| |

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Fuel

Tank System |

Corvette

and Cadillac XLR

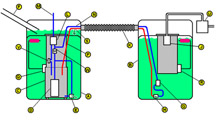

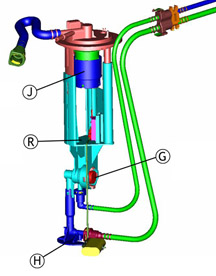

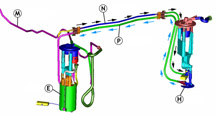

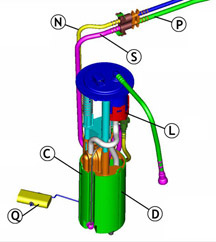

Partway through model year 2003, a new fuel tank system was introduced

on the Corvette (fig. 1). This system continues

with slight differences in the 2004 Corvette and Cadillac XLR.

TIP: For 2003

Corvettes only, this system was designated by RPO code FFS. However,

this name has been unofficially applied to all vehicles with the new

system.

Advantages and Features

The new fuel tank system was designed to accommodate future LEV 2 emission

requirements. This was accomplished by moving as many components and

fuel lines as possible inside the fuel tanks, to minimize hydrocarbon

emissions. A flexible metal crossover hose assembly replaces the former

rubber one, because the permeable rubber allowed a small amount of hydrocarbon

to pass through.

The redesign also includes more isolation and noise control for the

electric fuel pump, which now has greater flow capacity to supply higher

output engines.

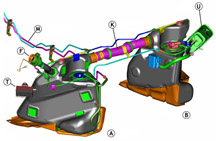

Component Layout

TIP: Use the

reference letters to identify and locate the various components.

A Left side tank

B Right side tank

C Fuel sensor reservoir

D Turbine fuel pump

E Venturi pump

F Fuel fill hose

G Secondary fuel pressure regulator

H Siphon jet pump

J FLVV

K Crossover hose

L Filter

M Fuel feed pipe to engine

N Fuel feed pipe to RH tank

P Fuel return pipe to LH tank

Q Left fuel level sensor

R Right fuel level sensor

S Anti-siphon hole

T Fuel pump speed control module

U EVAP canister

V Primary fuel pressure regulator

W Check valve

TIP: On the XLR

only, a speed control module (T) slows the fuel pump when the engine

is idling, to further control pump noise.

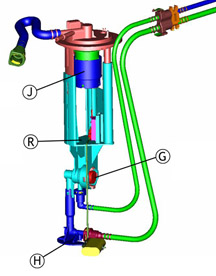

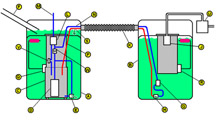

Two fuel tanks are used, and they’re joined by crossover plumbing

(fig. 2 and fig. 3). The left side (driver

side) tank (A) is considered the primary, and the right

side (passenger side) is secondary (B).

Each tank contains a sensor module, which includes a float and resistor

card.

On the left side, the sender module includes a reservoir (C),

containing the turbine fuel pump (D). There’s

also a primary fuel pressure regulator (V) and a venturi

pump (E). The left tank is also supplied by the fuel

fill hose (F), and has a rollover vent valve.

On the right side, the sender module contains a secondary fuel pressure

regulator (G) and a siphon jet pump (H).

There is also a fill limiting vent valve (FLVV) (J).

Operation

When the fuel tanks are filled, fuel first fills the left tank. As the

fuel rises to the level of the crossover (K), fuel

flows into the right tank. As fuel occupies the interconnected tanks,

air is forced to vent from the tanks, through the FLVV in the right

tank. When both tanks are full, the FLVV float in the right tank closes,

preventing fuel from entering the vent system. This also causes fuel

to back up in the fill hose, causing the gas pump nozzle to shut off.

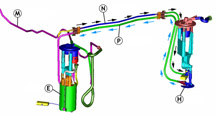

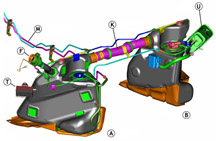

When the engine is running (fig. 4), the

turbine fuel pump (D) in the left tank pressurizes

the fuel feed pipe (M). The entire fuel supply system, from the pump

to the injectors, is pressurized. The turbine pump creates more pressure

and more fuel flow than the engine needs. Excess pressure and excess

fuel is allowed to bleed back into the left tank by the primary fuel

pressure regulator (V) within the tank.

TIP: The pressure

regulator is in the fuel tank, not on the fuel rail on the engine. This

type of fuel system is called returnless, or demand. This means that

excess fuel is diverted before it leaves the tank, instead of passing

through the fuel rail before being diverted. The result is that hot

fuel is not constantly returning from the engine compartment, so the

fuel in the tank stays cooler, improving evaporative emissions.

The majority of the pressurized fuel is directed through the filter

(L) and on to the fuel feed pipe (M) to the engine,

where it is injected into the cylinders for combustion.

Some of the pressurized fuel is directed through a feed pipe (N) inside

the crossover hose, to a siphon jet pump in the right tank. The jet

pump relies on the venturi effect to use pressurized fuel to draw additional

fuel from the tank. The combined fuel then flows from the right tank

to the left tank, through a return pipe (P) inside

the crossover hose. The jet pump is able to move enough fuel to ensure

that all of the fuel in the right tank is consumed before the level

in the left tank begins to drop.

TIP:

The return tube in the left tank has an anti-siphon hole (S), so the

fuel in the left tank does not siphon back to the right side when the

vehicle is shut down.

Some of the pressurized fuel is directed to a venturi pump in the left

tank. This pump uses fuel flow to siphon fuel from the main tank into

the reservoir, to keep the turbine pump supplied with fuel at all times.

As the left tank fuel level drops, the venturi pump scavenges all of

the remaining fuel into the reservoir, regardless of the vehicle’s

attitude.

When the engine is shut off and the turbine pump stops, a reverse flow

check valve (W) maintains pressure in the system to

ensure rapid pressure buildup during the next startup cycle.

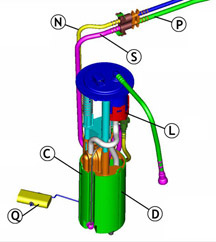

Operation of Fuel Level Gauge

When the fuel system is operating as designed, starting with both tanks

full, the left tank will remain full until the right tank is depleted.

Then the left tank will be emptied.

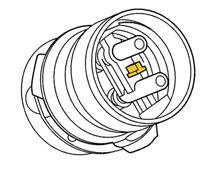

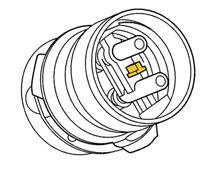

Each fuel tank has its own sensor (Q and R

in the illustrations). Modules are shown in figure

5 (LH module) and figure 6 (RH module).

The PCM supplies a reference of 5 volts to the two sensors. Each sensor

operates across a range from full (2.5 volts) to empty (0.7 volts).

The PCM monitors the fuel level sensor voltages and calculates how much

fuel is in the two tanks. The readout of the IP fuel level gauge is

a result of this calculation.

TIP: The fuel

level sensors can be monitored with a Tech 2.

Several “zones” are used to describe various combinations

of fuel levels in the two tanks.

Zone 1 -- The LH voltage is above its full threshold

(typically calibrated to 2.4 volts) and the RH voltage is above its

empty threshold (typically calibrated to 0.8 volts). Fuel volume = capacity

of LH tank + volume in RH tank. This is the normal condition, before

the fuel in the RH tank is completely consumed.

Zone 2 -- The LH voltage is above full threshold and

RH is below empty threshold. This is also known as the deadband zone.

Fuel volume = volume in LH tank + deadband volume - fuel used since

entering zone. This is also a normal condition. It occurs because the

actual amount of fuel in the tanks cannot be precisely indicated by

the positions of the floats. That is, when the float reaches the top

of its travel, it’s possible that the tank will hold additional

fuel, which does not cause the float to move higher. Similarly, when

the float reaches the bottom of its range, there may still be some fuel

in the tank, and the float does not move any lower as the remaining

fuel is consumed. So, the fuel in the bottom of the RH tank and the

top of the LH tank will be consumed without either float moving. This

is the “deadband.”

Zone 4 -- The LH voltage is below full threshold value.

Fuel volume = volume in LH tank. This condition occurs just after the

zone 2 “deadband” is passed. All of the fuel is gone from

the RH tank, and the LH sensor has begun to move down. The amount of

fuel in the LH tank is all that remains.

Zone 5 -- The LH voltage is below its full threshold

and the RH voltage is above its empty threshold. Fuel volume = volume

in LH tank = volume in RH tank. This is a condition that should not

occur in normal operation, because the RH tank should be consumed before

the float in the LH tank begins to drop. If the fuel system is in zone

5 for a certain amount of time, a DTC (1431, 2066 or 2636) will set,

and the fuel volume will be reported as zero by the fuel gauge.

A zone 5 condition could occur if the jet pump in the RH tank becomes

clogged, preventing fuel from being siphoned from the RH tank. In this

case, only fuel in the LH tank is available.

TIP: Service

kits are available for each sensor, including:

- float

- wire arm

- wiper

- card

- card holder

Diagnostic Situations

The following situations may apply to the Corvette (C5), the Cadillac

(XLR) or both, as noted.

Jet Pump Clog (C5, XLR) -- If the jet pump in the RH

tank becomes clogged, fuel will not transfer to the LH tank. When this

occurs, the vehicle eventually runs out of fuel, even though there is

actually some in the RH tank. When the DTC (1431, 2066 or 2636) sets,

the fuel gauge drops to empty and the customer perceives an “erratic

gauge.” One cause of this condition was a piece of plastic left

in the jet pump during the manufacturing process. This has been remedied.

Fill Quality (C5) -- A customer may comment that the

fuel nozzle shuts off prematurely, before the fuel tanks are full. The

maximum flow rate for gas station pumps is supposed to be 10 gallons

(37.9 L) per minute, and the fuel system is designed to accommodate

this rate.

TIP: In reality,

pump nozzles vary considerably in configuration, flow and shutoff sensitivity.

Ask the customer if the condition occurs at all stations, all the time,

or at just one pump. This could point to a pump nozzle problem, not

a vehicle problem.

Be sure the rubber hose to the canister vent solenoid (next to the transmission)

is not restricted and that the vent solenoid is not stuck closed. Both

can cause fuel to back up in the tanks and filler hose, causing the

pump nozzle to shut off.

TIP:

A replacement filler hose between the fill pipe and the LH fuel

tank is available with a smaller inside diameter for C5. Although this

sounds like it would make the condition worse, the smaller diameter

allows less swirling, creating smoother fuel flow. A bulletin is pending.

Regulator Not Seated, Clip Loose (C5, XLR) -- If the

clip retaining either regulator is not fully engaged, the fuel system

will lose pressure and the vehicle may stall. This condition was remedied

in production.

If the secondary regulator (right tank) is not seated, it could result

in fuel not transferring from the right tank. It could also cause long

crank times, because residual pressure is lost in the fuel feed pipe

to the engine when the engine is shut down.

TIP: With the

engine off, a pressure gauge connected at the fuel rail should indicate

52 psi (359 kPa). If pressure drops rapidly, the regulator may be unseated.

Open Fuel Level Sensor Circuit (C5, XLR) -- If an open

occurs in a fuel level sensor circuit, the fuel gauge will drop to empty

and a DTC will set. This could be caused by an unseated electrical terminal.

Check the wiring circuits before replacing fuel system components. Another

cause, which has been corrected, was the sensor wiper fingers not in

contact with the resistor card, over the full sweep of the sensor.

TIP: The DTC specifies which

sensor circuit has the issue. Only that sensor should be replaced.

LH Module Opening Too Small (C5, XLR) -- In some LH tanks,

the module opening was undersized, making it difficult or impossible

to remove the module. This has been corrected in production.

TIP: In any case,

be careful of the sensor float wire when removing the module, to avoid

damage.

Service Procedure Notes

TIP: Refer to IDL course 10260.22D, Technology

Close-Up from October 2002, for additional information.

TIP: Always consult SI before

performing a service procedure. The following are highlights and tips

only.

Removing Fuel Tanks -- The crossover hose must be disconnected

from a fuel tank which is being removed. The crossover is located above

the driveline and exhaust system, making removal appear difficult. Both

SI and the Labor Time Guide allow lowering the driveline and exhaust

for access. See Driveline Support Assembly Replacement in SI.

Once you have performed this procedure, you will gain enough knowledge

of the components that you may be able to do the procedure in the future

without lowering the driveline.

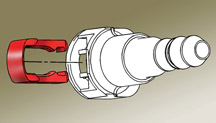

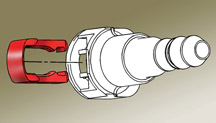

Crossover Hose -- The crossover hose is made of corrugated

flexible stainless steel. It is retained to each fuel tank by a collar

and a CPA (Connector Position Assurance). With the CPA aside, the collar

can be turned by hand. It may be necessary to wiggle the crossover while

pulling it straight out -- DO NOT TWIST.

The fuel feed and fuel return pipes for the transfer pump are inside

the crossover, and are sealed with O-rings. The crossover is sealed

to each tank with two O-rings. When installing the crossover, lube the

O-rings and O-ring sealing surfaces with 1051717 rubber lubricant. Then

align the pipes and push the crossover into place. DO NOT FORCE.

TIP:

There is a T-shaped alignment feature (fig.

7) between the feed pipes which can be assembled only one way.

With the crossover in place, turn the collar. If the crossover and pipes

are properly aligned and assembled, the collar can be turned with two

fingers. Then snap the CPA into place.

Fuel Tank Module Replacement -- It is necessary to

remove the fuel tank from the vehicle before removing the module. Procedures

are different for LH and RH tanks.

TIP: Fuel Sensor

Lock Ring Tool J-39765A is required.

When the lock ring is loosened, the module will spring upward, because

it is spring-loaded to ensure it is bottom-referenced and to resist

noise.

Follow the SI procedure exactly. It is necessary to disconnect and reconnect

numerous fuel lines. The only access is through the module and crossover

openings.

TIP: When the module is installed,

be sure to check the empty and full readings of the fuel level sensor.

Your DMM should read 40 ohms with the tank in vehicle orientation (simulating

empty) and 250 ohms with the tank upside down (simulating full).

Fuel Line Quick Connectors

Fuel lines use quick connectors, described in the February 2004 TechLink.

See page 6 for details.

TIP: To release, push on the retainer using

hand pressure only. Do not attempt to remove it.

If the retainer becomes broken, it can be replaced

(fig. 8) using the following part number.

5/16-inch

(0.3125) |

3/8-

inch (0.375) |

5/8-inch

(0.625) |

External

vapor and internal liquid lines |

Internal

liquid lines |

FLVV

connector to the evap canister |

214992748 |

22717568 |

21992746 |

Bulletin

02-06-04-010A -- This bulletin applies only to vehicles with

the previous fuel system, which could be affected by fuel with an aggressive

sulfur content. It does not apply to any XLR or 2003-04 Corvette with

the FFS fuel system. DO NOT use this bulletin to justify reprogramming

the PCM or replacing fuel sensors/modules in vehicles with the FFS fuel

system.

TIP: In the new

system, DO NOT reprogram the PCM unless specifically told to do so by

a diagnostic procedure.

-

Thanks to Dave Libby, Terry Stone and Dave Peacy |

|

figure

1 |

|

figure 2 |

figure

3

figure

3 |

figure

4

|

|

figure

5

|

figure

6 |

|

figure

7

|

figure

8 |

| return

to Table of Contents |

|

|

| Snapshot

During Cranking |

Here’s a useful service tip. You can use your Vehicle Data Recorder

J-42598 (either the original or the revised version) to take snapshots

during engine cranking.

The VDR will capture data from the time the ignition is turned on, through

the crank cycle, until the engine starts (or doesn’t start).

The data collected can be useful in diagnosing an intermittent or hard-start

condition.

To set up for this kind of snapshot, select the appropriate pre-built

engine data list. Be sure the data you think you need is in the list

you choose.

TIP: You can

set the trigger point anywhere you wish, but the best result is probably

to place the trigger point in the middle of the data collected.

Unless a diagnostic code sets as a result of the no-start, it will be

necessary for you to trigger the VDR manually.

-

Thanks to Mark Stesney and Mike Banar |

|

|

|

|

New Video Presentation of Recall Bulletin |

Product

Recall Bulletin 03044 has just been released, to explain a steering

knuckle modification on 2003 Chevrolet Astro and GMC Safari 2WD M-vans.

This bulletin is being supplemented with a narrated video, available

on SI (fig. 9).

This is a new method of delivering recall information. It allows you

to actually see the repair being performed, using the special tools

called for in the bulletin.

If this presentation method proves popular, it may be used in the future

to portray unusual or new service procedures.

How to Access the Video

Go to the SI home page in normal fashion: http://service.gm.com.

In Canada, access the video via GM InfoNET.

Click on Service Information.

Go to the bottom of the topic list and locate the link for 2003

Astro/Safari 2WD Steering Knuckle Modification Video -- Recall 03044.

TIP: The next

step is important.

RIGHT CLICK on the link. Then click on OPEN IN NEW WINDOW. This opens

the large-size video viewer. (If you left click, the viewer will open

at reduced size.)

TIP: On some

browsers, it may be necessary to drag the viewer to full size, using

the arrow in the lower right corner of the viewer.

Once the video has downloaded, click the PLAY arrow to view the video.

It runs about 4 minutes. Use the slider to control the volume of the

narrative sound track.

You may rewind the video and view it additional times. When you are

finished, click on the X in the upper right to close the video viewer.

TIP: Dealers

without high-speed internet connections may order a CD copy of this

repair procedure video at their own expense from the GM DealerWorld

DWD online store or by calling 1.866.700.0001.

- Thanks to Gary Smits |

|

figure

9 |

return to Table of Contents |

|

| New

Style Catalytic Converter |

The

2004 Chevrolet Malibu with the 3.5L V-6 (RPO LX9) is equipped with a

new style of catalytic converter, technically known as the close-coupled

catalytic converter. Each engine exhaust manifold bolts directly to

a catalytic converter, providing quick catalyst warm-up, resulting in

lower tail pipe emissions earlier in the vehicle operating cycle.

If a catastrophic engine failure were to occur (such as broken intake/exhaust

valve or piston), debris may be deposited in the converter through engine

exhaust ports. If a new engine were installed and debris is present,

the replacement engine may fail due to the debris being reintroduced

into the combustion chambers during negative exhaust back pressure events.

TIP: When servicing

an LX9 for a catastrophic engine failure, perform an inspection of the

catalytic converters for debris (on the exhaust manifold attachment

end).

TIP: In addition,

in cases where severe engine overheating is suspected of causing the

engine failure, inspect each catalytic converter ceramic brick for signs

of heat damage (melting or cracking of the ceramic brick). If heat damage

is noted, the converter should be replaced.

-

Thanks to John Fletcher |

| |

| return

to Table of Contents |

|

| 20-Inch

Wheels and Tires |

Additional

Information

IMPORTANT: The VCI fee and the labor to install the calibration

cannot be charged as a warranty claim. Dealer claims will be reviewed

and any dealer warranty claim for the installation of 20-inch wheels

and tires will be debited to the dealer.

The January 2004 issue of TechLink announced a new 20-inch wheel and

tire accessory package that dealers can offer to certain truck customers.

The article mentioned the need for obtaining a VCI number for reprogramming

the PCM as a part of the installation procedure. Techline charges a

fee for issuing the VCI number.

Installation of these accessory wheels, tires and additional parts and

related procedures are entirely at customer expense. |

| return

to Table of Contents |

|

| GM

Oil Life System, One More Time |

Attention Service Managers: If

your Service Consultants are already reading TechLink, great.

If not, now is the time to include them when handing out our

monthly newsletter. TechLink is a great source of information

that can be used when discussing vehicle issues with your customers.

The accompanying Oil Life System article is just one of many

with helpful information.

Mark

Stesney, Publisher

|

Where do you stand

on the following issues?

1. Do you want to continue to build customer loyalty and grow your business?

2. Do you want to show your customers you truly have their best interests

at heart?

3. Do you want to help improve the environment?

4. Would you like to quit being a part of the throw-away generation?

GM’s development of the Oil Life System and its relationship to

the new Simplified Maintenance Schedule have a direct bearing on how

well you can answer YES to all of these questions.

How the Oil Life System Works

We’ve explained the GM Oil Life System (GMOLS) in detail before

(March 2000, May 2003) so this is going to be brief.

GMOLS is a computer-based algorithm that assesses engine combustion

events, temperature, vehicle use, and other parameters to determine

optimum oil change intervals. Oil changes are now called for when actually

needed, instead of depending on generic time or mileage interval tables.

Mild highway driving in a mild climate can yield change intervals of

7,000 miles (11,000 km) or more, and as high as 12,000 miles (19,000

km) for some vehicles. Short trip driving in cold weather may reduce

intervals to 3,000 miles (5,000 km) or less. Most people driving a combination

of city and highway will likely see intervals of about 6,000 miles (10,000

km).

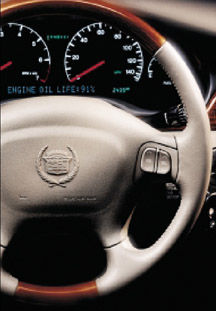

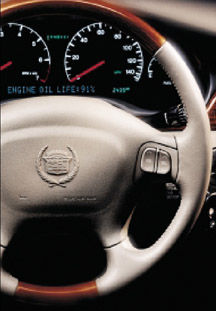

When GMOLS determines that an oil and filter change is needed, the driver

is notified by a Change Oil message on the instrument panel (fig.

10). Oil should be changed within 600 miles (1000 km).

TIP:

The Oil Life System must be manually reset when the oil is changed.

How the Oil Life System is Related to Maintenance

The previously complicated, traditional normal/severe maintenance schedules

required about 25 pages of explanation in the owner’s manual.

The new simplified maintenance schedules can be explained in about 3

pages (see TechLink May 2003 for a summary).

All routine maintenance is grouped into one of two schedules, Maintenance

I and Maintenance II. These services should be performed alternately,

each time the GMOLS message is displayed.

Benefits of GM Oil Life System and Simplified Maintenance

Benefits for the customer -- GMOLS takes the guesswork out of when oil

changes are needed; the owner doesn’t have to keep track of anything.

With maintenance intervals now aligned with oil changes, the customer

can conveniently have both done during one service visit.

Benefits for the dealer -- Because of the typically

extended oil change intervals, the customer may come back less frequently.

But when they do come back, it’s for more services. The inspection

and service points of both Maintenance I and Maintenance II are thorough,

and are intended to keep the vehicle in good working order. They also

give the technician the opportunity to locate, identify and recommend

other needed services.

Benefits for the environment -- With GMOLS now installed

on upwards of 20 million vehicles, if it’s used as intended, it

can save almost 100 million gallons of oil in 5 years. And remember

that every quart of oil poured into an engine eventually has to be drained

out and properly disposed of.

What’s Next?

In the next few months, GM is going to saturate owners with information

about the GMOLS. Radio interviews, TV talk shows, magazines, newspapers,

the internet and dealership kits will all be used to promote a proper

understanding of GMOLS and its benefits, and to promote its proper use.

GMOLS was also promoted at the National Auto Dealers Association (NADA)

convention in January of this year.

How Can You Prepare?

Because of GM’s media efforts, owners are going to become familiar

with GMOLS. It’ll be a good idea for you to get yourself up to

speed as well.

IDL Courses -- Three courses have been designed to

promote GMOLS and customer retention.

- Understanding the GM Oil Life System (PPS03.P1D) explains

the reasons and benefits behind the GMOLS and provides suggestions for

explaining it to customers.

- The GM Oil Life Maintenance Schedule -- Keeping the Cutomer at

the Dealership (PPS03.P4D) covers the benefits of the new maintenance

schedules and explains how to use them to benefit customer-pay business.

- Building Trust and Long-Term Customer Retention (PPS03.P6D) explains

how to earn and build customers’ trust and how to retain them.

Literature and Materials -- GMSPO is making Oil Life System

promotional material available through several sources. (fig.

11) You can download service reminder letters and maintenance

schedules at gmpartscoop.com. GMSPO-approved

vendors have a wide selection of new service reminders including a message

about GMOLS. A kit including poster, consumer brochures, and counter

display is available from gm-dealerworld.com.

Maintenance Reminder Stickers -- Traditional stickers

provided a place to write the date and/or mileage for the next oil change.

To encourage use of the Oil Life System, a new maintenance reminder

sticker (fig. 12) says the Change Oil Light

indicates a need for maintenance. It provides a place to check off whether

the next service should include Maintenance I or Maintenance II, plus

the date and mileage of the last maintenance performed.

TechLink Articles -- See the March 2000 and May 2003

issues of TechLink for summary information. If you cannot locate these

back issues, they’re still available on the internet at http://service.gm.com.

TIP: TechLink

also published procedures for resetting Oil Life Systems in January/February

2002, and May/June 2003.

-

Thanks to Chuck Burns |

figure

10 |

figure

11 |

figure

12

|

| return

to Table of Contents |

|

| Cooling

System Seal Tabs |

What’s

made of ground-up ginger root, almond shells and binder? And causes

confusion in auto service departments?

Some people call them coolant pellets, but the proper name is Cooling

System Seal Tabs. And we hope to clear up some misunderstandings about

them.

How They Work

Seal tabs are dissolved in the engine coolant and the resulting fibres

circulate through the cooling system. At a microscopic level, the tabs

break down into irregular, long, thin fibres. When a small leak or seepage

occurs, the coolant carries the fibres into the opening, where they

cluster up and jam together. (Think of logs and branches in a beaver

dam.) This mechanism is very effective at stopping leaks. Any fibres

that make it to the surface will crust over and enhance the seal.

This sealing method is useful only for small-scale leaks and seepage,

and tends to work best in conditions where the surrounding parts aren’t

moving. The seals tend to break down in areas between metals that are

expanding and contracting with temperature changes, for instance.

A Secondary Benefit

The traditional green-colored coolant, used until DEXCOOL® was introduced

in 1996, contained silicates, which deposit on cooling system surfaces.

The tiny fibres from the seal tabs acted as scouring pads, removing

silicate deposits from the water pump seal faces, which contributed

to longer water pump seal life.

Side Effects of Seal Tabs

In addition to the benefits of sealing small leaks and scrubbing silicates

from water pump seals, seal tabs also have some side effects.

After awhile, a brown, dirty-looking stain may form on translucent coolant

bottles. Residue may form on the backside of the radiator cap. And deposits

that resemble rust may be found in the cooling system.

These are not problems, in the sense that they cause no physical harm.

But their appearance can be alarming, especially on a new vehicle. Both

customers and well-intentioned technicians can be misled by these deposits.

Another side effect comes from overuse. When seal tabs are used in the

prescribed amounts, they will not cause restrictions or plugging in

an otherwise properly operating cooling system.

But, if a little is good, a lot must be better. Wrong!! Overuse can

lead to plugging, especially in the relatively small tubes used in heater

cores.

Some History

There was a time when seal tabs were installed in every new vehicle,

at the factory, to account for the inevitable small leaks that occur

in castings, joints, and so on. By the mid ‘90s, manufacturing

and machining techniques had improved to the point where the seal tabs

were no longer needed on a universal basis.

With the introduction of long-life coolant, silicate deposits were no

longer a concern, so the scrubbing action from the seal tab fibres was

no longer needed.

TIP: GM plants,

as well as other manufacturers, still occasionally use seal tabs to

address specific concerns.

Today’s Recommendations

In short, GM no longer endorses universal use of seal tabs. Procedures

in SI have been specifically written to discourage their use in most

cases.

When a condition appears in which seal tabs may be beneficial, a specific

bulletin is released, describing their proper use. One such bulletin

is Customer Satisfaction Program 03034, dated 7/7/03. This applies to

specific 3.8L engines only, and is in effect until July 31, 2005.

TIP: After performing

the procedure in the bulletin, be sure to install a recall identification

label to the vehicle to indicate that the seal tabs have been installed.

TIP: If seal

tabs were installed in a vehicle at the factory, it’s OK that

the proper amount of tabs be installed if the coolant must be drained

and replaced.

What’s a Recommended Dose?

TIP: Use this

information only when instructed to do so by bulletin or SI procedure.

The proper number of Cooling System Seal Tabs depends on the capacity

of the vehicle’s cooling system. Use between 1 and 1 1/2 grams

of tabs per liter of cooling system capacity.

TIP: Cooling System Seal

Tabs are packaged in two sizes.

12378254 |

Small

tabs (4 grams each) |

5

tabs per package |

3634621 |

Large

tabs (10 grams each) |

6

tabs per package |

-

Thanks to Greg Cockerill and Gary McAdam |

|

|

return

to Table of Contents |

|

| Service

Tips for Chevrolet Aveo (and Optra and Epica) |

The

service manuals (SI) for the Chevrolet Aveo, Optra, and Epica incorporate

content for more than 80 countries. Add-on titles are based upon region.

Three regions are used to differentiate content:

- North America

- Europe

- Neither North America nor Europe.

Too many countries are involved to list each country that uses a procedure.

If no add-on title is listed with the procedure or diagnostic title,

the procedure is common to all regions.

The Tech 2 software for the Chevrolet Aveo, Optra, and Epica incorporates

content for more than 80 countries. Technicians will need to select

the emissions package that is used in their country. The four options

are:

- ECE 83

- Euro II

- Euro III

- ULEV

Technicians in the US, Canada, and any other country that uses US emissions

(for example Guam) need to select ULEV.

- Thanks to John Bowman |

| |

| return

to Table of Contents |

|

| TAC

Corner |

Be

Prepared

Before calling the Technical Assistance Center, use the TAC form and

diagnostic worksheet to organize your call. The forms are tools to help

you provide quality service that will keep your customers coming back

to your dealership.

TIP: You can

locate the forms in the P&P Manual, Section 5.3.1.

The TAC Form is designed to help you make sure you have the essential

information you need in isolating a diagnostic path. When you take the

time to organize the information on the TAC form (TAIF), as well as

the diagnostic worksheet (DWS-01) which is filled out by the customer,

it may help get to the issue without generating a call to TAC. If a

call is necessary, using the form will reduce the time TAC needs to

assist you.

New Product Action Center

Another important topic is the Technical Assistance New Product Launch

Action Center. As most of you are already aware, TAC has initiated action

centers for each of the new products launched this past year.

The purpose of the Action Center is to quickly identify, communicate

and resolve product concerns on new vehicle launches. Special teams

receive dealer calls and take action as new vehicles arrive at GM dealerships.

This information is quickly relayed to the assembly plant, engineering

and Brand Quality to insure quick resolution of the customer's issue

and to help prevent additional occurrences.

The Action Centers are joint activities, which include the SPO Contact

Centers (TAC, SPAC, and Partech), Brand Quality, Assembly Plant Quality

Teams, Plant Training, Raytheon, Regional Service Engineers and the

CDC.

Each time a call comes in to the Action Center, the TAC call prompts

will guide the caller to an expert on the new product.

1. A TAC case is created, or updated.

2. Case closings on these cases are very important, as the information

is used by the Launch Team several ways:

- allows for real time changes to be made at the plant.

- reduces the number of quality related issues from reaching the customer.

There is a goal of 24-hour resolution/escalation. The Action Center,

as you can see, is tied directly to our Technical Assistance Center,

as well as to the assembly plants.

-

Thanks to Technical Assistance |

|

|

|

return

to Table of Contents |

|

| Leaking

or Broken Transmission Case |

The 4L60E/4L65E automatic transmission may experience a leak, inoperative/slipping

2nd, 3rd, and 4th gears or no movement (no forward or reverse) due to

excess fluid loss. This condition normally occurs at low mileage, usually

under 1,000 miles (1,600 km), and diagnosis may show a cracked or broken

case at the 2/4 servo bore.

This condition may be caused by a 2/4 servo cover retaining ring that

was not fully seated during transmission assembly. Pressure from the

servo cover against the partially seated retaining ring can cause the

case to crack or break.

If the fluid level drops due to the leak, it is likely that the 3/4

clutches will be damaged. This condition can usually be repaired by

replacing the case and any damaged clutches.

-

Thanks to Mark Gordon |

| |

|

return

to Table of Contents |

|

| XLR

Window Initialization |

This

information applies to the XLR if:

- the battery is disconnected

- the battery is in a run-down condition and requires a charge (such

as in an extended storage period)

- the window module has been disconnected.

If the window module loses battery power, the window module needs to

be initialized. The top will not operate and the window express-up and

express-down will not function unless the window module knows the window

position.

To initialize a window module, the top must be up, and the door for

the window being initialized must be fully closed. Turn the ignition

ON, engine OFF. (See February 2004 TechLink for this procedure.) Run

the window to the UP position and hold the switch continuously for a

minimum of 0.5 second. Run the window to the DOWN position and hold

the switch continuously for a minimum of 0.5 second. Once the window

module learns the window's positions, the top will operate properly.

TIP: If the door

window express-up or express-down function does not operate, use the

window initialization process before attempting any other repairs.

- Thanks to Jim Mikolaizik and Jason Macco |

| |

|

return

to Table of Contents |

|

| Allison

LCT1000 Transmission Conditions |

Chevrolet

and GMC C/K2500HD and C/K3500 trucks equipped with the Allison LCT1000

transmission may experience a condition in which the PRNDL display is

inoperative and the Tech 2 scan tool is unable to communicate with the

TCM. There are no transmission performance issues noted with this concern.

Circuit 2470 (yellow wire) may be backed out at terminal R of the C100

connector. See SI document 1243943 for clarity. C100 is located in the

I/P harness to engine harness, under the fuse block - underhood. See

SI document ID 799333 for clarity.

Terminal R should be seated and the harness positioned to prevent further

strain on the connector.

- Thanks to Mark Gordon |

|

|

| return

to Table of Contents |

|

| GTO

Vehicle Theft Deterrent |

The

GTO has a vehicle theft deterrent system which is unique to this vehicle.

When diagnosing this system, there are common symptoms which will shorten

the time spent attempting to resolve a concern with this system.

VTD Diagnostic

TIP: The vehicle

will momentarily start and stall, even if the wrong security code is received.

It takes a full second for the information from the key fob to travel

from the ignition contacts to the PCM and back.

The security light will give a clue as to where the breakdown in communication

may have occurred, if the vehicle will not stay running. After having

attempted to start the vehicle and the engine has started and stalled,

these symptoms maybe helpful in diagnosis:

- If the security light is flashing fast with the key in the ON position,

the concern is between the fob and the BCM.

- If the security light is not on with the key in the ON position, the

concern is between the BCM and the PIM.

- If the engine starts and stalls after waiting one second or longer in

the ON/RUN position, the concern is between the PIM and the PCM.

Recommendations

Repair switches, wiring and/or module connections as required.

-

Thanks to Jim Mikolaizik |

| |

|

return

to Table of Contents |

|

Car Issues – Fix It Right The First Time (new issues in bold)

Car Issues – Fix It Right The First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

Measure/document

rotor thickness and LRO – Turn rotor and brake align procedure. |

Don’t

replace brake rotor for pulsation. |

00-05-22-002

Know How Video 15040.01B |

2003-2004 |

Buick

Regal – Perceived Headliner Sag |

Show

customer Bulletin 03-08-110-007. Houses sunroof motor. |

Don’t

replace headliner for perceived “sag” |

03-08-110-007

|

2001-2003 |

Venture/Montana/Silhouette/Aztek

– Rattle/Buzz from Exhaust System |

Install

clamp. |

Don’t

replace catalytic converter. |

03-06-05-003 |

2003 |

DeVille

– No Crank/No Start Condition |

Inspect

base of UBEC to ensure wire connectors are fully seated and not

loose. |

Don’t

replace PCM. |

03-06-03-009

3 |

2004 |

Grand

Prix – Steering, Suspension or Cradle Click Noise |

Re-torque

right steering gear mount. |

Don’t

replace steering gear or cradle. |

03-02-32-048 |

2000-2004 |

XLR,

Impala/Monte Carlo/Grand Prix – Headlamp Replacement for

Condensation in Lamp |

Explain

that this is normal condition when limited to fog or fine mist

appearance in high humidity conditions. |

Don’t

replace headlamp assembly when no water droplets are evident or

condensation covers less than 50% of lens. |

01-08-42-001A

November 2003 TechLink |

2003-2004 |

Cavalier/Sunfire

– Grinding Noise on Clutch Apply (very low mileage) |

Replace

clutch hydraulic line. |

Don’t

replace clutch/bearing. |

03-07-31-005 |

2002-2004 |

All

cars with 4T40/4T45E and 4T65E – DTC P0716/P0717 and other

codes |

Disconnect,

inspect and reconnect transaxle wiring harness at transaxle. |

Don’t

replace input speed sensor. |

02-07-30-022B

September 2003 TechLink

December 2003 IDL |

2003-2004 |

CTS

– Variable Effort Steering (VES) “Service Steering

Message,” DTC C1241 or C0450 |

Replace

only VES solenoid. |

Don’t

replace entire steering gear. |

03-02-36-001 |

2003 |

All

cars with 4T40/45E, 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM Solenoid |

Don’t replace transmission or valve body assembly |

02-07-30-039B

Part numbers in bulletin have been superseded |

|

| return

to Table of Contents |

|

|

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2002-2004 |

Fullsize and Midsize Pickups and Utilities – Transfer Case

CNND Labor Operation |

Use

Labor Operation K9993 whenever a transfer case issue on a 4WD

or AWD vehicle cannot be duplicated or resolved after diagnostic

efforts. |

Don’t

use K9992, which is for manual concerns or K9995, which is for

automatic concerns. |

Service

VME

VSSM20030117 |

1999-2003 |

Fullsize Pickups – Rear Leaf Spring Slap Noise |

Replace

inserts and rubber washers. |

Don’t

replace leaf spring. |

03-03-09-002 |

1993-2004 |

All Passenger Cars and Trucks – Air Conditioner Compressor

Diagnosis |

Follow

SI and bulletin for diagnostic information before compressor replacement. |

Don’t

replace air conditioning compressor |

Service

VME, 10/31/03

01-01-38-013A |

2002-2004

(models with HomeLink option) |

All

TrailBlazers, All Envoys, Bravada, Rainier with HomeLink Universal

Transmitter – Programming Diagnosis |

Use

J 41540 – GM Integrated HomeLink Tester. Follow SI and refer

to customers to Owner’s Manual. |

Don’t

replace HomeLink Transceiver without validating internal fault

recognized by J 41540. |

01-08-97-001B |

2002-2003 |

All TrailBlazers, All Envoys, Bravada – Squeak/Rub/Scrub

Type Noise in Steering Column |

Lubricate

and remove material, per bulletin. |

Don’t

replace upper or lower intermediate shaft. |

02-02-35-006A |

2002-2004 |

All

TrailBlazers, Envoy, Envoy XL, Bravada, Rainier – Tail Lamp

Socket Circuit Board |

Replace

both tail lamp circuit boards |

Don’t

replace complete tail lamp assembly. |

Service

VME, 9/22/03

03-08-42-006A |

2003-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed. |

Don’t

replace complete mirror assembly. |

03-08-64-028 |

2003 |

Fullsize

Pickups and Utilities – Transfer Case Service Light/New

Venture Gear Transfer Case |

Verify

that encoder motor is primary cause. Replace encoder motor sensor

and reprogram TCCM. |

Don’t

replace module, encoder motor or transfer case for DTCs C0327,

P0836, P0500 |

03-04-21-001D |

2003 |

Fullsize

Pickups – 6.6L Diesel Engine ECM |

Follow

SI and bulletins for proper diagnostics for P0181. Refer to Owner’s

Manual (block heater and front cover) |

Don’t

replace ECM (DTCs P0540 and P0181) unless diagnostics confirm

need to replace |

02-06-04-048,

03-06-04-021, 02-06-04-058 |

2002-2003 |

TrailBlazer,

TrailBlazer EXT – Wavy Front Fascia |

Repair

fascia with Dual Lock |

Don’t

replace front fascia |

02-08-62-004 |

2002-2004 |

All TrailBlazers, All Envoys, Bravada, Rainier – Mirror

Erratic Return |

Replace

mirror actuator and reprogram module |

Don’t

replace outside mirror assembly |

02-08-64-021,

03-08-64-032,

03-08-64-033 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for April |

| |

|

| Know-How

Broadcasts for April |

| |

|

NOTE

TIME CHANGE |

| 10280.04D

Emerging Issues |

April

15, 2004 |

9:00

AM, 12:30 PM,

3:00 PM

Eastern Time |

| 10280.16D

New Model Features -- HUMMER H2 SUT |

April

29, 2004 |

9:00

AM, 12:30 PM,

3:00 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time (new issues in bold)

Car Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)