| |

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Chevrolet

Equinox Pre-Delivery and Unique Service Features |

To help understand

the unique service features of the new 2005 Chevrolet Equinox (fig.

1), refer to bulletin 04-00-89-006. It provides the complete

pre-delivery procedure and important service tips. Here are some highlights.

QUALITY PRE-DELIVERY INSPECTION

TIP: A quality

pre-delivery inspection is your dealership’s first contact with

a new vehicle. And, it’s your first opportunity to influence the

customer’s perception of your dealership and increase their satisfaction

with the new vehicle.

Be sure two keys and fobs are included with

the vehicle.

Ensure that the following loose items are

fitted to the vehicle:

- Floor mats

- Antenna

- Front license plate bracket

As soon as the vehicle reaches the dealership, remove the protective

film from:

- Front and rear fascias

- Mirrors

- Rocker panels

The vehicle is shipped with extra air in the tires. Adjust tire

pressure to 30 psi (207 kPa). The tire pressure label

is located at the bottom of the driver side B-pillar.

Where required, install the front license plate hardware.

The front fascia has two locating dimples for this purpose.

UNIQUE VEHICLE CHARACTERISTICS

There is airflow from the outer HVAC vents

in all modes, to improve side window defogging (fig.

2).

The Equinox is available with both FWD and AWD drivetrains. Some Equinox

models have a traction control button next

to the Equinox name in the center of the IP and some don’t.

Button -- FWD vehicles with ABS

No button -- FWD vehicles without ABS, AWD vehicles

TIP: AWD vehicles

can easily be identified by the emblem on the rear hatch.

The cigarette lighter and accessory power outlets

operate only with the ignition in ACC or ON position.

Only the radio is functional in the RAP (Retained

Accessory Power) mode. The power windows will not function

in RAP. This is normal.

The control for the outside rearview mirrors

is located to the left of the steering wheel on the IP.

The roof rack is located by the assembly plant

in the optimal location for minimizing wind noise.

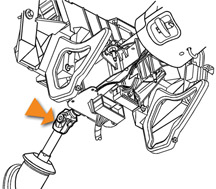

ENGINE

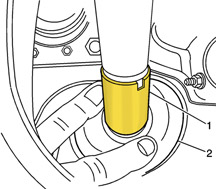

The 3.4L (RPO LNJ -- VIN F) engine is similar to other 3.4L engines,

but is not interchangeable (fig. 3).

TIP: An engine

exchange program is in effect for the first six months.

The crankshaft sensor is located on the right

side of the block, next to the bulkhead. The reluctor wheel

is located on the crankshaft.

It is important to follow the bulletin procedure to ensure air is removed

from the cooling system, to avoid coolant

noise concerns. If coolant must be drained, at least 5 liters (5.28

quarts) must be removed, and this is the minimum amount to be added

when the system is refilled.

TIP: It may be

necessary to raise the RH front corner of the vehicle 3 inches (76 mm)

to force trapped air toward the air bleed.

TRANSAXLE

The Aisin Warner AF33-5 transaxle has 5 speeds, is electronically controlled,

and features an adapt function.

Shift pressures are automatically adjusted for temperature, altitude,

and transaxle component wear, using a process called adaptive self-learning.

The adaptive procedure is based on counting the number of upshifts,

not driving time or distance.

TIP: It may be

necessary to drive far enough to consume a full tank of gas to allow

the transaxle to adapt to a particular driver’s habits.

TIP: If the transaxle

is replaced, the adaptive function must be reset to default settings,

using the Tech 2. Follow this path:

Enter F0: Diagnostics

Select 2005 Model Year

Select LD Truck

Select Chevrolet Truck

Select L Product Line

Confirm Engine (3.4L LNJ)

Confirm Trans 5 Spd - Auto

F0: Powertrain

F2: Special Functions

F1: Transmission Output Controls

F5: Reset Transmission Adapts

The Aisin AF33-5 provides uphill and downhill

modes. When driving uphill, the driver may notice that it is not necessary

to increase throttle position. This is because the transaxle up- or

downshifts as necessary to maintain speed. This is normal operation.

When driving downhill, the transaxle will

assist in maintaining speed by applying clutches to achieve automatic

grade braking. This feels similar to brake application, and is normal

operation.

The transaxle is equipped with an ATF oil life monitor,

which illuminates the SES light when oil life reaches 10%. A DTC P1868

indicates the need to change fluid.

TIP: Only T-IV

fluid may be used (US 88900925, Canada 22689186). DO NOT use Dexron

III.

Reset the oil life monitor accordingly.

Refer to the bulletin for additional mechanical service procedures,

including checking and adding fluid.

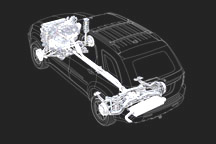

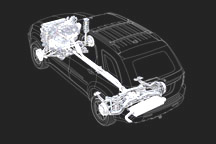

ALL-WHEEL DRIVE (AWD) SYSTEM

The all-wheel drive system uses the familiar Versatrak components to

provide power to the rear wheels if slip is detected at the front wheels

(fig. 4).

Refer to the bulletin and SI for service procedures.

ELECTRICAL ARCHITECTURE

The Equinox relies on both Class II and GMLAN for communication. The

following modules rely on GMLAN:

- Transmission control module

- Brake module

- ECM

- OnStar module (also uses Class II)

- BCM (gateway between Class II and GMLAN)

TIP: It is necessary

to use a CANdi module to communicate with the Tech 2. This has been

covered in numerous TechLink articles: Mar. 2003, Aug. 2003, Dec. 2003,

Jan. 2004.

CHASSIS/SUSPENSION

The suspension is independent at both front and rear, with MacPherson

struts in the front and four-link with coil springs in the rear (fig.

5).

Camber and toe can be adjusted in front and rear, but caster cannot

be adjusted at either end.

TIP: Alignment

cams are not installed in the rear suspension during production. Service

cams are available.

ELECTRONIC POWER STEERING (EPS)

EPS eliminates hydraulic lines and the belt-driven pump, reduces engine

load (potential mileage improvement), and reduces operating noise.There

are fewer components to service and diagnostics are more accurate.

Major components of the EPS system are the Power Steering Control Module

(PSCM), a torque sensor and the Electronic Power Steering motor. The

PSCM, torque sensor and motor are serviced ONLY as an assembly.

TIP: Whenever

a PSCM is replaced, it must be set up with the proper tuning profile.

AUDIO SYSTEM

The MP3 player accepts MP3 files that are recorded on an up-to-700 MB

CD-R. The player is able to read and play a maximum of 50 folders, 50

playlists, 10 sessions, and 255 files.

TIP: These capacities

may be reduced if long names are used, or a large number of elements

are stored.

TRAINING COURSES

Two training courses are available for learning more about the Equinox:

- 10280.14D New Model Features (EPS and AWD)

- 17341.10V Aision AF33-5 Automatic Transaxle

TIP: In Canada,

watch for the 2005 Equinox Features Know-How release..

-

Thanks to Ange Girolamo and Ann Briedis |

|

figure

1 |

|

figure 2 |

figure

3

figure

3 |

figure

4

|

|

figure

5

|

|

| |

| |

| return

to Table of Contents |

|

|

| Business

Grade PC Specifications |

A TechLink article in Dec. 2003 mentioned that GM Service Operations

is ending support for Windows 98, Millennium and NT operating systems,

effective January 15, 2004. For this reason, many dealers are upgrading

and adding PC equipment.

The right PC is as important to a technician’s efficiency and

productivity as having the right tools in the toolbox. Because it’s

important that dealers purchase the correct type of PC, here are some

reminders.

TIP: Refer to

Hardware Specs on http://service.gm.com for additional information on

minimum and recommended PCs.

Unlike a consumer grade PC, a business grade or commercial

PC is specifically configured for use in a business network

environment. PCs in this class have components designed and supported

for use in a network environment. Additionally, they have greater life

cycle stability due to designed-in serviceability. Techline applications

will not function properly on typical non-business grade hardware designed

for home use.

Although consumer grade PCs may have a more attractive price, their

limitations far exceed their initial cost savings, making them not much

of a bargain in the end.

Characteristics of Business Grade PCs

- Extended product availability cycles

- Built using same components for generally 3 to 6 months

- Ease of serviceability of internal components

- Preloaded with business software

- Network manageability, utilizing industry standards to manage setup

and maintenance

Characteristics of Consumer Grade PCs

- Designed with multi-media hardware features used for gaming, video,

music

- Preloaded with multi-media software designed for entertainment

- Multi-media software can cause conflicts with Techline application

software

- Not assembled with same internal components through product build

lifecycle

- Validation for Techline applications impossible, due to inconsistent

internal component build

- Designed for home networking configurations

- Preloaded with internet-ready configurations designed for the home

user

TCSC PC Support

Validated PC platforms (i.e., HP d530, IBM NetVista, Dell Optiplex,

and Gateway E Series) receive full hardware and software support.

Any PC that meets the minimum hardware spec (P III 600 MHz, 128 MB RAM,

WIN 2000 or XP Pro, serial port, IE 6.0, HD 20 GB) but is a non-validated

hardware platform will receive support for the Techline applications

only. Support ends if the problem is determined to be hardware related.

TIP: AMD and

Intel Celeron processors are non-supported hardware. Service Programming

Systems (SPS) does not function reliably with typical Celeron and AMD

processors. When a Techline PC is interfacing with the Tech 2, the bilateral

communication rate and data transfer speed is critical for SPS to function

successfully. These processors have proven unreliable in this process.

Dealers with PCs that do not meet minimum spec requirements are asked

to replace the PC or upgrade the operating system.

Before making a PC purchase, please contact your Regional Techline Field

Consultant (TC) to ensure your PC meets or exceeds the recommended specifications.

TC contact information can be found at http://service.gm.com

under the Techline tab, or call the Techline Customer Support Center

at 1.800.828.6860 for additional assistance.

-

Thanks to Mike Waszczenko and Shawn Sullivan |

|

|

|

|

XLR Electrical Switches |

Several

electrical switches have been replaced unnecessarily on 2004 Cadillac

XLRs.

Traction Control Switch

The traction control switch on the center console is a typical rocker

switch (fig. 6), intended to rock in only

one direction. To turn traction control off, press the switch. To turn

traction control on again, press the switch again.

TIP: Do not replace

the switch if the customer is concerned that it rocks in only one direction.

This is as designed.

Be sure you also understand the following traction control operating

conditions, to avoid unnecessary service.

TIP: When traction

control is turned OFF, a traction control warning light is illuminated.

The light is NOT illuminated when traction control is enabled.

TIP: Traction

control is re-enabled automatically each time the ignition is turned

on, even if it was manually turned off during the last ignition cycle.

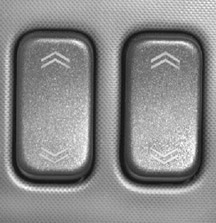

Power Window Switch and Module

The following is normal operation, and is not reason to replace the

switch or module (fig. 7).

If the window module sees voltage below 8v, it will set a DTC B1327

and the window will not operate.

TIP: The DTC

will not clear unless voltage is increased above 9v.

Once the battery is charged, or the engine is started, the DTC will

clear and the window will operate.

TIP: When voltage

raises above 9v, the DTC will move from current code to history code.

If you replace the module (which is not at fault) and then the voltage

is raised above 9v, it will look like replacing the module fixed the

“problem,” when actually there was no problem, other than

low voltage.

When the warranty claim is reviewed, if no trouble is found with the

replaced part, it will be charged back to the dealer..

- Thanks to Brad Thacher |

figure

6 |

|

figure

7

|

return to Table of Contents |

|

| Modular

Fuel Pump Terminals |

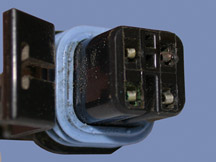

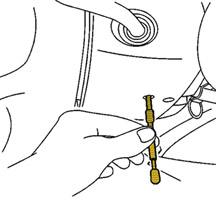

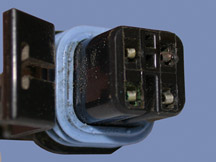

This

diagnostic tip applies to modular fuel pumps on C/K pickup, S-truck,

Cavalier, Sunfire and Malibu.

Before condemning a fuel pump, check the teminals in the connector on

the pump module (fig. 8) and in the wiring

harness connector (fig. 9). If a harness

terminal is spread apart, it will cause excessive resistance, which

leads to overheating of the terminal.

If you discover this condition, replace the harness connector and terminals

with the appropriate service pigtail, available from GMSPO.

-

Thanks to Dennis Kissack |

|

figure

8 |

figure

9 |

| return

to Table of Contents |

|

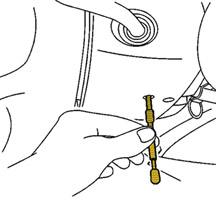

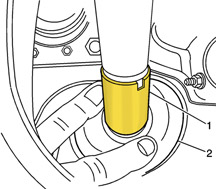

| Using

Anti-Rotation Pin |

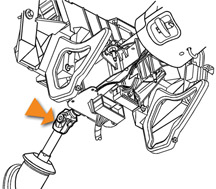

Most GM vehicles are equipped with a steering column that can be locked

using special tool J-42640 (anti-rotation pin). The pin fits into the

bottom of the steering column lower shroud (fig.

10).

The J-42640 must be installed whenever:

- the steering column is removed from the vehicle

- the intermediate shafts are disconnected

- wheel position sensor, steering wheel or SIR coil is removed.

Failure to lock the steering column could result in damage to the SIR

coil.

IMPORTANT: Do

not tilt the steering column with the J-42640 pin installed. Tilting

the steering column with J 42640 installed may cause damage to the steering

column or instrument panel lower trim panel.

IMPORTANT: You

MUST perform all of these steps to ensure that the intermediate shaft

does not become misaligned or the SIR coil become uncentered. Failure

to do so may cause damage to the SIR coil.

1. Position the wheels of the vehicle straight ahead.

2. Turn the ignition switch to the Lock position.

3. Install J 42640 (anti-rotation pin) to the steering column, if it

has an access hole in the lower shroud, to lock the steering column

shaft.

4. Make an alignment mark on the intermediate shaft to the steering

column, gear, or connecting shaft (upper to lower), to aid in re-installation.

TIP: Some steering

columns do not offer any external locking features. On these vehicles,

be careful to prevent the steering column shaft from rotating during

service of the steering column, intermediate shafts, steering wheel,

wheel position sensor, or SIR coil.

If it is determined that the steering column shaft has rotated, it will

be necessary to re-center the SIR coil. Refer to the SIR coil centering

procedure in SI.

-

Thanks to Steve Hathaway |

figure

10 |

| return

to Table of Contents |

|

| Ignition

Key Replacement |

This

information applies to 1997-2003 Buick Park Avenue.

A change was made to the ignition key for the model year 2004 Buick

Park Avenue, due to a change in supplier tooling. The head of the new

key P/N 89023231 is wider than the tabs of the ignition switch of 1997-2003

Park Avenues.

If 89023231 were used as a service replacement key on past model year

Park Avenues, the ignition cylinder would have to be replaced as well.

To avoid this, key P/N 88891799 is being released by SPO. This key will

fit the existing ignition cylinders on past model Park Avenues, eliminating

the need to replace the ignition cylinder.

-

Thanks to Kobie Glenn |

|

|

| return

to Table of Contents |

|

| Mis-Coded

Warranty Claims |

According

to a recent survey, over 75% of the warranty claims for engine oil dipsticks

are mis-coded. Here are the correct numbers.

J0920 |

Dipstick

(oil level indicator) |

J0930 |

Dipstick

Tube |

N4580 |

Oil

Level Switch (sensor) |

The dipstick (or

oil level indicator) is the graduated metal rod or wand that is used

to indicate the depth of the oil in the engine’s oil pan. The

dipstick is inserted into the dipstick tube in the engine block. And

the oil level switch (sensor) is an electrical sensor installed into

the engine oil pan that is used to detect when the oil has dropped below

a safe level.

-

Thanks to Tom Spix |

|

return

to Table of Contents |

|

| Air

Bag Module Checkout |

Extra

attention is needed if a vehicle comes in for service with the air bag

telltale illuminated. After reading diagnostic trouble codes and finding

that air bag loop faults and/or sensor faults are current, take the

time necessary to troubleshoot the wiring fully. Replacing the SDM (fig.

11) will not correct the fault in many situations. A detailed

check of continuity for the faulted lines is necessary.

TIP: Check all

wiring connections before removing and replacing the SDM.

- Thanks to Tom Nguyen |

figure

11 |

| return

to Table of Contents |

|

| Inadvertent

Switch Activation |

This information applies to 2003-04 Topkick and Kodiak C4500-C8500 series.

Bulletin 03-07-30-047 explains that inadvertent operation of several

instrument panel switches can cause unusual transmission performance.

If the Power Takeoff (PTO) switch is accidentally turned on, it will

limit engine operation to 2000 rpm, which results in long, delayed upshifts.

Also, changes in transmission operation or feel can result if the Overdrive

Defeat switch is left in the on position.

Before attempting shifting related repairs, check the position of these

two switches, and be sure the customer understands their operation.

TIP: A center

passenger’s knee can contact the PTO switch, resulting in it being

switched on unexpectedly.

-

Thanks to Dan Oden |

|

|

|

return

to Table of Contents |

|

| Temperature

Gauge Readings |

Starting in January 2004, the Buick Rendezvous is available with a new

3.6L LY7 engine. Customers may notice the engine temperature gauge reading

slightly past the mid point (fig 12) under

heavy loads, in high ambient temperatures, in stop and go traffic, and

mountain driving. This condition is a normal operating characteristic

of this powertrain.

A customer may also notice more movement in the engine temperature gauge

than is traditionally seen with other powertrains. Customers should

be reassured the gauge reading as described is normal for this vehicle.

TIP: A gauge

reading in the red zone indicates a true overheat condition.

In the LY7 engine, the coolant temperature sensor is located in an area

subjected to higher engine temperatures and more temperature fluctuations

during normal operation of the cooling system.

-

Thanks to Russ Gilbert |

figure

12

|

|

return

to Table of Contents |

|

| SSR

Remote Battery Terminal |

The

battery on the SSR is located beneath the rear of the vehicle.

Reviews of returned SSR electrical components (BCMs, RDMs, cooling fan

components and circuitry) indicate components are being damaged due

to improper jump starting and battery charging procedures.

Follow instructions in SI or the owner's manual. There is a remote battery

positive terminal located on the right front inner fender and a nearby

engine ground (fig. 13).

- Thanks to Dan Oden |

figure

13 |

|

return

to Table of Contents |

|

| Steering

Column Noise |

Owners

of some 2002-03 Chevrolet TrailBlazers, GMC Envoys and Oldsmobile Bravadas

may comment on a squeak noise coming from the steering column while

turning the steering wheel. Some customers may also comment on a rubbing

or scrubbing type noise or feel in the steering wheel during low speed

turns or parking maneuvers. The condition may be more pronounced in

cold temperatures.

Bulletin 02-02-35-006A provides details for lubricating the serration

(slip) joint of the upper intermediate shaft to address the squeak noise

(fig. 14).

The rubbing or scrubbing type noise may be addressed by removing material

from the upper intermediate shaft bushing to alleviate an interference

fit between the upper intermediate shaft boot seal and the intermediate

shaft bushing (fig. 15).

TIP: Do not replace

the upper or lower shaft to repair these conditions.

- Thanks to Don Sherman

| Part

Number |

Description |

12346293

(Canadian 992723) |

Lubriplate

Lubricant Spray Grease |

|

figure

14 |

|

figure

15

|

| return

to Table of Contents |

|

| Pictorial

Service Information |

GMSPO

(GM Service and Parts Operations) is working to develop a new way to show

mechanical service information in the service manual. At present, a step-by-step

approach provides a small illustration and some words to tell you what

steps to perform to remove and replace the part.

With this format, it can be hard to find some things, and the extensive

use of links can be confusing. Printing a procedure can take quite a few

pages, as well.

The new format is called “pictorial.” As the name implies,

it’s based on a much larger illustration that shows the parts according

to disassembly sequence. A new, easy-to-follow numbered table corresponds

to the parts shown in the illustration.

The table uses the same part name that the GM Parts catalog uses, along

with special tool references, torque values, cautions and notices, and

what we call a “tip.”

The Service Tips are shorthand for the procedure steps that need to be

performed. If the illustration needs clarification, or if there is something

we’d like to tell you about the step, we’ll include it as

a tip.

What we won’t do is to tell you the obvious. For example, if a part

is attached with four screws, and this is made obvious in the illustration,

then we’ll just give you the part name. It’s not necessary

to tell you to remove the screws.

The illustration itself will be as large as three quarters of a printed

page. The table will follow under the illustration. In most cases, if

you print the material on your printer, it will be no more than two to

four pages. Because torque values are included within the table, you won’t

need to print the torque specification page as a separate item.

The new illustrations are designed to provide you with enough information

so you know where things are on the vehicle – what we call “vehicle

context.” We will also show parts that help in understanding the

overall assembly, even though the detail for servicing them may be in

another section of the manual.

The Table of Contents will remain as it is today. The older format will

work just fine next to the new format, so there was no need to change

how you navigate around the system.

Another new feature -- “assembly illustrations” -- will be

included when there is sufficient complexity to warrant their use. For

example, the front brake system is fairly easy to show in one or two illustrations,

while the instrument panel is hard to show that way. Wherever possible,

the assembly illustration will be the same one used by the parts catalog.

So if you need a part, you can identify it on the service manual illustration

to show to the parts department.

We can also sequence you through a complex repair. You could start out

by looking at the assembly illustration. Depending on your level of experience

with a particular model, this might be all you need to complete the job.

If you need more information, a link will take you to the next step. If

you know exactly where you want to go, you can still use keywords, or

navigate with the mouse. Either way, you will be presented with a listing

of selections just as you are today. If you want to see the procedure

just for the radio, for instance, it will still be there in the list.

Click on it and you will be directed to it.

We’re pretty excited about this and think it will make your job

a little easier. You’ll print fewer pages. You’ll have the

correct part name, the torque value and appropriate service tips, and

in many cases, the same illustration used by the parts department.

You’ll start to see this new format roll into Service Information

as vehicle content changes over time. To change everything at one time

is more than we can do. Next month, we’ll talk in more detail about

these new features, and will show you what the new format will look like.

Then we’ll talk about what models and sections you’ll start

to see converted first.

As always, your feedback is really important to us. As you start to see

the new format and want to comment, we’ll be here and ready to listen.

- Thanks to Bob Scherer |

| |

| return

to Table of Contents |

|

| HVAC Cables |

Bulletin

03-01-38-005A covers various HVAC concerns on 2003-04 Chevrolet Cavalier

and Pontiac Sunfire related to mode and temperature control cables.

Be sure to refer to the bulletin for details. Here are some highlights.

Because symptoms show up as a control knob that is difficult to move,

blame is often placed wrongly on the control head. The control head

has not been identified as a cause of effort concerns, although the

head may become damaged by forcing a knob to overcome an operating condition

elsewhere.

TIP: Be sure the cable mounting tabs on the control

head are intact.

Cable Conditions

The bulletin points out that a cable may bind, or may become kinked,

due to:

- Improper cable routing -- Be sure routing does not

cause cable housing or cam interference when the control head knob is

operated.

- Improper cable clip positioning -- May have been

improperly installed at assembly, or may have pulled off by forcing

the control head.

- Cable interference with wiring -- Tie back wiring

as necessary.

- Stuck or binding valve -- The defrost valve arm may

drop off the edge of the surface and become stuck. The bulletin details

how to grind the area. Foam or adhesive may interfere with operaton

of defrost and mode valves (fig. 16). The

bulletin explains how to trim the material to allow free operation.

Repair Tips

Here are some general tips.

- For diffiucult mode valve operation, where the valve is not stuck,

check the mode cable housing for interference with the cam. The cable

can interfere with the cam during rotation (fig.

17), causing a condition of low effort, high effort then low

effort again.

- If a cable is kinked or stretched, replace it.

- Cables don’t have to be replaced in pairs.

- If routing or clip position was incorrect, be sure to fully function

test after making repairs.

- If a cable and clips are not damaged, the cable may be re-used.

TIP: Part number

89018237 (seal kit) is NOT required when replacing a cable. The parts

book will be updated on April 1.

- Thanks to Steve Oakley

| Part

Number |

Description |

| 89018243 |

Cable,

Mode Control |

| 89018243 |

Cable,

Temp Control |

|

figure

16 |

figure

17 |

| return

to Table of Contents |

|

| The

Value of Closing TAC Cases |

Why

spend the time to close a TAC case?

Case closings are one of the most important parts of using TAC. Case closing

information is specific repair knowledge that TAC learns from you and

other technicians. Your case closing helps provide how-to-fix information

to another technician with a similar condition.

The importance of case closing is also demonstrated by the use of your

closing information in PI (preliminary information) and/or service bulletin

development. These PIs and bulletins are then available to all dealers,

which in turn helps all of us provide outstanding repair service to our

customers.

Imagine a technician at a dealership in Oregon who finds the root cause

of a noise that has taken three days to diagnose. A detailed closing is

sent in to TAC, and a TAC consultant uses it to help a technician in Florida

repair another vehicle the next day, with all that time saved.

How to Close a Case

TIP: Specific case

closing details and guidelines are located in the Dealer P & P Manual

- Section 5.3.

Cases should be closed in a timely manner; ideally, on the same day the

vehicle is repaired or the repair order is closed. With timely closings,

you will be able to remember all the specific details of the repair.

US Dealers

The TAIF (Technical Assistance Information Form) asks for the following

basic information to close a TAC case.

- TAC Case Number

- Labor Op Number

- Detailed information on what actually fixed the vehicle.

There are two ways to close a TAC case:

1. Call the VME phone-in system at 1.888.446.8227, prompt 1

2. Use the fax-in system by sending a fax to 1.800.541.1761.

Canadian Dealers

Active TAC cases for your dealer code can be found on the GM InfoNET.

When the repair order is closed, locate the case on the GM InfoNET website

and submit explicit details of your resolution, a labor operation, applicable

part numbers and supporting attachments (such as pictures and Tech 2 snapshots).

So, why spend the time to close a TAC case? The answer is pretty simple.

Your closing helps other technicians, and other technicians’ case

closings help you. The more detailed and accurate closings we get, the

more we help each other. Thanks to all of you that send in detailed and

accurate case closings.

- Thanks to Dave Slaughter and Bill Szelag |

| |

| return

to Table of Contents |

|

| Intentional

Lack of Sealant |

Some

owners of regular and extended cab 2004 Colorado and Canyon pickup trucks

are commenting on the lack of seam sealer at the headboard of the pickup

box. These vehicles are built as designed and have successfully undergone

extensive corrosion testing. No repairs are necessary.

Engineering is making changes to provide a more finished appearance for

the unfinished edges. There is no plan to install sealer at this time.

- Thanks to Bill Detrick |

| |

| return

to Table of Contents |

|

| DVD

Player Concern |

On

the 2004 Chevrolet Malibu Maxx, do not swap the DVD player from a known-good

vehicle for diagnostic test purposes. The DVD player will operate ONLY

in the vehicle in which it was originally installed. It learns the vehicle's

VIN from the BCM on the first ignition cycle after it is installed.

A new VIN cannot be learned.

TIP: It is OK

to swap the LCD screen from a known-good vehicle for diagnostic test

purposes only.

-

Thanks to Bruce Moss |

| return

to Table of Contents |

|

| Delayed

Door Lock Feature |

The

2004 Cadillac SRX has a delayed door lock feature. If the customer does

not understand its operation, the normal function may appear as a problem.

TIP: Refer to

Owner's Manual page 2-9 (SI document 1206797) for an explanation of

how the Delayed Locking feature operates, and page 3-89 (SI document

894492) for the procedure to turn the feature ON and OFF using the DIC.

If the feature is turned ON and the customer presses the door lock switch

to the Lock position, a chime is heard, and the doors will lock about

5 seconds after the last door is closed. Pressing the Lock button a

second time or holding the switch down for 3-5 seconds will override

the Delayed Locking feature and will lock the doors immediately.

-

Thanks to Roger Jantz |

| return

to Table of Contents |

|

| Headliner

with Sunroof |

Owners

of some 2003-04 Buick Regals with sliding sunroof may comment about

a sagging headliner ahead of the rear window. This may be most noticeable

in the rearview mirror (fig.18).

The sunroof drive motor was relocated to the rear of the sunroof and

the headliner is reshaped to provide clearance.

TIP: This is

a normal condition and no repair should be performed. See bulletin 03-08-110-007

for details.

-

Thanks to Wayne Zigler |

figure

18 |

| return

to Table of Contents |

|

| SSR

Roof Operation when Cold |

Be

sure owners of the 2004 SSR understand this feature of top operation.

If the convertible top has not completed its movement from one position

to another within the programmed time limit, a Roof Cycle Timeout message

will be displayed on the DIC. When this message appears, the convertible

top will stop moving. Release the convertible top switch and make sure

there is nothing blocking the path of the top. If the path is clear, turn

the ignition off and on again. Then press the convertible top switch again.

When operating the top in low temperatures -- below 32°F (0°C)

-- the time needed to cycle the top will increase. This may cause the

top movement to stop and the Roof Cycle Timeout message to appear on the

DIC. If this occurs, release the convertible top switch and depress it

again to continue the cycle. Make sure nothing is blocking the path of

the top before depressing the switch again. It may be necessary to do

this several times to complete the cycle, depending on the outside temperature.

TIP: If the convertible

top switch is operated continuously while the ignition is in ACCESSORY,

the battery will drain and it may be difficult to start the vehicle. Do

not use the convertible top switch for extended periods of time when the

ignition is in ACCESSORY.

-

Thanks to Dan Oden |

| |

|

return

to Table of Contents |

|

Car Issues – Fix It Right The First Time (new issues in bold)

Car Issues – Fix It Right The First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

1.

Refinish brake rotor

2. Measure for LRO |

1.

Don’t replace the brake rotors.

2. Don’t fail to measure for LRO |

00-05-22-002C |

2003-2004 |

CTS

– Variable Effort Steering (VES) “Service Steering

Message,” DTC C1241 or C0450 |

Replace

only VES solenoid |

Don’t

replace the entire steering gear. |

03-02-36-001 |

2001-2003 |

All

cars with 4T40/45E, 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM Solenoid |

Don’t

replace transmission, torque converter or valve body assembly. |

02-07-30-039C |

2000-04 |

Cavalier/Sunfire

– Air Conditioning Compressor Noisy |

Inspect

for ground outs that can cause A/C compressor noise |

Don’t

replace A/C compressor for noise without inspecting for ground

outs. |

03-01-38-012 |

2004 |

Cavalier/Sunfire/Alero/Grand

Am – Inoperative Sunroof Module |

Retime

module or replace only motor |

Don’t

replace entire sunroof module assembly. |

03-08-67-009 |

2001-04 |

Century/Regal

– Intermittent SES, ABS or TCS Lamp Illuminated, Engine

No Crank/No Start, Various I/P Cluster Intermittents, DTCs Set,

Shifter Locked in Park |

Check

UBEC harness connectors for damage and replace damaged terminals |

Don’t

replace UBEC, ignition switch, SDM, BCM, shifter assembly or intermittent

clusters. |

03-08-45-004 |

1998-2004 |

Seville

– Heated Seat Inoperative |

Replace

only needed heating element. |

Don’t

replace entire seat cover |

01-08-50-002C |

2000-2004 |

All

Cars with 4T40/4T45E and 4T65E – Light On, Various Transmission

Codes Stored |

Check

trans 20-way connector for secure connection (disconnect, reconnect). |

Don’t

replace transmission, TCC PWM, VSS, PCS or valve body. |

02-07-30-022B |

2002-03 |

Impala

– Snap/Clunk when Window is Rolled to Full Up Position |

Replace

glass run channel with revised part. |

Don’t

replace front window regulator, door glass or align door glass |

03-08-64-034 |

1999-2004 |

1999-2003

Park Avenue, 2000-2004 LeSabre – Ash Tray Will Not Remain

Closed |

Use

I/P ash tray latch as service repair. |

Don’t replace complete ash tray assembly. |

03-08-49-005 |

|

| return

to Table of Contents |

|

|

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2002-04 |

Chevrolet Avalanche and Cadillac Escalade EXT – Cargo Covers

and Cladding Faded or Stained |

Thoroughly

clean, dry and treat components with Armor-dillo. To order (888)393-4722

or www.armor-dillo.net. |

Don’t

replace cargo covers for this condition. |

04-08-111-001 |

2002-04 |

Fullsize and Midsize Pickups and Utilities – Transfer Case

CNND Labor Operation |

Use

Labor Operation K9993 whenever a transfer case issue on a 4WD

or AWD vehicle cannot be duplicated or resolved after diagnostic

efforts. |

Don’t

use K9992, which is for manual concerns or K9995, which is for

automatic concerns. |

Service

VME

VSSM20030117 |

1999-2003 |

Fullsize Pickups – Rear Leaf Spring Slap Noise |

Replace

inserts and rubber washers. |

Don’t

replace the leaf spring. |

03-03-09-002 |

1993-2004 |

All

Passenger Cars and Trucks – Air Conditioner Compressor Diagnosis |

Follow

SI and bulletin for diagnostic information before compressor replacement. |

Don’t

replace air conditioning compressor |

Service

VME, 10/31/03

01-01-38-013A |

2002-04 |

All TrailBlazers, All Envoys, Bravada, Rainier with HomeLink Universal

Transmitter – Programming Diagnosis |

Use

J 41540 – GM Integrated HomeLink Tester. Follow SI and refer

customers to Owner’s Manual. |

Don’t

replace HomeLink Transceiver without validating internal fault

recognized by J 41540 |

01-08-97-001B |

2002-2003 |

All

TrailBlazers, Envoy, Envoy XL, Bravada – Squeak/Rub/Scrub

Type Noise in Steering Column |

Lubricate

and remove material, per bulletin. |

Don’t

replace upper or lower intermediate shaft. |

02-02-35-006A |

2003-04 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed. |

Don’t

replace the complete mirror assembly. |

03-08-64-028 |

2003 |

Fullsize

Pickups and Utilities – Transfer Case Service Light/New

Venture Gear Transfer Case |

Verify

that the encoder motor is the primary cause. Replace encoder motor

sensor and reprogram TCCM.

Labor Operation: K9980 |

Don’t

replace the module, encoder motor or transfer case for DTCs C0327,

P0836, P0500 |

03-04-21-001D |

2003 |

Fullsize

Pickups – 6.6L Diesel Engine ECM |

Follow

SI and bulletins for proper diagnostics for P0181. Refer to Owner’s

Manual (block heater and front cover) |

Don’t

replace ECM (DTCs P0540 and P0181) unless diagnostics confirm

need to replace |

02-06-04-048

03-06-04-021

02-06-04-058 |

2002-2004 |

All

TrailBlazers, All Envoys, Bravada, Rainier – Mirror Erratic

Return |

Replace

mirror actuator and reprogram module |

Don’t

replace outside mirror assembly |

02-08-64-008

02-08-64-021

03-08-64-033 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for May |

| |

|

| Know-How

Broadcasts for May |

| 10280.05D

Emerging Issues |

May

13, 2004 |

9:00

AM, 12:30 PM,

3:00 PM

Eastern Time |

| 10280.17D

New Model Features -- 2005 Cadillac |

May

27, 2004 |

9:00

AM, 12:30 PM,

3:00 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time (new issues in bold)

Car Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)