|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Sunroof

System |

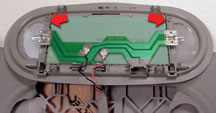

This

information applies to the sunroof system available in the Colorado

and Canyon pickup trucks (fig. 1).

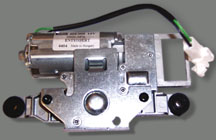

Controls

The power sunroof system is a press-and-hold style system, with no control

module involved. The power sunroof motor is controlled by the sunroof

switch through the open and close motor control circuits.

Ignition voltage is supplied to the sunroof switch (fig.

2) through the retained accessory power (RAP) relay from the

Sunroof 20A fuse in the underhood fuse block. While the sunroof switch

is in an inactive state, both switch contacts are closed to the sunroof

switch ground circuit. When an open or close button is pressed on the

sunroof switch, its switch contact is closed to the voltage supply circuit.

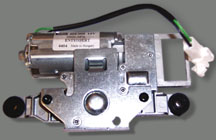

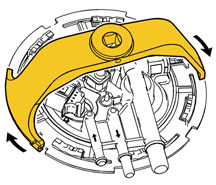

The motor is bi-directional (fig. 3), and

the direction of motor rotation is determined by which of the motor

control circuits is switched to positive voltage while the other remains

grounded.

Operation

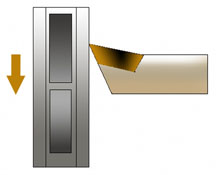

The glass travels from closed to vent to full open position, and can

be stopped in any position by releasing the sunroof switch. As the glass

reaches the open or closed limits, mechanical hard stops inhibit the

travel (fig. 4). The mechanical hard stops

stall the motor into an over-current condition, as an internal motor

device opens. Operation will resume once the over-current condition

is removed, by releasing the sunroof switch.

The glass travel for a regular cab is restricted by panel stops inserted

into the guides. The panel cannot extend beyond the rear edge of the

cab into the bed area. The extended cab and crew cab do not have these

panel stops.

The sunroof can be operated manually with the sun roof emergency crank/sunroof

key. The key and instructions can be found in the owner’s manual

supplement in the glove box.

Other Items of Interest

The sunroof system ground is in the vicinity of the motor, with a self-tapping

screw securing the ring terminal to the front header.

The in-line connector supplying the ignition voltage to the sunroof

switch is located behind the left A-pillar trim (fig.

5).

-

Thanks to Tony Martin |

|

figure

1 |

figure 2

|

figure

3 |

figure

4 |

figure

5 |

| return

to Table of Contents |

|

|

| Cadillac

ECM Reprogramming |

When reprogramming the engine control module on a 2004-2005 Cadillac

SRX, XLR, and STS with LH2 4.6L V8 engine, the following points may

be helpful:

1. The battery must be fully charged during reprogramming. Battery voltage

must be above 12 volts. Turn off electrical accessories that may drain

the battery during reprogramming, such as automatic headlamps, daytime

running lamps, interior lights, HVAC system, engine cooling fan, radio,

etc.

2. Ambient and coolant temperature during reprogramming should be above

41° F (5° C). If coolant temperature is below this, the vehicle

will go into reduced power mode on startup, due to insufficient throttle

learn.

3. A P2119 DTC may set after reprogramming due to low system voltage.

4. If the VIN is not properly entered into the ECM, a P0315 will continue

to set until the ECM VIN matches BCM.

5. Any time an ECM, crank sensor, crankshaft and/or engine are replaced,

a crankshaft position variation learn procedure must be performed.

6. After performing a crankshaft position variation learn procedure,

the ECM must do a proper power-down to store the values, or a P0315

will continue to set until values are stored.

Refer to Service Programming System in SI for more information on reprogramming

the ECM and performing the crankshaft position variation learn procedure.

- Thanks to Dave Dickey |

| |

|

|

| |

|

|

Air Bag Module Checkout |

TIP:

This information applies to all vehicles, although it is prompted by

warranty data from Sunfire, Cavalier, Grand Am, Alero and Malibu Classic.

Extra attention is needed if a vehicle comes in for service with the

air bag telltale illuminated. After reading diagnostic trouble codes

and finding that air bag loop faults and/or sensor faults are current,

take the time necessary to troubleshoot the wiring fully. Replacing

the SDM (fig. 6) will not correct the fault

in many situations. A detailed check of continuity for the faulted lines

is necessary.

TIP: Check all

wiring connections before removing and replacing the SDM.

-

Thanks to Tom Nguyen |

figure 6 |

return

to Table of Contents |

|

| Dexron

VI Followup |

As

a followup to the Dexron VI article in the February TechLink, here are

the current part numbers.

88861003 |

1

quart container |

DEXRON®

-VI

GM Vehicle Care |

88861037 |

1

quart container |

DEXRON®

-VI

AC Delco |

88861004

in Canada |

1

liter container |

DEXRON®

-VI

AC Delco |

GM

began factory-fill of the new transmission fluid on April 4, starting

with the new Hydra-Matic 6L80.

DEXRON®-VI will be available at GM authorized dealerships and service

centers in Summer 2005.

-

Thanks to Susan Leach |

|

| return

to Table of Contents |

|

| Upper

Manifold Gasket Leak |

This information applies

specifically to the 5.3L L59 (E85 capable), as well as the other Gen

3 and Gen 4 engines.

If a leak between the upper manifold and gasket causes a DTC P0300 to

set, do not replace the entire upper manifold assembly, upper plenum

and gaskets.

A new gasket made of FNK material (GM SPO p/n 89017589) has been released.

The new gasket material is teal green in color (fig.

7); the original gaskets are orange.

The service kit containing the new gasket was released in October 2004.

A small quantity of the old gasket kit, p/n 17113557, which contains

two p/n 17122608 (orange) gaskets, remains in the system.

Use only the 89017589 gasket (teal green) for repairs on the L59 engine,

and do not replace the upper manifold unless it measures outside of

the service manual specifications or is damaged.

The 17113557 gasket (orange) can be used on the other engines. Once

the 17113557 has been exhausted, only the 89017589 will be available

for all engines. |

figure

7 |

| return

to Table of Contents |

|

| Proper

Method of Measuring Intake Manifold |

SI

states, "An intake manifold with warpage in excess of 3 mm (0.118

in) over a 200 mm (7.87 in) area is warped and should be replaced."

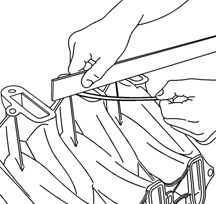

The 200 mm distance will cover two intake ports (fig.

8), not the entire distance of the four intake ports on one bank.

It is incorrect to place a straight edge across the

entire length of the upper manifold, along all four intake runners,

and then replace the manifold when all the runners are not adjacent

to the straight edge.

Unless there is visible physical damage to the upper manifold, or it

measures outside of the service manual specification of greater than

3 mm over 200 mm, it should not be replaced. |

figure

8 |

| return

to Table of Contents |

|

| Sunshade

Vanity Mirror Replacement |

This information pertains to the 2004-2005 Chevy Malibu, Malibu Maxx,

and Pontiac G6.

Customers may comment that the vanity mirror cover breaks during normal

operation. Replace the vanity mirror assembly rather than the entire

sunshade assembly.

The following procedure may be completed inside the vehicle for non-lighted

sunshades. For lighted vanities, remove the sunshade from the vehicle.

Refer to the Sunshade Replacement procedure in SI.

Insert finger tips or a plastic trim tool tool at the tab locations

to disengage the vanity mirror assembly from the sunshade assembly

(fig. 9).

For sunshade assemblies with non-lighted vanities, snap the new vanity

assembly into the sunshade assembly.

For lighted vanities, transfer the circuit board to the new vanity mirror

assembly.

Remove the circuit board from the vanity assembly (fig.

10).

TIP: Slightly

flex the vanity mirror assembly to release the circuit board from the

retaining tabs.

Install the circuit board to the new vanity assembly and route the wire

leads through the wire guides (fig. 11).

Snap the vanity mirror assembly into the sunshade assembly and install

the sunshade to the vehicle.

Parts will be available from GMSPO. Watch for an upcoming service bulletin.

-

Thanks to Joel Ebner |

| |

figure

9 |

figure

10

|

figure

11 |

| |

|

| Programmable

Truck Radios |

This

information applies to 2003-2005 C/K Trucks and Utilities and 2004-2005

S/T Trucks and Utilities. Service programming of the radio on these

vehicles requires the part number of the radio and the appropriate RPO

codes. You can reduce time in programming replacement radios on these

vehicles by following these steps.

1. Before installing a replacement radio, obtain the GM part number

from the label on the radio.

2. Verify that your Tech 2 has the latest software version.

3. Using the Tech 2, "Request Info" from the radio that is

going to be programmed. Always follow proper procedures and precautions.

4. Before entering TIS2000, enter your VIN into GM VIS to obtain the

RPO codes of the radio and speaker configuration for this vehicle. (For

example, verify if the vehicle was built with UQ3, UQ5, or UQ7 speakers,

with or without Y91/Y92.)

TIP: This will allow you to make the correct calibration

selections in TIS2000. Selecting the incorrect calibrations for your

vehicle configuration can damage the radio and lead to unnecessary delays

in repair time.

5. When replacing or installing a NEW radio, you must select "Replace

and Program Module" from the TIS menu.

6. Program the vehicle as usual.

TIP: If you are a valid GM dealer and require assistance

with this procedure, please contact the Techline Customer Support Center

(TCSC).

-

Thanks to Abby Slagor |

|

|

| |

| return

to Table of Contents |

|

| Tire

Pressure Monitor |

A

Tire Pressure Monitor (TPM) system was added to certain GMC and Chevrolet

full-size utility trucks for model year 2004 and continues for 2005.

The same style system will be rolled out on additional vehicles in 2006.

To help you understand this system, a Know-How video was prepared:

Course 10290.04D

Understanding TPM Systems for GM Trucks

March 2005 Emerging Issues

Here are some highlights. For details, refer to the video. A proper

understanding of the system, its components, and its operation will

help you properly diagnose operating conditions. You will learn to determine

when parts replacement and reprogramming are or are not required to

remedy the condition.

TPM System Components

The main TPM system components are:

- DIC

- Passenger Door Module (PDM)

- Instrument Panel Cluster

- 4 pressure sensors

- Serial data circuit

Tire Pressure Sensor Operation

The tire pressure sensors are incorporated into the valve stem of each

road wheel. The pressure sensor transmits a radio frequency message

which is received by a module in the vehicle.

When the vehicle is stationary, the sensor’s internal roll switch

is open, which puts the sensor into stationary mode. The sensor samples

tire pressure once every 30 seconds and transmits once every 60 minutes.

When the vehicle is moving, centrifugal force closes the sensor’s

internal roll switch, which puts the sensor into drive mode. The sensor

samples tire pressure every 20 seconds and transmits every 60 seconds.

Passenger Door Module (PDM) Operation

The PDM is the receiver in the full-size utility truck. The receiver

module varies by vehicle platform. The PDM receives each sensor’s

RF (radio frequency) transmission and translates the data into:

- sensor presence

- sensor mode

- tire pressure.

TIP: If the vehicle

is equipped with RPO UK3, the PDM sends tire pressure and tire location

data over the serial data circuit to the DIC, where they can be selected

and displayed.

In addition to the display of tire pressures, the DIC in full-size utility

trucks can also display two system messages -- “Check Tire Pressure”

and “Check Tire Monitor”. Here are the important differences.

“Check Tire Pressure” message -- If a sensor

detects a 1.6 psi (11 kPa) change in pressure, it transmits in re-measure

mode. If the system detects a significant loss of tire pressure in any

tire, the Check Tire Pressure message is displayed on the DIC and the

low tire pressure indicator is illuminated on the IPC.

TIP: A “Check

Tire Pressure” message will not set system codes. This is normal

operation of the system. The purpose of this message is to alert the

driver to check and adjust tire pressure.

TIP: Both the

message and indicator can be cleared by adjusting the tire pressure

to the recommended pressure.

“Service Tire Monitor” message -- If the

PDM detects a malfunction in the TPM system, it will cause the DIC to

display the Service Tire Monitor message.

TIP: The “Service

Tire Monitor” message is not a normal system operation. DTCs should

be set when this message is displayed.

Tire Pressure Sensor Relearn

DIAGNOSTIC TIPS:

- Try to determine from the customer which message has been displayed.

This is especially important when you cannot find TPM system related

DTCs stored.

- Always check and adjust the tire pressures COLD. As a rule of thumb,

tire pressure will change one psi for every 10° F (6.9 kPa for every

5.6° C).

- Always use a known accurate tire pressure gauge.

- Always ‘relearn’ the system before replacing a suspect

sensor.

Tech 2 Readouts

The Tech 2 can be used for Tire Pressure monitoring information and

functions:

- Display tire sensor IDs

- Display tire sensor mode

- Display tire pressure

- Initiate the TPM Learn procedure

- Set up or change tire pressure placard value for the vehicle

- Set up a Passenger Door Module for TPM operation. A service PDM does

not come ready for use with TPM. This function must be enabled when

a replacement PDM is installed.

When to Perform a Tire Pressure Relearn

The tire pressure sensor relearn procedure must be performed after every

PDM replacement, every sensor replacement, and every tire rotation.

Once the TPM learn mode has been enabled, each of the sensors’

unique ID codes can be learned into the PDM’s memory. There are

two ways to excite the sensors and enter the learn mode.

Pressure Change Method -- This is performed by increasing

or decreasing the air pressure in each tire by a specified amount, which

forces the sensors to transmit in re-measure mode.

TIP: This method

can be reviewed in SI and can also be viewed on the GM Common Training

Website.

J-46079 TPM Diagnostic Tool Method -- Turn the ignition

ON with the engine OFF, and set the parking brake. Place the PDM in

TPM learn mode by cycling the parking lamps ON and OFF 4 times within

4 seconds. The horn will chirp and the low tire pressure indicator will

begin to flash. This indicates the learn mode has been enabled.

Proceed in this order: left front, right front, right rear, left rear.

Starting with the left front tire, hold the antenna of the J-46079 against

the tire sidewall close to the wheel rim at the valve stem, and momentarily

press the activate button.

After the horn chirps, repeat the procedure for the other three wheels.

After all of the sensors have been learned, exit the learn mode by turning

the ignition OFF.

TIP: Before starting

this procedure, ensure that no TPM equipped vehicle nearby is having

its sensors relearned simultaneously, or its tire pressures adjusted.

It is possible for the PDM to learn a stray learn or re-measure mode

transmission from another vehicle’s sensors.

TIP: When a sensor

is changed or relearned, the vehicle must be driven above 20 mph (32

km/h) for the DIC to update.

Sensor Color

In early 2005, sensor part numbers and colors were changed. The 2004

and some early 2005 trucks have a blue color sensor, and most 2005 trucks

have a beige color sensor. If you find an early 2005 truck with blue

sensors, it is not necessary to replace them with beige ones.

Tool Tip

Here’s a tip regarding your J-46079 TPM Diagnostic Tool (fig.

12).

When the internal battery is fresh (fully charged), the indicator is

“full,” or all dark. When the battery is depleted, the indicator

shows “empty,” or all light.

When the battery is low enough to show empty, the tool may perform some

functions, but not others. For instance, it may perform the Simulate

function, but not the Learn function. If you cannot get a vehicle to

learn, don’t assume the sensors are bad. The tool may just need

a fresh battery.

- Thanks to David Roland and Ken Beish |

| |

| |

| |

| |

| |

| |

| |

| |

figure

12

|

| return

to Table of Contents |

|

| Fuel

Pump Module Lock Ring |

At the start of the 2004 model year, a new 130mm corporate fuel pump

module lock ring was introduced on numerous vehicle programs. In the

future, this fuel pump module lock ring will become standard for all

vehicles requiring a 130mm (5.1 inch) opening for the fuel pump module.

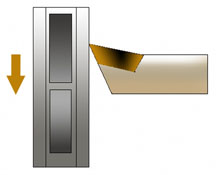

During the engineering development of this lock ring, a J-45722 tool

was created to remove and install the lock ring (fig.

13). The tool is necessary because of the increased installation

forces required to install the ring.

TIP: Never use

any tool other the J-45722 to remove or install the 130mm lock ring.

Never use impact tools with J-45722.

If improper tools such as screwdrivers, chisels, drifts, hammers, or

prybars are used in removal and installation, the lock ring will be

damaged (fig. 14), possibly degrading the

fuel pump module sealing. Damage to the ring may also create sharp edges

that may, in turn, damage the fuel tank. Damage to the tank and sealing

degradation can result in customer comebacks and dissatisfaction.

On some vehicles, the lock ring is captured on the fuel pump module

by line connections or swaged-on lines. In these cases, the lock ring

cannot be removed from the module and cannot be serviced individually.

Some examples of this are the 2004-06 Chevrolet Malibu and MAXX, and

the 2005-06 Pontiac G6. If the lock ring on one of these applications

is damaged, the entire fuel pump module assembly must be replaced.

Inspection of replaced lock rings at the Warranty Parts Center indicates

that numerous 130mm lock rings are being damaged and destroyed by improper

installation and removal methods.

When removing the lock ring, it is important to inspect it for damage

due to improper removal or installation procedures. If damage is found,

install a new lock ring (or the fuel pump module in captured-ring applications).

Don’t replace the lock ring unless it shows damage at the tool

notches or distortion greater than the 0.41mm specification.

On applications where it is possible to remove the lock ring from the

fuel pump module, place the ring on a flat surface and measure for flatness.

Measure even if damage is not readily visible.

1. Place the lock ring on a flat surface. Measure the clearance between

the lock ring and the flat surface using a feeler gage at 7 points (fig.

15).

2. If the warpage is less than 0.41 mm (0.016 in), the lock ring does

not require

replacement.

3. If the warpage is greater than 0.41 mm (0.016 in) the lock ring must

be replaced.

TIP: Some lock

rings were manufactured with DO NOT REUSE stamped into them. These lock

rings may be reused if they are not damaged or warped.

- Thanks to David MacGillis and Ken Billette |

figure

13 |

figure

14

figure

14 |

figure

15 |

|

return

to Table of Contents |

|

| Distorted

Rear Fascia |

On a 2000-05 Cadillac DeVille, a distorted or

warped rear fascia may appear after the vehicle has been exposed to

high ambient temperatures. This condition is more prevalent on darker

colors. To correct, replace the rear fascia and follow the repair procedures

outlined in Bulletin 02-08-62-002B, issued on March 10, 2005.

-

Thanks to Bill Denton |

|

|

|

return

to Table of Contents |

|

| Opening

Trunk without Lock Cylinder -- Part 2 |

An

article in the March TechLink discussed how to open the rear compartment

lid of vehicles that don’t have an external lock cylinder, in

case of a fault that prevents using the remote keyless entry or interior

switch. Here’s some additional information.

In the 2004 - 05 Pontiac GTO, there is a secondary trunk release handle

located under the passenger side rear seat head restraint. To access

this handle, lift the head restraint and pull the yellow ring. The vehicle

must not be moving.

-

Thanks to Art Spong and Ken Haneline |

|

|

return

to Table of Contents |

|

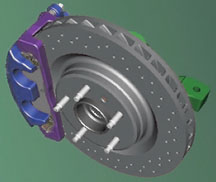

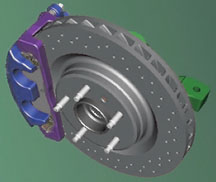

| Cross-Drilled

Rotors |

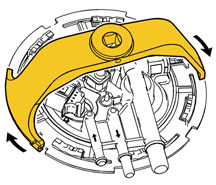

Cross-drilled brake rotors (fig.

16) are being used on the 2005 1/2 Pontiac Grand Prix GXP, and

available on the 2005 Chevrolet C6 Corvette and the upcoming Cadillac

XLR-V.

If required, these brake rotors can be machined on a lathe in a similar

manner to standard rotors.

TIP: When cutting

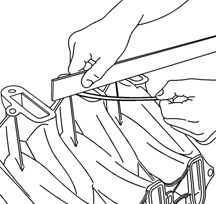

rotors, use positive rake tooling on the lathe (fig.

17). Positive rake tooling requires less cutting pressure, reduces

chatter, and improves surface finish. When setting up the brake lathe,

be sure to use a vibration dampener/silencer.

Using SI procedures, apply a non-directional finish to the rotor surface

after machining by using a sanding block and 150-grit aluminum oxide

sandpaper.

-

Thanks to Fred Tebbets and Rob Coultes |

|

figure

16

|

figure

17

figure

17 |

| return

to Table of Contents |

|

| A/C

System Break-in Process |

Follow

the recommended break-in process mentioned in bulletin 05-01-38-002

to avoid premature A/C compressor wear in the 2005 Vibe A/C system (fig.

18).

Lack of proper lubrication to the new A/C compressor may cause premature

wear or failure in certain conditions on some vehicles in new vehicle

inventory.

This condition is caused by refrigerant system oil migration (causing

compressor wash-out), which occurs on brand new vehicles that have not

had the A/C system on for an extended period of time (typically greater

than 100 days). For vehicles in this category, the A/C system should

not be run until the A/C compressor oil circulation procedure has been

performed.

This condition is not a quality problem that can be fixed simply by

the replacement of the compressor or by the addition of refrigerant

oil to the system. It is a condition caused by the vehicles sitting

outside, in the sun, for extended periods of time. This thermal cycling

causes the oil in the A/C compressor to migrate to the other A/C system

components. Furthermore, this condition does not occur on any A/C components

stored in parts inventory, such as A/C compressors. Continue to use

all service components for this vehicle as normally instructed.

A/C System Oil Circulation Procedure

Do not add additional refrigerant oil to the A/C system.

Perform A/C system operation to ensure proper lubrication of the A/C

compressor during the initial vehicle storage period.

Perform the following sequence to ensure proper lubrication of the A/C

compressor during new vehicle extended periods of inoperation. It is

required that this procedure be performed early in the morning when

the vehicle is cold and the ambient temperature is moderate -- approximately

50°F (10°C).

1. Make sure the air conditioning (A/C button) is off.

2. Put the mode selector in vent mode.

3. Start the vehicle and let engine RPM idle down to slow idle (1000

RPM or less).

4. Adjust the HVAC blower setting to high.

5. Turn on the A/C and allow the system to run for 90 seconds. This

gradual A/C system operation period will allow refrigerant oil to return

to the A/C compressor during critical initial break-in period.

6. Perform A/C system performance check.

IMPORTANT: The

A/C system on this vehicle will not operate when the ambient temperature

is below 35° F (2° C).

It is recommended that vehicles be started and the A/C system operated

(for at least 90 seconds) once per month to ensure proper A/C system

function until the vehicles are delivered or until the vehicle is driven

on a regular basis. Normal operation of the A/C system by the vehicle

owner will allow for sufficient compressor break-in and the oil circulation

procedure should no longer be required.

-

Thanks to Jeff Strausser |

figure

18

figure

18 |

| return

to Table of Contents |

|

| ABS

And Brake Lights |

On

the 2005 Chevrolet Equinox, the ABS and the brake lights may be on with

no codes set. The vehicle may not have come in for this concern. The

ABS and brake lights may have come on after clearing codes in another

module for an unrelated concern. When the Tech 2 is used, it will show

the EBTCM is commanding the lights on. The condition occurs because

the BCM is no longer broadcasting VIN digits 2-9 on the high speed bus.

1. Disconnect the battery cables from the battery and touch the cables

together for 30 seconds, then reconnect the cables.

2. Check to see if the ABS and brake lights are off, and no codes are

set. Check that you can read the whole VIN using the Tech 2.

3. If the ABS and brake lights are still on with NO codes set, follow

the flow chart for ABS Active Indicator Always On (SI document 1318351).

-

Thanks to Ron Erman and Angelo Girolamo |

|

|

| return

to Table of Contents |

|

| Emblem

Coming Off Grille |

Owners

of some 2004-05 Buick Rainiers may comment that the Buick emblem (fig.

19) on the grille has come off and is missing.

The clips may not be retaining the emblem to the grille mounting surface.

Replace the emblem by aligning the retaining tabs with the slot in the

grille and apply pressure to the emblem, p/n 89045663, described as

a Emblem Assembly - Radiator Grill. Parts are available from GMSPO.

This is covered in detail in bulletin 05-08-111-001 or SI document 1580217.

-

Thanks to Doug Daugherty |

figure

19

figure

19 |

|

return

to Table of Contents |

|

| 2005

Gasoline Engine Oil Requirements -- Additions |

2005

GM gasoline engines require the use of an engine oil that has the American

Petroleum Institute (API) Starburst AND states that it meets GM Standard

GM 6094M (non-synthetic) or GM4718M (synthetic). Failure to use the

recommended engine oil can result in engine damage not covered by warranty.

In the March issue, TechLink published a list of engine oil brands that

meet GM Standard GM 6094M and 4718M. This list has be updated through

April 12, 2005 and may be viewed in the TechLink Reference Guide at

http://service.gm.com.

TIP: This list

will be updated in the future as required, and will continue to be displayed

in the TechLink Reference Guide.

-

Thanks to Matt Snider, GM Powertrain |

|

|

| return

to Table of Contents |

|

| Synthetic

Oil Question |

We

recently received this e-mail from Mike McQuoid, at Norman Gale Pontiac

GMC, Cedar Knolls, NJ:

“In the March 2005 issue of TechLink, there is a list of motor

oils approved by GM for use in gasoline engines. I'm curious why so

many “full synthetic” oils are listed in the “non-synthetic”

list and not in the synthetic list.”

Here’s the answer from GM Powertrain:

“GM4718M is General Motors' High Performance engine oil specification.

Oils which meet GM4718M tend to be made from synthetic base stocks,

so it is often referred to as a "synthetic" specification.

“However, not all oils, synthetic or otherwise, are capable of

meeting the stringent requirements of GM4718M. Only the oils listed

on the GM4718M Registered Products sheet have proven their performance

to the specification.”

-

Thanks to Matt Snider, GM Powertrain |

| |

| return

to Table of Contents |

|

| OnStar

Personal Calling Inoperative |

Some

owners of the 2005 STS may comment that OnStar personal calling with

Navigation Radio RPO YQ4 does not work when using the voice recognition

button on the Steering Wheel Controls (SWC). Personal calling will work

from the white dot button on the Inside Rear View Mirror (ISRVM). 2005

Cadillac STS equipped with Navigation Radio RPO YQ4 have Bluetooth phone

capabilities. When pressing the voice recognition button on the steering

wheel controls and saying "phone," "telephone" or

"dial," the system will attempt to connect to the Bluetooth

phone.

In order to connect to OnStar personal calling using the SWC voice recognition

button, the owner must say "OnStar" and then "dial."

-

Thanks to Roger Jantz |

| |

| return

to Table of Contents |

|

| Power

Folding Top (Retractable Hardtop) |

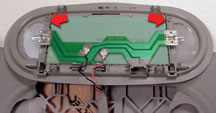

If

the power folding top (fig. 20) of the 2004-05 Cadillac XLR will

not function,

perform the following.

1. Start the engine and try the top again. This ensures the vehicle’s

battery is sufficiently charged.

2. While depressing the folding top button in the desired direction,

look at the Driver Information Center (DIC) for a message. If a message

is displayed, see DIC Warnings and Messages on page 3-61 in the owner’s

manual for more information.

TIP: Most messages

relating to top operation are displayed only while the folding top button

is depressed.

3. If no messages are displayed and the folding top will not operate,

perform the Power Window Initialize on page 2-17 of the owner’s

manual. The folding top system must know the window position to operate.

The position information can be lost if the vehicle has had a battery

disconnect or a run down battery. After performing this procedure, try

the top again.

4. It the top doesn’t operate, confirm that the hydraulic fluid

bypass valve, located above the pump motor, is in the operating position

(turned clockwise).

5. If the folding top will still not operate, see SI for additional

diagnosis.

-

Thanks to Paul Radzwilowicz |

|

figure

20

|

| return

to Table of Contents |

|

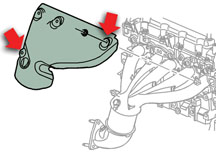

| Exhaust

Manifold Shield Noise |

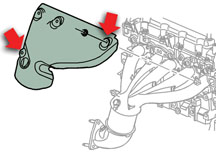

Owners

of some 2004-05 Chevrolet Colorado and GMC Canyon vehicles with the

3.5L engine may experience a buzz noise while the engine is under load

between 2200 and 2800 RPM. The noise sounds like it is coming from the

engine compartment (may sound like it is coming from the air cleaner

area) or the exhaust system.

Inspect the exhaust manifold for a loose exhaust heat shield. Inspect

all fastener positions, with emphasis on the nut above the O2 sensor

and the nut on the No. 1 exhaust tube (fig. 21).

Make sure the shield itself is not in direct contact with the manifold

other than at the fastener positions. Reposition the shield if necessary

to avoid contact.

-

Thanks to Dino Poulos |

|

figure

21

|

| return

to Table of Contents |

|

| Torque

Converter Assembly Design Change |

There

is a 4T80E Transmission Torque Converter Assembly Design Change in 2005

Cadillac Deville and Pontiac Bonneville.

Vehicles with the VIN listed below are built with automatic transmissions

that have a new broadcast code and transmission assembly part number.

These transmissions are built with an Electronically Controlled Capacity

Clutch (ECCC or EC3), a new upper control valve body assembly, a new

upper control valve body spacer plate, and a new powertrain control

module calibration.They will not have a viscous fluid converter.

VIN |

Model |

Transmission

Serial Number |

5U189285 |

GXP |

616MMNH0152 |

5U189290 |

DeVille |

616ABNH014H |

5U189292 |

DeVille |

616ABNH014F |

5U189298 |

DHS |

616ABNH014G |

5U189300 |

DeVille |

616ABNH014J |

5U189305 |

DeVille |

616ABNH0146 |

5U189309 |

DeVille |

616ABNH0145 |

5U189313 |

GXP |

616MMNH0154 |

5U189316 |

DeVille |

616ABNH0140 |

5U189319 |

DeVille |

616ABNH013Z |

5U189321 |

DeVille |

616ABNH0149 |

5U189322 |

DeVille |

616ABNH0134 |

5U189326 |

DeVille |

616ABHN0143 |

5U189328 |

DHS |

616ABNH0144 |

5U189331 |

DeVille |

616ABNH0147 |

5U189333 |

DHS |

616ABNH0148 |

5U189334 |

DeVille |

616ABNHO148 |

5U189342 |

DTS |

616MMNH0151 |

5U189356 |

DTS |

616MMNH0155 |

5U189363 |

GXP |

616MMNH0153 |

5U210345 |

DeVille |

615ABNH013Q |

5U210348 |

DeVille |

615ABNH013T |

5U210344 |

DeVille |

615ABNH013P |

5U210340 |

DeVille |

615ABNH013S |

5U210341 |

DeVille |

615ABNH013R |

Use

the current MY 2005 service information and diagnostic procedures for

transmission service requirements. All warranty labor codes and time

allowances remain the same.

IMPORTANT: When

ordering parts for these vehicles, the vehicle VIN, the transmission

broadcast code and the transmission assembly part number must be used.

Remanufactured torque converter part number for transmission code 5ABN,

3.11 axle ratio is 12491371. Remanufactured torque converter part number

for transmission code 5 MMN, 3.71 axle ratio is 12491372.

-

Thanks to Ronald Mitchell |

| |

| return

to Table of Contents |

|

Car Issues

— Fix It Right the First Time (new issues in bold) Car Issues

— Fix It Right the First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2003-2004 |

CTS

– DTC C0450 or C1241 Set, Service Steering System Message

On |

Replace

only VES solenoid. |

Don’t

replace entire steering gear. |

03-02-36-001A |

2003-2004 |

Cavalier,

Sunfire – Difficult to Adjust HVAC Control Head Mode Dial |

Replace

foam which delaminated from mode door and is causing bind. |

Don’t

replace HVAC control head, module or cables unless damaged. |

03-01-38-005B |

2002-2003 |

Impala

– Snap/Clunk When Window is Rolled to Full Up Position |

Replace

glass run channel with revised P/N. |

Don’t

replace front door window regulator, door glass or align door

glass. |

03-08-64-034 |

2003-2004 |

Cavalier,

Sunfire – Noisy A/C Compressor |

Inspect

for ground-out conditions that can cause A/C compressor noise

complaints. |

Don’t

replace A/C compressor for excessive noise without inspecting

for ground-outs. |

03-01-38-012A |

2005 |

Equinox

LT/LS (AWD Only) – Moan, Bind or Growl Coming from Rear

during Low Speed Parking Lot Turns |

Replace

RDM coupling (clutch pack) with proper sealers. Fill with Versatrak

fluid. |

Don’t

replace complete rear drive module. |

04-04-20-004 |

2005 |

Cobalt/Pursuit

(Built Before January 17, 2005) – Fuel Gauge May Not Go

Completely to Full |

Recalibrate

ECM with updated calibration, version 1.75. |

Don’t

replace fuel module, fuel level sensor assembly or fuel gauge. |

05-08-49-002A |

2002-2005 |

Cars

and Trucks – Multiple Driveability Symptoms/Clogged Fuel

Injectors |

Clean

fuel injectors as described in Bulletin. |

Don’t

replace fuel injectors. |

03-06-04-030A |

2004 |

Grand

Prix – Steering, Suspension or Cradle Click Noise |

Install

new two-piece sleeve and spacer to steering gear mounts. |

Don’t

replace steering gear or cradle. |

03-02-32-048A |

2000-2003 |

Century,

Regal, Lumina, Impala, Monte Carlo, Grand Prix, Intrigue with

3.8L L36 Engine – Coolant Leak |

Replace

upper intake manifold gasket only. |

Don’t

replace upper intake manifold assembly for coolant leak. |

03-06-01-016 |

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

Issue

One: Refinish brake rotor.

Issue Two: Measure for LRO |

Issue One: Don’t replace brake rotors.

Issue Two: Don’t measure for LRO |

00-05-22-002D |

|

| return

to Table of Contents |

|

|

Truck

Issues — Fix It Right the First Time

(new issues in bold) Truck

Issues — Fix It Right the First Time

(new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2003-2005 |

Full Size Pickups and Utilities – Rear Seat Audio and/or

Rear HVAC Controls Inoperative |

Replace

RSA. |

Don’t

replace console. |

03-08-44-018B |

2004-2005 |

Midsize and Fullsize Pickups and Utilities – CD Issues |

Load

new software calibration. |

Don’t

exchange or replace radio. |

04-08-44-020A |

2002-2005 |

Tahoe, Suburban, All Yukons, All Escalades, Avalanche, H2 –

Exhaust Pop/Ping Noise |

Replace

heat shield. |

Don’t

replace exhaust system. |

03-06-05-008B |

2003-2005 |

Full

Size Pickups and Utilities – Snap/Popping Noise from Front

of Vehicle |

Use

procedure in Service Bulletin. |

Don’t

replace crossmember. |

03-08-61-002D |

2004 |

Tahoe, Suburban, Silverado, Yukon, Yukon XL, Sierra, Escalade,

Escalade EXT, Escalade ESV, H2 – Passenger Door Module and

RKE Inoperative |

Re-flash

passenger door module. |

Don’t

replace passenger door module. |

04-08-52-005 |

2001-2003 |

Fullsize

Pickups – Injector Replacement for High Flow Rates |

Use

Corporate Bulletin Number 04-06-04-007A for injectors with high

fuel return rates. Use Special Policy 04039 for all 01-02 vehicles. |

Don’t

replace 8 injectors for any complaint other than high fuel return

rates. All other injector failures are fix as failed. |

|

| 2004-2005 |

All

Cars and Trucks – State-of-Charge Upon Delivery of a New Vehicle |

Check

battery’s state-of-charge per revised PDI procedure using

J 42000 or J 42000-EU. |

Don’t

remove and replace battery. |

02-06-03-009A |

| 2002-2004 |

Fullsize

and Midsize Pickups and Utilities – Labor Operation Assignments

for Control Module Reprogramming |

When

submitting claims for reprogramming an electronic module, use the

correct labor operation that reflects the module being programmed. |

Don’t

use K5364, which is for reprogramming a transmission control module

(TCM), when reprogramming a TCCM. |

02-04-21-006D

02-06-04-057D |

| 2002-2004 |

Chevrolet

Avalanche and Cadillac Escalade EXT – Cargo Covers and Cladding

Faded or Stained |

Thoroughly

clean, dry and treat components with “Armor-dillo.”

|

Don’t

replace cargo covers. |

04-08-111-001B |

2001-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed. |

Don’t

replace complete mirror assembly. |

03-08-64-028 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for June |

| |

|

| Know-How

Broadcasts for June |

| 10290.06D

Emerging Issues |

June

9, 2005, 9:00 AM, 12:30 PM Eastern Time

NOTE: Times published in magazine were incorrect. |

| New

Model Features and Technology Close-Up seminars |

Stay

tuned! These programs will return soon. Check the Service

Know-How section of the GM Training website (www.gmtraining.com)

for more details. |

| -

Thanks to Tracy Rozman |

|

|

| return

to Table of Contents |

|

figure

14

figure

14

figure

17

figure

17  Car Issues

— Fix It Right the First Time (new issues in bold)

Car Issues

— Fix It Right the First Time (new issues in bold)

figure

18

figure

18  figure

19

figure

19

Truck

Issues — Fix It Right the First Time

(new issues in bold)

Truck

Issues — Fix It Right the First Time

(new issues in bold)