| |

|

Note:

Clicking on any picture or illustration will open a larger version

of that art.

|

BREAKING

NEWS

|

2004

Cadillac CTS models with the 3.5L V6 engine (RPO LY7) require use

of the CANdi module when using the Tech 2. Refer to the March 2003

TechLink for installation and functionality testing. The CANdi module

can remain in place for all 2004 Cadillacs. http://service.gm.com |

| return

to Table of Contents |

|

|

|

Electric

Power Steering (EPS) |

For several years,

GM vehicles have offered steering systems involving electronics.

The Magnasteer system (TechLink Dec. 2000) uses an electronically

controlled magnetic unit to vary the amount of effort needed to steer

the vehicle. Quadrasteer (TechLink, Dec 2001) uses an electronically

controlled electric motor to provide steering for the rear wheels.

Now, the 2004 Chevrolet Malibu is offering an Electric Power Steering

(EPS) system (fig. 1), which uses an electric motor to provide steering

assist to the front wheels. This eliminates the power steering pump,

hoses, control valve and piston/cylinder assembly.

The EPS motor provides a variable amount of assist directly to the

steering shaft, based on vehicle speed and input torque. The motor

and the Power Steering Control Module (PSCM) are mounted as an assembly

directly to the steering column.

TIP: Unlike Magnasteer, which is controlled by the Electronic Brake

Control Module, the EPS has its own control module.

The EPS motor is a 65 amp, brushless, 12-volt reversible unit. It drives

the steering shaft through a worm shaft and 22:1 reduction gear.

This method of providing boost is considerably different from a hydraulic

assist. In the hydraulic system, pressure is applied directly to the

steering rack to help move it side to side. On the EPS system, boost

is applied to the steering shaft, which helps the driver turn the steering

pinion.

Because the electric motor draws a large amount of current when it

is running, the system has built-in overload protection. Heat build-up

may be a factor at high ambient temperatures, when a large amount of

steering wheel movements occur in a short period of time (such as repeatedly

performing lock-to-lock turns, while standing still). It’s unlikely

that a customer will experience this.

The software in the controller keeps track of current usage and compares

that with the known heat buildup of various components. If a heat threshold

is reached, the controller uses pulse width modulation (PWM) to temporarily

limit current to the motor. This is called de-rating. In this rare

instance, the driver would notice a temporary reduction in boost.

The EPS control module depends on various inputs:

- Vehicle speed

- Steering shaft torque sensor

- Steering wheel position sensor

In a hydraulic power steering system, the input and output steering

shafts are joined by a small torsion bar. Two halves of a hydraulic

flow valve are attached, one to each shaft. When torque is applied,

the torsion bar twists, the valve halves move relative to each other,

and fluid is allowed to flow. In the electric power steering system,

the upper and lower torque sensor rotors, which use resistive elements,

are mounted to the input and output shafts. When torque is applied,

the torsion bar twists, the rotors move relative to each other, and

the movement affects the difference in resistance between the two rotors.

This electrical information is used by the PSCM as the torque input.

Boost is provided, proportional to torque. The combined torque/hand

wheel position sensor assembly is contained within the steering column.

Each EPS unit is calibrated for the vehicle in which it is installed,

which ensures the proper amount of assist and road feel. The calibration

is called the Steering Tuning Selection and is specific to the vehicle’s

VIN. It can be read from the module, using the Tech 2.

Service

The EPS motor and control unit are replaceable as an assembly. The

torque sensor and steering wheel position sensor are serviced by replacing

the steering column assembly.

If components are replaced in the EPS system, it is necessary to perform

a hand wheel position sensor calibration so the system knows where

the center position is for the steering wheel.

There’s a torque sensor zero calibration, which affects on-center

effort bias.

And, the correct Steering Tuning Selection will also have to be made

so the system knows which boost curve to use for that particular vehicle.

Diagnosis

Diagnosis of the EPS system is aided by the following data readouts

using the Tech 2 scan tool:

- Battery Voltage

- Calculated System Temperature

- Engine Speed

- Motor Command

- Motor Feedback

- Steering Shaft Torque

- Steering Position Sensor

- Steering Tuning Selection

- Steering Wheel Position

- Torque Sensor Signal

- Vehicle Speed

The PSCM module communicates using the GMLAN network.

-

Thanks to David Juarez |

figure

1 |

|

|

|

|

|

|

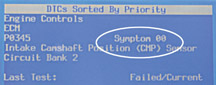

| DTC

Symptoms |

Background

As the complexity of GM vehicles has increased, so has the need

for additional DTC (Diagnostic Trouble Code) numbers.

For a given circuit or circuit type, 5 consecutive DTC numbers were

usually assigned in the following format:

B2700 Ignition Shift Interlock Circuit (base number)

B2701 Ignition Shift Interlock Circuit Range/Performance

B2702 Ignition Shift Interlock Circuit Low

B2703 Ignition Shift Interlock Circuit High

B2704 Ignition Shift Interlock Circuit Open

For some circuits, not all 5 of the assigned DTCs were actually needed.

But because assignments were made according to the formatting plan,

many new types of circuits consumed 5 numbers.

The list of numbers available for DTCs used on GM vehicles worldwide

was being rapidly depleted.

When the message structure of the GMLAN Serial Data Network was being

developed (see March 2003 TechLink), an additional byte of data was

included in each DTC Message. So, additional information could be displayed

on the scan tool for a circuit failure without assigning more than

one DTC number to a given circuit. This extra data is being called

the DTC Symptom.

This byte of data can be indicated with two alphanumeric characters.

The first character following the DTC indicates the DTC Symptom category

and the second character indicates the subtype of the DTC Symptom.

There’s a complete list of categories and subtypes in SI under

the 2004 XLR or the 2004 Malibu. Follow this path:

- “Build” the vehicle

- Vehicle Control Systems

- Vehicle DTC Information

- Description and Operation

- DTC Symptom Description

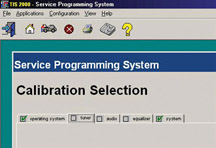

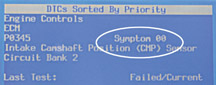

Display of DTC Symptoms

When DTC Symptoms are available on the scan tool, they will be displayed

separately from the DTC number (fig 2).

Service Information will also deal specifically with DTC Symptoms.

Information about the DTC Symptom(s) will be provided in the facing

page information for a DTC. See the accompanying sample from a facing

page (fig. 3).

In many cases, the diagnostic procedure in Service Information is the

same for a given DTC regardless of DTC Symptom. In some cases, different

diagnostic procedures will be used for different DTC Symptoms with

the same base DTC number. In either case, use the Search function in

ESI to find DTCs by base DTC number only, and if necessary, select

the appropriate procedure for the DTC Symptom after the search.

A special case of the DTC Symptom is when the base DTC is the only

malfunction identified. Additional information that a DTC symptom would

provide is not needed or recorded by the module. The base DTC number

and descriptor provide all the information that is available. In that

case, the DTC Symptom displayed is 00 (No Additional Information).

If 00 is displayed as a DTC Symptom, there is not a fault with DTC

display on the scan tool; it is just indicating that no additional

information is available..

-

Thanks to Gary Clark

|

figure

2

|

figure

3 |

| |

| |

|

|

Programmable

Radios |

At

present, radios are programmable on the following vehicles:

2003 C/K vehicles

2003 G/H vans

2003-04 Hummer H2

2004 all light and medium duty trucks

These radios must be programmed when a new unit is installed or radios

are swapped. In the past, it was necessary to call the Techline Customer

Support Center for a VCI number to complete the event. The new process

makes this phone call unnecessary.

Requirements

To use this procedure, you must be using TIS satellite version 9.0 and

Tech 2 software version 23.005 (or newer). This coverage was released

in late August.

Procedure

You will need the following information before you begin:

- RPO code of the radio you’re going to program

- RPO code of speakers

- On C/K trucks, observe if there’s a Y91 amplifier package

- On Hummer H2, observe if there’s a Y91, Y92, or no amp package

- Be aware that RPO UC6 is a six-disc in-dash CD changer.

TIP: On vehicles with RPO U42 DVD player, you must pull the DVD fuse

before programming the radio.

TIP: You must install the radio to be programmed in the vehicle before

beginning the request process.

Begin by requesting information from the vehicle. The Tech 2 will gather:

- Calibration numbers

- VIN

- Radio’s 8-digit GM part number

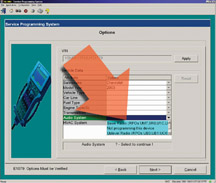

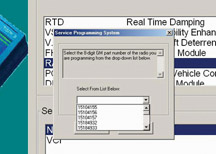

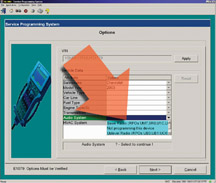

Connect the Tech 2 to a PC with the TIS application. The next part of

the process is automated and transparent. TIS will obtain the VIN and

radio 8-digit part number from your Tech 2, and will then locate and

display the appropriate Option Screen. In the turquoise area of the display

(fig. 4), make the necessary selection, based on the known radio RPO.

Fill in other option selections as required; i.e., HVAC.

TIP: Ordinarily, the Radio Part Number Select popup will not appear,

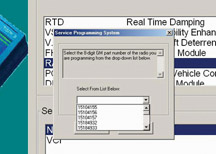

because TIS will obtain the number from the Tech 2. But if the popup

does appear (fig. 5), it may be because

- The Tech 2 does not contain software version 23.005 or newer. In

this case, you must manually select the correct radio part number from

the

list provided. You can obtain the number from the tag on the radio,

or by using the Tech 2 Diagnostic Functions to read the number from

the

radio.

- Something is wrong with the radio.

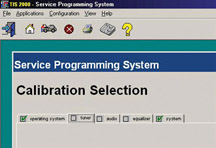

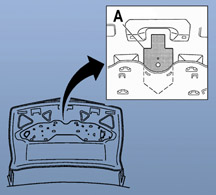

On the Supported Controller screen, select Radio and select Normal.

Then when the Calibration screen appears, deal with each available

tab, one

at a time (fig. 6).

Under the Tuner tab, specify the country in which the radio will be

operated. This affects the range of frequencies displayed.

Under the Audio tab, you will need to make a selection based on the

radio’s

RPO code.

Under the Equalizer tab, you need to know and specify the vehicle’s

cabin and speaker configuration. This affects how the radio sounds

in its surroundings.

Return to the vehicle and download the programming data to the radio.

TIP: If you make any errors during the selection process, improper

calibrations could result in no audio and/or no chime functions. (The

radio will light

up but has no volume.) If this occurs, DO NOT replace the radio. Start

the selection and calibration process again.

Finally, as with any programming event, check for codes.

- Thanks to Chris Jenkins, Craig Jones and

Mark Stesney |

| |

figure

4

figure

4 |

figure

5 |

figure

6 |

| return

to Table of Contents |

| |

| Accessing

GM Common Training Website (USA only) |

The

July issue of TechLink mentioned the Terminal and Connector Reference

Guide and gave the wrong instructions on how to obtain a copy.

We suggest following this path to obtain this information from the GM

Common Training website:

- https://www.gmcommontraining.com

- Use your ID and password

- Select Resources

- Select Training Materials

- Select 18043.05B - GM Terminals and Connectors Reference Guide

-

Thanks to Chris Wallace |

| |

| return

to Table of Contents |

|

| Corrections |

An

article in the July 2003 issue of TechLink involving Switch Plate

Bezel Removal contains an error in the applicable model years. It

applies to 2003 - 04.

An article in the August 2003 issue involving Front Stabilizer Shaft

Installation refers to 2003 vehicles. It should have said 2004.

|

| return

to Table of Contents |

|

| XM

Satellite Radio News |

There’s

a lot of news about XM™ Satellite Radio for the 2004 model

year.

New Models Added

First, a number of additional vehicles will be offering XM radio in 2004:

Canyon, Colorado, Envoy, Envoy XL, Envoy XUV, Grand Prix, Ion, Malibu,

Malibu Maxx, Montana, Rainier, SRX, Trail Blazer, Trail Blazer EXT, Venture,

Vibe, Vue, and XLR.

All vehicles that offered XM radio in the past will continue for 2004.

New Antenna Technology

Beginning with the 2004 model year, a new XM antenna is being installed

on some vehicles (fig. 7). The list includes Avalanche, Denali, Denali

XL, Escalade, Escalade ESV, Escalade EXT, Sierra, Silverado, Suburban,

Tahoe, Yukon, and Yukon XL. The DeVille, Seville, Bonneville, and LeSabre

will switch to this new antenna mid-year. And also mid-year, the 2004

Envoy, Envoy XL, Envoy XUV, Rainier, TrailBlazer, and TrailBlazer EXT

will switch to a different new antenna (fig. 8).

The XM antenna used in the 2002-03 model years included two different

elements, one to receive signals from the satellites, and a second one

to receive signals from the ground repeaters. Two coax cables were required.

The new antennas use one element to receive both sets of signals, and

only one coax cable is required.

TIP: The two types of antenna cannot be interchanged in service.

XM Radio Activation

At present, all vehicles with XM radio arrive at the dealership with

ten rotating free-to-air channels. It’s necessary to phone XM radio

at 800.556.3600 to activate the service. Beginning in October, the ten

free-to-air channels will be phased out. Dealers will be able to activate

all of the vehicles on their lot through a process called Rapid Activation,

turning all of their vehicles into XM demonstrators. The only information

needed to Rapid-Activate a vehicle is the 8-digit XM radio ID, obtained

by tuning to XM channel 0.

TIP: When a customer buys an XM-equipped vehicle that has been Rapid

Activated, an account is automatically set up at XM, when the Customer

Delivery Record is received.

Beginning early in calendar year 2004, all vehicles will arrive pre-activated

from the factory. Each customer will have several choices:

1. Accept the vehicle with the radio activated and enjoy 3 months of

free service before deciding to continue. XM will send information to

the customer about extending their subscription.

2. Sign up for a multi-year subscription.

3. Tell the dealer that they are not interested in 3 months of free service.

Theftlock

To deter theft, all XM receivers are programmed to learn the VIN of the

vehicle in which they are installed, using the Class 2 data line. As

soon as the VIN is learned, the unit becomes “locked.” That

is, it cannot be moved to a vehicle with a different VIN -- it will not

work. Once locked, the receiver can be installed only in the original

vehicle.

Cadillac XLR Antenna

On the XLR, the XM radio antenna must be installed during new vehicle

preparation, if the customer desires XM service. This is explained on

an instruction sheet accompanying the vehicle. It is also highlighted

in an accompanying article.

TIP: All XLR service stock antennas are unpainted, and must be painted

before installation.

Other

XM radio receivers are still on a parts restriction. After diagnosis,

call GM TAC at 877.446.8227. (The prompt for XM radio is combined with

the OnStar prompt.) After verifying your diagnosis, the TAC consultant

will order a replacement. Use the supplied pre-paid return label to return

the original receiver to avoid a non-return core charge.

Soon, you will be able to use the Tech 2 to read the serial number from

the XM radio receiver. TechLink will publish the necessary path when

it becomes available.

The XM antenna is molded of black plastic. Do not attempt to apply paint

or clearcoat; doing so can reduce system performance. This does not apply

to the Cadillac XLR antenna.

The factory location for each antenna was optimized for performance by

GM engineering. Do not attempt to relocate the antenna, as this can cause

degraded performance.

And finally, the antenna needs to be attached to a solid surface. Do

not install cloth or vinyl roof covers on XM-equipped vehicles. This

may cause degraded performance and could also lead to water leaks.

-

Thanks to Doug McKibbon

|

figure 7

|

figure

8 |

| |

| return

to Table of Contents |

|

| Console

Latch Lubricant |

Owners of some 1999-2003 Chevrolet and GMC fullsize pickups and utilities

with a center console may comment that the lid is hard to open or

close. According to bulletin 02-08-49-007, this may be caused by

insufficient lubrication on the latch.

TIP: Do not replace parts in an attempt to repair this condition.

TIP: If the lid will not open, depress the center console latch handle

button and give the top of the center console lid a sharp rap with your

hand.

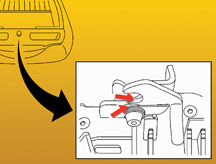

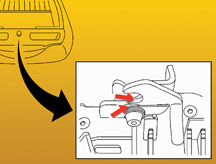

Apply a small amount of GM Dri Slide® Lubricant 1052948 (992926 in

Canada) to the center console latch, through the opening in the latch

trim plate (fig. 9). Operate the latch while spraying to work the lubricant

into the mechanism.

Open and close the console lid several times to verify the proper operation

of the latch.

- Thanks to Jerry Garfield |

figure

9 |

|

return

to Table of Contents |

|

| XM

Antenna Installation on XLR |

When

a 2004 Cadillac XLR is ordered with the optional XM radio, the antenna

is shipped loose. It must be installed before delivery of the vehicle

(at customer request). A detailed instruction sheet is supplied with

the antenna kit. Here are some highlights.

TIP: Install protective coverings over the rear compartment and adjacent

panels. The folding top must be in the lowered position and the compartment

lid open.

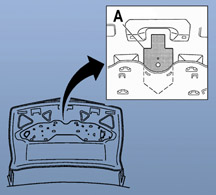

On all XLR models, an AM/FM antenna ground plate is attached to the underside

of the rear compartment lid. A supplemental ground plate/template is

supplied with the XM antenna. It must be positioned and installed before

the XM antenna is installed (fig. 10).

A Template

TIP: For the first several months of production, it will be necessary

to temporarily remove the large ground plate from the underside of the

rear compartment lid. In later production, it will be reshaped and can

be left in place. The instruction sheet provided with the antenna kit

will reflect the appropriate steps.

The XM antenna ground plate/template aligns to a recessed feature in

the rear compartment lid. It serves as a template to mark the locations

for two pilot holes on the underside of the rear compartment lid.

A strip of masking tape is used to protect the exterior surface of the

compartment lid while the pilot holes are enlarged as instructed.

TIP: After the pilot holes are drilled and enlarged, remove masking tape

and drilling remnants and use GM RTV silicone rubber sealant (12345739)

to seal the raw edges of the holes.

The XM antenna ground plate/template is equipped with an adhesive material.

Peel the backing and install the plate to the underside of the compartment

lid.

TIP: When the backing is removed, be sure the diecut discs are also removed

from the mounting holes.

Then follow the instructions to install the XM antenna, fasteners, and

wiring.

On early models, follow SI procedures to reinstall the large ground plate

to the rear compartment lid. On later models, this step will not be necessary.

Then use your Tech 2 to verify that the proper parameters are displayed,

and clear DTCs, following the instruction sheet.

The vehicle is now ready for the XM radio receiver to be activated.

- Thanks to Jason Macco |

|

figure

10

|

| return

to Table of Contents |

|

| Cadillac

XLR Trim Removal |

Here

are some tips to help avoid damage when removing the console trim

pieces on the new Cadillac XLR.

The two trim pieces are the console trim plate (which surrounds the shifter

and cupholder) and the instrument panel trim plate (which surrounds the

radio and HVAC controls).

Both of these trim pieces are retained by metal clips (fig.

11), which

must be loosened by prying.

TIP: Use a plastic trim removal stick, to avoid damage to the trim or

surrounding areas.

TIP: Be sure all clips are loosened before pulling on the trim plates,

to avoid deforming the metal covering.

Refer to SI for the complete procedure. The information here is additional

tips.

The console trim plate comes out first. Use a T-15 Torx bit to remove

the shifter handle. Then insert the trim removal stick under the edge

of the trim plate in the area of the rear clip and loosen the clip (fig.

12). Repeat this for each clip, then lift the trim plate off the console.

Refer to the photo for the clip locations (fig.

13).

With the console trim removed, you can remove the IP trim plate. Insert

the trim stick at the upper corner and loosen the top clips (fig.

14).

Work down the sides and loosen the center and bottom clips. Then remove

the trim plate. Refer to the photo for clip locations (fig.

15).

- Thanks to Brad Thacher

|

|

figure

11 |

figure

12 |

figure

13 |

figure

14 |

figure

15 |

| return

to Table of Contents |

|

| Quality

Pre-Delivery Inspection |

Most

customers consider the condition of their new vehicle during delivery

as a direct reflection on your dealership, and on your service department.

A quality pre-delivery inspection (PDI) is critical to customer satisfaction

with their new vehicle, which is reflected in CSI and various automotive

surveys.

Bulletin 03-00-89-006 addresses the PDI process. We’re including

some critical highlights here.

Steering Wheel, Seats, and Interior Door Panels

Interior components are frequently covered in protective plastic.

TIP: Do not use any sharp object or cutting utensil to remove any plastic

coverings.

Leather Steering Wheels -- With your hands at 11 o’clock and 2

o’clock positions, pull the plastic from behind the wheel toward

you and then downward. Do not allow it to twist or bunch up. If there’s

a second layer of thin plastic wound around the wheel, unwind it. Do

not twist it into a wire-like bunch. It could damage the leather.

Seats and Panels -- Plastic wrap caught behind moldings or bezels may

require removal of these trim pieces to remove the plastic. Do not remove

residual adhesive with a razor blade. Do not expose the surfaces to harsh

chemicals.

TIP: The bulletin lists adhesive removers and cleaners that can be safely

used on various interior surfaces. These products must be used with care.

Space does not permit repeating the instructions here. Follow the instructions

on the labels.

Tire Pressure

Tires are inflated at the factory to 35-41 psi (241-283 kPa) to assure

proper tire bead seating.

Tires must be inflated to the recommended pressure before delivery, including

the spare tire. Improper tire pressure may result in ride, handling and/or

noise concerns.

Verify and adjust the tire pressures to the PSI found on the tire placard.

The placard may be located on the front or rear door jamb, inner trunk

lid, or IP compartment lid, depending on model.

TIP: Do not set to the pressure indicated on the tire sidewall.

Exterior Protection

The following list, although not exhaustive, includes some ways you can

minimize damage to vehicles at your dealership.

- Leave exterior protection devices such as plastic sheeting and foam

block door protectors in place up to the time of delivery. (This does

not apply to display vehicles.)

- In northern areas, be careful with ice scrapers and snow shovels. Consider

using plastic implements in storage lots.

- Keep bushes and shrubs trimmed around vehicle storage lots.

- Maintain your dealership car wash equipment. Be sure personnel who

prep new vehicles avoid belt buckles, metal snaps, etc. on their uniforms.

Perceived Fuel Economy

In addition to the information in the bulletin above, there’s also

the matter of perceived fuel economy, particularly on vehicles with a

Driver Information Center (DIC). This is covered in Informational Bulletin

03-00-89-021.

To ensure that the fuel economy displayed is a reflection of the owner’s

driving habits and vehicle usage, it’s necessary to reset the fuel

economy readout just before delivery.

TIP: The way the vehicle is handled during manufacture and shipping may

leave inaccurate values in the DIC.

Refer to the appropriate Owner’s Manual for the reset procedure.

You will find all 2004 Owner’s Manuals on SI.

-

Thanks to Diana Sancya |

return

to Table of Contents

|

|

| Follow

the Links to Complete Diagnosis and Repair |

Following

a repair procedure or diagnostic chart in SI is much like following

written directions when you’re driving to an unfamiliar place.

That is, you must follow every step, in order, without skipping any.

Otherwise, you probably won’t end up where you’re supposed

to go.

In SI, many instructions contain links (underlined and displayed

in blue) that take you to additional, related instructions. It may be tempting

to ignore these links, but you must click each link and perform the instructions

they lead to. Doing otherwise could cause you to overlook or completely

miss important steps.

How SI is Organized

To understand this fully, it helps to know a little bit about how SI

is organized and developed.

Many service or diagnostic procedures are broken down into numerous subroutines,

which can be assembled by the SI developer as needed to complete an overall

procedure. Put another way, an overall procedure may consist of a string

of related subroutines. In many cases, a certain subroutine is used in

more than one procedure. To conserve space, the SI developer places a

link in the procedure to take you to the necessary subroutine, instead

of reproducing it each time it’s used.

(Your own toolbox works like this. You have only one 1/2-inch ratchet

wrench, but you assemble it with numerous different sockets and extensions

to perform countless different tasks.)

This places responsibility on you, the service technician. To get the

whole picture, you must follow each link as instructed.

An Example

An example taken from SI will help explain this.

Suppose you’ve just replaced the Sensing and Diagnostic Module

(SDM) in a vehicle’s airbag system. At the end of the installation

procedure, you’re told to enable the SIR system, and there’s

a link to Disabling and Enabling. If you ignore the link, simply plug

the fuse in and think you’re done, you’ve made a mistake.

In many cases, the vehicle’s BCM will not recognize a new SDM because

it hasn’t yet been set-up/programmed, and will set a code B1001.

And the SIR system will not operate. But, because you have skipped some

important steps, you don’t know that. So now, you can run yourself

in circles, trying to figure out what went wrong.

But, if you had followed the link, you would have discovered that the

AIR BAG indicator was not blinking properly and would have been instructed

to perform a Diagnostic System Check (follow the link!).

The Diagnostic System Check is designed to find symptoms, communication

faults and DTCs. In this case, it would have turned up the DTC B1001,

which would have linked you to the diagnostic table for that DTC. Here,

you would learn that it’s necessary to perform programming so the

BCM will accept the new SDM.

Following the chain of links is the quickest, surest way to reach the

desired outcome.

-

Thanks to Chad O’Brien |

| return

to Table of Contents |

|

| Electric

Mirror Short Circuit |

Product

Safety Bulletin 03006A (May, 2003) explains that a fused jumper harness

(fig.16) may need to be added to the electric mirror switch of certain

1997-98 trucks. This harness addresses the possibility of a short circuit

in the mirror switch. See the bulletin for details.

All steps of the installation procedure must be done, and must be done

in the order given.

TIP: To avoid damaging the fusing circuit contained in the recall harness,

DO NOT connect the two-cavity connector until instructed to do so.

TIP: All terminals must lock into the connectors (check by lightly tugging),

and all terminal position assurance (TPA) locks must be properly installed.

TIP: All connectors must plug together with an audible click.

TIP: If the wires of the original harness or the jumper harness are crossed

(installed into the wrong cavities) when the jumper is installed, improper

operation will result. If the mirrors operate only with the headlamps

turned on, you’ve made a mistake.

-

Thanks to Dan Oden |

figure

16 |

| return

to Table of Contents |

|

| Rusty

Front Brake Rotors |

This

information pertains to 1999-2002 Sierra and Silverado 1500 Series

pickups only.

A new, more-aggressive front brake pad was released for both production

and service in the 2003 model year.

This new pad material has the ability to keep front rotor braking surfaces

clean and free of rust. These pads will also fit 1999-2002 1500 series

pickups.

If you are in an area of high corrosion (for instance, use of road salt)

and are replacing the front rotors due to flaking red rust, you might

want to install this new pad to help prevent a repeat occurrence. The

new pad kit part number is 18048101.

TIP: The new pads will not clean rotors that already have the flaking

red rust condition. Also, these pads should not be used on rear rotors.

-

Thanks to Steve Love |

| return

to Table of Contents |

|

| Oil

Life Monitor Addition |

Please

make the following addition to the Truck Oil Life Monitor article in

the June 2003 issue.

Trucks with DIC

2003 - 04 Sierra

2003 - 04 Sierra Denali

2003 - 04 Silverado

2003 - 04 Yukon, Yukon XL

2003 - 04 Tahoe, Suburban

2003 - 04 Escalade, Escalade EXT

2003 - 04 Avalanche

2003 - 04 Yukon Denali

2003 - 04 Hummer H2

1. Press the fuel information button until ENGINE OIL LIFE appears in

the display.

2. To reset the Oil Life System, press and hold the select button while

ENGINE OIL LIFE is displayed.

OIL LIFE RESET will appear on the display for 10 seconds to let you know

the system is reset.

-

Thanks to Jerry Garfield |

| return

to Table of Contents |

|

| Transmission

Stuck in Gear |

The

1997-2003 Corvette, or 1993-2002 Camaro and Pontiac Firebird equipped

with the 6 speed manual transmission may exhibit the following.

Primary Condition

- Unable to shift out of fourth gear.

Other Conditions

- 3-4 upshift -- hard shift, gear clash, or block-out.

- 4-3 downshift -- hard shift, gear clash or block-out.

- 2-3 upshift -- hard shift, gear clash or block-out.

- third gear hop-out

- fourth gear hop-out.

Replace the aluminum 3-4 shift fork with an iron 3-4 shift fork. The

part number of the iron shift fork as of July 9, 2003 is 88996653 and

is available only through GMSPO.

The 3-4 synchronizer and 3-4 blocking ring should also be replaced at

the same time.

-

Thanks to Mark Gordon |

| return

to Table of Contents |

|

| Belt

Chirp at Shutdown |

Owners

of some 2001-03 Chevrolet and GMC pickups and utilities with the 6.6L

LB7 diesel engine may experience the drive belt chirping on shut down.

This is a normal characteristic of all diesels, caused by the rapid stop

of the cranktrain due to higher compression, compared with a gasoline

engine.

The chirp may or may not occur, depending on variations in temperature,

humidity, engine compression, internal engine friction, belt condition,

tensioner spring tension, tensioner position at the time of engine stopping,

pulley condition, drag imposed by accessory drive components, where the

crankshaft is positioned when the engine is shut down, and any other

possible variables that affect how fast the engine comes to a stop and

variations on belt tension/friction.

For noises with the drive belt at any other time, such as while the engine

is running, refer to SI2000 documents:

677248 -- Drive belt chirping diagnosis

677250 -- Drive belt squeal diagnosis

677252 -- Drive belt whine diagnosis

677254 -- Drive belt rumbling diagnosis

-

Thanks to Jack McVoy |

| return

to Table of Contents |

|

| Aftermarket

Aircleaner |

Owners

of some 2003 Hummer H2s may experience lack or power, transmission

will not upshift, or an erratic shift or stumble.

TIP: Check for an aftermarket air cleaner installed on the vehicle.

Some aftermarket air cleaners pull air directly from the underhood area

of the vehicle at a higher temperature than the OEM airbox. The increase

in temperature can cause erroneous readings from the MAF sensor, causing

the above concerns. If an aftermarket air cleaner is discovered, reinstall

the OEM equipment and re-evaluate.

Follow all SI related diagnostics if an OEM air cleaner box is installed

and the vehicle still exhibits these conditions.

-

Thanks to Sean Garrison |

| return

to Table of Contents |

|

Car

Issues – Fix It Right The First Time Car

Issues – Fix It Right The First Time |

Model

Year(s)

|

Vehicle

Line(s) --

Condition

|

Do

This

|

Don’t

Do This

|

Reference

Information / Bulletin

|

2001-2003

|

3800

L36 – Coolant Leak at Intake Manifold

|

Replace

the intermediate (upper) intake gasket

|

Replace

the intake manifold assembly

|

Bulletin

in process

VME to field 5/30/03

TechLink article in June

|

1998-2003

|

Seville – Rear

Seat HVAC Controls

|

Replace

the knob only

|

Replace

the entire rear seat blower switch assembly

|

03-01-39-001A

|

2000-2003

|

Cavalier/Sunfire/Grand

Am/Alero/Malibu – Inaccurate Fuel Gauge

|

Replace

sensor card for fuel gauge – accuracy issue

|

Replace

fuel sender/pump assembly

|

01-06-04-008D

|

1999-2003

|

Grand

Am/Alero – Window Disengagement, Broken Clips

|

Replace

sash clip only

|

Replace

door glass assembly

|

01-08-64-018

|

1997-2003

|

Grand

Am/Alero/Malibu – Brake Pulsation

|

Turn

rotor and brake align procedure

|

Replace

brake rotor for pulsation

|

00–05-23-002

01-05-23-001 (Know How Video #15040.01B)

|

2002-2003

|

Venture/Montana/Silhouette – Rear

Storage Compartment Link Arm Breaks

|

Replace

link arm

|

Replace

rear storage compartment

|

03-08-110-001

|

1997-2004

|

Century/Regal – HVAC

Operation, No “Auto” Light

|

Normal

in full heat or cold setting

|

Replace

HVAC control head for “Auto” light

|

99-01-39-007B

|

1999-2002

|

Corvette – Fuel

Gauge Intermittently Goes to Empty

|

Install

revised software

|

Replace

fuel senders or I/P cluster

|

02-06-04-010A

|

2003

|

All

cars with 4T40/45E, 4T56E and 4T80E – Code P0742

|

Replace

TCC PWM Solenoid

|

Replace

transmission or valve body assembly

|

02-07-30-039B

|

2002-2004

|

L61

EcoTech 4 Cylinder – Engine

|

Replace

Cylinder Bore Liner

|

Replace

Engine

|

03-06-01-018

|

|

| return

to Table of Contents |

|

|

Truck

Issues – Fix It Right The First Time Truck

Issues – Fix It Right The First Time

|

Model

Year(s)

|

Vehicle

Line(s) --

Condition

|

Do

This

|

Don’t

Do This

|

Reference

Information / Bulletin

|

2003

|

Fullsize

Pickups and Utilities – Transfer Case Service Light

|

Replace

encoder motor sensor and reprogram TCCM

|

Replace

the module, encoder motor or transfer case for DTCs C0327,

P0836, P0500

|

03-04-21-001B

|

1999-2002

|

Fullsize

Pickups and Utilities – Throttle Body Sticks

|

Clean

throttle body adjust blade and insert plugs

|

Replace

throttle body

|

02-06-04-054B

|

2003

|

Fullsize

Pickups – 6.6L Diesel Engine ECM

|

Follow

SI and bulletins for proper diagnostics for P0181. Refer to

the Owner’s Manual (block heater and front cover)

|

Replace

ECM (DTCs P0540 and P0181) unless diagnostics confirm need

to replace

|

02-06-04-048,

03-06-04-021, 02-06-04-058 and parts restriction

|

2003

|

Silverado,

Sierra, Savana, Express > 8600 GVW – ABS Lamp On

|

Reflash

for code C0550

|

Replace

ABS module

|

03-05-25-003

and parts restriction

|

2002-2003

|

TrailBlazer,

TrailBlazer EXT – Wavy Front Fascia

|

Repair

fascia with Dual Lock

|

Replace

front fascia

|

02-08-62-004

|

2002-2003

|

All

TrailBlazers, All Envoys, Bravada – Mirror Erratic Return

|

Replace

mirror actuator and reprogram module

|

Replace

outside mirror assembly

|

02-08-64-008

02-08-64-021

|

1999-2003

|

Fullsize

and Midsize Utilities – Sunroof

|

Install

clip or mechanism kits. GMSPO has component parts.

|

Replace

sunroof

|

02-08-67-009

03-08-67-004

|

1999-2003

|

Fullsize

Pickups and Utilities, Midsize Utilities – Noise on Steering

|

Lube

I-Shaft

|

Replace

I-Shaft

|

00-02-35-003B

02-02-35-006A

|

2002-2003

|

TrailBlazer,

Envoy, Bravada without G67 – Moan/Boom

|

Replace

rear coil springs

|

Repurchase

vehicle for rear axle vibration/boom noise

|

02-03-09-002A

|

2002-2003

|

All

TrailBlazers, All Envoys, Bravada – Inoperative Tail

Light

|

Replace

tail lamp circuit board and bulb

|

Replace

rear tail lamp assembly for brake light

|

03-08-42-006

|

|

| return

to Table of Contents |

|

|

|

Know-How

Broadcasts for October

|

| |

|

| Know-How

Broadcasts for October |

|

10270.10D

Emerging Issues

|

October

16, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

|

10270.22D

- New Model Features - 2004 Pontiac GTO

|

October

30, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

| |

Car

Issues – Fix It Right The First Time

Car

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time