Table

of Contents -- June 2003 |

| |

|

|

|

| |

|

|

|

| |

|

|

|

| —— |

|

|

—— |

|

|

|

Note:

Clicking on any picture or illustration will open a larger version

of that art.

|

|

Injector

Terminal Fretting -- The Invisible Menace |

The Mystery

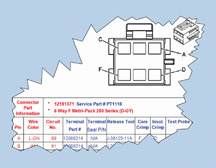

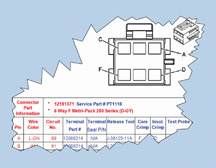

Over 1000 Multec 2 injectors are returned through the warranty system

every year (fig. 1). Every returned injector is put through a series

of functional tests to identify electrical faults, injector leaks

and incorrect injector flows.

Once a cause for failure is identified, the information is used to

take corrective action: improved manufacturing procedures, design or

materials enhancements, or improved service procedures.

About 60% of returned injectors pass all of the functional tests. Some

operate with no apparent failures when put on test vehicles in an effort

to reproduce the complaint. These injectors are called No Trouble Found

(NTF) injectors.

Over half of the vehicles which had NTF injectors replaced never returned

to the dealer for a similar complaint. The mystery is: how did the

replacement of what appears to be a good injector solve a driveability

problem?

The Investigation

An in-depth review of repair orders and warranty claims found that

DTCs P0300 and P0200 were the common link with injector replacements.

These clues triggered an investigation into the integrity of the Multec

2 electrical connector. Technicians who carefully document DTCs and

diagnostic test results provide valuable information for these types

of investigations.

The Invisible Menace Found

Because the female injector connector is rarely replaced, the study

focused on the injectors’ electrical terminal pins. To gain access

to the terminal pins, the surrounding plastic had to be cut away. The

terminal pins were examined with a high power microscope to see if

there were any indications of connection problems.

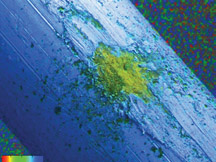

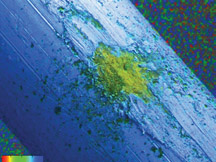

A thin layer of oxide was found to be forming on the injector male

pin terminal at the point where it contacts the female harness connection.

Invisible to the naked eye, “fretting corrosion” was found

on a majority of the NTF injector terminals (fig.

2).

“Fretting” describes a tiny rubbing motion that occurs between two

surfaces (usually on the order of 10-100 microns). “Fretting corrosion” refers

to a build up of insulating, oxidized debris that forms on electrical connections

due to a fretting action at the contact points. Injector vibration, engine vibration,

and electrical harness movement are contributors to the fretting motion.

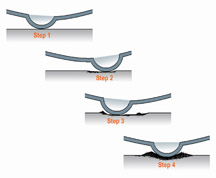

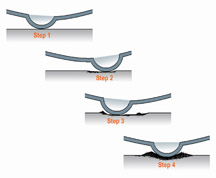

Refer to the accompanying illustrations (fig. 3).

Step 1 shows the tin oxide layer with clean tin-on-tin contact, resulting in

a stable connection.

Steps 2 and 3 show further progression of fretting corrosion (formation of oxide

layer).

Step 4 shows the contact point after numerous fretting cycles, resulting in an

unstable electrical connection.

The amount of oxide build-up determines how drastic the effect will be on the

injector circuit. Worst case is a total loss of continuity in the connection

resulting in P0200 (Injector Circuit Fault) and P0300 (Misfire) codes being set.

If the oxides create a high resistance circuit, insufficient current will be

available to properly open the injector, resulting in unstable fuel delivery

and ultimately a P0300 DTC. High resistance in the circuit will not necessarily

set a DTC P0200.

Keep in mind that a connection with fretting corrosion is unstable. Because movement

causes fretting, any vibration may create a condition where the connection varies

from an open circuit, to a high resistance connection, to a good connection.

What To Do?

Disconnecting and reconnecting the injector connector will temporarily scrape

the oxides off, creating a good connection. This explains why replacing a suspected

faulty injector with a new injector appears to repair the condition. But, if

the conditions still exist for fretting to occur, it will eventually come back.

Using lubricant part number 12377900 (in Canada, 10953529) to coat the terminals

is the best preventative measure to take. This provides a lubricant for the terminals

as well as providing an oxygen barrier to guard against oxide formation.

To apply the lubricant, gather a small amount (about the size of a BB) on the

end of your finger (fig. 4). Press it into the end of the disconnected female

connector, making sure to cover both cavities (fig. 5). Reconnecting the harness

connection onto the injector will wipe the lubricant onto the male terminal pins.

-

Thanks to Randy Pearl and Dave Sant |

figure

1 |

|

figure

2 |

|

figure

3 |

| |

figure

4 |

figure

5 |

|

|

|

| Breaking News

About Service Bulletins |

In

the past, your dealership has received an allotment of printed service

bulletins on a regular basis, in the Dealer World Delivery box. In

addition, many dealerships also subscribe to receive additional copies

to distribute to technicians. At the same time, service bulletins have

also been viewable on the Service Information (SI) website.

TIP: If you still do not have ID and password to access SI, contact your

Area Service Manager or call the Techline Customer Support Center at

800.828.6860.

By the end of June, 2003, there will be a change in the way printed bulletins

are distributed. Printed bulletins will no longer be sent automatically

to your dealership. You can continue receiving printed bulletins, at

the price of 10c per copy. Your service manager has received a Dealer

World subscription form on which to place your order. The subscription

will continue on a regular basis until you choose to change it.

Whether your dealership

chooses to subscribe to receive printed bulletins or not, here’s

how to find bulletins on SI.

- Go to the website at http://service.gm.com.

- Click on Service Information.

- Put in your ID and password.

- Click on Number Search if you know the number of the bulletin.

- Click on Latest News if you want to read a list of the most recent

bulletins issued (past 8 weeks). These are organized by Bulletins,

Campaigns and Preliminary Information. Within categories, the information

is organized

by typical SI topics, such as Engine, Steering, HVAC and so on.

- Click on the Y+P+K button if you want to see bulletins that pertain

to a specific year, platform and keyword.

Some printed material will continue to come, whether you subscribe

to printed bulletins or not.

1. Warranty Administration bulletins and Advanced Service Information

bulletins will continue to be distributed in printed form for the

foreseeable future.

2. Your dealership will receive a printed summary of bulletins

issued, every two weeks. This parallels the information on the

Latest News

page of the website.

3. And finally, your dealership will receive a blue-bannered

printed bulletin called the Field Product Reminder, every two

weeks. This

will contain a list of “Fix It Right The First Time” items

for cars and trucks. This list is also being repeated on the

rear cover

of TechLink each month.

TIP: You may want to remind owners that they can subscribe to

receive service bulletins as well. Every owner’s manual

contains the necessary ordering information.l.

- Thanks to Alan Srodawa and Frank Flees

|

| |

|

|

Additional

Training Sites Coming

|

In

the coming months, you will be able to get more hands-on training than

ever before. In an effort to help service technicians “fix it

right the first time” and to achieve their training requirements,

GM Service Technical College (STC) is opening an additional four satellite

locations (fig. 6) to supplement the current 23 training locations

nationwide.

Each satellite training site selection was based on population and dealer

density, and input from GM field personnel. New satellite locations include:

- North Central -- Stark State College of Technology, Canton, OH

- North East -- Mass Bay Community College, Ashland, MA (Boston)

- South Central -- St. Philip’s College, San Antonio, TX

- South East -- J. Sargeant Reynolds Community College, Richmond, VA

GM STC will be providing training dates and schedules in the coming weeks,

as information becomes available.

For questions, visit the GM Training Website (GM TW) at www.gmcommontraining.com

and select “Contact Us.”

- Thanks to Lisa Kennedy |

figure

6

|

|

|

| return

to Table of Contents |

|

| A/C

Sealant Detector |

TIP: Before connecting a suspect system to your equipment, first test the

refrigerant for the presence of stop-leak.

The GE-47548 Sealant Detector consists of a high-side coupler with a

built-in flow restriction cartridge, a hose, and a flowmeter (fig.

7).

There are two high-side couplers, one for R12 and one for R134a. Each

one has provision for the installation of a disposable flow restriction

cartridge. Before use, apply water to the cartridge, using the dispenser

provided.

The tool is connected to the A/C system’s high side. A small amount

of refrigerant is allowed to flow through the tool, causing the ball

in the flowmeter to rise. After two minutes, if the ball remains high,

there is no sealant in the A/C system. If the ball drops within this

time, it indicates that sealant in the refrigerant has cured in the passageway

in the cartridge, causing flow to drop or stop.

A plugged cartrige must be replaced before the tool is used again.

The GE-47548 Sealant Detector is available through Kent-Moore.

-

Thanks to Dave Roland, Derek Trimble and Gary Halpern |

figure 7

|

| return

to Table of Contents |

|

| A/C

Refrigerant System Sealer and Leak Detection Guidelines |

Refer

to bulletin 03-01-38-001 for details. Here are the highlights.

Various A/C system sealers, stop-leak, and seal conditioners are available

to consumers and to the A/C repair industry. Because they are easily

obtained, there’s a likelihood that you will encounter a vehicle

with an A/C system contaminated by one of these products.

TIP: A GE-47548 Sealant Detector is now available from Kent-Moore. It

is discussed in an accompanying article.

Products Not Endorsed

GM Service Operations does not endorse or approve use of such products

in any GM vehicle. These products may damage A/C systems and service

equipment.

IMPORTANT: A/C systems contaminated with sealers, stop-leak, or seal

conditioners are not covered by GM New Vehicle Warranty or Replacement

Part Warranty.

A typical stop-leak sealant is carried through the A/C system in the

refrigerant oil. If a leak occurs, some of the sealant passes out of

the refrigerant system into the atmosphere. It cures in the presence

of moisture, which is supposed to “seal” the leak. If there

is moisture in the vehicle’s A/C system, or in the plumbing of

your A/C service equipment, the stop-leak can cure there, causing circulation

problems.

In addition to stop-leak products, there is another family of products

which is not recommended or endorsed. These are the seal conditioners,

which cause system o-rings and other rubber components to swell to stop

leaks.

These seal swellers cannot be detected using the GE-47548 Sealant Detector

or any other known tool at this time. Seal swellers can cause similar

problems once added to A/C systems. The sealer swellers also pose a potential

threat to recover/scavenger units, because they contain rubber o-rings

and other parts.

The Approved Approach

Various federal, state/provincial and local regulations prohibit recharging

an A/C system with known leaks. In support of these regulations, GM Service

Operations recommends using recommended leak detection devices to locate

leaks, and then using recommended procedures to repair

or replace leaking

components.

Flushing

Using GM-approved (refrigerant-based) system flushing on a contaminated

system can introduce these contaminants into the A/C service equipment,

which may cause equipment damage.

It may be necessary to replace all components affected by the additives

to correct a contaminated system.

-

Thanks to Dave Roland |

| return

to Table of Contents |

|

| Door

Hinge Repair |

Owners

of 1999-2003 Chevrolet Silverado and GMC Sierra may comment that

a door sags or is hard to open or close.

A door hinge pin and bushing kit is available from:

Ken-Co Industries LTD

Burlington, Ontario, Canada

phone 1.800.263.4283

fax 1.905.335.1829

email info@ken-co.com

attention Ken Spragg

website www.ken-co.com

Each door requires 2 kits. The minimum order is 6 kits.

A kit includes 2 brass bushings (fig. 8), 2 zinc coated hinge pins (fig.

9), 2 nyloc locknuts, 1 washer, and instructions.

Using the kit (fig. 10) permits repairing and realigning the door without

having to cut off the hinge, and no painting is required.

-

Thanks to Steve Love |

figure

8

|

figure

9 |

figure

10 |

| return

to Table of Contents |

|

| Battery

Green Eye Eliminated

|

In

the next few months, you will begin seeing new vehicles equipped

with Delphi batteries that no longer have the “green eye” (built-in

hydrometer).

This is a rolling change which will eventually include all GM cars

and trucks. Service replacement batteries will be “eyeless” as

well, as current stock is depleted and replaced.

TIP: The green eye was never installed in the AGM battery, used in Corvettes

and the 2004 Pontiac Grand Prix, because these batteries do not contain

free liquid to operate the hydrometer.

State of Charge

You are of course familiar with the intended use for the green eye

-- indicating the battery’s state of charge. This information

is useful in determining whether a battery is charged, needs to be

charged, or

lacks sufficient electrolyte to permit charging.

The green eye information is largely redundant now that the Midtronics

J-42000-U conductance tester is in widespread use. This tester can analyze

a battery with a low state of charge, so long as it has sufficient voltage

to operate the tester.

There is another diagnostic test you can perform to determine the battery’s

state of charge, the Open Circuit Voltage (OCV) test.

Open Circuit Voltage Test

OCV may be used to estimate the state of charge. This method is generally

accurate +/- 10%. Temperature also affects OCV, so that must be taken

into account.

The voltmeter you use must be properly calibrated, capable of reading

to the nearest 0.01 volt, and accurate within +/- 0.005 volt.

The battery must be free of all current flow (that’s why it’s

called open circuit) -- it’s best to disconnect it entirely.

A battery becomes unstable for a period of time after it is charged

or discharged. So, it’s important to know what has happened to

battery before performing the OCV test.

If the battery has not been charged or discharged within 12 hours --

the OCV is fairly stable and the test can be performed using the OCV

vs % Charge table.

OCV |

%

Charge at 0°C

(32°F) |

%

Charge at 25°C

(75°F) |

12.75 |

100% |

100% |

12.0 |

100 |

90 |

12.60 |

90 |

75 |

12.45 |

75 |

65 |

12.20 |

65 |

45 |

12.00 |

40 |

20 |

If

the battery has been charged, discharged or used in a vehicle within

12 hours -- the OCV may not be stable enough for a reliable reading.

If the battery has been charged, you must first remove any surface

charge using a carbon pile. Discharge the battery at 300 amperes

for 15 seconds. Disconnect the pile, allow 15 seconds for recovery,

then read the OCV.

If the battery has only been discharged, just wait at least 15 seconds

for the voltage to stabilize after disconnecting the load before testing.

A battery with a 65% or greater state of charge is generally considered

charged enough to be returned to normal service.

TIP: If the battery will be used in slow traffic, short trips, or very

hot or cold weather, it should be at least 90% full charge before returning

to service.

If Charging is Required

The new “eyeless” batteries now include the battery’s

amp-hour (AH) rating on the label. This information can be useful in

setting up your battery charger. The AH rating was not previously available

for GM OE batteries.

TIP: Most battery replacement guides in the US will still be based

on the OE battery’s CCA and RC (Reserve Capacity) ratings. Don’t

confuse the RC and AH ratings when selecting a replacement battery

model – they are different tests.

- Thanks tozz |

| |

| |

|

return

to Table of Contents |

|

| Terminal

Repair Kit Update |

This

information will help you understand the J-38125-C Terminal Repair

Kit and use it more effectively (fig. 11).

Some definitions:

An electrical terminal is the formed metal attached to the end

of a wire to provide electrical connection with another wire or

with a component.

Groups of terminals are organized into molded plastic blocks called

connectors.

Groups of wires, with their terminals and connectors, are gathered

into wiring harnesses.

Differences Between Production and Service Terminals

Service terminals are not necessarily the same as production terminals.

A single service terminal may replace several production terminal numbers.

Service terminals are chosen so the crimp wings fit the crimp tools

in the J-38125-C. You should use the crimp matrix in the Terminal Repair

Kit Instruction Book for best results.

Service terminals may have more tin or gold content then the production

terminal.

Service terminals may have a higher contact force than the production

terminal. In the assembly plant, where actions are repetitive, connector

assembly effort is an issue that does not come up in service.

Where Do Service Terminals Come From?

Service terminals are NOT available from GMSPO. A parts bulletin IB03-044

has been issued to this effect.

All service terminals should be ordered from SPX (Kent-Moore) at 1.800.345.2233.

All components and tools of the J-38125-C Terminal Repair Kit should

be ordered from SPX (Kent-Moore) at 1.800.345.2233.

It will be important to keep the complete J-38125-C Terminal Repair

Kit in proper order and stocked with terminals and tools, as more wiring

suppliers make their appearance in GM vehicles.

What’s the Distinction Between Wiring Harness Suppliers

and Connection System Suppliers?

Wiring harness suppliers build harnesses according to engineering specifications.

This means that a wiring harness supplier will use their own connection

system, plus those from other suppliers, so most harnesses contain

an assortment of connection systems.

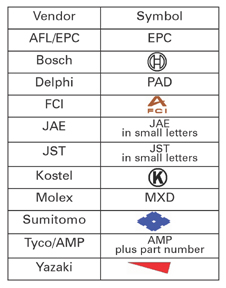

This is a list of connection system suppliers used by GM. Some of these

companies are also wiring harness suppliers.

- AFL/EPC

- Bosch

- Cinch

- Delphi

- FCI

- JAE

- JST

- Koste

- Molex

- Sumitomo

- Tyco/AMP

- Yazaki

There is an effort in engineering to limit the proliferation of connection

system suppliers.

How Are All These Terminals Organized in the J-38125-C Terminal Repair

Kit?

There are five Wiring Suppliers for GM Power and Signal Distribution

(PASD) systems:

- AFL

- Delphi

- Lear

- Sumitomo

- Yazaki

These five supply the wiring used in North American-engineered platforms.

TIP: Some platforms are not engineered in North America. These include

the International Joint Venture Vehicle Platforms (IJVP): Vibe, Tracker,

Isuzu-supplied MD trucks, and vehicles with pre-wired Honda engines.

Service terminals for these are not included in the J-38125-C Terminal

Repair Kit.

The J-38125-C Terminal Repair Kit was originally a Delphi terminal

repair kit only. Now we have Delphi trays, Lear trays, Sumitomo trays

and Yazaki

trays, with AFL to be added.

Trays are named for the five wiring harness manufacturers. If a harness

manufacturer also makes terminals, their terminals are in their trays.

Terminals from other terminal manufacturers may also be included

in the harness makers’ trays.

AFL/EPC is the wiring supplier for the ‘04 Corvette, and two other

future programs. An AFL tray will be added to the Terminal Repair Kit

in the near future and any AFL terminals used for the first time in the ‘04

Corvette will be in that tray.

Delphi is the wiring supplier for every truck platform except the M/L

Van. Delphi is also the wiring supplier for most car platforms. Delphi

has the most history with GM and has the most trays in the Terminal

Repair Kit. Delphi trays may also contain service terminals from:

- Delphi

- Bosch

- FCI

- JAE

- JST

- Molex

Lear is the wiring supplier for the M/L Van, and the Saturn Vue and

Ion. Lear makes no terminals or connection systems. Instead, they use

terminals

from other suppliers. Lear trays contain service terminals from:

- Bosch

- Molex

- Tyco/AMP

TIP: Tyco/AMP terminals used by all wiring harness suppliers, so a

Tyco/AMP terminal may be in any tray.

Sumitomo is the wiring supplier for a future truck program. Sumitomo

makes terminals and connection systems. The Sumitomo tray will be filled

in the near future.

Yazaki is the wiring supplier for the Cadillac CTS, the ‘04

Cadillac SRX and a future Cadillac program. Yazaki also makes terminals

and connection

systems. There are 5 trays of Yazaki service terminals. The Cadillac

CTS was first to use these terminals. Yazaki trays contain service

terminals from:

- Yazaki

- Kostel

- Molex

- Tyco/AMP

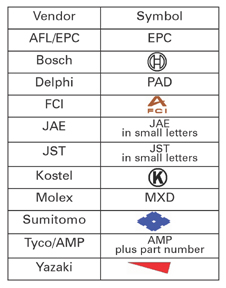

How Do You Know Whose Terminal You’re Looking At?

You can get your clue from the connector from which it was removed.

Look on the connector for these identifying symbols. Many are small

or difficult

to find.

Connector Symbols

All

suppliers use their own connection systems when they can, but most

will have a high Delphi connector content, because GM still uses

a high number of Delphi components.

What’s Coming?

A Federal Agency called USCAR sets test and footprint standards for

all US vehicle manufacturers. The effort to comply with USCAR will

be seen in all GM vehicles. This will ultimately result in connection

systems that will have the same look and feel, regardless of the supplier

(fig. 12). There is even an effort to have a GM-common terminal in

several popular sizes, which will greatly reduce the increasing number

of service terminals we now see in the J-38125-C Terminal Repair Kit.

Information included in SI is also being revised. A pilot for a new

connector end view is planed for the ‘04 Cadillac XLR service

information (fig. 13). This connector end view will give you the service

terminal number that is in the J-38125-C Terminal Repair Kit.

TIP: Because service terminals are not stocked in GMSPO, service terminals

have supplier part numbers. The new connector end view will for the

first time give you the real connector or pigtail part number, which

is stocked in GMSPO. This connector end view may take some time to

make its appearance in all the service information but every effort

is being made to do so.

A Word About Pigtails

A pigtail consists of a connector with terminals and short lengths

of wire already installed. They are available for numerous electrical

devices (up to 8 cavities), and are intended to be spliced in place

of a damaged connector.

Pigtails are sold through the AC Delco side of GMSPO. A GM Dealer parts

department can find a pigtail by application (2003 Cavalier generator,

for instance) but not by description (4-way female Metri-Pack 150 series).

AC Delco Catalog 16A-200 has a complete list and pictures of pigtails.

Call 1.800.ACDELCO (1.800.461.8606 in Canada) to find your local AC

Delco Parts distributor, who can assist you in obtaining a catalog.

There is also an AC Delco web site www.acdelco.com with online catalog

that will help, not only for pigtails but also for other items.

-

Thanks to John Roberts |

figure

11 |

| |

figure

12 |

figure

13

|

| return

to Table of Contents |

|

| Oil

Life System Reset Procedures -- Trucks |

Many

GM cars and trucks are equipped with an oil life system which determines

when an oil change is required. After the oil has been changed, it’s

necessary to reset the system.

Procedures for resetting 2001 through 2004 trucks are published here.

Passenger cars were published last month.

The information for this article is the same as you will find in the

applicable owner or service manual.

To find this information in SI:

- Select the vehicle

- Select category General Information

- Select category Maintenance and Lubrication

- Select category Maintenance and then GM Oil Life System-Resetting.

You may be able to use the Search function using the words Oil Life System

Resetting.

2001 - 04 Aztek

2002 - 04 Rendezvous

If the vehicle does not have the optional Driver Information Center (DIC)

do the following:

1. With the ignition key in ON but the engine off, fully push and release

the accelerator pedal slowly three times within five seconds.

2. Turn the key to OFF.

3. If the CHANGE ENGINE OIL message comes back on, the engine oil life

monitor has not reset. Repeat the procedure.

If the vehicle has the optional DIC, do the following:

1. Turn the ignition to ON with the engine off.

2. Press the MODE button until the DIC reads OIL LIFE LEFT/HOLD SET TO

RESET.

3. Press and hold the SET button until 100% is displayed.

You will hear three chimes and the CHANGE ENGINE OIL message will go

off. If the CHANGE ENGINE OIL message comes back on, the monitor has

not reset. Repeat the procedure.

2001 - 04 Montana

2001 - 04 Silhouette

2001 - 04 Venture

1. With the ignition key in RUN but the engine off, repeatedly push the

trip/reset button until OIL is displayed on the Driver Information Center.

2. Once OIL is displayed, push and hold the trip/reset button for five

seconds. The number will disappear and be replaced by 100 (indicating

100% oil life remaining).

3. Turn the key to OFF.

4. If the change engine oil message comes back on, the engine oil life

monitor has not reset. Repeat the procedure.

2002 - 04 Bravada

2002 - 04 TrailBlazer

2002 - 04 Envoy

2004 Ranier w/o DIC

1. Turn the ignition key to RUN with the engine off.

2. Fully press and release the accelerator pedal three times within five

seconds.

3. If the CHANGE ENG OIL light flashes for five seconds, the system is

reset. If the light does not flash, repeat the procedure.

2004 Ranier with DIC

1. Press the fuel information button until ENGINE OIL LIFE appears in

the display.

2. To reset the monitor, press and hold the select button while ENGINE

OIL LIFE is displayed.

2004 Canyon

2004 Colorado

1. Display ENGINE OIL LIFE on the DIC.

2. Press and hold the select button. The oil life will change to 100%.

3. Turn the key to OFF.

If the CHANGE/OIL message comes back on when you start the vehicle, the

engine oil life system has not reset. Repeat the procedure.

2004 SSR with DIC

1. Press the fuel information button until ENGINE OIL LIFE appears in

the display.

2. To reset the Oil Life System, press and hold the select button while

ENGINE OIL LIFE is displayed.

2001 - 04 Sierra

2002 - 04 Sierra Denali

2001 - 04 Silverado

2001 - 04 Yukon and Yukon XL

2001 - 04 Tahoe and Suburban

2001 - 04 Escalade

2002 - 04 Escalade EXT

2002 - 04 Avalanche

2001 - 04 Yukon Denali

2003 - 04 Hummer H2

2003 - 04 Express

2003 - 04 Savana

1. Turn the ignition to RUN but with the engine off.

2. Fully push and release the accelerator pedal slowly three times within

five seconds.

3. If the Change Oil Soon light flashes, the system is resetting.

4. Turn the key to OFF.

5. Start the vehicle.

6. The oil life will change to 100%.

7. If the Change Oil Soon light comes back on, the system has not reset.

Repeat the procedure.

2001 - 04 B7 Chassis Medium Duty

1. Turn the ignition to START but with the engine off.

2. Fully press and release the accelerator pedal three times within 10

seconds.

3. If the CHANGE OIL light flashes for five seconds, the system is reset.

4. If the light does not display for five seconds, you will need to reset

the system again.

2003 - 04 560 C-Series

1. Turn the ignition to RUN but with the engine off.

2. Fully press and release the accelerator pedal three times within 10

seconds.

3. If the CHANGE OIL light flashes for five seconds, the system is reset.

4. If the light does not display for five seconds, you will need to reset

the system again.

- Thanks to Jerry Garfield |

|

|

| return

to Table of Contents |

|

| HVAC

Afterblow Enable Procedure |

TIP: This is season-related information for many GM vehicles.

Operation of the blower motor after the engine has been turned off dries

the evaporator core, which reduces the amount of microbial growth, a

source of undesirable odors.

1998-2003 Cadillac Seville and 2000 Cadillac Deville

TIP: The afterblow mode can be enabled using the scan tool.

1. Connect the Scan Tool.

2. With the engine OFF, turn the ignition ON.

3. Select Instrument Panel Module.

4. Select Special Functions.

5. Select Miscellaneous Test.

6. Select IPM recalibration.

7. Select YES to enable afterblow.

2001-03 Cadillac Deville

TIP: The afterblow mode can be enabled using the scan tool.

1. Connect the Scan Tool.

2. With the engine OFF, turn the ignition ON.

3. Select Instrument Panel Module.

4. Select Special Functions.

5. Select Set Options.

6. Select Afterblow.

7. Select Yes to enable the afterblow.

This information can be found in SI documents 667536 and 784027.

Additional Vehicle Information

Information on enabling the afterblow mode on the following vehicles

will also be available in SI.

2003 - 2004 Cadillac CTS

2004 Cadillac SRX

2004 Chevrolet Impala

2004 Chevrolet Monte Carlo

2000 - 2004 Buick LeSabre

2000 - 2004 Buick Park Avenue

2000 - 2004 Pontiac Bonneville

2004 Pontiac Grand Prix

2001 - 2003 Oldsmobile Aurora

Some other vehicles have relay kits available through GMSPO as a dealer

installed feature.

-

Thanks to GM Technical Assistance |

| |

|

return

to Table of Contents |

|

| Squeak

Going Over Bumps |

Owners

of some 2003 S-10 and Sonoma Crew Cab models may comment that a high

pitch squeak can be heard outside and underneath the rear of vehicle

when driving over bumps. The park brake cable may contact the mounting

bracket. To correct the condition, secure the park brake cable away

from the mounting bracket.

-

Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

Car

Issues – Fix It Right The First Time Car

Issues – Fix It Right The First Time |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

1998-2004 |

J,

N, W, H cars and Trailblazer, Envoy, Blazer, Jimmy, Bravada – Sunroof

concerns |

Refer

to diagnosis procedures and replace only discrepant parts |

Replace

entire sunroof module |

Bulletin

being published – refer to parts

catalogue information |

2003 |

CTS

-- Service Stability System. DTC C1286 |

Reprogram

EBCM |

Replace

steering wheel position sensor |

02-05-25-004 |

2000-2003 |

Cavalier,

Sunfire, Grand Am, Alero, Malibu – Fuel gage accuracy

and pump concerns |

Replace

sensor card for fuel gauge accuracy issue |

Replace

the fuel sender / pump assembly |

01-06-04-008D |

1999-2003 |

Grand

Am, Alero – Door glass clip breakage |

Replace

sash clip only |

Replace

entire door glass assembly for broken clips |

01-08-64-018 |

1997-2003 |

Grand

Am, Alero, Malibu – Brake pulsation |

Turn

rotor and use brake align procedure |

Replace

rotors for pulsation |

00-05-23-002

01-05-23-001

Know How 15040.01B |

1997-2003 |

Venture,

Montana, Silhouette – Windshield water leaks |

Use

correct diagnosis procedures described in service bulletin |

Assume

that leak came from the windshield sealing |

01-08-57-006 |

1997-2003 |

Century,

Regal – HVAC “Auto” light function |

Normal

in full heat or cold setting |

Replace

HVAC control head for "Auto" light |

99-01-39-007B |

2001-2002 |

Corvette

- Fuel gauge goes to empty intermittently |

Install

revised software |

Replace

fuel senders or I/P cluster |

2002

MY 02-06-04-010, 2001 MY Software released, bulletin not updated |

2003 |

All

cars with 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM Solenoid |

Replace

transmission or valve body assembly |

02-07-30-039B |

2003 |

DeVille

with 4T80E Transmission - Code P0503 or Speedo Inop |

Reposition

coolant hose clamp and repair chafed wire |

Replace

vehicle speed sensors |

03-06-04-013 |

|

| return

to Table of Contents |

|

|

Truck

Issues – Fix It Right The First Time Truck

Issues – Fix It Right The First Time

|

Model

Year(s)

|

Vehicle

Line(s) --

Condition

|

Do

This

|

Don’t

Do This

|

Reference

Information / Bulletin

|

2003

|

C/K

Fullsize Pickups & Utilities -- Mirror Loose

|

Cycle

mirror

|

Replace

DL3 power folding mirror

|

03-08-64-010 &

Parts Restriction

|

1999-2002

|

C/K

Fullsize Pickups & Utilities -- Throttle Body

|

Clean

throttle body adjust blade and insert plugs

|

Replace

throttle body for idle instability or increased accelerator pedal

effort

|

02-06-04-054B & Parts

Restriction

|

2003

|

C/K

HD Silverado, Sierra, G Savana, Express >8600GVW -- ABS Lamp

On

|

Re-flash

for code C0550

|

Replace

ABS module

|

TIS

2000: 3.0 & 4.0

Service VME

|

2002-2003

|

Envoy,

Envoy XL, Bravada, with G67m -- Low in Rear

|

Replace

sash clip only

|

Replace

air suspension compressor

|

02-03-99-001

|

2002-2003

|

TrailBlazer,

TrailBlazer EXT Envoy, Envoy XL, Bravada -- Outside Rear View

Mirror Erratic Return

|

Replace

mirror actuator & reprogram module

|

Replace

OSRVM

|

02-08-64-008

02-08-64-021

|

1999-2003

|

C/K

Fullsize Utilities -- Sunroof

|

Install

clip or mechanism kits

|

Replace

sunroof

|

02-08-67-009

|

1999-2003

|

C/K

Fullsize Pickups & Utilities -- Noise on Steering

|

Lube

I-Shaft

|

Replace

I-Shaft

|

00-02-35-003B

|

1999-2003

|

TrailBlazer,

Envoy, Bravada,

without G67 -- Moan Boom

|

Replace

rear coil springs

|

Rear

axle vibration boom noise that can result in vehicle repurchase

|

02-03-09-002A

|

2002-2003

|

TrailBlazer,

TrailBlazer EXT -- Loose or Wavy Fascia

|

Repair

fascia

|

Replace

front fascia

|

02-08-62-001

02-08-62-004

|

2002-2003

|

TrailBlazer,

TrailBlazer EXT, Envoy, Envoy XL, Bravada -- Tail Light

|

Replace

tail lamp circuit board

|

Replace

rear tail lamp assembly, for brake light

|

Service

VME to use service part, listed in GMSPO catalog

|

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for July |

| |

|

| Know-How

Broadcasts for July |

|

Emerging

Issues

|

July

17, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

|

10270.19D – 2004

Chevy/GMC Truck New Model Features

|

July

31, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

|

|

Car

Issues – Fix It Right The First Time

Car

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time