|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Regulated

Voltage Control |

Basic Concept

and Benefits

Traditional charging systems use an internal temperature sensor inside

the generator to establish generator voltage set points. When the generator

is cold, it raises the voltage output set point. When the generator

is hot, it lowers the voltage output set point. This type of system

tends to overcharge the battery on long trips at highway speeds and

undercharge the battery on short trips with low vehicle speeds.

Regulated Voltage Control (RVC) is a new dynamic control of the vehicle’s

system voltage (fig. 1). It regulates the

generator’s output voltage, based mainly on estimated battery

temperature and battery state-of-charge. The main benefits of this system

are:

- Improved fuel economy

- Extended battery life

- Extended lamp life

- Extended switch life

There are two types of RVC systems used today -- integrated RVC and

stand-alone RVC (SARVC).

Integrated systems uses a battery current sensor to provide a body controller

(BCM) the amount the battery is charging or discharging. Accurate voltage

measurements are taken through the battery positive voltage and ignition

1-voltage circuits. The BCM then communicates information over serial

data circuits for the ECM/PCM to directly control the generator.

SARVC systems do not use the BCM for operation. They have a generator

battery control module mounted to the negative battery cable, to interpret

battery current, and voltage and battery temperature inputs. The battery

current sensor is internal to the module. This module also directly

controls the generator L-terminal duty cycle instead of the ECM/PCM.

Both types of system have two types of corrective actions to insure

the battery stays at an 80% state of charge. These include up to three

levels of load shed and up to three levels of idle boost operation.

Refer to the service manual Description and Operation for load shed

and idle boost.

We will discuss the basic operation of the RVC system, the three different

generations of systems used today on GM vehicles, components used on

each separate system and a general diagnostic information section.

System Operation

Not all systems will enter all modes of operation; refer to the applicable

service manual for exact Description and Operation.

The purpose of the RVC system is to maintain the battery state-of-charge

at 80% or above and support vehicle loads.

The six modes of operation include:

- Charge Mode

- Fuel Economy Mode

- Voltage Reduction Mode

- Start Up Mode

- Windshield Deice Mode

- Battery Sulfation Mode

The PCM/ECM (generator battery control module on full-size trucks) controls

the generator through the generator L-terminal control circuit. It monitors

the generator performance though the generator field duty cycle signal

circuit. The signal is a 5 volt PWM (pulse width modulated) signal of

128 Hz with a duty cycle of 0-100%. Normal duty cycle is between 5-95%.

The ranges between 0-5% and 95-100% are for diagnostic purposes. The

following table shows the commanded duty cycle and output voltage of

the generator:

| Duty

Cycle |

Generator

Voltage

Set Point |

| 10% |

11.0V |

| 20% |

11.56V |

| 30% |

12.12V |

| 40% |

12.68V |

| 50% |

13.25V |

| 60% |

13.81V |

| 70% |

14.37V |

| 80% |

14.94V |

| 90% |

15.5V |

The generator provides

a feedback signal of the generator load through the generator field

duty cycle signal circuit to the control module. The signal is a 5 volt

PWM signal of 128 Hz, with a duty cycle of 0-100%. Normal duty cycle

is between 5-99%. The ranges between 0-5% and 100% are for diagnostic

purposes.

Charge Mode -- The control module enters Charge Mode

whenever one of the following conditions is met:

- Under WOT conditions and when the fuel rate (sent by the ECM/PCM)

is greater than 21 g/s and the throttle position is greater than 90%.

- The headlamps are ON, low or high beam.

- The wipers are ON for more than 8 seconds.

- The electric cooling fans are ON high speed.

- The rear defogger is ON.

- The Battery SOC (state of charge) is less than 80%.

When one of these conditions is met, the control module ramps up the

voltage slowly to a level between 13.4 to 15.5 volts (depending upon

the mode of operation the system is presently in) at a rate of 8 mV

to 50 mV per second.

Fuel Economy Mode -- The control module enters Fuel

Economy Mode when the following conditions are met:

- The calculated ambient air temperature is above 0°C (32°F).

- The calculated battery current is less than 15 amperes and greater

than -8 amperes.

- The battery state of charge is greater than 80%.

- The generator field duty cycle is less than 99%.

Its targeted generator output voltage is 13.0 volts. The control module

will exit this mode once the criteria are met for Charge Mode.

Voltage Reduction Mode -- The control module will enter

Voltage Reduction Mode when the following conditions are met:

- The calculated ambient air temperature is above 0°C (32°F).

- The calculated battery current is less than 2 amperes and greater

than -7 amperes.

- The generator field duty cycle is less than 99%.

Its targeted generator output voltage is 12.9 volts. The control module

will exit this mode once the criteria are met for Charge Mode.

Start Up Mode -- After the engine has started, the

control module sets a targeted generator output voltage of 14.5 volts

for 30 seconds.

Battery Sulfation Mode -- The control module enters

this mode when the battery voltage is less than 13.2 volts for 45 minutes.

Once in this mode, the generator battery control module will set a targeted

output voltage between 13.9 to 15.5 volts for 5 minutes. The control

module will then determine which mode to enter depending on voltage

requirements.

RVC Mode -- The control module bases the charging voltage

on battery state of charge (SOC). Battery SOC is estimated during a

key off event every 8 hours, after 3 voltage measurements every 24 hours

thereafter, and then monitored constantly while the ignition is on.

These measurements of voltage are then compared to estimated battery

temperature, as battery temperature vs. battery voltage directly corresponds

to battery SOC. While the engine is running, the system uses both the

battery voltage and estimated battery temperature to determine the battery

current in and out of the battery. The control module then regulates

the charging voltage to keep the battery above an 80% SOC.

| Vehicles |

System

Generation |

Modes

of Operation |

Key

Components |

| 2004 Cadillac

CTS |

Generation

II |

RVC Mode |

DIM, PCM |

| 2004 Cadillac

SRX |

Generation

II |

RVC Mode |

DIM, ECM |

| 2005 Cadillac

STS |

Generation

III |

Charge Mode

and Voltage Reduction Mode |

Battery Current

Sensor, IPM, ECM |

| 2005 Full Size

Pick and Utilities under 8600 GVW |

Generation

IV |

Charge Mode,

Fuel Economy Mode, Voltage Reduction Mode, Start Up Mode, Battery

Sulfation Mode |

Generator Battery

Control Module, ECM/PCM |

| 2005 Chevrolet

Cobalt |

Generation

IV |

Charge Mode,

Fuel Economy Mode, Voltage Reduction Mode, Start Up Mode, Battery

Sulfation Mode |

Battery Current

Sensor, BCM, ECM/PCM |

| 2005 Buick

LaCrosse |

Generation

IV |

Charge Mode,

Fuel Economy Mode, Voltage Reduction Mode, Start Up Mode, Battery

Sulfation Mode |

Battery Current

Sensor, BCM, ECM/PCM |

| 2005 Pontiac

Grand Prix and Grand Prix GXP |

Generation

IV |

Charge Mode,

Fuel Economy Mode, Voltage Reduction Mode, Start Up Mode, Battery

Sulfation Mode |

Battery Current

Sensor, BCM, PCM |

| 2005 Chevrolet

Uplander, Pontiac Montana, Buick Terazza |

Generation

IV |

Charge Mode,

Fuel Economy Mode, Voltage Reduction Mode, Start Up Mode, Battery

Sulfation Mode |

Battery Current

Sensor, BCM, PCM |

Components

Battery Current Sensor -- Battery Current Sensor -- The battery

current sensor is a serviceable component that is connected to the negative

battery cable at the battery. The battery current sensor is a 3-wire

Hall-effect current sensor. The battery current sensor monitors the

battery current. It directly inputs to the BCM. It creates a 5 volt

PWM signal of 128 Hz with a duty cycle of 0-100%. Normal duty cycle

is between 5-95%. The ranges between 0-5% and 95-100% are for diagnostic

purposes.

Body Control Module (BCM), Instrument Panel Module (IPM) and

Dash Integration Module (DIM) -- The BCM determines the output

of the generator and sends the information to the ECM/PCM for control

of the generator L-terminal control circuit. It monitors the generator

field duty cycle signal circuit information sent from the ECM/PCM that

determines the generator electrical load. It monitors the battery current

sensor, the battery positive voltage circuit, and estimated battery

temperature to determine battery state of charge (SOC). The BCM performs,

or sends, commands to ECM or other controllers to perform idle boost

and load management operations.

ECM/PCM -- The ECM/PCM directly controls the generator field

control circuit input to the generator. The ECM/PCM receives control

decisions based on messages from the BCM/IPM. It monitors the generator

field duty cycle signal circuit and sends the information to the BCM/IPM.

On some vehicles, the ECM/PCM overrides the control decision of the

BCM/PCM when the following conditions are met:

- The engine cooling fans are ON high speed.

- There is a high fuel demand.

- The calculated ambient air temperature is less that 0°C (32°F).

Instrument Panel Cluster (IPC) -- The IPC provides

a means of driver notification in case of a charging system failure.

Refer to the service manual for exact operation.

Generator Battery Control Module -- It communicates

with the PCM, IPC and BCM for RVC operation. It is a serviceable component

that is connected to the negative battery cable at the battery. It directly

controls the generator field control circuit input to the generator.

It monitors the generator field duty cycle signal circuit, its internal

battery current sensor, the battery positive voltage circuit, and estimated

battery temperature to determine battery state of charge (SOC).

Diagnostics

Diagnostics are specific for each vehicle that uses this system. Refer

to the applicable service manual for DTC information.

For L-terminal diagnostics, set your DVOM to monitor frequency. When

the system is operating normally, you should read a duty cycle of 5-95%

depending on which mode the system is in and also the battery SOC. The

5-volt reference signal for the PWM signal is provided by the generator

and cycled to ground by the ECM/PCM or generator battery control module,

depending on the system.

For F-terminal diagnostics, set your DVOM to monitor frequency. When

system is operating normally, you should read a duty cycle of 5-99%

depending on which mode the system is in and also the battery SOC. The

ECM/PCM or generator battery control module, depending on the system,

provides the 5-volt reference signal for the PWM signal and is cycled

to ground by the generator.

The Tech 2 may include some of the following parameters:

- ECM/PCM

- Generator L-Terminal

- Generator F-Terminal

- Battery Voltage

- BCM/DIM/IPM

- Battery Current Sensor

- Battery Voltage

- Ignition Voltage

- Load Shed Level

- Idle Boost Level

The generator battery control module incorporates most of the scan tool

parameters, except load shed and idle boost, as this system does not

take corrective actions.

If you feel there is a charging system error, first check for related

charging system and low voltage DTCs set in the control module.

TIP: Diagnose

P codes first, as these DTC will set if there is a generator or control

circuit failure.

If no DTCs are present, refer to the Charging System test in the service

manual. If this test does not present a failure, you may need to test

drive the vehicle and monitor the idle boost and load shed parameters.

This may lead you to some type of high load condition that may be normal;

compare to a known-good vehicle.

- Thanks to Jim Mauney and John Spidle |

|

figure

1 |

|

|

| return

to Table of Contents |

|

|

| Tech

2 Diagnostic Pathing Cards |

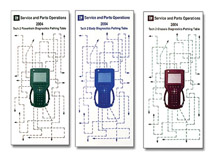

GM Service Operations announces the latest revision of the Tech 2 pathing

cards. These handy pocket-sized reference cards (Body, Chassis and Powertrain)

help you make the most of your Tech 2 diagnostic tool (fig.

2).

The cards cover model year 1992 through the present.

Simply select the item(s) you are looking for from the alphabetized

list, then follow the “path” provided. In most cases, you

will be selecting from the numerous data and input/output controls in

the Diagnostic Menu.

GM dealers will automatically receive two each of the

pathing cards at no charge. Individual cards and sets may be purchased

from the DWD Online Store.

Go to www.gm-dealerworld.com.

You will need your ID and password for access. Then click on the DWD

Store button in the upper left corner. The most direct way to locate

the item is to use Search and the item number. See the table below.

Non-dealers may purchase sets of three pathing cards

from the ACDelco online store.

Go to: http://www.acdelcotechconnect.com

and click the Training tab. Click the ACDelco Online Store link. Then

click Manuals and scroll to locate the desired item.

Functional Diagnostic Guide

A Functional Diagnostic Guide is available separately. Also pocket-sized,

this handy reference card uses the “Service Category” style

menu logic as found in SI. It will help you quickly locate items such

as data and input/output controls on your Tech 2. It’s a must

for anyone performing diagnostic procedures on current and future GM

vehicles utilizing GM LAN and Class 2 protocols.

- Thanks to Mark Stesney and Roger

Kneip

Item |

Item

Number from

DWD

|

Item

Number from

ACDelco

|

| Body Card |

ROM00173 |

- |

| Chassis Card |

ROM00174 |

- |

| Powertrain

Card |

ROM00175 |

- |

Set of cards

which includes:

ROM00173,

ROM00174 and

ROM00175

|

ROM00190 |

ROM00190 |

| Functional

Diagnostic Guide |

ROM00164 |

ROM00164 |

|

figure 2 |

| |

|

|

Correct Service Part Number for Equinox ECM |

There

has been some confusion regarding the proper service part number for

the ECM for the 2005 Equinox. Some improper part numbers were listed

on labels and in the parts system. These have been corrected. See the

accompanying table.

All of the electronic information has been corrected and will indicate

the correct service part number to order. The service CD correctly identifies

the utility file that is used to flash the Equinox.

- Thanks to John Fletcher and Craig

Jones

Service

Part Number |

Usage |

12581598 |

will

NOT work |

12591027 |

will

work fine |

12591279 |

will

work fine |

|

|

return to Table of Contents |

|

| Front

Hub Bearing Grease Leak |

On

the 2004-05 Chevrolet HD Silverado, GMC HD Sierra, and Hummer H2, the

front hub bearing assembly may be unnecessarily replaced for leaking

grease. This condition may be normal (fig. 3).

The hub bearing assembly contains 15% more grease at assembly than necessary,

to ensure adequate bearing performance. The additional grease will build

up on the seal, which acts as an additional barrier against contamination.

This is normal grease purge, and no repair is necessary.

TIP: Refer to

the wheel bearing diagnosis in SI if the integrity of the bearing is

questionable. Replace the bearing assembly only for noise or excess

end play.

-

Thanks to Steve Love and Dan Stress |

|

figure

3

|

| return

to Table of Contents |

|

| Malibu

Maxx Rear Sunshade |

This information pertains to 2004 Chevrolet Malibu Maxx.

Some customers may comment that the rear sunshade (fig.4)

comes unhooked from the rear sunroof trim and snaps shut. This may be

caused by wind buffeting from driving with the windows open, vibration

from driving over rough roads or solar exposure causing the rear sunroof

trim to soften and deform.

To correct this condition, install reinforcement 15227088 on the left

and right sides of the rear sunroof trim.

1. Remove any adhesive or foreign material from the back side of the

rear sunroof trim in the area where the reinforcement will be installed.

2. Clean the back side of the trim with isopropyl alcohol and allow

to dry.

3. Remove the protective backing from the reinforcement, pull back the

left side of the rear sunroof trim and carefully apply the reinforcement

to the back side of the rear sunroof trim (fig.

5).

TIP: Align the

slot in the reinforcement with the slot in the rear sunroof trim.

4. Repeat steps 1-3 for the right side.

Watch for a future bulletin.

- Thanks to Joel Ebner |

figure

4 |

figure

5 |

| return

to Table of Contents |

|

| Unique

Features of CTS-V |

Bulletin

04-00-89-027 has being released to inform dealers of the unique features

of the Cadillac CTS-V (fig. 6). Here are

highlights.

Stiff Ride

The CTS-V has a noticeably stiffer suspension than the CTS. Those with

traditional Cadillac expectations may not find this feature appealing.

Rear Axle Hop

In extreme loss of drive wheel traction or abusive applications of power,

the independent 5-link rear suspension will exhibit an abrupt wheel/axle

hop.

Handling in Snow

The P245/45WR18 Extended Mobility Tires (EMT, or run-flat) tires provide

the ultimate handling for the combination street and track environment.

They will not give optimum performance in mud or snow.

Brake Dust

A key requirement of the Brembo high performance brake lining is to

dissipate heat from the braking system, resisting fade, cooling rotors

and preventing brake fluid boil. A by-product of heat dissipation is

brake dust accumulation on wheel faces.

Brake Bind After Sitting

The Brembo brake components have a normal tendency to a light bind,

often noted as resistance, then a light clunk when attempting to move

the vehicle forward or rearward after a cold soak.

Critical Tire Pressure Monitor

The factory fill is 38 psi (260 kPa), to ensure proper bead sealing

and to prevent tire damage in tied-down shipping. If not adjusted to

the specified 30 psi (210 kPa), a warmed up tire will easily exceed

the 42 psi (290 kPa) limit on the TPM. Excessive pressures will also

turn an already very stiff ride into a harsh, poor-handling experience.

Rough Idle

A key element of the 400 horsepower LS6 V8 engine is better breathing

ability through unique valve lift and duration. A normal result of this

camshaft design is an unstable idle or random roughness.

1-4 Skip Shift

To help achieve the best possible fuel economy, the transmission forces

a 1st to 4th shift under the following conditions:

- coolant temperature above 169°F (76°C)

- vehicle speed 15-19 mph (24-31 km/h)

- throttle at 21% or less

The 1-4 indicator in the DIC is only momentary.

Driveline Clunk on Declutch in Parade Type Driving

A clunk-clunk noise from the driveline may be heard when depressing

and releasing the clutch pedal or between shifts while driving in a

steady, slow speed parade-type situation. This is a normal characteristic

of the driveline.

Oil Life Monitor and Mobil-1 Oil

Oils other than Mobil-1 (factory fill) may be used as long as they meet

GM Standard GM4718M. Oil life may seem shorter on the CTS-V than other

Cadillac vehicles because the OLM algorithm uses factors of engine RPM

and coolant temperature cycles, both of which the CTS-V will experience

in greater fluctuations.

Navigation But No Voice Commands

Because the steering wheel controls are for the I/P DIC, traction control,

and cruise control, there are no re-configurable controls, OnStar®

interface or voice command controls. Voice command is unavailable on

the CTS-V.

Memory Functions

Because the CTS-V has a manual transmission, the driver 1 and 2 seat

and mirror memory functions operate only when the parking brake is set,

whether the driver uses the RKE or the 1 and 2 buttons on the driver's

door panel.

G-Force Meter

A lateral accelerometer display located below the tachometer can be

accessed using the outermost rocker switch on the left steering wheel

spoke. To reset, press and hold the rocker switch while the G-force

meter is displayed.

-

Thanks to Brian Combs |

figure

6 |

| |

| |

|

return

to Table of Contents |

|

| Noisy

Blower Motor |

According to bulletin 04-01-39-005, owners of some 2004 Buick LeSabre

and Pontiac Bonneville models may comment on a noisy HVAC (heating,

ventilation and air conditioning) blower motor. Others may comment that

the blower motor emits a low-pitch hum.

Cadillac DeVille and Seville are covered in bulletin 03-01-37-001.

TIP: Although

the bulletins mention 2004 only, the fix applies to 2002-03 as well.

Install a new blower motor 89018521. For replacement instructions, refer

to the Blower Motor Replacement procedure in the Heating, Ventilation

and Air Conditioning section of SI.

Refer to figure 7 for a comparison. The

old blower motor is on the left and the new motor is on the right.

Parts are currently available from GMSPO.

-

Thanks to Bill Metoyer and Ed Kern

Part

Number |

Description |

Quantity |

89018521 |

Motor,

Blower (with impeller) |

1 |

|

figure

7 |

|

return

to Table of Contents |

|

| Tire

Pressure Sensor Learn |

Owners

of some 2000-04 DeVilles and Sevilles may comment on a SERVICE TIRE

MONITOR message being displayed through the DIC. In this case, follow

the diagnostic procedures outlined in SI. If no TPM system components

were replaced and normal TPM system operation was restored by performing

the tire pressure sensor learn procedure only, use labor operation E0715.

Labor operation E0715 has been established for those repairs deemed

warrantable. For warranty repairs, refer to Service Bulletin 04-03-16-001

for detailed information.

TIP: E0715 is

not to be used with RCDLR replacement, or sensor replacement op codes.

The labor ops for the procedure already include time for “learning”

the sensors.

TIP: Performing

the tire pressure sensor learn procedure due to customary maintenance

items (such as tire rotation) are not warrantable.

- Thanks to Bill Denton |

| |

| return

to Table of Contents |

|

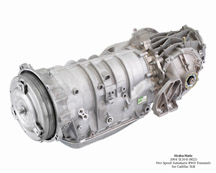

| Operating

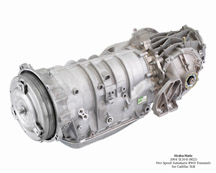

Characteristics of 5L40E/5L50E Transmissions |

The

Hydra-Matic 5L40E/50E automatic transmissions have some unique operating

characteristics that customers may not be familiar with. (fig.

8 5L40E, fig. 9 5L50E, fig. 10 5L50E XLR) They have been designed

to provide more of a manual transmission feel than other Hydra-Matic

automatic transmissions.

These transmissions are used in 2004-05 Cadillac CTS, SRX, STS, and

XLR as indicated in the accompanying table. Here are descriptions of

the unique operating characteristics.

Normal Mode Operation (CTS, SRX, STS, XLR) -- During

normal mode operation, drivers may notice increased powertrain braking

after releasing the accelerator pedal. The vehicle will not coast freely

when the accelerator pedal is released but will start to gradually slow

down as if the brakes were lightly applied. This feels very similar

to releasing the accelerator pedal on a vehicle equipped with a manual

transmission.

Sport Mode Operation (CTS, SRX, STS) -- Typically,

Sport mode delays upshifts. The Sport mode simulates the performance

driving of a manual transmission. Under certain conditions, the vehicle

will maintain specific gears longer than a traditional automatic would.

When driving in Normal mode in 5th gear, depressing the Sport button

causes an immediate 5-4 downshift, which will be maintained for ten

seconds. In any other gear, no downshift takes place when Sport is engaged.

In Sport mode, the vehicle has firmer shifting and increased performance,

and the transmission may remain in a gear longer than it would in Normal

mode.

Driver Shift Control (DSC) (SRX, STS, XLR) -- The driver

manually overrides the automatic gear selection. Various mechanization

options for input device and degree of override allowed.

Performance Algorithm Shifting (PAS) (XLR, 2004 SRX) --

Override of usual automatic gear selection during closed throttle high

lateral acceleration maneuver. Lower gear is accompanied by near synchronous

engine speed control for quick response upon re-opening throttle (enable

threshold bias in Sport mode).

TIP: On SRX, this feature

is enabled in Sport. On XLR, it is always enabled.

Performance Algorithm Liftfoot (PAL) (CTS, SRX, STS, XLR) --

Prevents liftfoot upshifts while maintaining engine braking during repeated

aggressive cornering.

Winter Mode (CTS) -- The vehicle launches in 2nd or

3rd gear instead of 1st, to avoid wheel spin in snow or ice, if selected

by the driver.

Shift Stabilization (CTS, SRX, STS, XLR) -- Shift stabilization

is used to minimize shift busyness, or hunting between ranges. Based

on several inputs and a map of engine torque at various RPM and throttle

position, the TCM determines before making an upshift whether the engine

will be able to maintain vehicle speed in the next higher range. If

it calculates that it cannot maintain speed, it will prevent the upshift

from occurring.

Downgrade Detection Brake Assist (CTS, SRX, STS, XLR) --

Shift to lower gear with braking on downgrade based on fuzzy logic rules

calculated from a thermal brake model, terrain detection, desired acceleration,

vehicle speed, and mass detection.

Adapts (CTS, SRX, STS, XLR) -- Continual comparison

of actual shift times to desired shift times. The transmission controls

make hydraulic adjustments to assure the actual shift times approach

the ideal shift time the next time the shift is made for similar operating

conditions of vehicle rpm, engine load, and road load conditions. The

adaptive shift process continues for the life of the vehicle, to provide

consistent and optimized shifts.

- Thanks to Robert Martin and Chris Anderson

- |

2004-05

CTS

|

2004-05

SRX

|

2005

STS

|

2004-05

XLR |

Transmission |

5L40E |

5L40E/50E |

5L40E/50E |

5L50E |

Normal

Mode Operation |

X |

X |

X |

X |

Sport

Mode Operation |

X |

X |

X |

- |

Driver

Shift Control |

- |

X |

X |

X |

Performance

Algorithm

Shifting

|

- |

X

(2004 only)

|

- |

X |

Performance

Algorithm

Liftfoot

|

X |

X |

X |

X |

Winter

Mode |

X |

- |

- |

- |

Shift

Stabilization |

X |

X |

X |

X |

Downgrade

Detection Brake Assist |

X |

X |

X |

X |

Adapts |

X |

X |

X |

X |

|

figure

8 |

figure

9 |

figure

10 |

| return

to Table of Contents |

|

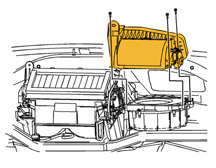

| HVAC

Module Service |

This information applies to the 2004 Cadillac XLR and the 2005 Chevrolet

Corvette and newer.

Use special care when removing or installing the HVAC module for service.

The HVAC module is seated between a non-removable upper and lower tie

bar

(fig. 11). The HVAC module must be partially

disassembled before removal and installation (fig.

12).

Refer to SI 2000 to obtain the service procedure for correctly removing

and installing the HVAC module. Failure to do could result in damage

to the HVAC module.

-

Thanks to Chris Semanisin |

figure

11 |

figure

12 |

|

return

to Table of Contents |

|

| Duramax

Diesel 6.6L Diagnostic Tips (Changes) |

Here are some diagnostic tips you may find useful when diagnosing driveability

concerns on the Duramax 6.6L diesel engine. This information

replaces the July 2001 Techlink article on Duramax Diagnostic Tips.

Misfire

If there is a misfire code, or a misfire can be detected during operation,

connect the Tech 2. Look on the Engine Data 2 list to find the Balancing

Rates for the cylinders. Do not use Balancing Rates to diagnose

symptoms that do not occur at idle. Use the fuel Injector Balance Test

with Tech 2 to diagnose symptoms at higher engine and vehicle speeds.

Balancing Rates

Normal fuel delivery to each cylinder is around 1 cubic millimeter (mm3)

for the pilot injection and 7 mm3 for the main injection. The balancing

rates are the measurements of the amount of fuel removed from or added

to these normal fuel quantities during each combustion event.

Balancing rates are available and accurate only during stable idle.

These numbers tell you whether or not you have a possible compression,

injector control, or injector issue.

Once the misfire is detected, the balancing rate of the cylinder that

has the misfire will be as high as 15 mm3. The misfire codes (P0300,

P0301-P0308) will set only after the first 90 seconds on Federal LB7s

(30 seconds on California LB7) of engine operation and will set only

when the balancing rate goes above 15 mm3.

The normal values that should be seen on the balancing rate parameters

will range between -4.0 and +4.0 in Neutral or Park (-6.0 to +6.0 in

Drive when the brake is fully applied). Suspect a possible problem when

the balancing rate of a particular cylinder starts to increase out of

the normal operating range. An example of a possible problem cylinder

would be a balancing rate of 7 mm3 or so. Once the numbers start to

increase out of the normal range, the cylinder is progressively contributing

less power than the other cylinders.

Diagnosing "Fuel Knock"

Perform the diagnostics listed in the Fuel Knock symptom table.

Vacuum/Pressure Gauge

The vacuum/pressure gauge is also useful when diagnosing the Duramax

6.6L diesel (fig. 13). In the case of a

complaint of “starts, runs, then dies,” or if the vehicle

will not start after sitting for a period of 30 minutes or longer, hook

up the vacuum/pressure gauge to the Schraeder valve on the right front

valve cover to determine if air intrusion into the fuel system is the

root cause of the complaint. With the vacuum/pressure gauge hooked up,

prime the fuel manager until 10 psi is reached. If pressure does not

reach 10 psi after twenty or so pumps, air intrusion is the cause. Refer

to the fuel system diagnostic in the manual.

In the case of a “cranks, no start” condition, use the Tech

2 to check for codes. If no codes are present, use the vacuum/pressure

gauge to check the fuel supply system vacuum to the pump while cranking.

If the vacuum increase to more than 5 in. Hg, there is a restriction

in the fuel system between the fuel tank and the high pressure pump.

If the vacuum is ok, ensure that pressure is being made under Engine

Data 1, looking at Actual Fuel pressure.

Observe the Engine Cranks but Does Not Run Diagnostic and follow the

guidelines provided in order to determine if the pump or the fuel injectors

are the problem.

-

Thanks to William Smithers |

| |

figure

13 |

|

return

to Table of Contents |

|

| A/C

Low Pressure Switch Diagnosis |

The

A/C low pressure switch open/close pressure switch point cannot be accurately

determined by measuring pressure at the low side service port on 1999-2005

C/K trucks and 2003-05 Hummer H2.

Because the evaporator is between the low side service port and the

A/C low pressure switch, pressures measured at the port may not be the

same as those at the switch. This difference can cause misdiagnosis

of switch operation.

A new bulletin 04-01-38-010 details the use of a new A/C diagnostic

tool GE-47742, available from SPX Kent-Moore. Here are the highlights.

GE-47742 allows you to monitor the actual pressures at which the switch

opens and closes in the vehicle’s refrigerant system. The tool

is a three-way T-fitting.

With the switch removed from the accumulator, the switch installs into

the GE-47742 tool. The tool installs in place of the switch in the accumulator.

Finally, the low side gauge of the ACR2000 connects to the service port

on the tool.

The tool installation is shown in figure 14:

A - GE-47742

B - Connection to accumulator

C - Low pressure switch

D - ACR2000 low side gauge hose

IMPORTANT: Before

plugging in the switch wire harness, temporarily remove the seal from

the connector. The “plunger effect” of plugging the sealed

connector into the switch induces a 5-10 psig (35-69 kPa) pressure on

the back side of the switch. This pressure will skew the opening/closing

characteristics of the switch as much as 5-10 psi (35-69 kPa) until

the pressure bleeds off, which can take 20 minutes or longer.

Operate the A/C system under the following conditions:

- Engine (On)

- 1500 RPM

- A/C (On)

- Blower (Low)

- Aux Blower (Low)

- Temperature (Full Cold)

- Aux Temp (Full Cold)

- Inside air/Re-circ

- No sun load (in the shade)

Use the Tech 2 to determine the low pressure switch status and the ACR2000

to determine low side pressure.

The Tech 2 displays switch status as “Normal” for Closed

and “Low Pressure” for Open.

A properly operating switch should open between 20-25 psi (138-172 kPa)

and close between 40-46 psi (275-317 kPa).

IMPORTANT: Remember

to install the seal onto the A/C low pressure switch connector when

the diagnosis is complete.

- Thanks to Frank Rogers and Steve Love |

| |

figure

14 |

|

return

to Table of Contents |

|

| Tire

Pressure Monitor Diagnostic Tool |

A

new essential diagnostic tool J-46079 for Tire Pressure Monitor Systems

(TPMS) is now being shipped to dealers (fig. 15).

It works on all GM vehicles equipped with Radio Frequency (RF) Direct

Sense TPM systems.

These TPM systems consists of an RF-transmitting pressure sensor inside

each tire/wheel assembly and a receiver inside the vehicle. The pressure

sensor transmits an RF signal, and the receiver interprets the signal.

The diagnostic tool completely tests the TPM system.

To verify the sensors can transmit valid data with good signal strength

in response to a low frequency or magnetic activation, J-46079 TPM Tester

receives the RF signal from the sensor and displays the sensor’s

transmitted data (tire pressure, sensor ID number, sensor mode) on the

tester’s LCD screen.

TIP: The tool

cannot determine if the sensor internal roll switch is functioning.

For that, a test drive is necessary.

To confirm the operation of the vehicle’s receiver, J-46079 TPM

Tester transmits four simulated sensor signals to the receiver. Once

the vehicle receives the signals from J-46079 TPM Tester, the simulated

data (tire pressure, ID number and sensor mode) can be viewed accessing

the module data with a Tech 2 scan tool.

TIP: On

some vehicles, only the tire pressure can be viewed on the scan tool.

J-46079 TPM Tester can also be used on some vehicles when performing

the sensor learn procedure after tire rotation. This simplifies and

speeds up the procedure.

This tool is simple and easy to use and assures that the tire pressure

monitor system is functioning properly. For more information on the

J-46079 Tire Pressure Monitor Tester, contact Kent-Moore at 1.800.345.2233.

- Thanks to Mike Banar and Scott Bower |

|

figure

15 |

| return

to Table of Contents |

|

| 4T65E

Valve Body |

A

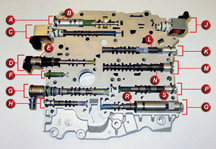

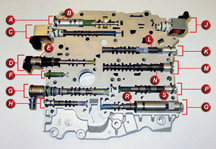

recently released bulletin 02-07-30-013B refers to 2001-04 vehicles

with 4T65E automatic transmission (RPOs M15, MN3, MN7, M76). The bulletin

refers to various transmission conditions, including incorrect shifts,

poor performance, harsh upshifts, slipping, TCC stuck on or off and

various DTCs. The bulletin relates all of these conditions to debris

in the valve body and case oil passages.

Refer to the bulletin for details.

Figure 16 is a color photo of a valve body

cutaway, to show you the actual locations of various bores, items and

functions mentioned in the bulletin.

- Thanks to Darryl Butler

ID |

Bore

No.

|

Item

Name |

Function |

A |

1 |

Pressure

Regulator |

- |

B |

1 |

- |

Reverse

Boost Valve inside bushing |

C |

2 |

1-2

Shift Valve Solenoid A |

- |

D |

4 |

Torque

Signal Valve |

- |

E |

4 |

- |

Pressure

Control Solenoid |

F |

5 |

Pressure

Relief |

- |

G |

6 |

PWM

and TCC Control |

- |

H |

7 |

TCC

Regulator Apply |

- |

J |

16 |

Solenoid

B |

- |

K |

11 |

3-4

Shift Valve |

- |

L |

11 |

- |

4-3

Manual Downshift |

M |

12 |

2-3

Shift Valve |

- |

N |

12 |

- |

3-2

Manual Downshift |

P |

14 |

Secondary

1-2 Accum |

- |

Q |

15 |

- |

- |

R |

15 |

2-3

Accumulator Valve |

- |

S |

15 |

3-4

Accumulator Valve |

- |

|

figure

16 |

| return

to Table of Contents |

|

| Quick

Upshifts |

Some

1993-2005 light duty trucks and utilities may experience quick upshifts

and be in fourth gear with the TCC applied by 20 mph. Sometimes DTC

P1875 may accompany the concern. The owner may also describe the condition

as a lack of power, chuggle, miss, shake, or surge. This condition can

also occur on 2WD models.

The ECM, PCM, or VCM may believe that the Transfer Case is in 4low and

change the shift pattern accordingly. Use the Tech1/Tech2 to verify

the status of the 4low input. If the 4low input status is YES or ENABLED

with the Transfer Case in 2wd or 4wd High or if this is a 2wd vehicle,

the 4low signal circuit is shorted to ground. Or the TCCM and or ECM,

PCM, or VCM is taking the circuit to ground.

1. Disconnect the TCCM if equipped. If the concern goes away, replace

the TCCM. If the concern is still present, go to step 2.

2. Remove the 4low signal circuit from ECM, PCM, or VCM connector. If

the concern goes away, inspect the 4low signal circuit for being shorted

to ground. If concern is still present with the 4low signal circuit

removed from ECM, PCM, or VCM connector, replace the ECM, PCM, or VCM.

-

Thanks to Rusty Sampsel |

| return

to Table of Contents |

|

| Theater

Lighting |

Some

owners of the 2005 Chevrolet Equinox may comment that the interior lights

will not theater dim.

This is normal operation. The interior lights on Equinox do not theater

dim. The service information and the owner’s manual will be updated

to reflect the correct operation of the interior lights.

- Thanks to Chuck Krepp |

|

|

|

return

to Table of Contents |

|

| Clutch

Pedal Squeak |

On

some 2001-03 Chevrolet Silverado and GMC Sierras with ML6 Manual Transmission,

the clutch pedal may squeak. The condition typically occurs during hot

ambient temperature.

Replace the clutch pedal assembly with part number 15120866.

-

Thanks to Rusty Sampsel |

|

|

| return

to Table of Contents |

|

| Axle Water

Contamination |

Some

2001-04 Chevrolet S-10 and GMC Sonoma 4- Door Pickups may experience

water contamination inside the rear axle.

Inspect the location of the rear axle vent hose to see if it is positioned

in a location that is directly below the gap between the cab and the

bed. If so, relocate the vent hose to a new location that will prevent

rain water from entering the vent hose.

-

Thanks to Rusty Sampsel |

| return

to Table of Contents |

|

| Chafed

Wires |

Some

2005 Chevrolet Equinoxes may exhibit power mirrors inoperative, seat

belt warning light on, no audio/poor audio and/or various class 2 communication

faults.

During assembly of the lower A-pillar trim or kick panel, the clip on

the trim panel has chafed the wire(s), resulting in a short to ground

or an open fuse. The C204 connector contains circuits for ignition 1,

power mirrors, seatbelt warning, audio speakers and class 2 communication.

Remove the lower left trim panel, inspect for any chafed wires near

the C204 connector and repair as necessary. Reroute the harness to prevent

future contact.

-

Thanks to Chuck Krepp |

|

|

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time

Car Issues – Fix It Right The First Time |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2004 |

Grand

Prix – Steering, Suspension or Cradle Click Noise |

Re-torque

right steering gear mount. |

Don’t

replace the steering gear or cradle. |

03-02-32-048

|

2000-2003 |

Century,

Regal, Lumina, Impala, Monte Carlo, Grand Prix, Intrigue with

3.8L L36 Engine – Coolant Leak |

Replace

upper intake manifold gasket only. |

Don’t

replace upper intake manifold assembly for a coolant leak condition. |

03-06-01-016 |

2002-2003 |

Impala

– Snap or Clunk When Window is Rolled to Full Up Position |

Replace

glass run channel with revised part. |

Don’t

replace front door window regulator, door glass or align door

glass for snapping noise when window reaches full up position. |

03-08-64-034 |

2001-2004 |

Aztek

(01-04), Rendezvous (FWD, 02-04), Venture/Montana/Silhouette (01-04)

– Pop and/or Rattle in Exhaust Down Pipe |

Follow

procedure in bulletin 03-06-05-003 using clamp P/N on down pipe

to correct rattle/buzz noise. |

Don’t

replace converter assembly for rattle/buzz noise without completing

instructions in 03-06-05-003. |

03-06-05-003 |

2000-2004 |

All

Cars with 4T40/4T45E and 4T65E – Light On/Various Transmission

Codes Stores |

Check

transmission 20-way connector for secure connection (disconnect

and reconnect). |

Don’t

replace transmission, TCC PWM, VSS, PCS or valve body. |

02-07-30-022B

|

1998-2004 |

Seville

– Heated Seat Inoperative |

Replace

only needed heating element. |

Don’t

replace entire seat cover if heated seat element is inoperative. |

01-08-50-002C |

2001-2004 |

Century/Regal

– Intermittent SES, ABS or TCS Lamp Illuminated, Engine

No Crank/No Start, Various I/P Cluster Intermittents, DTCs U1000,

B1422, B2957, B2958 Set, Shifter Locked in Park (BTSI Inoperative) |

Check

UBEC harness connectors for damage and replace damaged terminals.

Use labor operation with appropriate terminal part number. |

Don’t

replace the UBEC, ignition switch, sensing diagnostic module (SDM),

body control module (BCM), shifter assembly (Regal) or intermittently

inoperative clusters. |

03-08-45-004 |

2000-2004 |

Cavalier/Sunfire/Alero/Grand

Am – Inoperative Sunroof Module |

Retime

module or replace only motor for inoperative complaints. |

Don’t

replace entire sunroof module assembly. |

03-08-67-009A |

2003-2004 |

Cavalier/Sunfire

– Air Conditioning Compressor Noisy |

Inspect

for ground out conditions that can cause A/C compressor noise

complaints. |

Don’t

replace A/C compressor for excessive noise complaint without inspecting

for ground outs. |

03-01-38-012

|

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

Issue

One: Refinish brake rotor.

Issue Two: Measure for LRO

|

Issue One: Don’t replace brake rotors.

Issue Two: Don’t measure for LRO

|

00-05-22-002D |

|

| return

to Table of Contents |

|

|

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2001-2003 |

Fullsize Pickups – Injector Replacement for High Flow Rates |

Use

Bulletin 04-06-04-007A for injectors with high fuel return rates.

Use Special Policy 04039 for 01-02 vehicles. |

Don’t

replace 8 injectors except for high fuel return rates. Other injector

failures are fix as failed. |

Special

Policy

04039 |

2004-2005 |

All Cars and Trucks – State-of-Charge Upon Delivery of New

Vehicle |

Check

battery’s state-of-charge per revised PDI procedure |

Don’t

remove and replace battery. |

02-06-03-009A |

2003-

2005 |

Avalanche, Suburban, Tahoe, Silverado, Yukon/XL, Sierra, Escalade

– Snap/Popping Noise from Front of Vehicle |

Slot

left side mounting holes on front crossmember per bulletin. |

Don’t

replace crossmember. |

03-08-61-002B |

2002-2004 |

Fullsize

and Midsize Pickups and Utilities |

When

submitting claims for reprogramming an electronic module, use

correct labor operation that reflects module being programmed. |

Do

not use K5364, which is for reprogramming transmission control

module (TCM), when reprogramming TCCM. |

02-06-04-057D |

2002-2004 |

Fullsize and Midsize Pickups and Utilities – Sleepy New

Venture Gear Transfer Case Control Module |

Verify

sleepy module as primary cause, per bulletin. Reprogram TCCM with

latest software released 3/11/04. |

Don’t

replace encoder motor or transfer case. Replace module only if

C0550 DTC shows as current or in history. |

02-04-21-006D |

2002-2003 |

Chevrolet

Avalanche and Cadillac Escalade EXT – Cargo Covers and Cladding

Faded or Stained |

Thoroughly

clean, dry and treat the components with “Armor-dillo.”

To order call (888)393-4722 or online at www.armor-dillo.net. |

Don’t

replace cargo covers for this condition. |

04-08-111-001 |

| 2002-2004 |

All

Passenger Cars and Trucks – Air Conditioner Compressor Diagnosis |

Follow

SI and bulletin for diagnostic information before compressor replacement. |

Don’t

replace the air conditioning compressor. |

01-01-38-013A

03-01-38-019

|

| 2002-2004

(models with HomeLink™ option) |

All

TrailBlazers, All Envoys, Bravada, Rainier with HomeLink Universal

Transmitter – Programming Diagnosis |

Use

J 41540 – GM Integrated HomeLink Tester. Follow SI and refer

customers to Owner’s Manual. |

Don’t

replace HomeLink Transceiver without validating internal fault recognized

by J 41540. |

01-08-97-001B |

| 2002-2004 |

All

TrailBlazers, Envoy, Envoy XL, Bravada – Squeak/Rub/Scrub

Type Noise in Steering Column |

Lubricate

and remove material, per bulletin. |

Don’t

replace upper or lower intermediate shaft. |

02-02-35-006A

|

2001-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed. |

Don’t

replace complete mirror assembly. |

03-08-64-028

|

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for October |

| |

|

| Know-How

Broadcasts for October |

| October

14, 2004 |

10280.10D

Emerging Issues |

|

| October

28, 2004 |

10280.22D

2005 Chevrolet Cobalt |

9:00

AM, 12:30 PM,

3:00 PM Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

|

Car Issues – Fix It Right The First Time

Car Issues – Fix It Right The First Time

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)