Table

of Contents – October 2002 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Wheel

and Tire Balancing |

Consider a Chevrolet

TrailBlazer travelling at 60 miles per hour. The P245/70R16 tires have

a diameter of 29.6 inches. At 60 miles per hour, they're running 703

rpm. If a tire is out of balance, at that speed it introduces 703 vibrations

per minute into the vehicle. The tire is slapping the pavement 12 times

per second (12 Hz). You think the customer is going to notice that?

Actually, tire related shake or vibration is one of the most common

customer dissatisfiers, and it's most easily noticed when driving on

a smooth highway. There are three causes: out-of-round, imbalance, and

radial force variation (RFV). Each one of these conditions can result

in shake or vibration, but the causes and cures are different for each.

They are not necessarily related, but each of them must be addressed.

Here's where to find guidance in SI:

- "build"

the vehicle

- General Information

- Vibration Diagnosis

and Correction

- Diagnostic Information

and Procedures

- Vibration Analysis

-- Tire and Wheel

The Vibration Analysis

chart contains thorough test procedures. The exact path you will follow

depends on what you find on the vehicle you're diagnosing, but in general,

you will check in this order: runout, imbalance, and RVF.

Runout (Out-of-Round)

TIP:

It's

tempting to start with wheel balance, but it's important to measure

on-vehicle runout first. If runout is the cause of the vibration, balancing

won't fix it. But removing the wheel/tire assembly to check balance

can disturb runout evidence. This is because a small amount of runout

in the wheel may cancel or accentuate a small amount of runout in the

mounting surface, depending on which position the wheel is mounted.

This is referred to "stack-up" of runout.

Wheel/tire runout is measured two ways, on-vehicle and off-vehicle.

The on-vehicle measurement includes possible runout of not only the

wheel and tire but also the mating hub/axle flange and studs. Off-vehicle

runout measures only the wheel and tire assembly. Further, it may be

necessary to measure runout of just the wheel, with the tire dismounted.

The diagnostic chart explains how to interpret and correct various runout

conditions you detect.

One of the repair methods is called match-mounting (vectoring). This

procedure permits you to move the tire on the wheel to determine if

the low and high spots cancel each other out. In a similar fashion,

it may be possible to match-mount the wheel to the mounting flange.

See SI for details.

Imbalance

Wheel/tire balance is fairly easy to

understand, and of all the conditions mentioned here, offers the most

visible evidence. The weights are there for everyone to see. However,

if runout or RFV is the cause of the vibration, checking balance is

not going to fix the condition.

That having been said, there is an appropriate time to check and correct

wheel/tire balance, according to the diagnostic chart.

TIP: Be sure

to check for foreign materials, particularly inside the wheels, and

particularly when the vehicle has been driven in snowy, icy or offroad

conditions. Correcting an imbalance condition may be as simple as removing

a chunk of mud.

The readily available off-vehicle, two-plane dynamic balancer is the

equipment of choice for checking and correcting imbalance.

As with any precision tool, proper calibration, proper maintenance,

and proper use are all important in obtaining satisfactory results.

Radial

Force Variation

Radial force variation (RFV) refers to variations within the construction

of the tire. All tires have splices in the various plies. These resulting

stiffer spots do not cause problems unless they are excessive.

The causes of radial force variation are impossible to see, so RFV is

the least understood cause of vibration.

TIP: RFV can

masquerade as excess runout or imbalance. RFV can cause vibrations even

though the wheel/tire assembly has acceptable runout and is properly

balanced. If you've eliminated these two conditions, RFV is your likely

culprit.

TIP: The Vibration

Analysis chart in SI contains a link to an Isolation Test, which can

help you identify which wheel/tire assembly is the source of the vibration.

As you can see in figure 1, it's helpful

to think of the tire's sidewall as a series of coil springs. If one

of the "springs" is considerably stiffer than the others,

the tire will bump each time that portion contacts the pavement. This

will be perceived as a vibration.

RFV is measured by specialized equipment in which the mounted tire is

pressed against a load wheel. The load simulates the weight of the vehicle.

As the tire is rotated, the equipment measures the variations in the

tire's radial force.

Most vehicles will tolerate these RFV values:

P-metric

tires

on passenger cars |

18

lbs (8.1 kg)

or less |

P-metric

tires

on light trucks |

24

lbs (10.8 kg)

or less |

LT

tires

on light trucks |

30

lbs (13.5 kg)

or less |

TIP:

Technical

Assistance has information on tire parameters that may deviate from

these guidelines.

Correcting radial force variation is similar to correcting for runout.

The stiffest part of the tire is matched up with the lowest part of

the wheel.

Hunter GSP9700

The Hunter GSP9700 Vibration Control System (figure

2) is now available from GM Dealer Equipment (1.800.GMTOOLS).

A major benefit of the GSP9700 is that a single piece of equipment can:

- measure off-vehicle

runout

- check and correct

balance

- check and correct

radial force variation

The tire, spinning

at 90 rpm, is contacted by a load roller (figure

3). The roller's radial position is affected by the varying stiffness

of the tire as it rotates. While the tire rotates 4 revolutions, sensors

take 128 readings per revolution.

Inner and outer Dataset® arms equipped with sensors measure the

wheel's runout (figure 4).

TIP: There is

a high correlation between inside and outside measurements on most wheels.

In cases where external measurements cannot be made, the tire must be

removed to measure the inside dimensions of the bead seat.

By combining the data from the roller and Dataset sensors, the GSP9700

can calculate vectoring and weight requirements. There is even a feature

which determines where to place weights so they don't show on spoked

wheels.

Important

When mounting a GM wheel to a balancing machine, always

use the center pilot hole with a back cone. Use a flange plate to clamp

the wheel to the cone and machine.

Any type of service equipment that removes tread rubber by grinding,

buffing or truing is NOT recommended, and may void the tire warranty.

Tires may have been ground by the tire company as part of the manufacturing

process, and this is a legitimate procedure.

- Thanks to Dave Scribner at Hunter Equipment, and to Russ Dobson |

|

figure

1

|

figure

2 |

figure

3 |

figure

4 |

| return

to Table of Contents |

| |

| Valve

Index Balancing

|

This applies to

trucks with 16 and 19 1/2 inch hub-centric offset dual wheels. The term

hub-centric means that the wheel is oriented to the vehicle by means

of the hub hole in the wheel, not by the mounting studs and nuts.

The procedure ensures that the wheel is mounted to the balancer and

to the vehicle using the same location method.

TIP: The adapter

and backing plate used to align the hub of the wheel to the balancer

are relatively new, and are available by calling 1.800.GMTOOLS (1.800.468.6657).

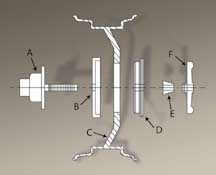

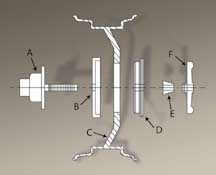

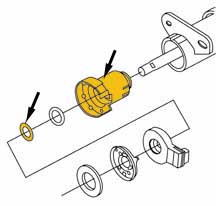

Mount the wheel on the balancer using the parts shown in figure

5.

A - Balancer Faceplate

B - Backing Plate

C - Wheel

D - Adapter

E - Cone, Used as Spacer

F - Nut

Rotate the wheel/tire assembly until the valve is at 12 o'clock. Loosen

the nut. If the hub hole in the wheel does not fit the adapter snugly,

the wheel will drop slightly and "hang" on the adapter, with

the valve at 12 o'clock position. Then tighten the nut to secure the

wheel to the balancer.

Balance the wheel/tire assembly in the usual manner.

With the vehicle raised, mount the wheel/tire to the vehicle with the

valve and the hub pilot tab at 12 o'clock position. Again, if the hub

hole does not fit the mounting flange snugly, the wheel will drop slightly

and "hang" on the tab. Then, tighten the wheel nuts to secure

the wheel.

IMPORTANT: Rotate

the wheel to place the valve at 6 o'clock.

Lower the vehicle and torque the wheel nuts to specification.

- Thanks to Tom Bussard at Hennessy Industries,

Inc. |

figure

5 |

| return

to Table of Contents |

|

| Class

2 Corner Tip of the Month |

Dynamic

menu building is a technique by which the Tech 2 will poll the Class 2

bus to find out what controllers are installed on the vehicle before it

builds the menu choices to display. For instance, when Body is selected

from the Powertrain/Body/Chassis selection menu, the Tech 2 will first

inquire about what body related controllers are installed and build the

menu accordingly. This is a more efficient use of the Tech 2's resources,

but can cause problems for you when diagnosing a Class 2 related problem.

For example, if a 2001 Suburban has a BCM related fault and you select

Body on the Tech 2, the menu selections displayed by the Tech 2 may be

erroneous because the BCM was unable to respond properly when the Tech

2 polled the bus. One indication that this has happened is that when you

select the BCM, the Tech 2 displays only DTC Info. When you select DTC

Info, you end up at the Class 2 DTC Check, which is under the Diagnostic

Circuit Check.

The Tech 2 provides a Bypass Mode which can be enabled under Tool Options

from the main menu. This will allow you to select the combinations manually.

Try playing with the Bypass Mode before you need it, to be familiar with

the feature.

- Thanks to Mark Harris |

| return

to Table of Contents |

|

| Know-How

Broadcasts for November |

| |

|

| Know-How

Broadcasts for November |

Emerging

Issues |

November

14 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

Technology

Close-Up |

November

21 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

| New

Airbag Features in 2003 Full-Size Pickup Trucks |

Supplemental

Inflatable Restraint (SIR) technology is moving to another level of sophistication

in the 2003 C/K trucks.

TIP: The

dual-stage inflator module feature and the instrument panel disable switch

continue to be used.

There are three interrelated parts to the new SIR system:

- Passenger Presence

System

- Seat Belt Tension

Retractor Sensor

- Seat Position

Switch

Here's a brief explanation

of each. You can find additional information in SI:

- "build"

the vehicle

- Restraints

- SIR

- Description

and Operation

Passenger

Presence System (PPS)

The only readily visible evidence of a change is the

inclusion of a new telltale in the rearview mirror (figure

6). It reads either PASSENGER AIR BAG ON or PASSENGER AIR BAG

OFF.

A Passenger Presence System (PPS) sensor in the passenger seat detects

the size of the passenger, based on weight. If the passenger does not

exceed the PPS weight threshold, the instrument panel (I/P) airbag is

disabled. In the event of an accident, the I/P airbag does not deploy.

Also, if the front passenger seat is empty, the I/P airbag will not

deploy.

The PPS sensor consists of a gel-filled bag (figure

7) mounted beneath the seat cusion foam, which operates an electrical

pressure sensor. The pressure sensor converts the pressure from the

occupant to an electrical signal and sends the signal to the PPS module.

PPS Diagnostics

The PPS module monitors itself for faults. The PPS module

communicates with the SDM to turn on the AIRBAG indicator in the instrument

cluster when a fault is present. When a Tech 2 is used, the PPS module

will flash DTCs using the rear view mirror indicators.

PPS Service

IMPORTANT:

The PPS is a calibrated unit. When replacing the assembly, all parts

in the service kit must remain together. Do not mix any of the old parts

with the new parts. After repairing or replacing the PPS, the system

must be rezeroed in order to function correctly.

See SI for details.

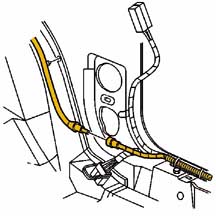

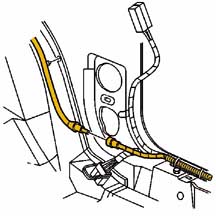

Seat Belt Tension Retractor Sensor

The second addition to the SIR system is the Seat Belt

Tension Retractor Sensor (figure 8), which

enhances the PPS when an infant seat is properly restrained on the front

outboard passenger seat.

When an infant seat is properly restrained, the seat belt is tightly

secured. This pulls on the tension retractor sensor in the lower seat

belt anchor. The PPS module uses this information, along with a signal

from the PPS sensor in the seat, to determine if the I/P airbag should

be enabled or suppressed.

Seat Belt Tension Retractor Sensor Diagnosis

If a fault is detected, the PPS module sets a DTC 023.

The code may be flashed by the rear view mirror indicator, using the

Tech 2.

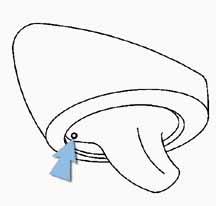

Seat Position Switch

And third, a seat position switch (SPS) is used to determine

how close a front seat occupant is to the frontal airbag. In the event

of an airbag deployment, the SPS determines whether to enable or disable

Stage 2 deployment. There is an SPS for each front seat, and each SPS

affects only the airbag on the side of the vehicle where the SPS is

located.

The SPS consists of a Hall-effect switch, mounted to the seat track

(figure 9). The Hall-effect switch divides

the seat travel into two parts: seat forward or seat rearward.

In the seat rearward position, Stage 2 deployment is enabled. In the

seat forward position, Stage 2 deployment is disabled, and only Stage

1 is permitted.

TIP: The SPS

is secondary to the PPS status. And the SPS and PPS are secondary to

the manual I/P disable switch. If the manual I/P disable switch is in

the disable mode, the passenger airbag will not deploy, regardless of

SPS or PPS status.

SPS Diagnosis

The SDM monitors the SPS circuit, and if a fault is detected,

the SDM will set codes B0083 or B0084. And the SDM defaults to disabling

Stage 2 frontal deployment.

Airbag Deployment Summary

In the event of an accident, the airbag SDM deploys the

frontal airbags in response to inputs from the deployment sensors.

The SDM uses information from the seat position sensors to determine

whether to enable or disable Stage 2 deployment. The driver side and

passenger side are treated separately.

In addition, passenger frontal airbag deployment will be suppressed

by any of the following:

- manual I/P disable

switch turned to the disable position

- weight on the

passenger seat below the PPS threshold

- presence of

an infant seat, as detected by PPS and passenger seat belt tension

retractor sensor.

-

Thanks to Chuck Wieseckel |

figure

6 |

figure

7 |

figure

8 |

figure

9 |

| return

to Table of Contents |

|

| Multi-port

Flexible Injection System (MFI) |

Last

October, we introduced you to a new MFI fuel system on 2002 Chevrolet

Astro and GMC Safari Vans and 2002 Silverado and Sierra pickups equipped

with the LU3 V6 engine and YF5 California emissions package.

Now that you've had a chance to view this system and possibly service

it, here are some reminders about this new fuel system.

The injector at the end of the fuel tube is a Multec 2 injector. This

is the same injector that is used on most passenger cars. In this case,

it's attached to a fuel tube and a fuel meter body rather than a fuel

rail.

It is possible to differentiate the new Multi-port Flexible injection

from the earlier generation SCPI system by simply removing the manifold

injector connector and looking inside the cavity. Both the SCPI and the

MFI have two electrical pins visible inside the cavity.

TIP: You

can also look at the VIN number which for this engine is X.

On the SCPI system, between the two electrical pins is a small black hole,

used to remove the injector from the fuel meter body with a small screwdriver

(figure 10).

On the MFI system, between the two electrical pins is a small white post

in a hole. This is where you push with a screwdriver to remove the injector.

The white plastic tip added to the end of the fuel tube is a retainer

used to hold the fuel tube securely in place with the injector spray pointed

toward the intake port (figure 11). This

tip also moves the injector further away from the heat of combustion which

actually protects the injector from building up deposits on the tip. Moving

the injector further from the heat and vapors formed inside the intake

manifold keeps the injector very clean.

TIP: As with any

other Multec 2, cleaning of this system is not recommended by the manufacturer.

Remember that MFI and SCPI systems are similar in appearance but different

when it comes to servicing the system.

- Thanks to Dan Wimer |

figure

10 |

figure

11 |

| return

to Table of Contents |

|

| Pontiac

Vibe EVAP System |

This

condition can affect All Wheel Drive Pontiac Vibes. With the check engine

light illuminated, there may be DTCs P0440, P0441, P0442 and P0446. The

codes refer to a condition with the EVAP system, most often with the fuel

tank vent hose connection at the ORVR valve. The valve is located at the

top right corner of the fuel tank.

First connect the Evaporative Emissions System Tester J-41413-200 to the

underhood EVAP service port. The port can be identified by the green cap

covering the port.

TIP: At

first, leave the gas cap untouched to verify that the customer didn't

leave the gas cap loose.

When the tester starts to force smoke through the EVAP system, you will

notice smoke leaving the EVAP canister vent hose. This is normal. Pinch

off the vent hose before looking for signs of a leak. If smoke is found

to be leaking from the top right front corner of the fuel tank, the plastic

quick disconnect vent hose may either be partially disconnected or there

is too much of a strain at the connection between the ORVR valve and the

vent hose (figure 12).

To resolve the concern without dropping the fuel tank, grasp the plastic

vent hose close to the top of the tank and push towards the ORVR valve.

If the hose was partially disconnected, you will hear a click.

Retest the system with the EVAP system tester. If you still see smoke,

rotate the vent hose toward the center of the vehicle. Remove the vent

hose from the side of the fuel tank. Grasp the hose at the top of the

tank and gently move the hose toward the middle of the vehicle. You should

only have to move the valve slightly to correct the leak (figure

13).

Retest the system for leaks. When the leak is corrected, you will no longer

notice smoke leaving the EVAP system. Make sure you clear the DTCs before

returning the vehicle to the customer.

- Thanks to Jeff Strausser |

figure

12 |

figure

13 |

| return

to Table of Contents |

|

| Powertrain

Quality Center Update |

A

new Powertrain Quality Center (PQC) was implemented July 1 to obtain faster

and more accurate quality information on all replaced assemblies (August

2002 TechLink).

This information and more is included in a new bulletin 02-07-30-029A

issued in September.

TIP: Before replacing

an OEM engine or transmission, service assembly or over-the-counter assembly,

be sure to follow instructions in bulletin 02-07-30-029A.

The new bulletin explains which engine and transmission assemblies are

involved, how to obtain pre-approval, and how to submit warranty claims.

It also includes a two-page template which acts as a guide to the information

required by PQC for pre-approval of warranty engine assemblies.

TIP: Fill out a

copy of this template before calling PQC, to expedite the phone call and

avoid callbacks.

- Thanks to Jim Colyer |

| return

to Table of Contents |

|

| |

Owners

of some 2002 Oldsmobile Alero and Pontiac Grand Am models may comment

about poor radio reception. This condition may be caused by a poor antenna

co-ax connection at the passenger side lower kick panel (area in front

of door, under the instrument panel). To correct this condition, remove

the lower kick panel (figure 14), re-connect

the antenna co-ax and tape the connection securely to avoid any future

disconnection.

- Thanks to Ray Romeo |

figure

14 |

| return

to Table of Contents |

|

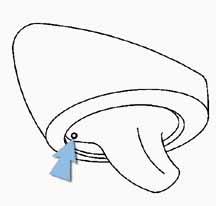

| Visor

Contacts Inside Mirror |

Owners

of some 2000-03 Buick Century or Regal models may comment that the visor

contacts the rear view mirror when moving the visor downward. This condition

may be more likely with the OnStar® mirror.

This condition, which may caused by the inside rear view mirror being

placed in a higher position during the assembly process, is easily correctable.

The mirror has a ball pivot on the windshield side (toward front of vehicle)

and a ball pivot on the mirror side (toward rear of vehicle). The rear

ball pivot must be moved downward. This places the mirror assembly lower

on the windshield, allowing clearance between the visors and mirror. Minor

adjustment may be necessary, right or left.

After completing the previous process to center the mirror between the

sun visors, adjustment for rear vision is made using the ball socket on

the mirror side.

TIP: This same

procedure may be used to remedy comments about being able to see the roof-mounted

console in the rear view mirror on some vehicles.

- Thanks to Wayne Zigler |

| return

to Table of Contents |

|

| Sunshade

Removal Tips |

The

new style 2002 -2003 S/T GMC Envoy, Chevrolet TrailBlazer, Oldsmobile

Bravada, GMC Envoy XL and Chevrolet TrailBlazer EXT vehicles are all equipped

with a tab-retaining sunshade system that attaches to the roof sheet metal.

Sunshade Removal Procedure

The sunshade can be removed without degradation to the retaining system

or to the roof sheet metal by following the removal procedure in the GM

service manual.

This is the recommended service manual method for removing the sunshade

.

- Remove the windshield

garnish molding.

- Release the

front assist handle from the headliner.

- Recline the

bucket seat and release the upper portion of the center pillar trim

panel.

- Open and rotate

the sunshade parallel to the side window.

- Insert a small

tool into the bezel access hole (figure 15).

IMPORTANT:

Midway through the rotation cycle the tool will move further into the

access hole.

- Push upward

on the tool while rotating the sunshade parallel to the windshield.

The sunshade pivot arm bezel should appear to be recessed into the

bezel.

IMPORTANT:

Ensure the pivot arm is recessed into the bezel before removing the

sunshade from the headliner.

- Apply outbound

pressure to the sunshade while the sunshade is parallel to the windshield

(figure 16).

- Pull the sunshade

downward while maintaining outbound pressure to the sunshade. You

will notice a separation between the headliner and the sunshade bezel.

- In order to

remove the sunshade from the headliner, carefully grab the headliner

at the windshield pillar area and apply downward pressure while gently

rocking the sunshade up and down.

- Remove the inboard

retainer screw.

- Remove the inboard

retainer from the headliner.

- If equipped

with lighted sunshades, perform the following:

- Reach above

the headliner to access the electrical connector.

- Remove the electrical

connector from the headliner substrate.

- Disconnect the

sunshade electrical connector from the headliner harness.

- Remove the sunshade

from the vehicle.

Roof Sheet

Metal Inspection

Following the recommended removal method in sequence

will ensure the integrity to the roof sheet metal. In the event the

sunshade was removed before reviewing the service manual, inspect the

roof sheet metal for any potential degradation and straighten the effected

areas before installing the sunshade (figure 17).

Installation

Refer to the GM Service Manual for the installation procedure

of the sunshade and inboard retainer, and the torque specifications

to the inboard retaining screw.

- Thanks to Jim Clower and Andy Slawick |

figure

15 |

figure

16 |

figure

17 |

| return

to Table of Contents |

|

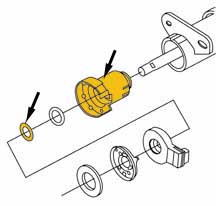

| Steering

Clunk Noise |

Owners

of some 1998-2002 Cadillac Sevilles may comment about a clunking or rattling

noise heard while travelling over bumps. The sound comes from the lower

steering column, and may be caused by the clearance between the steering

shaft and lower steering column shaft bearing.

A new bearing 26100500 and retainer 07847029 have been released to address

this condition. Figure 18 shows the retainer

on the left and the bearing on the right.

TIP: The retainer

is used on power tilt and telescope columns only.

Refer to bulletin 02-02-35-004 for details.

- Thanks to Bill Denton |

figure

18 |

| return

to Table of Contents |

|

| Blower

Motor Inoperative |

Owners of some 1999-2002

Oldsmobile Alero and Pontiac Grand Am models may comment that the blower

motor is inoperative. If the correction requires resistor replacement,

check the resistor for signs of corrosion. If signs of corrosion are

present, refer to bulletin 01-08-57-003 and verify that the air intake

foam sealing strip is correctly positioned and securely adhered. This

additional step will help prevent repeat occurrences of this issue.

- Thanks to Ray Romeo |

| return

to Table of Contents |

|

| Hose

Clamps Eliminated |

Clamps

have been eliminated from both ends of the radiator overflow hose on mid-year

2002 S/T vehicles. This is not a production error; do not install clamps

under warranty.

- Thanks to Dan Oden |

| return

to Table of Contents |

|

| Radio

Programming |

In

the past few months, GM Service and Parts Operations has fielded a variety

of calls from technicians who have encountered programming issues with

up-level radios which have been swapped from another vehicle.

The following procedures must be followed when swapping up-level radios

for:

- 2003 C/K Trucks

and Sport Utilities

- G and H Vans

- Hummer H2

- C Series Medium

Duty Trucks.

NOTICE:

Failure to do so will cause permanent damage to the

radio.

- First, ensure

that the TIS software is up to date at the Techline client and then

update the Tech 2 accordingly.

- Check the RPO

code of the original radio in the vehicle. If the RPO code of the

radio being installed is the SAME as the RPO code of the original

radio, program as normal.

- If the RPO code

of the radio being installed is DIFFERENT from the RPO code of the

original radio that is being removed or swapped, you must call the

Techline Customer Support Center (TCSC) for a VCI number BEFORE programming

the radio.

US dealers call

1.888.337.1010 (Prompt 3).

Canadian dealers call 1.800.828.6860 (English) or 1.800.503.3222 (French).

If you need assistance with programming, please contact the Techline

Customer Support Center at the number listed above.

- Thanks to Craig Jones and Rich Adkins |

| return

to Table of Contents |

|

| Key

Release Difficulty |

Owners

of some 2003 Cadillac CTS models may experience the inability to remove

the key from the ignition lock cylinder, even though the battery is in

a good state of charge.

This condition may be caused by a misadjusted transmission shift control

linkage. The gate-release button on the shift knob has a micro-switch

which allows the ignition key to be released. The cable adjustment is

crucial to the proper operation of the key. Refer to current document

ID 792993 in SI for the proper shift control linkage adjustment procedure

before proceeding with additional diagnosis.

- Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

| New

Engine Coolant Fill Procedure |

On 2003 G and H

vans with a 4.8, 5.3, or 6.0L Gen III V8 engine, there is a new engine

coolant fill procedure. It is necessary because the engine cooling system

does not use a pressurized coolant surge tank.

After the engine coolant has been drained from the engine, if engine

coolant is added only through the radiator neck and engine coolant overflow

reservoir, the engine coolant may not flow beyond the closed thermostat,

located on the engine at the lower radiator hose connection. Although

the engine coolant level may appear full in the radiator neck, the system

may be 4 to 6 quarts low, and a major engine overheat condition may

occur.

After correcting the reason for the coolant drainage, use the following

procedure to fill the entire engine cooling system to capacity.

Remove the upper radiator hose at the radiator. Remove the half-inch

diameter coolant air bleed hose from the radiator, located 5 inches

below coolant pressure cap.

Slowly fill the cooling system through the upper radiator hose with

coolant mixture until it flows without air bubbles from the coolant

air bleed hose, and coolant level stabilizes in the upper radiator hose.

Install the coolant air bleed hose and the upper radiator hose to the

radiator. Fill the radiator with coolant mixture and install the coolant

pressure cap.

Start and run the engine at 2000-2500 RPM until the engine reaches normal

operating temperature. Then, allow the engine to idle for 3 minutes.

Shut the engine off and allow the engine to cool. Top off the coolant

as necessary in the reserve tank, inspect the concentration of the engine

coolant, rinse away any excess coolant from the engine and the engine

compartment, and inspect the cooling system for leaks.

The written procedures on the GM SI website will be corrected shortly

and a Service Manual Update bulletin will be published.

- Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

| Headlamp

Replacement Due To Moisture |

Owners of some 2000-2003

Chevrolet Malibus may comment on moisture in one or both headlamps.

This may be due to normal atmospheric conditions.

The headlamps on the Malibu are vented, and may exhibit fine condensation

on the inner surface of the lens under certain atmospheric conditions.

This condensation will clear more quickly with the headlamps turned

on or when the vehicle is in motion. It may take up to six hours for

the moisture to clear under these conditions.

Headlamps should not be replaced for fine condensation on the inside

of the lens that clears with operation of the lamps. Headlamps should

be replaced only if:

- there is water

accumulated in the bottom of the lamp

- the moisture

does not clear with operation of the lamps

- comparison with

the lamp on the opposite side of the car indicates a difference in

performance.

TIP:

The black rubber seal around the outside of the lamp is for appearance

only, and does not seal the lamp from moisture.

For more information on evaluating exterior lamps for moisture inside

the lamp, please refer to bulletin 01-08-42-001.

- Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

| Power

Door Lock Programming |

On 2003 Chevrolet

Tahoe, Suburban, Silverado C/K Pickup, and GMC Yukon, Yukon XL, or Sierra

C/K Pickup, customers may have difficulty in programming the automatic

door locks, following the procedure in Section 2 of the owner's manual.

The corrected procedure is located in SI under document number 866362

and can be made available to your customers. These procedures are not

part of the Driver Information Center programming feature found in Section

3 of the owner's manual.

TIP: When cycling

through the lock and unlock modes by using the lock and unlock switches

on the door, count the number of chimes heard after each press of the

switch to determine each lock option.

- Thanks to GM Technical Assistance |

| return

to Table of Contents |

|

| Bulletins

- October, 2002

This review

of service bulletins released through mid-September lists the bulletin

number, superseded bulletin number (if applicable), subject and models. |

00

- General Information

02-00-89-014; New Labor Operation Codes for Dealer-Installed GM Accessories

Replaced During Warranty Coverage Period; 2002 and Prior GM Passenger

Cars and Trucks, 2003 Hummer H2

02-00-89-015; Dealer Installed Regular Production Accessories (RPA);

2003 Buick Rendezvous, Pontiac Aztek

01 - HVAC

02-01-39-004; New PAG Oil Released; 2002 Chevrolet Cavalier, Oldsmobile

Alero, Pontiac Grand Am, Sunfire, with 2.2L Engine (VIN F -- RPO L61),

all 2002 Passenger Cars, Trucks and Hummer H2

03 - Suspension

02-03-09-002; Intermittent Boom, Rumbling Noise and/or Disturbance Heard

in Passenger Compartment While Driving at Highway Speeds (Replace Rear

Coil Springs); 2002 Chevrolet TrailBlazer, GMC Envoy with Rear Coil

Springs

02-03-10-005; Diagnostic Tips for Steering Wheel Shake/Vibration (Oscillation)

Concerns; 2003 Chevrolet Kodiak and GMC Topkick C4500-C5500 Conventional

Cab

05 - Brakes

02-05-25-005; Diagnostic Trouble Code C0201 Set and Stored in History;

2003 Chevrolet Express and GMC Savana 2500/3500 Vans, Chevrolet Silverado

and GMC Sierra 2500/3500HD Pickups with Manual HVAC (RPOs CJ3 or C42)

06 - Engine/Propulsion System

02-06-01-027; Higher Than Expected Oil Consumption; 2002-03 Chevrolet

Silverado and GMC Sierra 2500-3500, 2003 Chevrolet Kodiak and GMC Topkick

C4500-C5500 with 6.6L Duramax(tm) Diesel Engine (VIN1 -- RPO LB7)

02-06-01-028; Engine Crankcase Flush; 2003 and Prior GM Cars and Trucks,

2003 Hummer H2 with Gasoline Engines

02-06-03-008; replaces 43-64-07A; Low Voltage Display on IP Gauge, Lights

Dim at Stop Lights, Battery Discharged, No Start, Slow Cranking, Dim

Lights at Idle, Low Generator Output; 1990-2003 Passenger Cars and LD

Trucks, 2003 Hummer H2

02-06-03-009; Battery Charging Tips; 1990-2003 Passenger Cars and LD

Trucks, 2003 Hummer H2

02-06-04-041; Diagnostic Hints/Troubleshooting Guide for Denso Common

Rail Fuel Systems; 1999-2002 Chevrolet and GMC C-Model MD Tilt Cab,

2000-03 Chevrolet and GMC WT5500 MD Tilt Cab

02-06-04-043; Revised DTC P0340 Camshaft Position Sensor (CMP) Sensor

Circuit Diagnostic; 1996 Chevrolet Astro Van, GMC Safari Van with 4.3L

Engine (VIN W -- RPO L35)

02-06-04-044; Service Engine Soon (SES) Light Illuminated, DTC P0440

Set (Replace Fuel Tank Evaporative Emissions Control System EVAP Vent

Solenoid Harness); 2000-02 Chevrolet Cavalier, Pontiac Sunfire

02-06-04-045; Revised DTC P0327; 2002 Chevrolet Cavalier, Oldsmobile

Alero, Pontiac Grand Am, Sunfire

07 - Transmission/Transaxle

02-07-30-022A; replaces 02-07-30-022; Service Engine Soon (SES) Light

On with DTCs P0716 and/or P0717, P0730, P0753, P0758, P1860, P1887,

or other Miscellaneous Transmission Trouble Codes Set (Repair Wiring

at Transaxle Wiring Pass-thru Connector); specified 2000-03 Passenger

Cars and Vans with 4T65-E, 4T40-E or 4T45-E Transaxle (RPOs MN3, MN7,

M15, M76, MN4, MN5)

02-07-30-025A; replaces 02-07-30-025; Harsh Shifting, Delayed Upshifts,

Possible CHECK TRANS Lamp Illuminated, Possible DTC 21 Stored in TCM

Memory (Follow TPS Relearn Procedure); 1999-2003 Chevrolet and GMC W-Series

MD Tilt Cab Models with Diesel Engine and Aisin Automatic Transmission

02-07-30-030; Transmission 1-2 Shift Shudder, Vibration, Slips, Chuggle

(Install Generator Voltage Sense Circuit); 2001-03 Chevrolet Silverado,

GMC Sierra with 4L60-E Automatic Transmission (RPO M30)

08 - Body and Accessories

01-08-66-005B; replaces 01-08-66-005A; Availability of Pickup Box Reinforcement

Kits for Toolbox/Rear Window Barrier/Ladder Rack Applications; 1999-2003

Chevrolet Silverado and GMC Sierra (New Body Style) Pickups with Steel

Fleetside Pickup Box (RPO E63), Except Dual Rear Wheel (RPO R05), Stepside

(RPO E62) and Inner Composite (RPO E37) Pickup Boxes

01-08-66-014A; replaces 01-08-66-014; Pickup Box Sheet Metal Fracture/Damage

with Aftermarket Accessories Installed (Repair Pickup Box Fracture/Damage

and Install Pickup Box Reinforcements); 1999-2003 Chevrolet Silverado

and GMC Sierra (New Body Style) Pickups with Steel Fleetside Pickup

Box (RPO E63), Except Dual Rear Wheel (RPO R05), Stepside (RPO E62)

and Inner Composite (RPO E37) Pickup Boxes

02-08-44-012; Enable or Disable Remote Keyless Entry (RKE) Radio Personalization

Feature; 2000-02 Chevrolet Cavalier, Malibu, Oldsmobile Alero, Pontiac

Grand Am, Sunfire

02-08-61-003; Side Assist Step Pad Warping (Install New Step Pad Kit);

2001 GMC Sierra C3 Luxury Pickup Models with Uplevel Side Assist Steps

(RPO BVF)

02-08-62-001; Front Fascia Loose (Replace Front Fascia Pencil Braces);

2002 Chevrolet TrailBlazer, GMC Envoy, Oldsmobile Bravada built before

VIN breakpoint

02-08-64-017; No Start, Service Engine Soon Lamp On, ABS Warning Lamp

On, Air Bag Light On, DTCs Set, Various Door Electrical Functions Inoperative

(Replace Driver and/or Passenger Door Harness and/or Repair Body Harness

Connector); 2002 Chevrolet TrailBlazer, GMC Envoy, Oldsmobile Bravada

built before April 2002

02-08-66-005A; Loose or Broken Rear Compartment Opening Molding (Install

New Molding Assembly); 1997-2002 Chevrolet Malibu, 1997-99 Oldsmobile

Cutlass, 1999-2002 Oldsmobile Alero and Pontiac Grand Am

02-08-98-001A; Metal Panel Bonding; 2003 and Prior GM Passenger Cars

and Trucks, 2003 Hummer H2 |

| return

to Table of Contents |

|

|

|