| |

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Remote

Vehicle Start |

The all new 2004

Chevrolet Malibu is GM’s first production vehicle with a Remote

Vehicle Start (RVS) system. (fig. 1) The

option is available on vehicles equipped with RPO AP3. The system has

a range of up to 197 feet (60 meters). (fig. 2)

RVS provides several customer-satisfying features:

- Saves time normally spent scraping ice off windows

- Comfort of entering a pre-heated or pre-cooled vehicle

RVS is integrated with the current anti-theft and RFA systems to provide

a very robust system. And it provides user feedback of the event and

the ability to enable/disable the feature.

Enable and Disable Procedure

The current state of the RVS function can be viewed through the driver

information center (DIC) display. Press the Menu button on the DIC until

REMOTE START appears. The display will read ON or OFF, depending on

the last setting.

To enable the RVS function:

1. Turn ON the ignition, with the engine OFF.

2. Press the Menu button on the DIC until REMOTE START is displayed.

3. Press the Enter button on the DIC until ON is displayed.

To disable the RVS function:

1. Turn ON the ignition, with the engine OFF.

2. Press the Menu button on the DIC until REMOTE START is displayed.

3. Press the Enter button on the DIC until OFF is displayed.

Operation

TIP: The system

must be enabled to operate.

To operate the function, first press and release the LOCK button on

the key fob, then press the RVS button for 2 seconds.

When the remote control door lock receiver receives the start signal,

it sends a GMLAN message to the BCM, and the BCM enables the Run/Crank

relay. Once the relay is turned on, the BCM sends a message to the PCM

to start the engine. The PCM then performs a starter-based algorithm

to start the engine. (fig. 3)

The vehicle park lamps will be illuminated to indicate that the engine

is running. The vehicle doors will be able to be unlocked.

If the engine does not start within three attempts to crank the engine,

RVS will not attempt another start until it is reset. Reset consists

of inserting the ignition key and rotating it to the Run position.

The RVS function is allowed to start the vehicle for two 10-minute intervals.

If the BCM receives a second request for an RVS event while already

operating in RVS, the second timer starts immediately. For example,

if the RVS button was pressed for the first time and then 7 minutes

later the RVS button was pressed a second time, the total time for the

RVS event would be 17 minutes.

To drive the vehicle, the door must be unlocked, and the ignition must

be placed in the RUN position. This unlocks the gear selector lever.

The RVS event can be deactivated:

- by pressing the RVS button on the key fob

- by turning the ignition key from the OFF position to any other position,

then back to the OFF position

- by pressing the hazard switch to the ON position.

There are other safety and security features built into the system.

The following conditions must be met in order for the RVS function to

operate:

- The hood switch inputs to the BCM must indicate that the hood is closed.

- The accelerator pedal is not being pressed during the event.

- There is no current PCM DTC

- There is no current DTC set for the hood switch, hazard switch or

the brake transmission shift interlock (BTSI).

- The hazard switch is in the OFF position.

- There is not a key in ignition input to the BCM.

- The BCM has not lost communication with the PCM.

-The transmission must be in the PARK position.

If any of these conditions are present during an RVS event, the vehicle

park lamps will flash to indicate that the signal was received and the

operation is disabled.

During an RVS event, the engine will be turned OFF if any of the following

conditions are met (the first four serve as anti-theft provisions):

- Throttle position is greater than 10% for 2 seconds.

- Engine speed is greater than 2000 RPM for 30 seconds.

- Engine speed is greater than 4000 RPM for 2 seconds.

- Vehicle speed is greater than 0 km/h

- Engine crank time is greater than 30 seconds

- Engine oil pressure is low.

- Engine is overheating.

- A DTC is set that causes the MIL to illuminate.

- Engine run time has exceeded 10 minutes

- A BTSI Auto Trans Shift Lock Control fault has occurred

- Content theft system is activated

- Hazard switch is turned ON

- The hood is opened

- An ignition switch input fault is detected

- A low voltage condition is detected by the PCM

HVAC Operation, RVS Enabled

The HVAC control module receives three separate GMLAN messages from

the BCM to enable HVAC operation during an RVS event. They include:

Remote

Start Status |

ACTIVE |

Power

Mode Message |

OFF |

Power

Mode Validity |

VALID |

If there is a communication failure between the BCM and the HVAC control

module during an RVS event, the HVAC function will be inoperative.

While in an RVS event, the HVAC control module will not respond to input

of a button press or the turning of a control knob. The LED display

will display AS, referring to the vehicle being in an Auto Start mode.

All other HVAC displays will be disabled. If the A/C is activated, the

LED will not be turned on.

TIP: During the

RVS event, the HVAC system will operate according to the following tables.

However, if the HVAC was turned off the previous time the vehicle was

driven, it will return to OFF as soon as the RVS event ends.

The HVAC control module is programmed to take the following actions

when in an RVS event:

Inside

Air Temperature Input

Below 22°C (72°F) |

Blower

motor |

High

speed |

Mode

door |

Defrost |

Temperature

door |

Full

hot |

Recirculation

door |

Outside

air |

Inside

Air Temperature Input

Above 26°C (79°F) |

Blower

motor |

High

speed |

Mode

door |

Panel |

Temperature

door |

Full

cold |

Request

A/C compressor operation |

Recirculation

door |

Outside

air |

Inside

Air Temperature Input

Between 22°c (72°f) and 26°c (79°f) |

Blower

motor |

Medium

speed |

Mode

door |

Panel |

Temperature

door |

Full

cold |

Request

A/C compressor operation |

Recirculation

door |

Outside

air |

Once the ignition

key is placed in the RUN position, the HVAC system reverts to its last

know setting.

Diagnosis

Refer to SI for appropriate diagnostic procedures. Basically, diagnostics

of the RVS system are based on inputs from other systems, and the RVS

diagnostic tables contain links to faults in those systems.

-

Thanks to Jim Mauney |

figure

1 |

figure 2 |

figure 3 |

| |

| |

| |

| |

| return

to Table of Contents |

|

|

| Unable

to Program Replacement PCM |

According to PI01357, when servicing a 1999 Chevrolet Camaro or 1999

Pontiac Firebird, the following diagnosis might be helpful if the vehicle

exhibits these symptoms: Crank No Start, Hesitate, Idles Rough, MIL

/ DTC, No Start, Runs Rough, Stall.

The original or service replacement PCM may not be programmed successfully.

There may also be a DTC P0606 and or a P1516 set. The concern is with

the PCM replacement part numbers.

- Part number 09374997 is mislabeled on the PCM and is part number 09361735,

which is for a non ETC 3800 V-6 application.

- PCM part number 09374997 is for an ETC application but was changed

to part number 12209624.

- PCM part number 12209624 is for a non-ETC application.

- At this time, GMSPO does not have a PCM available for a 3800 V6 ETC

application.

If you are trying to program PCM part number 12209624, 09361735 or 09374997,

call TCSC (1.800.828.6860) and advise the TCSC helpdesk coordinator

that you are not able to program the replacement PCM. TCSC will send

an archive file, which is a software patch that will reset the EEPROM

map for the 1999 F-car. The GM dealer should accept a new PCM part number

to be released into GMSPO service in the near future.

Please follow this diagnosis process thoroughly and complete each step.

If the condition exhibited is resolved without completing every step,

the remaining steps do not need to be performed. If these steps do not

resolve the condition, please contact GM TAC for further diagnostic

assistance. This diagnostic approach was developed for the vehicle with

the VIN you entered and should not automatically be used for other vehicles

with similar symptoms.

-

Thanks to Hassan Abdallah |

|

|

|

| Passkey

III+ Key Data Retrieval |

This

information applies to the 2004 Chevrolet Malibu.

SI document 1352053 contains two procedures for setting up a new Theft

Deterrent Module, within Programming Theft Deterrent System Components.

One procedure uses existing keys and one uses new

keys.

IMPORTANT: The procedure called "Set Up a New Theft Deterrent Module

(TDM) Using Existing Keys" may not function correctly. The corrected

software will not be available on the Scan Tool until CD release 13.

This is due to be broadcast to dealers on December 15. The CD will be

shipped to dealers on approximately December 19.

Until this scan tool release is available, and when using the “Set

Up a New Theft Deterrent Module (TDM) Using Existing Keys” procedure,

it will be necessary to contact Technical Assistance for the necessary

Tech 2 software.

TIP: If the “Set

Up a New Theft Deterrent Module (TDM) Using New Keys” is performed,

the current scan tool setup procedure will function correctly. If a

new Theft Deterrent Module has to be special-ordered, be sure the required

number of keys will be available at the time the new module is installed.

- Thanks to Brent Drendall and Mike McClure |

|

return

to Table of Contents |

| |

| Child

Comfort Clip |

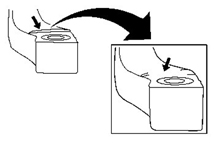

On

Venture, Silhouette, and Montana vehicles, a child comfort clip is sewn

into the rear seats, and is tucked into a fold on the outboard shoulder

seam. (fig. 4) This clip may get damaged

or pull out.

A replacement service clip (fig. 5) for

2002-03 vehicles is available from the Warranty Parts Center, according

to Bulletin 03-09-50-001. It explains how to get the part and how to

install it.

TIP: Install

the replacement clip rather than replacing the seat back cover.

-

Thanks to Tom Geist |

figure 4

|

figure

5 |

| return

to Table of Contents |

|

| Outer

Tie Rod End Service Kit |

This

information applies to:

1997-2001 Buick Century, Regal, Chevrolet Venture, Oldsmobile Silhouette,

Pontiac Grand Prix, Montana

1997-2003 Cadillac Seville

1998-2001 Oldsmobile Intrigue

2000-01 Chevrolet Impala, Monte Carlo

2000-03 Buick LeSabre, Park Avenue, Cadillac DeVille, Pontiac Bonneville

2001-2003 Oldsmobile Aurora

2001 Pontiac Aztek

A new outer tie rod end service kit has been released which is the same

tie rod end that went into production on the vehicles listed above.

The kit includes:

- a revised tie rod end with improved boot that eliminates the possibility

of water intrusion into the tie rod end which can cause premature wear

out condition

- emory cloth

- an instruction sheet.

When replacing the outer tie rod ends, use the improved tie rod end

service kit and modify the knuckles according to this procedure.

- Remove the outer tie rod end from the inner tie rod assembly; count

the number of revolutions it takes to remove the outer tie rod from

the inner tie rod and record it. Discard the outer tie rod end.

- Use the emery cloth supplied in the service kit to remove the sharp

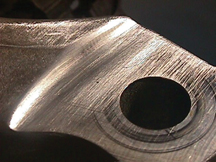

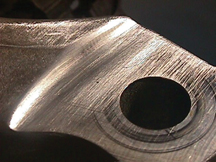

edge on the knuckle. The photos show the knuckle before (fig.

6) sanding and after (fig. 7) sanding.

IMPORTANT: When sanding

the knuckle, AVOID REMOVING excessive material. USE ONLY the emery cloth

supplied in the service kit. DO NOT use any other abrasive, which may

remove excessive material from the knuckle.

- Ensure that the sharp edge and the flashing on the knuckle are removed

from the outer tie rod end boot/seal area. (fig.8)

- Install the new outer tie rod end supplied in the service kit by screwing

the outer tie rod end onto the inner tie rod end assembly.

- Turn the outer tie rod end as many turns as it took to remove the

old outer tie rod end from the inner tie rod end assembly.

- Install the prevailing torque nut to the outer tie rod assembly.

- Inspect the front toe and adjust if necessary. Refer to Front Toe

Adjustment, SI Document 580777.

-

Thanks to Gary McAdam

Outer

Tie Rod End Service Kit |

89047698 |

Grand

Prix, Montana, Silhouette, Venture |

89047749 |

Park

Avenue, DeVille, Seville, Bonneville, LeSabre, Aurora |

89047697 |

Century,

Regal, Impala, Monte Carlo, Intrigue |

89047756 |

Aztek |

|

figure

6 |

figure

7 |

figure

8 |

|

return

to Table of Contents |

|

| Using

“Getting to Know” Materials Effectively |

"Getting

To Know" your vehicle guides are included in the glove box of most

GM car and trucks sold in the US. (fig. 9)

In addition, some vehicles, like the 2004 Trailblazer, will include

a "Getting To Know" your vehicle CD. The GTK guides are designed

to provide a convenient overview of the operation of the vehicle --

specifically, its features and controls. It is not intended to take

the place of the Owner's Manual.

TIP: New vehicle

preparation personnel should take care to be sure the GTK guide and/or

CD is in the vehicle.

A clear understanding of a vehicle’s operation and features contributes

greatly to a customer’s satisfaction with their new vehicle, and

that’s reflected in J.D. Power and CSI survey results.

GTK materials provide the salesperson an excellent aid when explaining

the features of a new vehicle to the owner during delivery. In the same

way, service advisors and technicians can gain quick insight into a

vehicle’s operating features, from an owner’s standpoint,

by studying the GTK guides.

TIP: Pay particular

attention to the key five J.D. Power customer dissatisfiers: RKE Operation,

HVAC Controls, Audio Systems, Memory and Personalization Features, and

Perceived Fuel Economy.

Electronic copies of the 2004 GTK guides can be obtained by US dealers

on the web at www.gmcommontraining.com.

- Thanks to Diana Sancya |

figure

9 |

| return

to Table of Contents |

|

| “Rotten

Egg” Exhaust Odor |

Three conditions

are necessary for "rotten egg" or hydrogen sulfide odor to

be present in exhaust gasses:

- Hot catalytic converter

- Sulfur in the fuel

- Rich air-fuel ratio, at least momentarily.

Of these three, the quantity of sulfur present in the fuel is the most

variable, and most difficult to control for both a vehicle manufacturer

and a customer.

High amounts of sulfur in fuel can cause not only a rotten egg odor

in exhaust gasses, but also certain re-active sulfurs can corrode silver

contacts in the fuel level sender, causing erroneous fuel gauge readings.

At present, there is no EPA requirement for the level of sulfur in fuel,

outside of the state of California, and the ASTM (American Society for

Testing and Materials) specification limit is 1000 parts per million

(PPM). To put that number into perspective, the current limit for sulfur

in California phase 2 gasolines requires an average of less than 30

PPM.

In 2004, the EPA will begin limiting the sulfur content in gasoline.

In 2004, the EPA limit for the corporate average sulfur content will

be 120 ppm, and no single gasoline can exceed 300 ppm (except for small

refiner exemptions). By 2006, the corporate average will be limited

to 30 ppm (the current California limit), with a maximum of 80 ppm (except

for small refiner delays). California Phase 3 gasoline, which will be

available next year, will have a maximum sulfur content of 15 ppm.

In the absence of an identified vehicle condition, customers can be

advised to temporarily change to a premium grade brand of fuel from

a major supplier such as Shell, Exxon, Texaco or Chevron. Premium fuels

in general have been found to have lower sulfur levels. However, even

these suppliers can be susceptible in areas where base fuels are delivered

either by pipeline or from the same refinery.

TIP: Dealers

should refrain from attempting repairs or replacing catalytic converters

for odor complaints, unless there is a MIL indicating a part deficiency.

-

Thanks to Bob Furey and Jay Dankovich

|

|

return

to Table of Contents |

|

| Interior

Light Override Feature |

Customers continue to be confused by the operation of their vehicle’s

interior lights. Many cars and trucks have override switches (fig.

10), which disable the function of interior lights, when light

is not wanted. Customers who are unaware of the switches may assume

the vehicle doesn’t have interior lights or that they are malfunctioning.

Two things will help minimize this confusion.

TIP: During pre-delivery

inspection, be sure the override switch is off, so the interior lights

are not disabled.

TIP: Be sure

the customer understands the functioning of all systems when the vehicle

is delivered.

- Thanks to Tom Geist |

figure

10 |

|

return

to Table of Contents |

|

| Squeaking

Seatback Clip |

On

Buick LeSabres, the rear upper seat back may squeak when pressure is

applied to the back. This is caused by metal to metal contact between

the seat anchor clip and the seat cross brace (fig.

11).

Install mylar or equivalent tape over the seat clip anchor hole, then

reinstall the seat back.

- Thanks to Bill Metoyer

|

figure

11 |

| return

to Table of Contents |

|

| Envoy

XUV Rear Wiper |

The

2004 Envoy XUV features a unique power sliding rear roof and dual function

end gate with sliding power window (fig.12).

The rear wiper system for this vehicle is designed to park the wiper

arm in a depression, or pocket, in the end gate applique.

“Timing” Procedure

If the wiper arm is removed for any reason, it’s necessary to

“time” the motor assembly before installing the wiper arm

to the vehicle.

TIP: If the timing

is not done, the wiper arm will not park properly, and may interfere

with the operation of the end gate window.

1. With the rear wiper arm removed, turn the igntion to RUN, with the

engine OFF.

2. Turn the rear wiper switch to full speed (position 3) and verify

that the wiper arm pivot shaft is functioning.

3. Locate and remove the rear wiper fuse No. 9, located under the LH

rear seat. Verify that the wiper arm pivot shaft is NOT functioning.

4. Turn the wiper switch OFF.

5. Install fuse No. 9.

6. Turn the ignition to LOCK OFF.

IMPORTANT: Do not turn

on or cycle the rear wiper after step 6 until the wiper arm nut is fully

torqued. If the vehicle is turned on, start over at step 1.

7. Install the washer hose end connection into the end gate, route the

hose clockwise around the shaft and connect to the elbow.

8. Install the rear wiper arm. Align the park finger of the arm into

the park pocket in the applique.

9. Tighten the nut to 6-10 N.m (55-89 in.lb.).

10. Secure the wiper arm nut cover.

11. Turn the ignition to RUN, engine OFF.

12. Cycle the rear wiper and verify the park location of the wiper arm

into the applique pocket (fig. 13).

13. Inspect the operation of the end gate window.

TIP: SI document

1326065 is being revised to include this procedure.

- Thanks to Brandon Snyder and John Force |

figure

12

|

figure

13 |

| |

| return

to Table of Contents |

|

| Trim

Panel Removal |

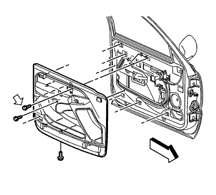

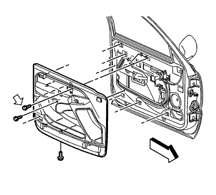

This

applies to the removal of the front door trim panel on a 2003-04 C/K truck.

TIP: To avoid damage

to the panel, don’t forget to remove the screw hidden behind the

manual lock lever, indicated in figure 14.

This screw is referred to as number 2 in the SI procedure.

TIP: Also refer

to the Switch Plate Bezel Removal article in the July 2003 TechLink for

more information on servicing these door panels properly.

-

Thanks to Mark Freigruber |

figure

14 |

return

to Table of Contents |

|

| Seat

Belt Extender |

A

change was made to the seat belt system on Venture, Silhouette, and

Montana models in October, 2002. Model year 2003 vehicles built before

October 7 had 2002 parts, and those built after October 7 have the new

parts. The parts are not interchangeable. New retractor-side and buckle-side

belts give better insertion effort and improve customer satisfaction

with seat belt operation.

Seat belt extenders are now available for the new design seat belt system.

If a customer has a vehicle built after 10/7/02 and needs a seat belt

extender, use the new part numbers listed below.

-

Thanks to Tom Geist

Part

Number |

Description |

88956963 |

Extension

Kit, Front Seat Belt (9 inch) |

88956964 |

Extension

Kit, Front Seat Belt (15 inch) |

|

|

return

to Table of Contents |

|

| Resistance

Calculated Oxygen Sensor Heater Temperature (RCOHT) |

On

some vehicles, GM is using a relatively new oxygen sensor temperature

control strategy called RCOHT (Resistance Calculated Oxygen Sensor Heater

Temperature).

TIP: It’s

important to perform a reset procedure after replacing an oxygen sensor

on a vehicle using RCOHT.

How does RCOHT work?

The RCOHT strategy will learn the resistance of the oxygen sensor heater

circuit, at start-up, after a cold soak has occurred. At start-up, the

engine controller briefly samples the oxygen sensor heater current; it

then calculates the resistance of the oxygen sensor heater, based on the

sampled current and the measured supply voltage (system voltage). Once

the initial resistance is known, a resistance-to-temperature model can

be followed as the calculated resistance changes during operation. From

this model, the engine controller can very accurately control the temperature

of the oxygen sensor heater.

An expected range of oxygen sensor heater resistance characteristics is

stored within the engine controller for that specific package. The engine

controller must know the initial resistance of the heater in order to

determine which resistance model to follow. The initial resistance calculation

can be made only after an extended soak period, so the engine controller

can accurately determine the equivalent “room temperature resistance”

of the oxygen sensor heater. This “room temperature” is based

on the engine coolant temperature sensor (ECT) and intake air temperature

sensor (IAT) values. In other words, the engine controller can safely

assume that when the extended soak conditions have been met, the oxygen

sensor will be at the same temperature as the ECT and IAT. Although not

specific to any particular platform, an extended soak can be roughly defined

as: The engine has been off for more than 10 hours AND the ECT and IAT

are within 8° C (14.4° F) of each other at start-up.

Why use a new strategy?

RCOHT provides much more accurate control of the oxygen sensor heater

temperature. Other temperature control strategies attempted to “predict”

the oxygen sensor temperature by using some form of a temperature prediction

model.

RCOHT allows accurate oxygen sensor heater control even if there is a

resistance variation between newly manufactured oxygen sensors or if the

resistance changes as the sensor ages. One problem faced in the past was

the possibility of over predicting the heater temperatures of a high resistance

oxygen sensor and the possibility of under predicting the heater temperatures

of a low resistance oxygen sensor. Because the engine controller is now

calculating the resistance of the oxygen sensor after each extended soak,

the temperature of the sensor heater can be more accurately controlled

throughout the life of the sensor.

What happens if there is a failure with the heater circuit or

the engine controller does not learn the sensor resistance?

A gross failure (open, short to ground, short to voltage) on the heater

circuit should set a heater driver code (P0030-0058) and/or a heater current

monitor code (P0135, P0155, P0141, P0161). If there is a high resistance

condition within the heater circuit, it is possible the engine controller

will learn an incorrect heater resistance value and not set one of the

above DTCs. At this time, no dedicated DTC will set for this particular

failure! On some applications, a failed learn or an incorrect learn will

cause DTC P0135, P0155, P0141, or P0161 to set. The diagnostic tables

for these DTCs have taken this possibility into account and will provide

appropriate testing procedures. Some vehicle applications do not report

a failed or incorrect resistance learn to the previously mentioned DTCs.

In these applications, the following DTCs may set in the event of heater

degradation or failure: P0133, P0153, P0136, P0156, P0140, P0160.

On certain applications, starting in the 2005 model year, there will be

specific DTCs (P0053, P0054, P0059 and P0060) for a failed learn or a

learned resistance that is out of range.

What to do when an oxygen sensor is replaced?

When a new oxygen sensor with the same part number is installed, it may

have a different heater resistance than the previous sensor. In most cases,

an extended soak does not occur, nor is it realistic to expect it to occur,

immediately after oxygen sensor replacement. However, we do not want the

engine controller to control the new sensor based on the calculated resistance

of the old sensor. This may cause under or over prediction of the heater

temperature of the new sensor. Therefore, some type of reset procedure

is required to prevent the possibility of heater damage (high temperature)

to the new oxygen sensor. This will allow the vehicle to be returned to

service as quickly as possible.

TIP: To reset the

oxygen sensor learned resistance, a code clear is required. The reset

procedure is required after the sensor is replaced, REGARDLESS OF WHETHER

OR NOT ANY DTCs ARE PRESENT!

When a reset procedure is performed, a default resistance value will be

used until an extended soak occurs. This default resistance will allow

the new sensor to operate without the possibility of heater damage until

an extended soak occurs.

Summary

More and more engine applications will incorporate the use of the RCOHT

strategy.

TIP: Refer to the

appropriate service manual oxygen sensor diagnostic information and replacement

procedures for the vehicle you’re servicing. This will provide you

with a notice to perform a code clear after sensor replacement.

In the future, there will be a scan tool feature available to reset the

learned resistance without performing a code clear.

-

Thanks to Jim Hanna, O2S Signal Delivery Subsystem Team |

| return

to Table of Contents |

|

| Memory

Seat Calibration |

On

vehicles with memory seats, the memory seat module uses position sensor

inputs to establish soft stop locations for the adjuster motors, several

millimeters ahead of the physical limits of the adjuster assembly. After

replacing a memory seat module or adjuster components, it may be necessary

to reset the adjuster motor soft stop locations. When the repair procedure

has been completed, operate the seat adjuster switch in every direction

until the seat adjuster reaches its mechanical hard stop, by repeatedly

pressing and releasing the switch as necessary.

-

Thanks to Devin Koski |

| return

to Table of Contents |

|

| Oil

Viscosity Usage |

For

2003 L36 and L67 engines, the vehicle owner’s manual recommends

10W30 motor oil, while the engine oil fill cap may state to use 5W30 motor

oil.

For the 2003 model year, 10W30 or 5W30 motor oil is appropriate for the

L36/L67 3800 applications. The use of either 10W30 or 5W30 motor oil will

provide necessary lubrication for engine component wear protection.

-

Thanks to John Fletcher |

| |

| return

to Table of Contents |

|

| AC

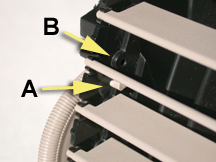

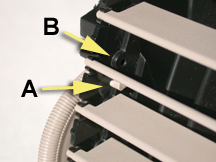

Vent Louver Repair |

The

2000-04 Impala and Monte Carlo I/P trim plate has integrated A/C vents

that are not serviced separately. Many trim plates are replaced for inoperative

louvers in the vent assembly.

If the round peg on the end of a louver has come out of its mating hole

in the thumbwheel actuator, the louver will not open or close when the

thumbwheel is turned (fig. 15).

A Peg on louver

B Hole in actuator

To avoid unnecessary replacement of the I/P Trim Plate, shine a light

into the vent and see if the inoperative louver still has the round peg

on the end. If the peg is still present, flex the louver, reinstall the

peg into the thumbwheel actuator, and check for correct operation.

-

Thanks to Gary McAdam |

figure

15 |

| return

to Table of Contents |

|

| Poor

HVAC Blower Vent Performance |

According

to bulletin 03-01-38-013, owners of some 2002- 03 Buick Rendezvous and

2001-03 Chevrolet Venture, Oldsmobile Silhouette, and Pontiac Aztek and

Montana may comment that the airflow volume from the dash vents is noticeably

reduced when switched from cold to hot. Also, hot airflow volume may seem

less from the dash vents when compared to the floor ducts.

The following procedure may improve the above condition by disabling the

temperature sub damper door.

1. Move HVAC temperature settings to full cold position.

2. Remove passenger side lower instrument panel trim, glovebox and door,

and hush panel. The passenger side actuator should be visible.

3. Disconnect actuator connector. Remove 2 actuator screws and actuator.

4. Remove 2 screws that hold the actuator mounting plate to the module.

Remove the plate, exposing the levers underneath.

5. Carefully remove mode door lever by lifting the mode lever locking

tab at pivot point and simultaneously pry outwards on the base of the

lever with a flat screwdriver. Pry as close to the shaft as possible.

Remove and discard. With the mode lever removed, swing the temp sub-damper

lever fully up. This opens the door fully on the inside of the HVAC case.

6. To keep the sub-damper door fully open, use a small plastic tie strap

to fasten its lever to the upper actuator attachment boss (fig.

16). Loop the strap through the channel of the lever and around

the upper actuator attachment boss. Make sure to get the strap over the

side ribs, as the side ribs are the locating feature for the actuator

backing plate. Ribs used as actuator backing plate locating feature must

not be obstructed by tie-strap.

7. Install actuator mounting plate.

8. Install temperature actuator.

9. Reconnect actuator wiring connector. Cycle the temperature door from

full cold to full hot a few times and check proper operation.

10. Reinstall passenger side lower instrument panel trim, glovebox and

door, and hush panel.

-

Thanks to Phil Race |

figure

16 |

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time

Car Issues – Fix It Right The First Time |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2000-2004 |

Cavalier/Sunfire

– O/S Rearview Mirror Vibration |

Align

insulator patch and tighten nuts to specification. |

Don’t

replace the entire mirror assembly. |

03-08-64-011A |

2003-2004 |

Venture/Montana/Silhouette

– Alarm Goes Off (Non Theft Deterrent-Equipped Vehicles

(UA6)) |

Disable

the theft deterrent using the owner’s manual directions. |

Don’t

replace the MALL module. |

03-08-64-004 |

2004 |

Grand

Prix with Monsoon Audio System – Speaker Buzz |

Re-pin

the speaker wires in the I/P fuse panel connector. |

Don’t

replace the speaker, amplifier or radio. |

03-08-44-015 |

2003-2004 |

Impala/Monte

Carlo – Condensation in Headlamp |

Normal

condition when limited to fog or fine mist appearance in high

humidity conditions. |

Don’t

replace the headlamp assembly when no water droplets are evident. |

01-08-42-001

September 2000 TechLink |

2003-2004 |

CTS

– Variable Effort Steering (VES) “Service Steering

Message,” DTC C1241 or C0450 |

Replace

the only the VES solenoid. |

Don’t

replace the entire steering gear. |

03-02-36-001 |

2003-2004 |

Vibe

– Normal Exhaust Odor |

Provide

a copy of the service bulletin to the customer. |

Don’t

replace the catalytic converter. |

03-06-05-006 |

1998-2004 |

All

Cars and Trucks – Wabasto Sunroof |

Repair

the sunroof module. |

Don’t

replace the sunroof module. |

03-08-67-004 |

1997-2004 |

Grand

Am/Alero/Malibu – Brake Pulsation |

Turn

rotor and brake align procedure |

Don’t

replace brake rotor for pulsation |

00-05-23-002

01-05-23-001 (Know How Video #15040.01B) |

2003 |

All

cars with 4T40/45E, 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM Solenoid |

Don’t

replace transmission or valve body assembly |

02-07-30-039B |

2004 |

L61

EcoTech 4 Cylinder-2.2L Engine – Misfire, DTC P0300 |

Replace

spark plug sets |

Don’t replace PCM or ignition cassettes |

Recall

03042 |

|

| return

to Table of Contents |

|

|

Truck Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2002-2004 |

C/K Fullsize Pickups and Utilities – Tail Lamp Socket Circuit

Board |

Replace

both tail lamp circuit boards with P/N 16532713 (TrailBlazer,

TrailBlazer, EXT), P/N 16532716 (Envoy, Envoy XL) or P/N 16532715

(Rainier, Bravada). |

Don’t

replace the complete tail lamp assembly. |

Service

VME, 9/22/03

03-08-42-006A |

2003-2004 |

Fullsize Pickups and Utilities – Door Trim Panel |

Remove

the front door panel then remove the switch bezel retaining screw. |

Don’t

pry the switch bezel out of the door trim panel without first

removing the retaining screw. |

Service

VME

03-08-64-022 |

2003-2004 |

Fullsize Pickups and Utilities – Servicing Wide Load Mirrors

(RPO DPF) |

Replace

individual parts as needed. |

Don’t

replace the complete mirror assembly. |

03-08-64-028 |

2002-2003 |

All

TrailBlazer, All Envoy, Bravada – Windshield Washer Nozzle |

Replace

with windshield washer nozzle P/N 15173510 |

Don’t

replace the complete cowl assembly. |

Service

VME dated 06/25/2002 |

2003 |

Fullsize Pickups and Utilities – Transfer Case Service Light |

Replace

encoder motor sensor and reprogram TCCM |

Don’t

replace the module, encoder motor or transfer case for DTCs C0327,

P0836, P0500 |

03-04-21-001B |

2003 |

Fullsize

Pickups – 6.6L Diesel Engine ECM |

Follow

SI and bulletins for proper diagnostics for P0181. Refer to the

Owner’s Manual (block heater and front cover) |

Don’t

replace ECM (DTCs P0540 and P0181) unless diagnostics confirm

need to replace |

02-06-04-048,

03-06-04-021, 02-06-04-058 and parts restriction |

2003 |

Silverado,

Sierra, Savana, Express > 8600 GVW – ABS Lamp On |

Reflash

for code C0550 |

Don’t

replace ABS module |

03-05-25-003

and parts restriction |

2002-2003 |

TrailBlazer,

TrailBlazer EXT – Wavy Front Fascia |

Repair

fascia with Dual Lock |

Don’t

replace front fascia |

02-08-62-004 |

2002-2003 |

All

TrailBlazers, All Envoys, Bravada – Mirror Erratic Return |

Replace

mirror actuator and reprogram module |

Don’t

replace outside mirror assembly |

02-08-64-008

02-08-64-021 |

2002-2003 |

TrailBlazer,

Envoy, Bravada without G67 – Moan/Boom |

Replace

rear coil springs |

Don’t

repurchase vehicle for rear axle vibration/boom noise |

02-03-09-002A |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for December |

| |

|

| Know-How

Broadcasts for December |

| 10270.12D

Emerging Issues |

December

11, 2003 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| 10270.24D

- CTS-V 6-Speed Manual Transmission |

December

18, 2003 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

| |

Car Issues – Fix It Right The First Time

Car Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time