| |

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Why

the GMLAN? |

GM has been using

on-board computers to control various vehicle functions for over

20 years. Beginning in 1980, a UART system was used to control engine

functions. Later, in 1995, the Class 2 data system permitted numerous

modules on the vehicle to communicate with each other over a common

data line.

With each change, it’s been possible to increase the speed of

data transmission to accommodate an ever-growing number of functions.

Now, starting with 2004, a new GMLAN (Local Area Network) system is

being introduced. It will appear first on the Saturn Ion and 2004 Cadillac

XLR, and will eventually spread to other vehicle lines (fig.

1).

GMLAN is a reliable, cost effective, flexible, and modular way to handle

information sharing between different electronic control units (ECUs)

in the vehicle through the means of a family of serial communication

buses.

While the domestic automakers were developing UART and Class 2, the

European industry was developing a system that operates on the CAN

(Controller Area Network) protocol. With the introduction of GMLAN,

which also uses the CAN protocol, a common architecture now permits

sharing of components from both sides of the ocean.

Some Features of GMLAN

The Class 2 system had only one baud rate -- data was all transmitted

at a single speed.

Using the CAN protocol, GMLAN has two different communication links

with different data baud rates available -- low speed and high speed.

GMLAN Low Speed Bus

This bus will be typically used for operator controlled functions (for

instance, door lock, window motor, etc.) where the system response

time requirements are on the order of 100 - 200 msec.

It uses a single wire (also referred to as single wire CAN or SWCAN).

GMLAN High Speed Bus

The high speed bus is typically used for sharing real-time data. Systems

with these requirements are primarily powertrain and chassis devices

(engine, transmission, brakes). This bus uses two wires, and operates

at 500 kbps.

Because there is a common communications protocol on all buses, it’s

easier to transfer data from one bus to another.

In the Class 2 system, state of health messages pass from module to

module continually. This requires all of the modules to be continually “awake.”

In GMLAN, modules can remain asleep, in a low power state, until asked

to perform. Some ECUs may be communicating while others are in low

power state. Only those ECUs necessary to participate in a common function

are required to be awake. In effect, communication between any collection

(or sub-system) of ECUs can be started or stopped independently of

any other collection.

Present GMLAN Application

The 2004 Cadillac XLR and Saturn Ion use the GMLAN high speed bus for

powertrain applications. Class 2 continues to be used for body and

accessory controllers.

CANdi Module and Tech 2

Vehicles equipped with GMLAN require the use of a CANdi module for

communication with the Tech 2. Class 2 data will pass through the CANdi

module, so it can stay in place regardless of which protocol is being

scanned.

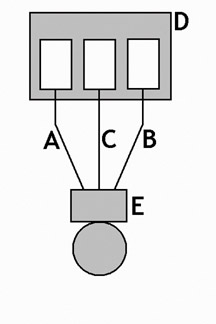

The CANdi module (controller area network diagnostic interface) is

installed in the data cable between the Tech 2 and the DLC (fig.

2).

The fact that GMLAN can operate at different baud rates enhances the

efficiency of vehicle operation and communication. However, the Tech

2 snapshot display frame rate is unchanged.

TIP: Simultaneous to the introduction of the GMLAN is a new diagnostic

process called Functional Diagnosis. Watch for more information on

this in upcoming issues of TechLink.

-

Thanks to John Dobbs |

figure

1 |

|

|

|

|

| |

figure

2 |

return

to Table of Contents

|

|

Attention

Cadillac Dealers

|

In

a few months, the 2004 Cadillac XLR will begin to ship to dealers. This

revolutionary new Cadillac automobile will be the first GM vehicle serviced

by TechLink readers to use the GMLAN (local area network) data communication

system.

TIP: You can

learn more about the GM LAN system in the Know-How broadcasts on March

27 (10270.15D – Tech 2 Functional Diagnostics & GM-LAN).

The Cadillac XLR will use the GMLAN primarily in the powertrain and brake

systems, while the familiar Class 2 data system will be used for body

and accessory controllers.

Your Tech 2 will require an interface called the CANdi module, to communicate

with the GM LAN. CANdi stands for controller area network diagnostic

interface. The CANdi modules and instructions for use will begin arriving

at your Cadillac dealerships shortly.

TIP: It’s

strongly recommended that you perform the Tech 2 functionality test

before you connect the CANdi module.

In preparation for this new Tech 2 use, you must perform a functionality

test on your Tech 2 to be sure the circuits used by the CANdi module

are operating properly.

TIP: An explanation of the functionality test is being sent to Cadillac

dealers along with this March issue of TechLink.

To perform the functionality test, you will need:

- Tech 2

- Tech 2 cable

- ALDL loopback adapter

- VCI

The instructions will guide you to perform the following routines built

into your Tech 2:

- VCI Automated Test

- VCI Dual UART Test

- VCI TPU Option F6 Test

- VCI J1708 Test

These routines verify that a Tech 2 and VCI are working according to

specifications and able to work with the CANdi module. These tests can

also be found on your Tech 2 User Guide CD.

You can perform the functionality test quickly. Do it right away. This

will allow sufficient time if your Tech 2 needs repair.

TIP: The August 2002 issue of TechLink contained a thorough explanation

of how to obtain repair for the Tech 2, whether or not it is in warranty

or under a service contract. Guidance is available at the Techline Customer

Support Center (1.800.828.6860 English or 1.800.502.3222 French).

-

Thanks to Mark Stesney, Matt Singer, Craig Jones and Richard St.

Pierre |

| return

to Table of Contents |

|

| Drive Axle Nut |

When

servicing the drive axle nut on the 1997-2003 Chevy Malibu and 1999-2003

Olds Alero and Pontiac Grand Am, use 10289657 and torque to 235 N.m (173

lb ft). This is a torque-prevailing nut and is silver colored. The old-style

nut is black and has a sheet metal cage around the nut. Using 10289657

will provide a more consistent clamp load on the wheel bearing and should

help prolong bearing life.

TIP: Whenever the axle nut is removed, a new nut should be installed.

-

Thanks to Dave Dickey |

| return

to Table of Contents |

|

|

Know-How Broadcasts

for April |

| |

|

| Know-How

Broadcasts for April |

| Emerging

Issues |

April

10, 2003 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| Technology

Close Up --

2004 Pontiac and Oldsmobile New Model Features |

April

24, 2003 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| |

|

|

Steering

Wheel Leather Conditions

|

Damaged

leather steering wheels can lead to customer dissatisfaction. Before

replacing a wheel under warranty, look at the accompanying photos.

The following are warranty concerns:

fig. 3 - leather coming apart

fig. 4 - high stitch

fig. 5 - peeling

fig. 6 - loose or pulled stitch

fig. 7 - supplier defect

The following are not warranty concerns:

fig. 8 - scrape

fig. 9 - cut

Avoiding Pre-Delivery Damage

Use care when removing the protective wrap on steering wheels during

Pre-Delivery Inspection. If the protective wrap is pulled or ripped away,

it will scar the steering wheel with permanent scuff marks. If the wrap

is cut away, the steering wheel will likely be cut as well. In an effort

to improve customer satisfaction, follow removal instructions for the

protective wrap by unwrapping the steering wheel.

TIP: To assist in unwrapping the steering wheel, look for a yellow starter

pull-tab (fig. 10) on the plastic wrap.

- Thanks to Monica Pruett and Lorenzo Barone |

figure

8

|

figure

9

|

|

figure

10 |

return

to Table of Contents |

| |

| Minor

Scratches to Wood Steering Wheels |

This

information applies to all 2000-03 Cadillac vehicles with wood steering

wheels (fig. 11) and will be covered in detail in upcoming bulletin

03-02-35-002.

Some customers may comment that the wood section of their steering wheel

has minor scratches in the clear coat.

Here are the highlights.

Remove the steering wheel, following procedures in the Steering Wheel

and Column subsection of the Service Manual.

Wash the wood section of the wheel with wax and grease remover, then

mask off the non-wood area of the steering wheel.

Sand with 400 grit sand paper, followed by 600 grit.

IMPORTANT: Do not sand through the clearcoat.

Wash the wood section of the wheel with wax and grease remover.

Clear coat the steering wheel. Refer to the 2003 GM Approved Refinish

Materials Booklet, GM 4901 M-D-2003 (English) or GM 4901 M-D-F2003 (French).

Then install the steering wheel, following procedures in the Steering

Wheel and Column subsection of the Service Manual.

-

Thanks to Brian Dotterer

|

figure

11

|

| |

| return

to Table of Contents |

|

| Power

Outlets |

Beginning

with the 2003 model year, a new service manual subsection was created

called Power Outlets. This new subsection includes all the needed

information on the 115 volt accessory power receptacle used in the

Pontiac Vibe.

Beginning with the 2004 model year, Power Outlets will also include schematics

and replacement procedures for cigar lighters and 12 volt accessory power

outlets (receptacles) for all vehicles.

-

Thanks to Eric Baur |

| return

to Table of Contents |

|

| Two

Theft Deterrent Subsections in Service Manuals -- Reminder |

Some

2002 and 2003 service manuals will contain two Theft Deterrent subsections.

Use ONLY the subsection titled Theft Deterrent for diagnosing the

theft deterrent system.

The subsection titled Theft Deterrent - Immobilizer is for vehicles sold

outside the United States and Canada. DO NOT use it for vehicles operated

within the United States or Canada.

-

Thanks to Dale Tripp |

| |

| return

to Table of Contents |

|

Intermediate Shaft Boot |

Owners of some 2003 Buick

Centurys and Regals may comment about increased steering effort when

turning right or left. This condition may be caused by possible interference

between the intermediate shaft and intermediate shaft boot (fig.

12).

A quick determination can be made whether the intermediate shaft and

intermediate shaft boot are in contact. Raise the vehicle. With the ignition

on and the engine off, have an assistant turn the steering wheel from

right to left. Grasp the intermediate shaft boot. While the steering

wheel is being rotated, there should be no contact felt between the intermediate

shaft boot and the intermediate shaft. If contact is felt, replace and

properly position the intermediate shaft boot.

TIP: An additional symptom of this condition may be the appearance

of a white powdery substance on the "top hat" portion of

the steering gear, which has been analyzed as material from the intermediate

shaft

boot.

-

Thanks to Wayne Zigler |

figure

12 |

| return

to Table of Contents |

|

| Rear

Park Assist Update |

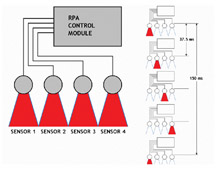

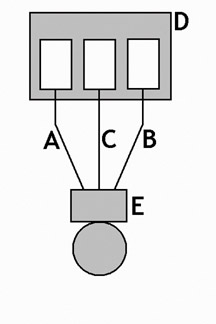

Numerous GM cars, trucks and vans now offer the Rear Parking Assist

(RPA) system (TechLink, August 2000). The RPA helps the driver know

how close the rear bumper is to an object when backing up (fig.

13).

RPA uses an array of four object sensors in the rear bumper which transmit

ultrasonic sounds. By comparing signals that bounce back to the object

sensors, the RPA control module can calculate how far away an object

is. The normal range extends about 5 feet (1.52 m) behind the vehicle,

from 10 inches (25.4 cm) above ground level to the top of the bumper

(fig. 14).

RPA operates when the shift lever is moved to Reverse and the vehicle

is moving below 3 mph (5 kph) (higher speeds interfere with the ultrasonic

signal).

Telltale Light Operation

A display of telltale lamps, two amber and one red, is located above

the rear window and is visible in the rear view mirror.

Initially, all three lamps come on momentarily to indicate that the system

is working.

TIP: If something is wrong with the system, the red lamp flashes and

the system disables.

When the vehicle backs up and RPA detects an object 5 feet (1.52 m) behind

the vehicle, the first amber light comes on and a chime sounds. At 40

inches (101.6 cm), the second amber light comes on and the chime sounds

again. At 20 inches (50.8 cm) the red light comes on and the chime sounds

continuously.

The telltale lamps are also used for diagnosis, explained later.

Special Operating Conditions

The lamp may flash red if the ultrasonic sensors are not kept clean.

Be sure to remove mud, dirt, ice or slush. A particle of dirt lodged

between the sensor membrane and body can result in a false alert.

Some conditions outside the vehicle may cause the red lamp to flash.

These include vibrations such as from a jackhammer or the operation of

air brakes on a very large truck.

TIP: In the diagnostic stall, the operation of an air powered tool nearby

can cause interference, also.

All of these flashing lamp conditions are normal and do not require repair.

Brief Explanation of Sensor Operation

A later section outlines approved diagnostic procedures. Some technicians

choose to attempt diagnostic steps not included in the SI charts, such

as using a digital volt-ohmmeter to test the wiring at the object sensors.

The data obtained from this test is meaningless.

The following explanation will help you understand the RPA system, and

is intended to point out why a voltage check at the sensors will not

work.

The four sensors “fire” individually, in a continuous cycle

that repeats every 150 milliseconds. This means that each sensor has

only 37.5 milliseconds to arm, fire and receive the returning signal.

The resulting voltage changes in the sensor circuits occur far too

fast to be discerned by a volt-ohmmeter.

To make the point, here’s a breakdown of the cycle for one sensor.

Remember, all of this occurs about 27 times per second.

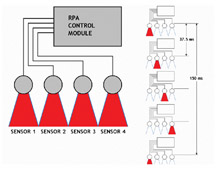

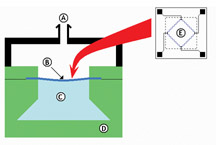

Refer to figure 15. Note that there are three wires at the sensor:

A 8 volt supply line

B low reference line

C sensor signal line

The other components shown include:

D RPA module

E RPA sensor

There is voltage between the supply and low lines at all times. At the

beginning of the cycle (fig. 16), the module pulls the signal line low,

telling the sensor that its turn is coming. The sensor responds by pulling

the sensor line low at its end. This tells the module to start its timer.

At the same time, the sensor transmits its ultrasonic beam, using the

8 v and low lines for power.

During the transmission time, the sensor line is neutral. As soon as

the sensor receives a bounceback signal, it again pulls the sensor line

low, telling the module to stop the timer. From the amount of time recorded,

the module can calculate the distance to the object.

Diagnosis

The RPA control module is capable of detecting faults and storing diagnostic

trouble codes. To put the control module into the code display mode,

ground the diagnostic connector at the control module, turn the ignition

on, and shift to Reverse within 5 seconds. The lamps then display codes

using various light patterns. Refer to the service manual to interpret

the codes and make the repairs listed.

TIP: The flashing

lamp codes are used to indicate failures of various components in the

system. There is no flashing lamp code to indicate

module failure. The system simply doesn’t work in this case.

To erase diagnostic codes, be sure the diagnostic connector is not grounded.

Drive the vehicle forward at least 15 mph (24 kph), then stop and turn

the ignition off to clear codes. Codes may also be cleared by turning

the ignition on, shifting to Reverse within 5 seconds, and turning the

ignition off.

TIP: On some vehicles, vans in particular, the geometry of the rear bumper

affects the operation of the RPA. Be sure the bumper cover is not distorted

or sagging toward the ground, which could cause the RPA signals to detect

the ground as an object. This is not a fault of the system, but a fault

of the bumper position.

TIP: When diagnosing the system in a service stall, be sure to remove

all objects from behind the vehicle. A tool on the floor, a stack of

tires nearby, or other objects may cause false alerts.

Refinishing

TIP: The

object sensors are sensitive to paint thickness. If the paint is

too thick, the red diagnostic lamp will remain on. When painting

a

replacement sensor, refer to basecoat/clearcoat paint procedures.

Be sure the paint thickness does not exceed 6 mils (0.006-inch,

0.15 mm),

as determined by a non-ferrous paint thickness gauge.

- Thanks to Paul Ogu and Kevin Fondaw |

figure

13

figure

13

|

figure

14 |

figure

15

figure

15

|

figure

16 |

|

return

to Table of Contents |

|

| Auxiliary

Gasoline Generators Will Not Run |

Owners

of some 2002 Chevrolet Express or GMC Savana Vans may comment that

their vehicle's auxiliary gasoline generator (installed by a dealer

or an upfitter) will not run when the vehicle is not running.

Vehicles built with reverse flow check valve (RFCV) fuel sending units

will not allow fuel through the sending unit check valve into the auxiliary

generator with the vehicle shut off.

Replace the vehicle's fuel sending unit with a non-RFCV fuel sending

unit. Refer to Fuel Sender Assembly Replacement (SI Document ID 693842).

Observe SI cautions when working on a fuel system.

A bulletin is expected.

- Thanks to Dan Oden

| 25314353 |

Fuel Sending Unit, Non RFCV, 31 Gallon, California Emissions |

| 25314352 |

Fuel Sending Unit, Non RFCV, 31 Gallon, Federal Emissions |

| 25326140 |

Fuel Sending Unit, Non RFCV, 35 Gallon, California Emissions |

| 25326141 |

Fuel Sending Unit, Non RFCV, 35 Gallon, Federal Emissions |

|

|

|

|

|

| return

to Table of Contents |

|

| Accelerator

Pedal Buzz and Vibration |

This

condition affects some 2003 Silverado, Suburban, Tahoe, Avalanche,

Sierra, Yukon, Denali, Escalade, and EXT vehicles.

Owners may experience a buzz noise which can be heard and felt, from

the accelerator pedal area on the first acceleration after starting the

vehicle. It will occur only the first time the vehicle reaches approximately

10 mph (16 kph) after start-up. It will not occur again until the key

is cycled off then on. Based on the driving habits of the owner, the

condition may occur at approximately the same time as the 1-2 shift of

the automatic transmission.

This noise is caused by the Supplemental Brake Assist (SBA) performing

a self-test. The SBA, which is mounted to the brake vacuum booster canister,

is new for 2003 and provides vacuum for the brake booster in case of

low vacuum or vacuum loss.

This is a normal condition and no repair attempts should be made.

The SBA is used only on vehicles equipped with vacuum brake boosters

and is not used on vehicles equipped with Hydra-Boost brake systems.

- Thanks to GM Technical Assistance |

|

|

| return

to Table of Contents |

|

| Engine

Noise and Vibration |

Owners

of some 2002 Chevrolet TrailBlazers, GMC Envoys and Oldsmobile Bravadas

with the 4.2L LL8 engine may experience noise and vibration between

800 - 900 rpm. They may comment about engine buzz noise, and vibration

felt at the accelerator pedal, steering wheel, and center console.

Verify that the intake pre-plenum is securely mounted. Press down on

the plastic intake pre-plenum. If the vibration is eliminated, replace

the intake pre-plenum with part number 15176239.

- Thanks

to GM Technical Assistance

|

| |

|

return

to Table of Contents |

|

| MAP

Sensors |

The

MAP sensor is an important part of the modern engine control system.

When asked, “What does MAP mean?” most technicians could

correctly answer, “Manifold Absolute Pressure.”

The next question, though, would stump most.

What is absolute pressure?

In absolute measurement, the zero point (where the measuring device indicates

zero) is an absolute zero pressure. That means no pressure, or in other

words, a 100% vacuum.

The pressure gauges I have indicate zero when no pressure is being measured.

Isn't this absolute zero?

No. Most pressure or vacuum gauges indicate zero pressure when not connected,

or when there is no pressure or vacuum being measured. However, there

actually is pressure -- the atmospheric pressure that surrounds the earth.

You mean barometric pressure?

Yes, even though your pressure or vacuum gauge may indicate zero, the

atmospheric or barometric pressure is always present. Conventional gauges

always measure gauge pressure.

What is gauge pressure?

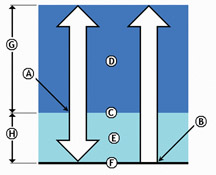

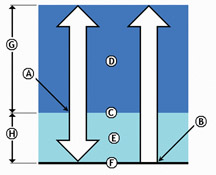

Gauge pressure has its zero point at the current barometric pressure

(fig. 17). Everything above barometric pressure is called pressure and

everything below barometric pressure is called vacuum.

A - Gauge Pressure Zero indicated here

B - Absolute Pressure Zero indicated here

C - Current barometric pressure

D - Atmospheric Pressure

E - Vacuum

F - Perfect Vacuum

G - Operating Range of Standard Pressure Gauge

H - Operating Range of Standard Vacuum Gauge

Conventional pressure or vacuum gauges are constructed to measure gauge

pressure to keep the cost affordable.

An absolute pressure gauge is bulky and expensive. Laboratory-grade devices

that measure absolute pressure cost over $1000.

Tell me about atmospheric, or barometric, pressure.

The two terms are interchangeable. Atmospheric pressure at sea level

on a standard day is approximately 14.7 pounds per square inch (psi),

or 29.9 inches of mercury (HG), or 101 kilopascals (kPa), or 1 Bar.

These various standards differ only in the units of measure used to express

them.

Does atmospheric pressure always stay the same?

No. Two factors can make the atmospheric pressure vary. First, at an

altitude above sea level the atmospheric pressure goes down, because

the density of the air goes down.

Second, weather or climate can change the atmospheric pressure -- high

pressure or low pressure days. This is why the standard sea level atmospheric

pressure is listed as being on a standard day.

How do my conventional pressure or vacuum gauges act at various altitudes?

They react the same at high altitude as at sea level, which is exactly

the point we are getting to.

Conventional pressure gauges have no way to compensate for different

altitudes or weather changes. They will indicate zero either at sea level

or at the top of a mountain. However, the atmospheric pressure is certainly

different at these two extremes.

Why is this atmospheric pressure measurement so important?

The air in the atmosphere contains oxygen. An engine burns a mixture

of oxygen and fuel. For an engine to burn efficiently, it has to have

just the right mixture of fuel and oxygen.

To determine the correct air/fuel mixture and the correct ignition timing,

the PCM must know the atmospheric (BARO) pressure. If the PCM is to compensate

for changes in altitude or weather, it must have an input signal that

reflects these changes in atmospheric pressure.

The Manifold Absolute Pressure sensor does this?

Yes. And, on engines that do not have a Mass Air Flow (MAF) sensor, the

MAP sensor signal is also used by the PCM to calculate engine load --

how hard the engine is working. This is called the speed-density method

of calculating engine load for engines without MAF sensors. It is because

of this engine load calculation for speed-density engines that the accuracy

of the MAP sensor signal is so critical.

On OBD-II engines, the MAP sensor signal is also used for EGR diagnosis.

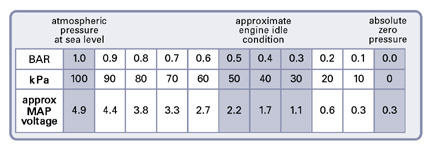

What are the normal ranges of the sensor's output voltage?

The most common MAP sensor generates an output voltage between 0 and

5 volts, depending on the pressure being measured. It must be able to

measure atmospheric pressure at the lowest elevations, which in some

areas is slightly below sea level. The standard atmospheric pressure

at sea level is about 101 kPa. In the Death Valley, Utah, which is below

sea level, the atmospheric pressure can be higher than 101 kPa. At the

top of Pikes Peak mountain in Colorado, which is more than 14,000 (4,267

m) feet above sea level, the baro pressure is less than 65 kPa. So, the

MAP sensor must have a measurement range of 105 kPa to about 15 kPa.

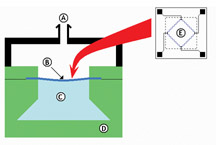

How does the MAP sensor measure pressure UP from absolute zero?

Imagine two glass jars glued together at the open ends, with a flexible

membrane sealed between them. Drill a hole into the bottom of each jar,

and glue a tube into each hole. Now, connect a powerful vacuum pump to

one of the tubes.

When the vacuum pump removes ALL the atmospheric pressure from the jar,

seal the tube, trapping the vacuum in the jar. The flexible membrane

will be pushed in towards the vacuum chamber jar by the atmospheric pressure

in the open jar.

The vacuum jar has absolutely no pressure in it, so it becomes the absolute

zero reference point.

Any pressure on the atmospheric side will push the flexible membrane

in, but higher pressure will push it in further.

Remember, high pressure in this case equals atmospheric pressure, about

101 kPa at sea level.

Now, attach a hose from the intake manifold of your engine to the open

jar. Devise an electrical circuit to measure how far the membrane flexes,

and you have the basic idea of how a MAP sensor works (fig.

18).

A - Hose fitting to manifold

B - Thin silicon diaphragm

C - Reference pressure chamber (Absolute vacuum, zero pressure)

D - Pyrex glass

E - Sensing resistors on silicon diaphragm

When would I ever measure a reading as low as 15 kPa?

The sensor is called a manifold absolute pressure sensor because its

sensing element is connected to the intake manifold, either through a

hose or a direct mount. When the engine is not running, the pressure

inside the intake manifold is equal to atmospheric pressure, and the

PCM will use this "engine not running" MAP signal as the BARO

reading.

A running engine acts like a large vacuum pump. When the throttle is

nearly shut, the pressure in the intake manifold is very low -- as low

as 15 kPa at a high-speed, closed-throttle deceleration. As the throttle

is opened, the pressure inside the intake manifold increases because

the atmospheric pressure outside the intake manifold is rushing in, limited

only by the engine's throttle blade opening.

The accompanying chart shows that low manifold pressure (engine idling)

equals low MAP output voltage, and high pressure (engine at WOT or not

running at all) equals high MAP output voltage.

What is the function of the three wires leading to the MAP sensor?

One of the wires provides a precise 5 volt power supply from the

PCM. Another wire provides the ground circuit, grounded only through

the PCM.

The third is the signal wire, carrying the signal voltage generated

by the MAP sensor to the PCM.

-

Thanks to Jack Woodward |

figure

17 |

| |

figure

18

|

| |

| |

|

|

|

New Tech

2 Programming Function |

A

new Service Programming function is being added to the Tech 2. It

will be released on CD 3, which will reach the field in March.

TIP: This new Tech 2 function will apply first to the 2004 Pontiac Grand

Prix and will spread across all model lines in 2004. Pontiac dealers

can expect to see their first 2004 Grand Prix models this month.

Occasionally, when you’re using your Tech 2 to diagnose a control

module on a vehicle, you may conclude that it’s necessary to reprogram

that module with the latest calibrations. At this point, you’re

already in the Diagnostic Menu of the Tech 2.

In the present Tech 2 version, you have to return to the Main Menu to

select Service Programming System (SPS) Request Info to enable the Tech

2 to obtain the necessary information from the vehicle.

There are two disadvantages to this. First, you have to do a lot of button

pushing to get to where you want to be. And second, when the command

is given, simultaneously every module on the vehicle that can be reprogrammed

is requested to respond.

Revised Method in the New Software

In the new software, there’s a way to go directly from diagnostics

to programming. While you’re in the Diagnostic Menu, simply press

Special Functions.

TIP: Some modules don’t support Special Functions. For these, you

will continue to use the existing method.

In the Special Functions menu, one of the choices is SPS Request Info.

Choose this and you will be ready to request the necessary information

from the vehicle.

TIP: When you use this new method, only the module you’re working

on is commanded to respond, which speeds up the process.

Downloading from TIS Terminal

With your Tech 2 hooked up to the TIS terminal, you must make the proper

module selection from the menu.

TIP: This selection must match the module on the vehicle you downloaded

identification from. Improper module selection will cause a Programming

Failed message at the vehicle when trying to program it.

Programming Event

Once the appropriate new data has been downloaded from the TIS terminal

into your Tech 2, the actual programming event proceeds as it always

has. That is, you will go to the Main Menu and select Service Programming

System.

Final Tip

For the foreseeable future, the old Information Request method will remain

on the Tech 2 for those who want to continue to use it. You will now

have two methods to choose from.

-

Thanks to Glen Crifasi |

| |

| |

| return

to Table of Contents |

|

| New

TIS Feature |

TIS

is an evolving product supporting more modules and more vehicles, not

just in North America but globally. It now supports China, Daewoo,

Holden, and Toyota, for instance.

To accommodate additional vehicles, an Options Menu has been added to

Remote Programming (fig. 19).

In the Options menu, you will now have to make additional selections

(make, model year, option content).

These selections must be made before selecting the module to be programmed.

You can then view the available calibrations for the specified vehicle

and complete the download.

The look of some graphics will change, but functions remain the same.

This change will be effective in the 3.2 release in mid-March.

-

Thanks to Mark Stesney

|

figure

19

|

| return

to Table of Contents |

|

| Crew

Cab Wind Noise |

Owners

of some S-10 Crew Cab pickups with ZR5 sports package may comment about

a wind noise. This may be caused by the roof rack.

Check the position of the forward cross-bar of the roof rack. It should

be slightly rearward of the B-pillar (fig. 20). This helps alleviate

the sound pressure at the A-pillar, where it’s most sensitive to

driver and passenger.

All vehicles leave the assembly plant with the cross-bar in this position,

but it may be relocated by the owner when the roof rack is used.

-

Thanks to Dan Oden |

figure

20

|

| return

to Table of Contents |

|

| Bulletins – February,

2003

This review

of service bulletins released through mid-February lists the bulletin

number, superseded bulletin number (if applicable), subject and models. |

00

– General Information

02-00-89-019; Labor Operation Times and Straight Time Pilot Updates;

2003 Cadillac CTS

01 – HVAC

01-01-39-004A; replaces 01-01-39-004; A/C Not Cold Enough, A/C Blows

Warm Air with Vehicle at Extended Idle (Install Auxiliary Electric

Coolant Fan); 2002-03 Cadillac Escalade, Chevrolet and GMC Pickup and

Utility with 6.0L Engine (VINs U, N -- RPOs LQ4, LQ9)

03 – Suspension

00-03-10-003D; replaces 00-03-10-003C; GM Tire New Vehicle Warranty

Program; 1996-2003 Passenger Cars and Light Duty Trucks, 2003 Hummer

H2

02-03-10-008; Recommended Wheel Nut/Bolt Torque Specifications; 2003

Passenger Cars and LD Trucks, Hummer H1, H2

03-03-10-001; Tire Slowly Goes Flat and/or Excessive Wheel Vibration

(Replace Wheels with New Heavy Duty Rim Version); 1999-2003 Chevrolet

and GMC 1500 Series Pickup Models with 6-Bolt, 16 x 6.5 Full Face Steel

Wheel (Base and RPO PY2)

04 – Driveline Axle

02-04-19-001; Revised Differential Carrier Assembly Replacement; 2002

Chevrolet TrailBlazer, GMC Envoy, Oldsmobile Bravada

03-04-95-001; Revised Wheel Drive Shaft Outer Joint and Seal Replacement

and Wheel Drive Shaft Inner Joint and Seal Replacement Procedures;

2001-03 Chevrolet Corvette

05 – Brakes

02-05-23-005A; replaces 02-05-23-005; Required Use of Silicone Lubricant

on Brake Caliper Slider Pins; 2003 Chevrolet and GMC C4500/C5500 Series

02-05-25-007; Parts Restriction Program for Vehicle Stability Enhancement

System (Stabilitrak); 2003 Cadillac Escalade, Chevrolet and GMC Utility

03-05-25-001; Thumping Noise/Feel in Brake Pedal (Replace Electronic

Brake Control Module); 2003 Chevrolet and GMC 1500/2500 Series HD Cargo

Van with GVW of 8600 -- 11000 lbs

06 – Engine/Propulsion System

02-06-01-039; Whine or Growl Noise from Engine After Cold Start --

Normal Characteristic; 2003 Chevrolet Impala with Police Package (RPOs

9C1, 9C3)

02-06-04-059; Engine Runs Rough, SES Light On, DTCs P0300 or P0335

Set (Shim Crankshaft Sensor); 2002-03 Chevrolet and GMC Pickups, Vans

and Utilities with 4.3L V6 Engine (VINs W, X -- RPOs L35, LU3)

02-06-05-005A; replaces 02-06-05-005; Exhaust/Muffler Heat Shield Rattle,

Popping Noise Under Vehicle (Install Heat Shield Retaining Straps on

Muffler); 2002-03 Cadillac Escalade, Chevrolet and GMC Pickup and Utility,

Hummer H2 with 5.3L or 6.0L Gas Engine (VINs T, N -- RPOs LM7, LQ9)

Except 1500 Series

03-06-04-001; Revised DTC P0122; 1996-97 Chevrolet and GMC C/K pickups,

S-trucks, Vans, and Utilities with 4.3L, 5.0L, 5.7L, or 7.4L Engine

(VINs W, X, M, R, K, N, J -- RPOs L35, LF6, L30, L31, LO5, L19, L29)

03-06-04-002; Vehicle No-Start in Extreme Cold (Install Injection Pump

Heater); 1999-2003 Chevrolet and GMC W-Series MD Tilt Cab with 4HE1-T

Diesel Engine

03-06-04-003; Use of New Special Tool J-46363 -- Fuel Line Disconnect

Tool for Fuel Filter Removal/Installation Procedure; 2002-03 Chevrolet

and GMC Pickup and Utility with 5.3L Flexible Fuel Engine (VIN Z --

RPO L59)

03-06-04-004; Revised DTC 0341; 1996 Buick Century, Regal, Skylark,

Chevrolet Beretta, Corsica, Lumina, Monte Carlo, Oldsmobile Achieva,

Ciera, Cutlass Supreme, Pontiac Grand Am, Grand Prix with 3.1L Engine

(VIN M -- RPO L82)

03-06-04-005; Revised DTC P0230; 1998-99 Chevrolet Camaro, Pontiac

Firebird with 3.8L Engine (VIN K -- RPO L36)

03-06-04-006; Revised Electronic Ignition (EI) System Diagnosis; 2001-02

Chevrolet Impala, Monte Carlo with 3.8L Engine (VIN K -- RPO L36)

03-06-04-007; Revised DTC P0443; 2001-02 Oldsmobile Aurora, Intrigue

with 3.5L Engine (VIN H -- RPO LX5)

03-06-04-008; Exhaust Gas Recirculating (EGR) Valve Cleaning Prior

to Potential Replacement; 1999-2000 Chevrolet Tracker with 2.0L Engine

(VIN C -- RPO L34)

03-06-04-009; Engine Deceleration Hesitation, Loss of Power on Vehicles

with Police Package (Reprogram PCM); 2001-02 Chevrolet Impala with

3.8L Engine (VIN K -- RPO L36) and Police Package (RPOs 9C1 or 9C3)

04-06-05-002; SES Light On, Reduced Vehicle Performance, Acceleration

and Top Speed (Replace Catalytic Converter and Brake Vacuum Booster

Hose with Thermo Protection); 2001-02 Chevrolet Impala with 3.8L V6

Engine (VIN K -- RPO L36) and RPOs 9C6 Taxi Cab, 9C1 Police Car and/or

9C3 SEO Vehicle Police Car, Limited Content

07 – Transmission/Transaxle

02-07-30-012A; replaces 02-07-30-012; Hydra-matic 5L40-E Serviceable

Components and Labor Operations; 2003 Cadillac CTS with 2.6L or 3.2L

Engine (VINs M, N -- RPOs LY9, LA3) and 5L40-e (RPO M82) Transmission

08 – Body and Accessories

02-08-43-005; New Windshield Wipe Motor Assembly; 2003 Chevrolet

Cavalier, Oldsmobile Alero, Pontiac Grand Am, Sunfire

02-08-43-006; Revised Wiper Inoperative-Rear Diagnostic; 2002 Chevrolet

TrailBlazer, GMC Envoy, Oldsmobile Bravada

02-08-49-011; Console Air Deflectors Inoperative, Broken or Missing,

Door Latch Broken (Replace Appropriate Component); 2002-03 Buick

Rendezvous

02-08-67-009; Sunroof Jams When Closing (Install Guides); 2002-03

Cadillac Escalade, Chevrolet and GMC Utilities

03-08-44-001; XM Radio Labor Operation Codes; Specified 2003 Vehicles

03-08-47-001; Cigar Lighter and Accessory Power Outlets Time Out

After 10 Minutes (Relocate Fuse); 2000-03 Cadillac DeVille, Seville,

CTS

03-08-48-001; Windshield Stress Cracks (Replace Windshield); 2002

Chevrolet Tracker

03-08-49-001; Rattle in Floor Console Cupholder Door (Add Felt Washer);

2003 Cadillac Escalade, GMC Sierra, Yukon with Luxury Package (RPO

Y91) and Custom Front Floor Compartment (RPO D07)

03-08-50-001; Second Row Seat Center Armrest Panel Warping (Replace

Panel); 2003 Cadillac Escalade, Chevrolet Avalanche, Chevrolet and

GMC Pickup Crew Cab and Utility

03-08-52-001; Remote Keyless Entry (RKE) System Inoperative (Reprogram

Passenger Door Module); 2003 Cadillac Escalade, Chevrolet and GMC

Utilities, Hummer H2

03-08-64-001; Sliding Side Door Effort (Install Retainer); 2002-03

Chevrolet Astro, GMC Safari

03-08-66-001; Deck Lid Not Flush With Left Hand Quarter Panel (Install

Struts, Replace Right Deck Lid Hinge); 2003 Chevrolet Corvette Convertible

and Z06)

03-08-110-001; Rear Storage Compartment Tray Hinge Support Link Breaks

(Replace Link); 2002-03 Chevrolet Venture, Oldsmobile Silhouette,

Pontiac Montana

|

| return

to Table of Contents |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|