|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Remote

Vehicle Start Accessory Kit |

Remote

Vehicle Start (RVS) has been a popular factory-installed option since

being introduced on the 2004 Chevrolet Malibu (RPO AP3). Because RVS

is integrated with the vehicle’s anti-theft and remote keyless

entry systems, it is very robust, unlike aftermarket systems that cannot

offer the same level of security and integration. It provides owners

with the comfort of being able to enter a pre-warmed or pre-cooled vehicle.

In response to popular demand, dealer-installed RVS accessory kits are

now available for selected vehicles (fig. 1).

Kits can be obtained from GMSPO or from your local Accessory Distributor/Installer

(ADI).

IMPORTANT: You must specify which vehicle the kit

will be installed on.

Once properly installed, the kit is integrated into the vehicle’s

systems, just like the factory-installed equipment. And the kit is also

covered by the GM warranty. AP8 and RVS kits will be introduced throughout

2005, following this tentative schedule.

Second Quarter

Buick LaCrosse and Allure (Canada)

Chevrolet Malibu

Pontiac G6

Pontiac Grand Prix

Third Quarter

Buick Lucerne

Chevrolet Impala/Monte Carlo

Fourth Quarter

Buick Terraza

Chevrolet Uplander

Pontiac Montana SV6

Saturn Relay

Chevrolet Avalanche, Suburban, Tahoe*

GMC Yukon, Yukon XL, Yukon Denali*

*2007 MY

IMPORTANT: To qualify for installation of the RVS

accessory kit, the vehicle must be equipped with an automatic transmission

and RPO AP8 (Lock Control, Entry - Remote Entry, Extended Range). While

AP8 may be standard equipment on some vehicles, it must be ordered for

others. The accessory kit cannot be installed on vehicles that do not

have these two items.

Contents of RPO AP8 -- The vehicle with AP8 is remote-start

ready, for quick and easy installation of the accessory kit. All necessary

hardware is already there, including a hood-ajar switch and associated

wiring. The remote control door lock receiver and two key fob transmitters

have extended range. Extended range is typically 2-4 times greater than

standard remote keyless entry. An antenna is included in the front or

rear glass on some vehicles.

TIP: These transmitters

are for RKE only, and cannot be used for remote start.

Contents of Remote Start Accessory Kit -- The accessory

kit includes two additional key fob transmitters with remote

start capability (with extended range, typically 2-4 times greater than

standard remote keyless entry), software download instructions, and

a SPID label.

INSTALLATION PROCEDURE

Installation is a quick and easy process. When a customer purchases

the Remote Start Accessory Kit, the vehicle software must be loaded.

This requires obtaining a new VCI number (see below), and downloading

the necessary software to the vehicle.

TIP: Pass Thru

programming must be used for some vehicles. See the appropriate kit

instruction sheet for details.

Apply the SPID (Service Parts ID) label from the kit. It must be placed

on a smooth, clean surface near the existing SPID label, for future

service parts identification. Do not cover up any existing labels.

Watch for additional information in an upcoming service bulletin and

accessory bulletin.

REQUESTING A VCI NUMBER

The February 2004 issue of TechLink contained an in-depth explanation

of the Vehicle Configuration Index (VCI) number. Briefly, a VCI number

is assigned to a valid calibration or group of calibrations for each

module for a specific vehicle that is programmed using the Service Programming

System (SPS). A VCI number becomes a permanent part of one specific

vehicle’s engineering data. For this reason, a specific VCI

number is valid only for the vehicle and control module(s) it is issued

for and cannot be used to program another vehicle.

In the case of the Remote Vehicle Start kit, each kit is identified

by its unique Authorization Code, and each vehicle is identified by

its unique VIN.

IMPORTANT: Once the VCI number is issued, that

specific kit can be installed only on that specific vehicle. A specific

VCI number cannot be used for any other kit or any other VIN.

To request a VCI number, call the Techline Customer Support Center (TCSC)

at 1.888.337.1010 (1.800.503.3222 for French).

- You must identify yourself as a dealer or an ADI.

- You must provide the VIN of the vehicle involved.

- You must provide the Authorization Code affixed to the instruction

sheet that is supplied with the kit.

TIP: Don’t

request the VCI number until you’re ready to install the kit.

That way, you can be sure the specific vehicle VIN and specific kit

Authorization Code are physically matched at the time the VCI number

is requested.

-

Thanks to Joyce Henk, Sharon Folts, and Mark Stesney |

figure 1 |

| |

| |

| |

| |

| return

to Table of Contents |

|

|

| GM

Service Information |

Faster Searches

GM Service and Parts Operations (SPO) is following a plan of continuous

improvement to the Service Information (SI) website. The SI website

is updated daily, so it’s your best source for the absolutely

latest service information. Here are the details of several recent enhancements

to the SI website.

Keyword Search

The SI home page has a bold red headline that says “Now with faster

searches.” The operative word here is FASTER. And that’s

no exaggeration. By expanding the web server resources, keyword search

speed has been dramatically increased. It’s now as much as 10

times faster.

Another improvement is the kinds of characters you can type when doing

a keyword search. Until now, you were limited to letters and numbers,

without punctuation. Now, you are able to use two punctuation characters,

the period and the slash. So you can search such items as A/C and 3.4L

engine. Other characters will be added in the future.

Keyword search now allows you to use five keywords instead of three.

Depending on the type of search you prefer, filtering by “any”

or “all,” the search results will be greater or fewer, respectively.

Latest News

As before, you can click the Latest News button to see the newest bulletins,

campaigns and preliminary information. Also as before, you can choose

to see the information released in the past 1, 2, 4, 6 or 8 weeks, using

the pulldown menu.

Latest News has also been infused with SPEED. The requested listing

now appears much quicker.

And, you’re sure to appreciate a new feature coming this summer.

You will soon be able to filter the display by division. Want to see

only the information that applies to Buick? Just go to the pulldown

menu at the top of the Latest News page and click Buick. Or GMC, or

Chevrolet, or whatever your choice.

Labor Time Guide

The GM Labor Time Guide is now available as a web publication in SI.

Service managers, warranty administrators, general managers and office

managers will have access through Dealer World. The publication is refreshed

the first day of every even-numbered month.

Service Information DVD

Because the SI website is now updated daily, it’s the best place

to go for the most up-to-date information. The SI CD and GM ACCESS SI

incremental updates have been phased out.

Your dealership recently received a Service Information DVD (updated

March 1, 2005). You should regard it as a backup only, for instance

if your Internet service provider experiences problems. Additional information

is available at http://service.gm.com/index_en-US/techline.html.

- Thanks to Lisa Scott |

|

|

| |

|

|

New Radio Antenna Connector |

GM

is introducing a new line of radios for the 2006 model year for use

in these vehicles:

- Impala

- Monte Carlo

- Lucerne

- VUE

- Solstice

- DTS

These radios are easily recognized by the large center-mounted ON/OFF/VOLUME

knob (fig. 2) . You may familiarize yourself

with the operating features of these radios, using the appropriate owner’s

manual available on SI.

Disconnecting Antenna Lead

Although the antenna lead visually resembles those used on other radios,

there is an important difference.

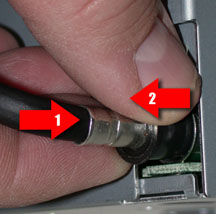

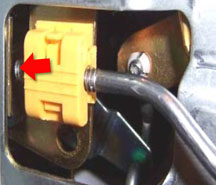

The antenna connector has internal fingers (fig.

3) that grip the center portion of the socket on the rear of

the radio chassis. The main circuit board (fig.

4) can be damaged if you attempt to simply pull the antenna lead

to disconnect it from the radio chassis.

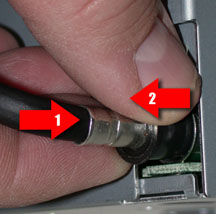

Instead, (1) slightly push the antenna lead toward the radio to relieve

tension on the internal fingers (fig. 5). Then (2) pull back on the

spring-loaded locking ring and remove the connector from the radio.

To install the antenna lead, simply plug it into the socket until it

clicks.

Testing Antenna Lead

Due to the configuration of the antenna lead connector, it is not recommended

that you probe it directly with your multimeter test probes.

Plug the EL-47749 Test Adapter onto the antenna connector (fig.

6). Then plug your multimeter test leads (without probes attached)

into the color matching sockets on the tester. You can now use your

multimeter to test the antenna for continuity and resistance, following

SI procedures.

TIP: Red is the

center conductor and black is the outer shield conductor.

-

Thanks to Nohr Tillman and Jim Hughes |

figure 2 |

figure 3 |

figure

4

|

figure 5 |

figure

6 |

return

to Table of Contents |

|

| Mode

Door Actuator |

This information applies to the 2002 Chevrolet TrailBlazer, GMC Envoy

and the Oldsmobile Bravada.

According to bulletin 05-01-38-001A (SI document 1645422), there’s

a new procedure for HVAC Mode Door Actuator replacement. Refer to the

bulletin for details.

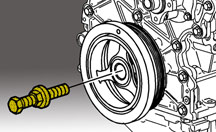

Using Puller GE-47676 permits removing the Mode Door Actuator (fig.

7) from underneath the IP carrier. It’s no longer necessary

to remove the entire IP carrier for access to the Mode Door Cam Assembly.

A Mode Valve Actuator is now available under p/n 89018539. For this

new procedure, do not use Mode Valve Cam Assembly p/n 89018525 (fig.

8).

The service procedure in SI and the labor time have been changed to

reflect use of the new tool.

-

Thanks to Doug Daugherty |

figure

7 |

figure

8 |

| return

to Table of Contents |

|

| E-85

Fuel |

With the escalating cost

of fuel, customers have inquired if they are able to use E-85 fuel in

non E-85 compatible vehicles. Only vehicles designated for use with

E-85 should use E-85 blended fuel.

The only E-85 compatible vehicles produced by General Motors are 2000

- 02 S series pickups equipped with the 2.2L L43 4-cylinder engine and

2002 - 05 full-size pickups and utilities equipped with the 5.3L L59

VIN code Z V8 engine. All other gasoline engines including all 5.3L

V8 with VIN designators other than the letter Z are not E-85 compatible.

E-85 compatibility is designated for vehicles that are certified to

run on a mixture of up to 85% ethanol and 15% gasoline. All other gasoline

engines are designed to run on fuel that contains no more than 10% ethanol.

Use of fuel containing greater than 10% ethanol in non E-85 designated

vehicles can cause driveability issues, Service Engine Soon lights,

and increased fuel system corrosion.

-

Thanks to Jay Dankovich |

| |

| return

to Table of Contents |

|

| Side

Differential Case Bearing Removal |

Camaro

and Firebird

When removing the side differential case bearings, you may discover

that J-22888-20A does not work, because some limited slip differential

cases do not have notches for the jaws of the puller. Use J-34168 to

press the bearing off the case.

-

Thanks to Lance Mossman, Applegate Chevrolet, and Jon Garfield |

| |

| return

to Table of Contents |

|

| TECHAssist

Path |

The April issue of TechLink provided information on when and how to

call Technical Assistance and Techline. Here’s a revised path

for locating training for the Technical Assistance Preparedness Information

Form on the www.gmtraining.com website.

- Menu

- Service Know-How

- Launch TECHAssists

- Technical Service Bulletin Enhancements

- Then scroll to 010089011BT1 --Technical Assistance Preparedness Information

Form.

-

Thanks to Rebecca Farrand |

| |

| |

| |

|

| STS

Tire Pressure Monitoring System Issues |

This

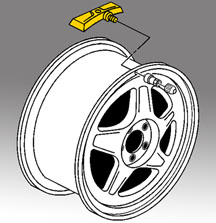

information applies to the 2005 Cadillac STS (fig.

9).

Rear Window Antenna Grid Coaxial Connection

The tire pressure sensor transmissions are received by the remote control

door lock receiver (RCDLR) through the antenna grid in the vehicle’s

rear window. The grid is connected to the RCDLR by a coax cable.

A TPM system malfunction can occur if the connection at the RCDLR is

loose, the center wire in the coax is bent, or the shielding is not

fully secured to the connector end, causing a poor connection.

Always inspect this connection thoroughly before replacing any TPM system

components.

Rear Defroster Grid Micro Arcing

The tire pressure sensors transmit on the FM band at a frequency of

315 MHz and are received by the RCDLR through the antenna grid in the

vehicle’s rear window. Extremely small cracks may develop in the

rear defroster grid that are not visible. When the defroster is turned

on, micro-arcing of electrical current that occurs at the cracks resonates

at a frequency of 315 MHz. Due to the close proximity of the defroster

grid to the antenna grid, this micro-arcing (noise) can interfere with

tire pressure sensor transmissions, causing a TPM system malfunction

to occur.

To verify this condition, use your scan tool to clear any stored TPM

DTCs, test drive the vehicle above 20 mph (32 km/h) for at least 10

minutes, to verify normal system operation. Turn on the rear defroster

and note if the TPM system malfunction correlates with rear defroster

activity. If so, replace the rear window.

Uncommon Tire Pressure Sensor Pressure Sampling Rate

Each sensor takes a tire pressure sample every 30 seconds while in stationary

mode. If the tire pressure increases or decreases by more than 1.6 psi

(11 kPa) from its last transmitted pressure, another pressure sample

will occur immediately to verify the change in pressure. If the pressure

change has indeed occurred, the sensor will transmit in re-measure mode.

This transmission occurs to keep the TPM system updated of any changes

in tire pressure and is an integral part of the pressure increase/decrease

method of the tire pressure sensor learn procedure.

The sensor on the Cadillac STS samples pressure only once every 15 minutes

while in stationary mode. However, the sensor’s “service

period” begins when the sensor’s internal roll switch opens

as vehicle speed decreases, and it lasts for 15 minutes. During this

15 minute service period, the sensors sample pressure once every 30

seconds.

TIP: This is

the only window of opportunity the customer or technician has to perform

the tire pressure sensor learn procedure, using the pressure increase/decrease

method. Otherwise, the verifying horn chirp will not occur.

Refer to the “important” information preceding the learn

procedure in SI. It is also important to note that this sensor cannot

be activated using J-41760 tire pressure sensor activating tool (magnet).

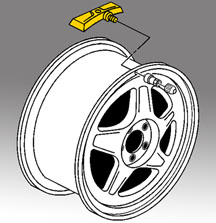

The J-46079 TPM diagnostic tool (fig. 10)

must be used to activate this sensor.

-

Thanks to John Spidle |

|

figure

9 |

figure

10

|

| return

to Table of Contents |

|

| Tire

Pressure Monitoring Issues |

Tire

Mounting and Dismounting

This information applies to the 2000--05 Cadillac Deville, Seville,

STS, 2004--05 Cadillac CTS, Escalade, SRX, XLR, 1999--2005 Chevrolet

Corvette, 2004--05 Chevrolet Tahoe, Suburban, 2004--05 GMC Yukon, Yukon

XL.

When dismounting and mounting tires, be careful when breaking the bead

loose from the wheel rim (fig. 11 and 12).

If the tire machine's bead breaking fixture is positioned too close

to the TPM sensor, or pressed down directly on top of it, it may contact

the sensor as the tire bead breaks away from the wheel rim. This can

damage the TPM sensor and require the sensor to be replaced.

Also be careful when transferring the tire bead to the other side of

the wheel rim. As the tire machine rotates and the tire bead is stretched

around the wheel rim, the bead can come in contact with the sensor.

This can also cause sensor damage, requiring replacement. Damage can

be avoided by correctly positioning the wheel and tire in relation to

the mounting/dismounting head.

Tire Dismounting Tips

Refer to SI -- Tire Mounting and Dismounting section for more information.

- Place the sensor's cap and valve on a dry, clean surface after removal.

The cap is aluminum and the valve is nickel-plated to prevent corrosion.

Do not substitute a cap made of any other material.

- When separating the tire bead from the wheel, position the bead breaking

fixture 90° from the valve stem.

- Position the mounting/dismounting head so the tire iron or pry bar

can be inserted slightly clockwise of the sensor body when prying the

tire bead up and over the mounting/dismounting head.

- Using the tire machine, rotate the tire/wheel assembly clockwise when

transferring the tire bead to the outside of the wheel rim.

Tire Mounting

- Position the mounting/dismounting head 180° from the valve stem.

- Position the bead transition area 45° counterclockwise of the

valve stem.

- Using the tire machine, rotate the tire/wheel assembly clockwise when

transferring the tire bead to the inside of the wheel rim.

- Thanks to John Spidle |

figure

11 |

figure

12 |

| return

to Table of Contents |

|

| Transmission

Control Module |

Many electronic control modules have internal circuitry that connects

the outer metal case to internal ground circuits. When +12 volts is

connected to the metal case, damage occurs inside the control module.

This principle applies to all electronic control modules in all GM vehicles.

The following information pertains specifically to the TCM on 2005 Chevrolet

Cobalt and the Saturn ION.

On these vehicles, the Transmission Control Module (TCM) is located

in a plastic bracket mounted on the front of the Underhood Fuse Block/Electrical

Center (fig. 13). The electrical center

contains a remote battery (+) jump-start terminal. The TCM location

is near the jump-start terminal. When the electrical center’s

plastic cover has been removed for diagnostic purposes, the TCM is very

close to the exposed jump-start terminal. If the control module's metal

case accidentally contacts any source of +12 volts (such as the jump-start

terminal), the control module will become nonfunctional. TCM-related

DTCs will set that previously were not stored.

NOTICE: Control

module damage may result when the metal case contacts battery voltage.

DO NOT contact the control module metal case with battery voltage when

servicing a control module, using battery booster cables or charging

the vehicle’s battery.

Field returns of the TCMs from these vehicles often display internal

damage, likely due to accidental contact with the remote positive (+)

battery jump-start terminal with the plastic cover removed. If the TCM

is for any reason not installed into its bracket, and the vehicle battery

is connected, the controller has enough wiring harness length to allow

it to touch the jump-start terminal.

One possible solution is to disconnect the wiring harness connector

from the TCM before performing any work in the area. This will prevent

a shorted out TCM in the even the controller case comes in contact with

B+.

TIP: If the ignition

is turned on with the TCM disconnected, U-code communication DTCs may

set. As always, correct the condition and clear DTCs before releasing

the vehicle.

- Thanks to Steve Bezdek and Jack Woodward |

figure

13 |

|

return

to Table of Contents |

|

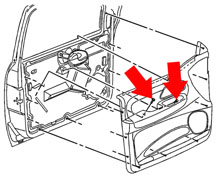

| Front

Door Trim Panel Replacement |

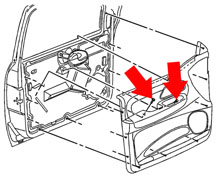

In SI Document 734557, the procedure has been

modified for Front Side Door Trim Panel Replacement on the 2002-05 Envoy,

Rainier, and Trailblazer. The illustration now has callouts showing

the two bolts that must be removed before removing the panel from the

vehicle (fig. 14).

Failure to remove both bolts will result in damage to the trim panel

L-bracket(s). In the event of damage, the L-bracket(s) are not serviced

separately, but are included with the armrest assembly available through

GMSPO.

-

Thanks to Scott Brewster |

figure

14 |

|

return

to Table of Contents |

|

| Weatherstrip

Lubricant |

Krytox®

lubricant is suitable for all weatherstrip and seal applications, including

sunroof seals. It is available in 1 oz. (29 ml) bottles, under the following

GM p/n.

Krytox®

Lubricant |

3634770

US |

10953518

Canada |

TIP:

Use sparingly. The container has a built-in applicator, which allows

for a thin film to be applied.

-

Thanks to Jerry Garfield |

|

|

return

to Table of Contents |

|

| Stanadyne

Diesel Injection Pump Replacement |

This information refers to Special Policy Adjustment

bulletin 00064F, dated September 2004, and applies to 1994-2002 Chevrolet

and GMC trucks with 6.5L diesel engines.

Technician Responsibilities

Before calling the phone number in the bulletin to obtain an exchange

pump, complete the Diesel EFI Diagnostic Worksheet, included in the

bulletin.

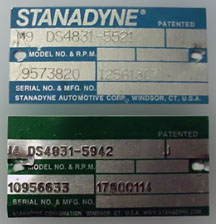

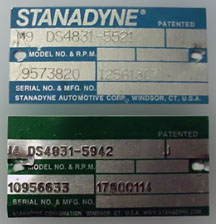

Check the injection pump for tags (fig. 15),

stickers or Stanadyne tags that have been altered, indicating that the

pump has been remanufactured. Reman pumps are not covered under the

special policy.

When requested, all parts including the injection pump must be returned

to the Warranty Parts Center. Failure to return all parts associated

with the repair will result in a debit to the dealer’s parts account.

Removed pumps are not to be sold by the dealer for remanufacturing,

rebuilding or scrap.

TIPS: Take note of the following.

1. You must obtain the exchange pump from GM TAC, by calling the phone

number in the bulletin. Special policy pumps will have a green tag with

part number 17800113 or 17800114. The pump must be installed on the

vehicle listed in the TAC case.

2. You must return all removed parts when requested.

3. The build date on the returned pump must correspond with the last

pump replacement in the warranty history for the vehicle.

4. Pumps obtained from other sources (such as remanufactured, or direct

from Stanadyne) are not covered by this policy or GM part warranty.

-

Thanks to Ian Doran |

figure

15 |

| return

to Table of Contents |

|

| 4T65E

Intermittent Shift Conditions |

Owners

of some 2004-05 Impalas or Monte Carlos equipped with 4T65E Transmission

(MN3, MN7) may comment that the speedometer intermittently drops or

fluctuates, engine appears to miss, or harsh shift. Diagnosis may not

indicate any codes stored or any abnormal condition.

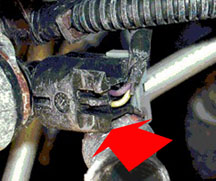

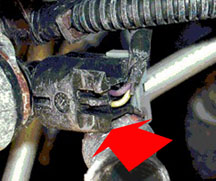

Inspect the routing of the power steering hose near the transmission

output speed sensor connector. The power steering hose may be contacting

the output speed sensor connector (fig. 16),

causing an interruption or open in the output speed sensor circuit.

Carefully reposition the hose to prevent contact with the output speed

sensor connector.

This information was posted on the Service Information Forums website

by Red Oil Man. Thank you for your contribution.

-

Thanks to Darryl Butler |

figure

16

|

| return

to Table of Contents |

|

| Allison

Transmission Filter |

Service Interval Clarification

The first service interval for the Allison transmission is at the pickup

truck’s first maintenance. Change the external spin-on filter

only (fig. 17). Every 50,000 miles (80,000

km) (normal service) or 25,000 miles (40,000 km) (severe service), change

the spin-on filter and fluid. Change the sump filter only during overhaul.

-

Thanks to Bert Druelinger |

figure

17 |

| return

to Table of Contents |

|

| Crankshaft

Balancer Tool |

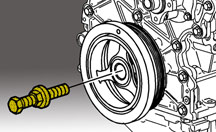

When

installing the crankshaft balancer on the L5 engine in the Colorado/Canyon,

you will discover that the bolt that is part of installer J-41478 is

too long for use on the L5 engine. The tool interferes with the radiator.

An M16 x 2.0 x 220mm bolt is supplied with installer J-41478 (fig.

18). For the L5 procedure, obtain and substitute an M16 x 2.0

threaded rod or bolt, 6.5 inches (165mm) long.

-

Thanks to Lance Mossman, Applegate Chevrolet, Flint Michigan |

figure

18 |

|

return

to Table of Contents |

|

| A/C

Refrigerant Loss |

This

information applies to all GM vehicles.

On the A/C system, the cap with gasket is the primary seal for the high

and low side ports. If the cap gasket is missing, it could cause a small

refrigerant leak and over time lose enough refrigerant to create a customer

comment.

Unless care is taken when the high or low side port cap is removed,

the gasket may not be retained within the cap. It may fall to the floor

or get lost.

When servicing an A/C system or inspecting for a refrigerant leak, verify

that the port cap gasket is present and properly installed.

-

Thanks to Jim Will |

| |

| return

to Table of Contents |

|

| Windshield

Wiper and Washer Issues |

On

some 2002-05 Chevrolet, GMC, Oldsmobile and Buick mid-sized utilities,

the windshield wiper/washer may not shut off, or may have other issues.

The primary concern is that the wiper motor or washer pump will not

turn off. These and other customer concerns have been isolated to the

control module.

Verify the concern and replace the wiper control module only, not the

entire motor assembly.

-

Thanks to Dino Poulos |

| |

| return

to Table of Contents |

|

| HVAC

System Noise |

Owners

of some 2001-05 Chevrolet Venture, Pontiac Montana and Oldsmobile Silhouette

models may report a high pitched whistle or air rushing sound when the

HVAC system is set to full floor and the blower fan is set on high.

The noise may come and go with the fan speed. A possible cause of the

noise is that the defogger vent assembly is not completely seated into

the HVAC plenum.

If all diagnostic procedures have been exhausted and the noise remains,

the cause may be the defogger vent assembly. Follow these steps to correct

the noise.

1. Remove the windshield garnish molding (SI document 508258).

2. Remove the upper trim pad (SI document 630216).

3. Remove the side window defogger outlet ducts (SI document 858993).

4. With both hands, lift up on the center defogger outlet vent until

you hear a small pop or the assembly returns to the seated position.

5. Keep pressure applied to the center defogger outlet vent and follow

it downward until you reach a void between the center defogger outlet

vent and the HVAC plenum.

6. Cut a piece of stiff packing foam into a wedge approximately 2 1/2

inches thick, by 3 inches long, by 2 inches wide (fig.

19).

TIP: The protective

door foam that is shipped with a new vehicle is ideal.

Install the foam wedge between the center defogger outlet vent and the

HVAC plenum on both sides (fig. 20), while

maintaining upward pressure on the defogger outlet vent assembly.

TIP: After steps 4, 5 and 6 have been completed,

test the system to ensure that the complaint is corrected and the center

defogger outlet vent has not become unseated.

7. The wedges will keep the center defogger outlet vent in position

and provide support once the upper trim pad is re-installed.

8. Reverse the first three steps and test the system to ensure that

the concern is repaired.

-

Thanks to Charles Avritt, and Steve Wamback at St. Clair Motors |

figure

19 |

|

figure

20

|

| return

to Table of Contents |

|

| Sliding

Side Door Operation |

The

sliding door may be hard to open or will not open from the inside door

handle on some 2003-05 Chevrolet Express and GMC Savana vans.

The lock rod may not be adjusted correctly, and can make hard contact

with a gold-colored bracket on the latch assembly. This can make the

sliding door hard to open or cause the lock rod to become disconnected

from the retaining clip on the latch assembly.

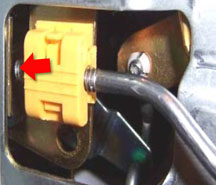

The lock rod has a threaded end that snaps into a yellow retaining clip

on the latch assembly (fig. 21). When the

lock rod is installed into the yellow retaining clip, the exposed threads

on the rod should be just about equal on both sides of the retaining

clip. After the lock rod is reattached to the yellow retaining clip,

operate the inside door handle and make sure the lock rod does not make

hard contact with the gold colored bracket on the latch assembly and

that the door opens properly.

-

Thanks to Ron Erman |

|

figure

21

|

| return

to Table of Contents |

|

| Power

Door Locks Inoperative |

On

the 2005 Chevrolet Equinox, the power door locks may be inoperative

and the 20 amp DR LCK fuse is open.

Inspect the wire harness in both front doors for chafing on the front

of the window regulator. Repair the wire harness as needed and reroute

to prevent any further chafing.

-

Thanks to Ron Erman |

| |

| return

to Table of Contents |

|

| False

DTC B0595 |

For

2004 - 05 Malibu/Malibu Maxx and 2005 G6, a false DTC B0595 is being

set in the BCM. DTC B0595 cannot be erased. Do not replace the BCM.

When perfoming any functions on a BCM, you must use Tech 2 version 25.002

(minimum).

IMPORTANT: This

code has no effect on the vehicle. DO NOT replace any modules for this

code.

-

Thanks to John Mason |

| |

| return

to Table of Contents |

|

| Plastic

Wheel Nut Caps |

Owners

of some 2005 Chevrolet Silverado and GMC Sierra trucks may comment that

the plastic wheel nut caps are coming loose and/or falling off. This

may occur if the plastic wheel nut caps get hot from excessive brake

use; i.e., going down hill, towing, hauling, etc.

To correct this concern, replace only the plastic nut caps with p/n

9596657. The new caps are made of a more heat-resistant material and

are less susceptible to heat distortion.

The original caps are black. The new nut caps are dark gray. All nut

caps on the vehicle must be replaced (24 nut caps on 6-bolt vehicles

and 32 nut caps on 8-bolt vehicles).

Snap the old (black) nut caps out of the wheel covers, and snap the

new (dark gray) nut caps into place. When installing the wheel covers

on the vehicle, refer to bulletin 03-03-10-002A for the correct procedure

for hand tightening the nut caps.

-

Thanks to Jim Will |

| |

| return

to Table of Contents |

|

| Instrument

Pointer Position |

On

some 2005 Chevrolet Cobalts and Pontiac Pursuits, the instrument panel

gauges may be inoperative. The speedometer pointer will appear frozen

at an offset position of 10° to 340°. In addition, the fuel

and tachometer pointers may appear offset by 10°.

An IPC software issue may cause the described condition, when system

voltage drops as result of a slow drain. This may occur due to an abnormally

high parasitic draw or the ignition switch being left on for long periods.

As system voltage drops, the IPC will reset. Upon exiting reset, the

IPC will move the speedometer pointer by 10°. Each time the IPC

resets, the speedometer pointer moves an additional 10°, up to 340°

total. Once the battery voltage begins to rise, the fuel and tachometer

pointers will move up 10°.

This condition can be corrected by disconnecting the battery or the

cluster fuse. Do not replace the IPC. Service software for the IPC is

expected to be available at the end May 2005.

-

Thanks to John Mason |

| |

| return

to Table of Contents |

|

| Low

or Completely Discharged Battery |

Owners

of some 2004-05 Cadillac XLRs and 2005 Chevrolet Corvettes may comment

that the battery has a low charge or is completely discharged at times.

If a cause can not be located with normal diagnosis, check with the

customer or the sales department to determine if the vehicle is equipped

with an aftermarket security system. These systems use a small transmitter

or GPS locator that is hidden in the vehicle and is usually unknown

to the technician. The transmitter is typically installed in the hot-at-all-times

dome lamp circuit and prevents the Body Control Module (BCM) from entering

the sleep mode.

-

Thanks to Paul Radzwilowicz |

| |

| return

to Table of Contents |

|

| Rear

Cargo Cover Opening |

The

owner’s manual for the 2003 - 05 Chevrolet SSR states that up

to 4 key fobs can be programmed. The 3rd and 4th key fobs programmed

will lock and unlock the doors and the panic button will function correctly.

But the 3rd and 4th key fobs will not open the rear cargo cover.

This is normal operation of the remote keyless entry system. Do not

make any repair attempts for this concern.

-

Thanks to Ron Erman |

| |

| return

to Table of Contents |

|

| Ignition

Key Programming |

When

adding or replacing an ignition key on a Cadillac CTS or SRX, you may

not be able to program the replacement key to the vehicle. This will

result in a no-crank no-start condition or a vehicle that starts and

runs with the security light on when using the new key. This may be

accompanied by a DTC B3976 and/or a DTC B3031.

Some replacement keys have been produced without configuring the transponder

in the key head. If you are attempting to add or replace a key and you

experience this symptom, obtain another replacement key and follow the

published SI procedures to program.

TIP: You may

need to try several replacement keys before you get one that will work.

The manufacturing process is being modified to correct this concern

as soon as possible.

-

Thanks to David Wells |

| |

| return

to Table of Contents |

|

Car Issues

— Fix It Right the First Time (new issues in bold) Car Issues

— Fix It Right the First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2003-2004 |

CTS

– DTC C0450 or C1241 Set, Service Steering System Message

On |

Replace

only VES solenoid. |

Don’t

replace entire steering gear. |

03-02-36-001A |

2003-2004 |

Cavalier,

Sunfire – Difficult to Adjust HVAC Control Head Mode Dial |

Replace

foam delaminated from mode door, causing bind. |

Don’t

replace HVAC control head, module or cables unless damaged. |

03-01-38-005B |

2002-2003 |

Impala

– Snap/Clunk When Window is Rolled to Full Up Position |

Replace

glass run channel with revised P/N. |

Don’t

replace front door window regulator, door glass or align door

glass for snapping noise when window reaches full up position. |

03-08-64-034 |

2003-2004 |

Cavalier,

Sunfire – Noisy A/C Compressor |

Inspect

for ground-out conditions that can cause A/C compressor noise

complaints. |

Don’t

replace A/C compressor for excessive noise without inspecting

for ground-outs. |

03-01-38-012A |

2005 |

Equinox

LT/LS (AWD Only) – Moan, Bind or Growl Coming from Rear

during Low Speed Parking Lot Turns |

Replace

RDM coupling (clutch pack) with proper sealers. Fill with Versatrak

fluid. |

Don’t

replace complete rear drive module. |

04-04-20-004 |

2005 |

Cobalt/Pursuit

(Built Before January 17, 2005) – Fuel Gauge May Not Go

Completely to Full |

Recalibrate

ECM with updated calibration, version 1.75. |

Don’t

replace fuel module, fuel level sensor assembly or fuel gauge. |

05-08-49-002A |

2002-2005 |

Cars

and Trucks – Multiple Driveability Symptoms/Clogged Fuel

Injectors |

Clean

fuel injectors as described in Bulletin. |

Don’t

replace fuel injectors. |

03-06-04-030A |

2004 |

Grand

Prix – Steering, Suspension or Cradle Click Noise |

Install

new two-piece sleeve and spacer to steering gear mounts. |

Don’t

replace steering gear or cradle. |

03-02-32-048A |

2000-2003 |

Century,

Regal, Lumina, Impala, Monte Carlo, Grand Prix, Intrigue with

3.8L L36 Engine – Coolant Leak |

Replace

upper intake manifold gasket only. |

Don’t

replace upper intake manifold assembly for coolant leak. |

03-06-01-016 |

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

Issue

One: Refinish brake rotor.

Issue Two: Measure for LRO |

Issue One: Don’t replace brake rotors.

Issue Two: Don’t measure for LRO |

00-05-22-002D |

|

| return

to Table of Contents |

|

|

Truck

Issues — Fix It Right the First Time

(new issues in bold) Truck

Issues — Fix It Right the First Time

(new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2003-2005 |

Full Size Pickups and Utilities – Rear Seat Audio and/or

Rear HVAC Controls Inoperative |

Replace

RSA. |

Don’t

replace console. |

03-08-44-018B |

2004-2005 |

Midsize and Fullsize Pickups and Utilities – CD Issues |

Load

new software calibration. |

Don’t

exchange or replace radio. |

04-08-44-020A |

2002-2005 |

Tahoe, Suburban, All Yukons, All Escalades, Avalanche, H2 –

Exhaust Pop/Ping Noise |

Replace

heat shield. |

Don’t

replace exhaust system. |

03-06-05-008B |

2003-2005 |

Full

Size Pickups and Utilities – Snap/Popping Noise from Front

of Vehicle |

Use

the procedure found in Service Bulletin. |

Don’t

replace crossmember. |

03-08-61-002D |

2004 |

Tahoe, Suburban, Silverado, Yukon, Yukon XL, Sierra, Escalade,

Escalade EXT, Escalade ESV, H2 – Passenger Door Module and

RKE Inoperative |

Re-flash

passenger door module. |

Don’t

replace passenger door module. |

04-08-52-005 |

2001-2003 |

Fullsize

Pickups – Injector Replacement for High Flow Rates |

Use

Corporate Bulletin

04-06-04-007A for injectors with high fuel return rates. Use Special

Policy 04039 for all 01-02 vehicles. |

Don’t

replace 8 injectors for any complaint other than high fuel return

rates. All other injector failures are fix as failed. |

|

| 2004-2005 |

All

Cars and Trucks – State-of-Charge Upon Delivery of a New Vehicle |

Check

battery state-of-charge per revised PDI procedure using J-42000

or J-42000-EU. |

Don’t

remove and replace battery. |

02-06-03-009A |

| 2002-2004 |

Fullsize

and Midsize Pickups and Utilities – Labor Operation Assignments

for Control Module Reprogramming |

When

submitting claims for reprogramming an electronic module, use correct

labor operation that reflects module being programmed. |

Don’t

use K5364, which is for reprogramming a transmission control module

(TCM), when reprogramming a TCCM. |

02-04-21-006D

02-06-04-057D |

| 2002-2004 |

Chevrolet

Avalanche and Cadillac Escalade EXT – Cargo Covers and Cladding

Faded or Stained |

Thoroughly

clean, dry and treat components with “Armor-dillo.”

|

Don’t

replace cargo covers for this condition. |

04-08-111-001B |

2001-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed. |

Don’t

replace complete mirror assembly. |

03-08-64-028 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for July |

| |

|

| Know-How

Broadcasts for July |

| 10290.07D

Emerging Issues |

July

21, 2005, 9:30 AM and 12:30 PM, Eastern Time |

| New

Model Features and Technology Close-Up seminars |

Stay

tuned! These programs will return soon. Check the Service

Know-How section of the GM Training website (www.gmtraining.com)

for more details. |

| -

Thanks to Tracy Rozman |

|

|

| return

to Table of Contents |

|

Car Issues

— Fix It Right the First Time (new issues in bold)

Car Issues

— Fix It Right the First Time (new issues in bold)

Truck

Issues — Fix It Right the First Time

(new issues in bold)

Truck

Issues — Fix It Right the First Time

(new issues in bold)