|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Proper

Terminal Removal Procedures for the Delphi .64 Connection System |

If

you’ve been following the various stories in TechLink about electrical

terminals, you know that over the past few years, numerous new types

of terminal and connector systems have been introduced (TechLink, Sept.

2002, June 2003, Feb. 2004 and Jan. 2005).

In the January issue of TechLink, we reviewed the various suppliers

of .64 terminals now in use in GM vehicles, and the slight differences

between them.

We reviewed the J-35616-64A and the J-35616-65 test probes and the fact

that the J-35616-64A (male) and J-35616-65 (female) test probes are

correctly sized to work with both the round and square styles of .64

terminals.

We reviewed various connector types from various suppliers that use

.64 terminals.

This article is about the proper terminal removal process for Delphi

.64 connector systems (fig. 1), of which

there are five different types. Type 4 (not shown) is not used in North

America at this time.

Type 1

Type 2

Type 3 (hybrid)

Type 5 (Saturn only)

The Wire Dress Cover

On all but Type 1, start the disassembly process by removing the wire

dress cover (if used), which requires a small screwdriver. There are

two popular versions, with one tab (fig. 2)

or two (fig. 3).

After loosening the tab(s), simply rock the cover up and off (fig.

4).

Terminal Position Assurance (TPA)

The next step is removal of the comb style TPA (Terminal Position Assurance).

Be very careful, because the TPA can break very easily (fig.

5), particularly if you try to pry the head of the TPA out of

the connector.

On Type 1 connectors, push the TPA from the end of the connector opposite

the head (fig. 6). This will get the TPA

past the detent that retains it in the connector. Then grasp the head

and pull the TPA out of the connector.

On the other types, use a prying tool to reach inside the connector

to push the TPA loose from the end opposite the head (fig.

7). Once the TPA is loosened, you can use the tool to extract

it through the hole in the connector body (fig.

8).

TIP: On the Type

3, there is no access hole for loosening the TPA. Instead, use the tool

as a lever to pry the TPA loose (fig. 9).

Nose Piece (Type 5 only)

In the Saturn LS only, a 64-way Delphi .64 connection system is used

on a Bosch ECM. For this application only, the Type 5 connector uses

a nose piece that covers the release holes for the terminals (fig.

10).

Pry the nose piece off for access to the TPA, which is similar to the

Type 3. Once it is removed, you can remove the terminals.

TIP: The Type

5 connection system uses a .64 terminal p/n 15410621 found in tray 4

position 24. This is slightly different from all other .64 terminals,

which are p/n 15359541.

Terminal Removal

For all four connector types, use the 15381651-2 terminal release tool.

Push it into the small hole positioned between the two terminal cavities

(fig. 11). In some small .64 connectors

with one row of terminals, the terminal release hole is just to the

side of the terminal cavity.

Assembly

After replacing the terminal, assemble the connector in the order opposite

to disassembly.

TIP: The TPA

has an lug which must be aligned with the corresponding depression in

the connector (fig. 12). This assures that

the detents on the TPA contact the detents in the connector body, to

retain the TPA.

Recovery

TIP: Do not disassemble

the Delphi connector body beyond removing the dress cover, the TPA and

the nose piece (if equipped).

If for some reason a Delphi .64 connection system has been dissembled

incorrectly (fig. 13), this is the process

for getting it all back together.

Remove all the wires with their terminals from the connector. Reassemble

the connector, leaving the TPA and wire dress cover off. Using the Connector

End View information in SI, reassemble the wires into the connector,

starting with the shortest wires and ending with the longest. Once the

circuits have been correctly placed into the connector, replace the

TPA and dress cover.

A Final Word About Testing a Round .64 Terminal

The .64 terminal is very small and will not withstand excessive probing,

especially with an incorrect tool (fig. 14).

A J-35616-6 probe with 100 terminal

B J-35616-64A probe with .64 terminal

The ability of the J-35616-64A Test Probe to “hang” in a

round type .64 terminal will be minimal. The drag that you feel is much

less than you’re accustomed to in a larger terminal.

TIP: Square style

.64 terminals will have a much better test probe feel relative to their

size than the round style.

-

Thanks to John Roberts |

|

|

| return

to Table of Contents |

|

|

| Truck

Body Controller Replacement |

This information applies to 2002-04 GMT 360/370 (TrailBlazer, Rainier,

Envoy and Bravada).

If replacing TBC (Truck Body Controller) part number 09352135 with a

TBC part number 15065293, 15114669 or 15122670, you MUST contact Techline

Customer Support Center (800.828.6860) for assistance or the TBC will

be permanently damaged.

TIP: Before programming,

remove LGM/DSM (Liftgate Module/Driver Seat Module) fuse 6 from the

rear fuse block, or programming errors may result.

- Thanks to Craig Jones |

| |

| |

|

|

New Tech 2 Cable |

A

new, more-robust Tech 2 DLC cable is now available for purchase. It

can be obtained from GMDE by ordering GM p/n 3000095.

TIP: Warranty

replacement cables are available on exchange from Vetronix.

These are the improvements:

- Added a "dog-ear clamp" on both connectors to help prevent

the cable from detaching from the connector.

- Improved strain relief by strengthening ribs.

- Reduced hardness of the cable's PVC material. The new cable is more

flexible and forgiving, putting less stress on a given point.

- A new wire “lay” results in a more flexible cable.

-

Thanks to Mark Stesney |

| |

|

return to Table of Contents |

|

| Drain

Plug Sealing Washer |

When

changing the engine oil on the following vehicles, it is necessary to

replace the oil pan drain plug sealing washer. The drain plug sealing

washer, which is part number 94525114, is not reusable. Reusing the

old washer may result in an oil leak.

-

Thanks to John Bowman

2004-06 |

Chevrolet

Aveo |

US

and Canada |

Chevrolet

Epica |

Canada |

Chevrolet

Optra |

Canada |

Pontiac

Wave |

Canada |

|

| |

| return

to Table of Contents |

|

| Floor

Pan Repair |

Owners of some 2000-05 LeSabre,

DeVille, Aurora, or Bonneville vehicles may comment on corrosion in

the floor pan in the area where the battery is located. This may be

caused by acid weeping from the battery, or from a dislodged battery

vent tube. A new repair floor pan kit p/n 88948594 has been released

to assist in the repair of this condition. Refer to Bulletin 05-08-61-002

for repair procedures and part number information.

TIP: Clean the

area of the floor pan where acid may have been present, using a solution

of baking soda and water. Rinse and dry the area thoroughly.

-

Thanks to Bill Denton |

| |

| return

to Table of Contents |

|

| Transmission

Lubricant |

There

are two manual transmissions used in the 2005 Cobalt. The transmission

in the base vehicle (fig. 15) and the transmission

in the SS Supercharged vehicle (fig. 16)

require different lubricants.

-

Thanks to Jerry Garfield

Cobalt |

Getrag

5-Speed Transmission |

Dexron®

III Automatic Trans Lubricant |

Cobalt

SS

Supercharged |

MU3

5-Speed Transmission |

21018899

Manual Trans Fluid |

|

figure

15

|

figure

16

|

| return

to Table of Contents |

|

| 2005

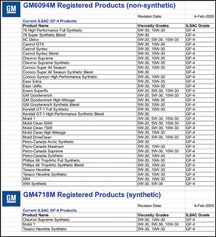

Gasoline Engine Oil Requirements |

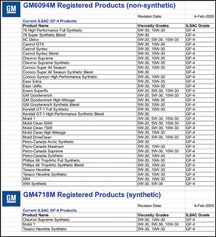

2005 GM gasoline engines require the use of an engine oil that has the

American Petroleum Institute (API) Starburst AND states that it meets

GM Standard GM 6094M (non-synthetic) or GM4718M (synthetic). Failure

to use the recommended engine oil can result in engine damage not covered

by warranty.

Figure 17 is the list of engine oil brands

that meet GM Standard GM 6094M and 4718M as of February 4, 2005.This

list will be updated and will be in the Techlink Reference Guide available

at http://service.gm.com.

-

Thanks to Robert Stockwell and Matthew Snider |

| |

figure

17 figure

17 |

| |

|

| Driver

Information Center Language Choice |

The

procedure for changing the DIC language on the Colorado/Canyon is correct

in the owner’s and service manuals but some owners apparently

are omitting the last step, which is critical. This has led to unnecessary

warranty claims.

TIP: This information will also apply to the upcoming

Hummer H3.

Before servicing the system, be sure the owner is following this procedure.

1. With the engine off, turn the key to ON.

TIP: You can't

get to the LANGUAGE screen if there are messages on the DIC.

2. Close all doors. Ensure that NONE of the following messages is displayed

in the DIC:

DOORS

PORTES

PUERTAS.

If so, check the doors again.

3. For 2004-05 vehicles, disengage the park brake. Ensure that NONE

of the following messages is displayed in the DIC (Colorado/Canyon only):

PARK BRK

FREIN A MAIN

FRENO DE MANO.

4. Press and release the reset stem until the language is shown on the

DIC display.

5. To view the next available language, press and hold the reset stem

for approximately 2 seconds. Release the reset stem and press and hold

again to view each language. You can choose from English (default),

Spanish or French.

TIP: For 2004-05 vehicles, not all languages are

available. You can choose from English (default) and Spanish for clusters

with miles as the major speedometer scale, or English (default) and

French for clusters with Km as the major speedometer scale.

6. Once the desired language is displayed on the DIC, briefly press

the reset stem to set your choice.

Users are not performing step 6 and are just cycling the ignition once

the language of their choice is displayed.

-

Thanks to Anna West |

|

|

|

| return

to Table of Contents |

|

| SSR

Hydraulic Clutch Bleeding |

The

hydraulic clutch bleeding procedure has been changed for the SSR. Follow

the improved bleeding procedure in SI document 1550985.

The procedure involves using Mity Vac J-35555 and adapter J-43485 to

apply a vacuum to the clutch reservoir. This draws air from the system.

Refer to the document for specifics.

TIP: This procedure

applies to all 2005 and prior passenger cars, light duty trucks, and

T-Series MD Tilt Cab models.

- Thanks to Dan Oden |

| |

| return

to Table of Contents |

|

| HomeLink

Transmitter |

Unlike other GM vehicles, the 2005 LaCrosse (Allure in Canada) must

have the engine running or the ignition key in the run position before

the HomeLink transmitter can be programmed or operated.

TIP: This is

normal operation, and no repair is required.

- Thanks to Wayne Zigler |

| |

|

return

to Table of Contents |

|

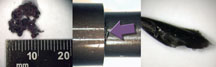

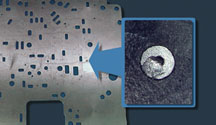

| Debris

in Spacer Plate |

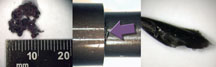

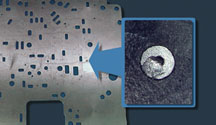

According to bulletin 01-07-30-036D, there are

several reasons for a 4L60E (RPO M30) or 4L65E (RPO M32) transmission

to set a DTC P0756 (2-3 Shift Solenoid Performance).

Two possible causes described in the bulletin are a cracked, broken

or leaking 2-3 shift solenoid and a stuck or hung-up 2-3 shift valve.

Another possible cause is chips or debris (fig.

18) plugging the filtered AFL oil at orifice 29 on the top of

the spacer plate. Because this orifice is so small, it can be plugged

by a very small amount of foreign material.

Remove the spacer plate and inspect orifice 29

(fig. 19) and the immediate area for the presence of chips or

debris. Also, inspect the transmission case passage directly above this

orifice and the valve body passage directly below. Clean the area of

any chips or debris found.

-

Thanks to Mike Johnson |

figure

18 figure

18 |

figure

19 figure

19 |

|

return

to Table of Contents |

|

| Cold

4th Gear Upshifts |

The

Chevrolet Aveo/Pontiac Wave automatic transmission prevents 4th gear

upshifts when the transmission fluid temperature is below 15°C (59°F).

This is intended to improve vehicle emissions and heater performance.

No corrective action is necessary. Replacing the ECM or TCM will not

correct this condition. Refer to SI document 1339794 for additional

information.

-

Thanks to John Bowman |

| |

|

return

to Table of Contents |

|

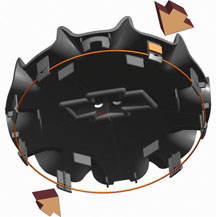

| SSR

Center Caps Loose -- Update |

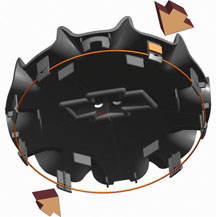

An article in the December 2004 TechLink explained

how to repair center caps that are loose and rotate, then do not align

with the wheel spokes.

This involves adding pieces of polyurethane tape to two opposing legs

of the center cap 180° apart (fig. 20).

According to PIT3196A, the tape is now available by filling out the

template at the bottom of the PI and faxing it to the WPC. The WPC will

send out a service kit that consists of 8 pieces of polyurethane tape

(2 pieces per wheel). The part number of this kit is TAC 306.

-

Thanks to Dan Oden |

figure

20

|

| |

| return

to Table of Contents |

|

| Crankcase

and Subsystem Flushing |

Bulletin

04-06-01-029 was recently released to reinforce GM’s position

on system-flushing tools, equipment and procedures.

Please read the bulletin in detail and observe its contents. Highlights

are mentioned here.

Flushing Not in Maintenance Schedule

In normal usage, GM vehicles do not require additional procedures or

additives beyond what’s presented in the former Vehicle Maintenance

Schedules and the current Simplified Maintenance Schedules. Maintenance

schedules do not call for flushing of engine crankcases, fuel injectors,

A/C lines, radiators, transmission coolers, brake systems, or power

steering systems as a part of regular scheduled maintenance.

TIP: Do not confuse

aftermarket flushing machines with the fluid-changing equipment available

from Kent-Moore/SPX. Fluid-changing equipment is designed to aid and

accelerate fluid changing when required, as part of a specific repair

performed, or when directed to do so in the former Vehicle Maintenance

Schedule or current Simplified Maintenance Schedule.

GM Service Instructions

If a specific model vehicle or powertrain need is identified, GM will

issue an Authorized Service Document specifying the procedure, machine,

tool or chemical needed to accomplish the proper vehicle servicing.

An example of this is fuel injector cleaning, which may be necessary

due to fuel quality in different parts of the country. Under normal

circumstances, though, this is not part of the scheduled maintenance

requirements.

Crankcase Flushing

Crankcase flushing is not endorsed or recommended for any GM gasoline

or diesel engine. Some aftermarket materials for this purpose may be

incompatible with engine components, and may damage some engine seals

and bearings. Damage of this sort is not covered under the new vehicle

warranty.

Other Systems

Other subsystems, such as power steering, A/C, or cooling systems may

be flushed after catastrophic failure or extreme corrosion. Specific

bulletins or procedures in SI exist to cover these conditions. Routine

flushing of these systems is not part of the scheduled maintenance requirements. |

|

|

| return

to Table of Contents |

|

| Opening

Trunk without Lock Cylinder |

These

cars don't have rear compartment (trunk) lid lock cylinders:

2004 1/2 - 05 Monte Carlo

2005 LaCrosse/Allure

2005 Grand Prix

2005 Cadillac STS

The following procedures explain how to open the lid on these vehicles

in case of an electrical fault that prevents opening the lid with the

remote keyless transmitter or the interior release switch.

With fold-down rear seat back:

Fold down the seat back. Using a long tool that will reach the rear

compartment latch, operate the release handle and open the lid.

With rear seat back-to-rear compartment access door:

Fold down the access door. Using a long tool that will reach the rear

compartment latch, operate the release handle and open the lid.

Without fold-down rear seat back or access door:

Remove the rear seat cushion, seat back and rear compartment-to-seat

back panel. Using a long tool that will reach the rear compartment latch,

operate the release handle and open the lid.

-

Thanks to the GM SPO Interior Partition |

|

|

| |

| return

to Table of Contents |

|

| Hidden

I/P Trim Screw |

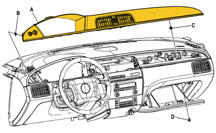

On

the 2005 Buick LaCrosse (Allure in Canada), the instrument panel trim

plate bezel is retained by four clips, one nut and one screw (fig.

21). These are shown in SI document 1538590.

A Trim plate

B Clip

C Nut

D Hidden screw (access behind striker)

Open the IP compartment door and release the check strap. Refer to SI

document 1538593 for procedures.

Use a 10mm socket and extension to remove the hidden screw through the

access hole behind the door latch striker (SI document 1538602, item

4).

TIP: If this

hidden screw is not removed, the trim plate bezel will be damaged.

- Thanks to Wayne Zigler |

figure

21 |

|

return

to Table of Contents |

|

| Roof

Beacon Switch Indicator |

A

2003-05 Chevrolet or GMC Full Size Truck equipped with VYU option (Snow

Plow Provision Package) may not have the roof beacon light connected.

If the customer inadvertently presses the roof beacon switch to the

ON position, the roof beacon indicator will illuminate on the switch.

If the ignition is turned off and the beacon switch is left on, a battery

draw (140 Ma) will occur, evantually causing battery discharge.

The roof beacon switch indicator will not illuminate when the key is

turned off. However, the roof beacon relay is still energized. It's

suggested that the roof beacon switch be turned off before turning the

ignition off to avoid a battery drain.

TIP: If the roof

beacon is not being used, pull the SEO B1 fuse to disable the relay.

This can be done on all vehicles with VYU option except vehicles equipped

with option 8S8 (Speedometer Security) or have an overhead universal

garage door opener.

-

Thanks to Jim Will |

| |

| return

to Table of Contents |

|

| Console

Cupholder and Ashtray |

Owners

of some 2003 -05 GMC Sierra Denali, Yukon Denali/XL and Cadillac Escalade/EXT/ESV

may comment that the center console cupholder and ashtray lid will not

close.

When opening the cover, customers may be incorrectly pulling up on the

cover as opposed to pushing down on the cover to let the automatic release

work properly. During the pull-up motion of the cover, an over-design

force is applied, causing the latch to be pulled out of the retainer

while it is in the lock position.

Replace the latch assembly with p/n 89040109, as well as both the ashtray

door and cupholder door latches. This will eliminate the customer returning

with the same condition.

TIP: Do not re-use

any latch that has become loose. Do not replace the lower bezel assembly.

If the latch is missing during diagnostics, inspect the area inside

the lower console and remove the broken latches, to prevent squeaks

and rattles.

-

Thanks to Jim Will |

| |

| return

to Table of Contents |

|

| Dome

Light Liftgate Operation |

Owners

of some 2005 Chevrolet Equinoxes may comment that intermittently the

dome light does not turn on when the liftgate is opened. This will usually

happen after the vehicle sits for an extended period of time. If the

liftgate is opened after all the modules go to sleep, the dome light

will not come on. The liftgate ajar switch input to the BCM will not

wake up the BCM once it has gone to sleep, so the dome light will not

come on. Once the BCM gets an input to wake it up (from RKE or door

handle), the dome light will turn on when the liftgate is opened.

This is normal operation and no repairs should be made.

-

Thanks to Ron Erman |

| |

| return

to Table of Contents |

|

| Voltmeter

Fluctuation |

Some

customers may comment that their instrument panel voltmeter is fluctuating

between 12 and 14 volts on their new 2005 model year light duty full

size pickup/utility vehicle.

For 2005 model year, light duty full size pickups and utilities, are

equipped with a new Regulated Voltage Control (RVC) system, covered

in the September 2004 TechLink. The RVC system allows changes to vehicle

voltage, up or down, under various scenarios. Battery state of charge

and the vehicle’s present electrical needs are only two of numerous

conditions taken into account.

This will cause the voltmeter to fluctuate between 12 and 14 volts.

By comparison, conventional systems usually maintain a more consistent

reading of 14 volts.

This fluctuation with the RVC system is normal system operation and

no repairs should be attempted.

-

Thanks to Jim Will |

| |

| return

to Table of Contents |

|

| Fifth

Wheel Trailering |

The

2004-05 Chevrolet Silverado and GMC Sierra C/K 1500 Crew Cab with 5'

8" bed is not recommended for fifth wheel trailering.

With a cab-to-axle (CA) distance of 32 inches, there is no available

fifth wheel hitch that will allow the truck and trailer to approach

90° articulation. This means that in parking lot maneuvers and sharp

turns, there will eventually be contact between cab and trailer, and

damage will result to one or both vehicles.

TIP: A CA distance

of at least 52 inches is best (with 8 foot box) for fifth wheel trailing.

The extended pins and sliding 5th wheels were developed in the 1990s

to accommodate short box (6' 6") models with 38 inch CA lengths,

but that is the lower limit.

-

Thanks to Jim Will |

| |

| return

to Table of Contents |

|

| Upper

Radiator Hose Coolant Leak |

On

some 2004-05 Chevrolet Express and GMC Savana vehicles, the upper radiator

hose may have a coolant leak, because it has rubbed through on the fan

shroud.

If the upper radiator hose (p/n 25757841) needs to be replaced, it will

be necessary to cut 50mm (1.9 in.) off the radiator end of the hose.

This will prevent the upper radiator hose from rubbing on the fan shroud.

-

Thanks to Ron Erman |

| |

| return

to Table of Contents |

|

| Corvette

I/P Compartment Door |

Owners

of some 2005 Corvettes may comment that the I/P compartment door appears

warped and extends outward near the center IP. This may be caused by

the torque sequence when the door is installed by the plant.

To correct the condition, loosen the attaching screws at the bottom

of the door. Then retighten the screws, beginning with the outboard

screw, the one on the right side and then the inboard screws.

-

Thanks to Paul Radzwilowicz |

| |

| return

to Table of Contents |

|

Car Issues

— Fix It Right the First Time (new issues in bold) Car Issues

— Fix It Right the First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2005 |

Equinox

LT/LS (AWD Only) – Moan, Bind or Growl Coming from Rear

during Low Speed Parking Lot Turns |

Replace

RDM coupling (clutch pack) with proper sealers. Fill with Versatrak

fluid. |

Don’t

replace complete rear drive module. |

04-04-20-004 |

2005 |

Cobalt

(Built Before 01-17-05) – Fuel Gauge May Not Go Completely

to Full |

Recalibrate

ECM with updated calibration, version 1.75. |

Don’t

replace fuel module, fuel level sensor assembly or fuel gauge. |

05-08-49-002A

|

2003-2004 |

Cavalier,

Sunfire – HVAC Control Head, Difficult to Adjust the Mode

Dial |

Replace

foam delaminated from mode door which can cause

bind condition. |

Don’t

replace HVAC control head, module or cables, unless damaged. |

03-01-38-005B

|

2002-2005 |

Cars

and Trucks – Multiple Driveability Symptoms/Clogged Fuel

Injectors |

Clean

fuel injectors as described in Bulletin. |

Don’t

replace fuel injectors. |

03-06-04-030A |

2004-2005 |

Grand

Prix – Outside Rearview Mirrors |

Replace

glass or motor, whichever is defective. |

Don’t

replace complete mirror assembly. |

04-08-64-009 |

2004 |

Grand

Prix – Steering, Suspension or Cradle Click Noise |

Install

new two-piece sleeve and spacer to steering gear mounts. |

Don’t

replace steering gear or cradle. |

03-02-32-048A |

2000-2003 |

Century,

Regal, Lumina, Impala, Monte Carlo, Grand Prix, Intrigue with

3.8L L36 Engine – Coolant Leak |

Replace

upper intake manifold gasket only. |

Don’t

replace upper intake manifold assembly for coolant leak condition. |

03-06-01-016 |

2001-2004 |

Aztek

(01-04), Rendezvous (FWD, 02-04), Venture/Montana/Silhouette (01-04)

– Pop and/or Rattle in Exhaust Down Pipe |

Follow

procedure in bulletin using clamp P/N on down pipe to correct

rattle/buzz noise. |

Don’t

replace converter assembly for rattle/buzz noise without completing

instructions in bulletin. |

03-06-05-003

|

2000-2004 |

Cavalier/Sunfire/Alero/Grand

Am – Inoperative Sunroof Module |

Retime

module or replace only motor. |

Don’t

replace entire sunroof module assembly. |

03-08-67-009A |

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

Issue

One: Refinish brake rotor.

Issue Two: Measure for LRO |

Issue One: Don’t replace brake rotors.

Issue Two: Don’t measure for LRO |

00-05-22-002D |

|

| return

to Table of Contents |

|

|

Truck

Issues — Fix It Right the First Time

(new issues in bold) Truck

Issues — Fix It Right the First Time

(new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2002-2005 |

Tahoe, Suburban, All Yukons, All Escalades, Avalanche, H2 –

Exhaust Pop/Ping Noise |

Replace

heat shield. |

Don’t

replace exhaust system. |

03-06-05-008B |

2005 |

All Escalades, Tahoe, All Yukons, Suburban, Avalanche, All TrailBlazers,

All Envoys – Adjustable Pedals Don’t Recall Preset

Positions and/or Front Heated Seats Turn Off After 30_Seconds |

Replace

brake pedal position switch. |

Don’t

replace brake pedal assembly. |

05-08-143-001 |

2003-2005 |

Full Size Pickups and Utilities – Snap/Popping Noise from

Front of Vehicle |

Slot

left side mounting holes on front crossmember using procedure

in Bulletin. |

Don’t

replace crossmember. |

03-08-61-002B |

2002-2004 |

Chevrolet

Silverado, GMC Sierra – Accumulator/Accumulator Bracket |

Replace

accumulator and/or accumulator bracket. |

Don’t

replace compressor. |

02-01-38-007C |

2004 |

Tahoe, Suburban, Silverado, Yukon, Yukon XL, Sierra, Escalade,

Escalade EXT, Escalade ESV, H2 – Passenger Door Module and

RKE Inoperative |

Re-flash

passenger door module. |

Don’t

replace passenger door module. |

04-08-52-005 |

2001-2003 |

Fullsize

Pickups – Injector Replacement for High Flow Rates |

Use

Corporate Bulletin Number 04-06-04-007A for injectors with high

fuel return rates. Use Special Policy 04039 for all 01-02 vehicles. |

Don’t

replace 8 injectors for complaint other than high fuel return

rates. All other injector failures are fix as failed. |

|

| 2004-2005 |

All

Cars and Trucks – State-of-Charge Upon Delivery of a New Vehicle |

Check

battery’s state-of-charge per revised PDI procedure using

Tester, J 42000 or J 42000-EU. |

Don’t

remove and replace battery. |

02-06-03-009A |

| 2002-2004 |

Fullsize

and Midsize Pickups and Utilities – Labor Operation Assignments

for Control Module Reprogramming |

When

submitting claims for reprogramming an electronic module, use correct

labor operation that reflects the module being programmed. |

Do

not use K5364, which is for reprogramming transmission control module

(TCM), when reprogramming TCCM. |

02-04-21-006D

02-06-04-057D |

| 2002-2004 |

Chevrolet

Avalanche and Cadillac Escalade EXT – Cargo Covers and Cladding

Faded or Stained |

Thoroughly

clean, dry and treat components with “Armor-dillo.”

|

Don’t

replace cargo covers for this condition. |

04-08-111-001B |

2001-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed. |

Don’t

replace complete mirror assembly. |

03-08-64-028 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for April |

| |

|

| Know-How

Broadcasts for April |

| 10290.04D

Emerging Issues |

April

14, 2005, 9:00 AM, 12:30 PM, and

3:00 PM Eastern Time |

| New

Model Features and Technology Close-Up seminars |

Stay

tuned! These programs will return soon. Check the Service

Know-How section of the GM Training website (www.gmtraining.com)

for more details. |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

figure

17

figure

17 figure

18

figure

18 figure

19

figure

19

Car Issues

— Fix It Right the First Time (new issues in bold)

Car Issues

— Fix It Right the First Time (new issues in bold)

figure

4

figure

4

figure

6

figure

6

figure

14

figure

14

Truck

Issues — Fix It Right the First Time

(new issues in bold)

Truck

Issues — Fix It Right the First Time

(new issues in bold)