-048

03-06-04-021

02-06-04-058

Parts Restriction

|

2003

|

C/K

HD Silverado, Sierra, G Savana, Express >8600GVW -- ABS Lamp

On

|

Re

flash for code C0550

|

Replace

ABS module

|

TIS

2000: 4.0

Service VME

|

2002-2003

|

Envoy,

Envoy XL, Bravada, with G67m -- Low in Rear

|

Replace

check valve service kit

|

Replace

air suspension compressor

|

02-03-99-001

|

2002-2003

|

TrailBlazer,

TrailBlazer EXT Envoy, Envoy XL, Bravada -- OS RVM Erratic Return

|

Replace

mirror actuator & reprogram module

|

Replace

OSRV-mirror

|

02-08-64-008

02-08-64-021

|

1999-2003

|

C/K

Fullsize Utilities - Sunroof

|

Install

clip or mechanism kits

|

Replace

sunroof

|

02-08-67-009

|

1999-2003

|

C/K

Fullsize Pickups & Utilities -- Noise on Steering

|

Lube

I-Shaft

|

Replace

I-Shaft

|

00-02-35-003B

|

1999-2003

|

TrailBlazer,

Envoy, Bravada,

without G67 -- Moan Boom

|

Replace

rear coil springs

|

Repurchase

vehicle for rear axle vibration/boom noise

|

02-03-09-002A

|

2002-2003

|

TrailBlazer,

TrailBlazer EXT, Envoy, Envoy XL, Bravada -- Tail Light

|

Replace

tail lamp circuit board

|

Replace

rear tail lamp assembly, for brake light

|

Service

VME to use service part, listed in GMSPO catalog

|

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for August |

| |

|

| Know-How

Broadcasts for August |

|

10270.08D

Emerging Issues

|

August

14, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

|

10270.20D – 2004

Buick New Model Features

|

August

23, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

|

|

Car

Issues – Fix It Right The First Time

Car

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time