| |

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Terminal

Repair Kit Update J-38125-710 |

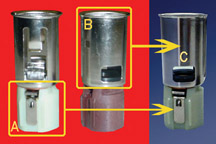

This continuing

information will help you understand the J-38125-D Terminal Repair Kit

and use it more effectively (fig. 1). This

information supplements the TechLink article published in September

2002.

Some Definitions

An electrical terminal is the formed metal attached to the end of a

wire to provide electrical connection with another wire or with a component.

Groups of terminals are organized into molded plastic blocks called

connectors.

Groups of wires, with their terminals and connectors, are gathered into

wiring harnesses.

Production vs. Service Terminals

TIP: There are

differences between production terminals and service terminals. A single

service terminal may replace several production terminal numbers.

Service terminals are chosen so the crimp wings fit the crimp tools

in the J-38125-D kit. You should use the crimp matrix in the Terminal

Repair Kit instruction book for best results.

Service terminals may have more tin or gold content than the production

terminal.

Service terminals may have a higher contact force than the production

terminal. In the assembly plant, where actions are repetitive, connector

assembly effort is an issue that does not come up in service.

Where Do Service Terminals Come From?

Service terminals are NOT available from GMSPO. A parts bulletin IB03-044

has been issued to this effect. There have been many ParTec orders placed

in error because of this.

Because service terminals are not stocked by GMSPO, the service terminals

in the J-38125-D Terminal Repair Kit have supplier part numbers.

All service terminals and all components and tools of the J-38125-D

Terminal Repair Kit should be ordered from SPX (Kent-Moore) at 1.800.345.2233.

It is important to keep the complete J-38125-D Terminal Repair Kit in

proper order and stocked with terminals and tools, as more wiring suppliers

make their appearance in GM vehicles.

How Are Terminals Organized in the J-38125-D Terminal Repair

Kit?

There are five wiring suppliers for GM Power and Signal Distribution

(PASD) systems:

- AFL

- Delphi

- Lear

- Sumitomo

- Yazaki.

These five supply the wiring used in North American-engineered platforms.

The J-38125-D Terminal Repair Kit was originally a Delphi terminal repair

kit only. There are now Delphi trays, Lear trays, Sumitomo trays and

Yazaki trays, with AFL to be added in 2005.

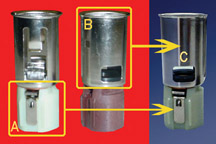

The 2003 Up-Date (J-38125-710)

You have just received the 2003 J-38125-710 up-date to the J-38125-C

Terminal Repair Kit, making it now the J-38125-D Terminal Repair Kit.

This is perhaps the largest up-date to the base J-38125 Terminal Repair

Kit to date. The reason is to add all the new service terminals now

in GM vehicles that have not been serviced since 1998.

The up-date consists of eight new trays of terminals, numbered 7, 14,

15, 16, 17, 18, 19 and 20. Tray 7 has been filled with new terminals

and replaces the existing Lear tray 7.

TIP: You may

want to organize your Terminal Repair Kit by supplier (without regard

to tray numbers): e.g. Delphi, Lear, Sumitomo and Yazaki.

You will also receive three new terminal release tools. The J-38125-24

green tool is for a very small Tyco terminal found at some sunroof and

door modules. The J-38125-211 blue tool is for a JAE terminal found

in some steering column connectors. The J-38125-212 green tool is for

a Tyco male JPT terminal found in some engine harnesses.

There four cable seals to add to Yazaki tray 13.

The reference guide is completely new and has a complete inventory of

the J-38125-D Terminal Repair Kit.

Additional guides can be ordered from SPX (Kent-Moore) under p/n J-38125-620.

Finally, there are new tray labels for the first five Delphi trays and

Delphi tray eight.

Setting Up Your Trays

Take your time getting the old labels off, cleaning the tray lids and

carefully positioning the new labels on the tray lids so the terminals

are correctly identified.

These new tray labels are very important, because a number of old terminals

have been replaced or deleted. The new tray labels provide two pieces

of information.

- The new service terminal part number.

- The tray in which it is stocked.

There is also a small stick-on label for tray 13, identifying the new

cable seals in this up-date.

The metal cabinets that hold the terminal trays can also be ordered

from SPX (Kent-Moore) under p/n J-38125-610. The J-38125-710 up-date

will fill four of these cabinets. If you have some of the tool trays,

you may need a fifth cabinet. You can use tool trays to hold the terminal

release tools and Ultratorch.

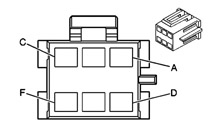

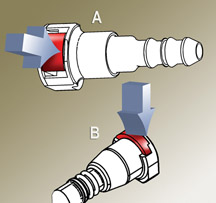

A Word About the Terminal Test Kit J-35616-B

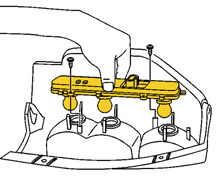

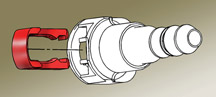

A number of test probes are added to the J-35616-B Terminal Test Kit,

due to the number of new terminals in the J-38125-D Terminal Repair

Kit. (fig. 2)

There has never been a good way of relating any given terminal to its

proper test probe. So with this up-date, all terminal descriptions will

have within them a terminal size: e.g., M/P 150 series male. The 150

will now relate directly to a 150 test probe. The test probe will be

called the 150 male probe adaptor – gray.

All the test probes will be renamed and a new label will be sent with

the up-date for the J-35616-B Terminal Test Kit in 2004. The J-35616-B

Terminal Test Kit will then become the J-35616-C Terminal Test Kit.

What’s Coming?

Under consideration for 2004 is an AFL service terminal tray, along

with new Sumitomo service terminals to the existing Sumitomo tray 6.

Additional Sumitomo trays may be added at that time.

There should not be a need for any new crimp tools in 2004.

Information included in SI is being revised. A pilot for a new connector

end view is planed for the ‘04 Cadillac XLR service information.

This connector end view will give you the service terminal number that

is in the J-38125-D Terminal Repair Kit.

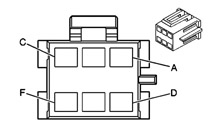

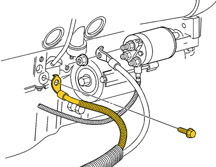

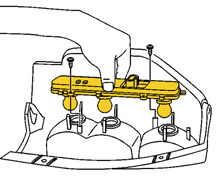

TIP: The new

connector end view (fig. 3) will for the

first time give you the real connector or pigtail part number, which

is stocked by GMSPO. This connector end view may take some time to make

its appearance in all the service information, but every effort is being

made to do so.

-

Thanks to John Roberts and Jim Willockx |

|

figure

1 |

|

|

figure 2 |

figure

3

|

| return

to Table of Contents |

|

|

| VCI

Number |

Let’s begin with a definition. A Vehicle Configuration Index (VCI)

is a number assigned to a valid calibration or group of calibrations

for each module for a specific vehicle that is programmed using the

Service Programming System (SPS). Each VCI represents a specific vehicle

configuration. Multiple VCI numbers can be assigned to the same Vehicle

Identification Number (VIN) based on the number of SPS programmable

modules on the vehicle. When programming using a VCI number, keep in

mind that it is valid only for the vehicle and control module that it

is issued for, and cannot be used to program another vehicle with the

same configuration.

TIP: Also VCI

numbers will always take you to the latest calibration or group of calibrations

available in TIS.

When the vehicle leaves the assembly plant, a database has already been

created for it. This is called the “as-built” data. At that

time, VCI numbers are assigned to each VIN and control module based

on variables such as engine type, transmission type, tire size, axle

ratio, etc.

If a dealer adds certain equipment to a vehicle, or changes certain

equipment on a vehicle, the “as-built” data are no longer

representative of the vehicle. So, it is necessary to obtain a new VCI

number to represent the “as-is” content of the vehicle.

An example is installing an optional wheel/tire size.

TIP: It is necessary

to call the Techline Customer Support Center (TCSC) at 1.800.828.6860

to change a vehicle’s VCI.

TIP: For a given

vehicle, it is possible to obtain VCI numbers only for combinations

of components and specifications approved by General Motors.

Important Benefit of the VCI Number

The VCI concept provides an important benefit to dealers: the reconfiguration

history of a vehicle does not need to be known before programming. It

works like this. If a vehicle’s content is changed, requiring

module reprogramming, a different VCI number is needed before the Techline

terminal and Tech 2 can be used. Only TCSC can issue VCI numbers. When

TCSC issues a new VCI number for a vehicle, the changes made to the

vehicle now become a part of the vehicle’s VIN data record. Once

the database has been updated, subsequent Techline releases will contain

the new information and a VCI number will no longer be required.

20 Inch Wheel and Tire Example

As explained in the January 2004 issue of TechLink, Chevrolet and GMC

dealers can now obtain accessory wheels and tires from SPO and install

them on certain trucks. Refer to bulletin 03-03-10-006 for specific

details and exceptions.

Because these wheels and tires are larger than the standard ones, it

is necessary to recalibrate the PCM and ABS modules.

In order to reprogram the PCM, a new VCI number must be input. The dealer

has to call TCSC to obtain it. At that time, TCSC modifies the vehicle’s

database to reflect the new wheel and tire size.

IMPORTANT: Because this is not a warranty procedure, but is

customer paid, TCSC charges a fee for this service.

TIP: In the future,

if original equipment size wheels and tires are again installed on the

vehicle, it is necessary to contact TCSC, to obtain the necessary VCI

number to recalibrate the vehicle again.

-

Thanks to Dave Puzzuoli and Mark Stesney |

|

|

|

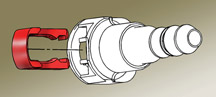

| Fuel

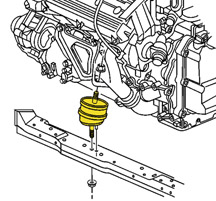

Sender Lock Rings |

GM

Fuel Systems has developed a common fuel sender closure (lock ring)

which will be implemented on most GM vehicles beginning in model year

2004.

The tool needed to properly service this closure is J-45722 (fig.

4).

Because the removal and installation forces are higher than typical,

use a long breaker-bar with J-45722. Have an assistant secure the fuel

tank if necessary.

TIP: The lock

ring and tool will rotate approximately 16 degrees. Ensure that the

J-45722 is positioned so as to prevent damage to the fuel sender when

unlocking or locking the system.

TIP: Any time

the fuel sender closure is opened, the fuel sender closure seal must

be replaced.

SI procedures are being revised to reflect this change.

- Thanks to Kevin Willcock |

|

figure

4

|

return to Table of Contents |

|

| Wiper

Blade Optimizer |

Effective

immediately, the assembly plant will be putting two Optimizer pads in

the glove compartment of each 2004 Venture, Silhouette, and Montana.

The Optimizer is a wiper blade element cleaning pad. It uses a specific

Isopropanol-based formula to remove wax, dirt, and other contaminants

from the wiper blade element.

Wiper blade elements all contain wax in the rubber to prevent cracking

or deterioration under the effects of ozone, heat and sunlight. It is

normal for some of this wax to slowly bleed out over time.

TIP: The wax-removing,

cleaning effect has the most impact when performed just before delivery

of the vehicle to the customer. Because the PDI process may be done

well in advance of delivery, please ensure that this wiper blade cleaner

is applied during the final wash and prep just before delivery.

-

Thanks to Tom Geist |

| |

| return

to Table of Contents |

|

| Elimination

of LH Hood Assist Rod |

The

number of hood assist rods has been reduced from two to one on the 2004

Cadillac CTS. Vehicles built after VIN breakpoint 40137492 will feature

a high pressure single hood assist rod located on the RH side.

TIP: Any attempts

to modify or add an additional hood assist rod could result in damage

to the vehicle.

-

Thanks to Terry Bordeau |

| |

| return

to Table of Contents |

|

| XLR

Keyless Ignition |

The

Cadillac XLR keyless access system does not use a traditional key for

door locks or ignition. Instead, the driver carries a transmitter fob

(fig. 5). When the vehicle senses the presence

of the correctly coded transmitter fob, the doors can be opened. With

the transmitter fob inside the passenger compartment, the engine can

be started by pressing the START button on the instrument panel (fig.

6).

Key On, Engine Off Mode

There may be times, such as when you are performing diagnostics on the

vehicle, that you need to have the ignition turned on, with the engine

not running. In this mode, all modules are powered up and communicating

on the serial data line.

TIP: This information

is covered in SI. Follow this path: Accessories > Keyless Entry >

Description and Operation > Keyless Entry System Description and

Operation

- Make sure the transmitter fob is inside the passenger compartment.

- Depress the brake pedal.

- Be sure the transmission is in Park or Neutral.

- Press the ACC button and hold for 5 seconds. The instrument panel

will light up and the ignition will be turned on, but the engine will

not start.

TIP: If you press

the ACC button only briefly, the accessory mode will be turned on. This

is not the same as turning the ignition on.

It is imperative that you press ACC again to turn the ignition off.

TIP: Retained

Accessory Power will function for 10 minutes after the ignition is turned

off, or until a door is opened.

-

Thanks to Brad Thacher |

figure

5 |

figure

6 |

| return

to Table of Contents |

|

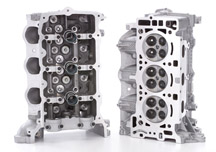

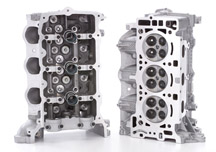

| 3.6L

V-6 VVT Engine (RPO LY7) |

For

2004, GM Powertrain has introduced an all-new 60° DOHC V-6 engine

(fig. 7). It will initially be used in

the Cadillac CTS and SRX and the Buick Rendezvous. This engine offers

contemporary world-class features:

- all-aluminum construction

- dual overhead camshafts (DOHC)

- 4-valves per cylinder

- roller-finger follower valvetrain

- continuously variable cam phasing

- electronic throttle control

- forged-steel crankshaft

- piston-cooling oil jets

- Oil Life System

- 32-bit microprocessor

- coil-on-plug ignition

Design Philosophy

This 60° DOHC V-6 engine was developed by GM technical centers in

Australia, Germany, North America and Sweden for global application

in premium and high-performance vehicles. It applies the most advanced

technology available. The modular design assures multiple displacement,

configuration and content possibilities. The result is an engine that

delivers good specific output, high torque over a wide rpm range, fuel

economy, low emissions, excellent noise, vibration and harshness (NVH)

control, durability, and low maintenance requirements.

Although the initial offering will be 3.6L displacement, variants can

be manufactured in 2.8L, 3.2L and 3.8L sizes. Power will range from

200 to 370 hp, while torque will run from 200 lb-ft to more than 350

lb-ft. The 3.6L will provide 255 hp and 250 lb-ft of torque.

The engine was designed to be installed in multiple orientations:

- front-wheel drive, typically transverse

- rear-wheel drive, typically longitudinal

- all-wheel drive, either transverse or longitudinal

Manufacturing

The DOHC V6 engines will be built in GM Powertrain facilities in Port

Melbourne, Victoria, Australia and St. Catherines, Ontario, Canada.

Initially, rear-wheel drive engines will be built in Canada and front-wheel

drive engines will be built in Australia.

Block and Heads

The engine block and cylinder heads are cast of A319 aluminum alloy,

for lower weight. This translates to improved fuel economy. Math-based

structural analysis permits maximum performance and durability with

minimum mass.

The block is cast using the precision sand-mold method, with iron cylinder

bore liners in place (fig. 8). Precision

casting reduces the need for machining, and reduces material waste.

Attachment points are included for all drive configurations in all castings,

and are machined as needed depending on application.

The 60° cylinder arrangement provides for smooth, vibration-free

operation without the balance shafts typically needed in 90° V6s.

Vibration is further limited by the deep-skirt design. Sintered steel

main bearing caps are attached with six bolts, a premium feature.

The heads are cast in semi-permanent molds (fig.

9). Inlet passages are designed for optimum airflow, for reduced

operating noise. Exhaust ports allow maximum flow, while preserving

heat for quick catalyst light-off.

Valvetrain

The LY7 has fully variable valve timing for both intake and exhaust.

This electronically controlled, hydraulically operated system places

a phaser on each of the four camshafts (fig. 10).

The phaser enables changing the timing of the camshaft relative to the

crankshaft, over a range of 50° of crankshaft rotation. Fixed camshafts

compromise between smooth idle, good low-rpm torque and high-rpm power.

Variable camshaft timing accommodates the sometimes divergent needs

for power, driveability, economy and emission control.

At idle, the exhaust cams operate at full advance, for minimum valve

overlap. Optimizing valve overlap eliminates the need for a separate

exhaust gas recirculation (EGR) system and air injection reaction (AIR).

By closing the exhaust valves late, at the appropriate times, the desired

amount of exhaust gas is forced back into the combustion chamber for

burning in the next cycle.

The camshafts are driven by a roller chain. A hydraulically operated

tensioner keeps proper tension on the chain, even as it stretches with

mileage (a normal occurrence in all chains), which eliminates need for

periodic replacement or adjustment.

The cams operate directly on roller-finger followers (fig.

11), which actuate the valves. Hydraulic lash adjusters provide

automatic adjustment.

TIP: Setting

the camshaft timing is necessary whenever the camshaft drive system

has been disturbed such that the relationship between any chain and

sprocket has been lost. Even when only one sprocket is involved, multiple

crankshaft rotations will not produce conditions where correct timing

can be confirmed. Refer to the complete procedure in SI. Follow the

left bank secondary camshaft drive chain replacement procedures to reset

the camshaft timing.

Variable Intake Manifold and Electronic Throttle

The variable cam timing is supplemented by a dual-stage variable intake

manifold (VIM) (fig. 12). When the VIM

switch is shut, at low and mid speeds, the cylinders feed from two separate

plenums. At higher speeds, the switch opens, causing the cylinders to

feed from a single common plenum, boosting cylinder charging. Because

the intake runners are all precisely the same length, airflow is consistent

to all cylinders. This reduces the intake noise sometimes associated

with high-revving engines.

The electronically controlled throttle (ECT) eliminates the traditional

throttle cable between the pedal and the throttle body. Driver input

is registered by a throttle position sensor at the pedal, and precision

throttle rate and angle are provided by a computer-controlled stepper

motor (fig. 13). The ECT also incorporates

cruise control, which eliminates components, wiring, and complexity.

Pistons and Crankshaft

Pistons are manufactured of forged aluminum, which is lighter than conventional

steel pistons (fig. 14). Reduced mass provides

greater operating efficiency and reduced noise and harshness.

The full-floating 24-mm wristpins are retained in the pistons by snap

rings, but are otherwise free to float in both the piston and connecting

rod. This permits tighter tolerances and reduces friction and operating

noise.

Pistons are coated with polymer, applied to the skirts. This reduces

bore scuffing, despite reduced piston-to-bore clearances.

An oil jet sprays the underside of each piston and surrounding cylinder

wall, for reduced friction and extra cooling (fig.

15).

The crankshaft is forged steel, which is inherently stiffer than cast

iron, for reduced vibration (fig. 16).

The crankshaft sprocket is cushioned with a molded-rubber ring. And

the crank seals are made of Teflon, which is impervious to oil and gases.

Electronics

A single microprocessor (fig. 17), mounted

directly to the engine, manages numerous functions:

- cam phasing

- electronic throttle

- torque management

- fuel injection

- ignition and knock sensors

- variable intake manifold

At the heart of all this electronic wizardry is a sate-of-the-art 32-bit,

25 MHz microprocessor, the most powerful in use in the industry.

All electronic circuitry is embedded in a 4-layer sandwich substrate.

This drastically reduces size and offers increased durability. It can

withstand temperatures of 230°F and vibration up to 30 g, allowing

it to be attached directly to the engine. This simplifies wiring, with

fewer junctions. It also frees space in the vehicle, and simplifies

assembly at the plant.

Maintenance Requirements

Despite its sophistication, the LY7 engine requires surprisingly minimal

maintenance. The cam drive, cam phasing and valvetrain components require

no scheduled maintenance. Cam tensioner, cam phasing components and

valve lash adjusters ensure optimal valvetrain performance for the life

of the engine with no adjustment.

Spark plugs have dual-platinum electrodes, for a service life of 100,000

miles without spark degradation. Even so, the plugs are easily removed

from the center of the cam covers (fig. 18).

There is a separate ignition coil mounted to each spark plug.

Extended life coolant retains cooling and corrosioin-inhibiting properties

for 100,000 miles of normal use. And the two accessory drive belts,

manufactured of EPDM, using a lapless method, are also intended to last

100,000 miles.

An oil level sensor advises the driver if the oil level drops below

a prescribed level. The GM Oil Life System calculates oil life based

on engine speed, operating temperature, load or rpm variance, and operation

at load and temperature. Oil changes are recommended when they are actually

needed. And when an oil change is performed, only the cartridge, not

the entire filter, needs to be changed.

-

Thanks to Ron Caponey |

figure

7

|

figure

8 |

figure

9 |

figure

10 |

figure

11 |

figure 12

figure 12 |

figure

13 |

figure

14 |

figure

15 |

figure

16 |

figure

17 |

figure

18 |

|

return

to Table of Contents |

|

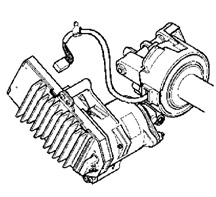

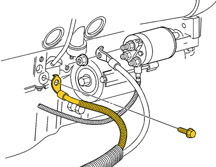

| Electric

Power Steering Diagnosis |

This

additional information pertains to the Electric Power Steering (EPS)

on the 2004 Chevrolet Malibu (see details in the September 2003 TechLink).

The power steering motor and power steering control module (PSCM) are

serviced as an assembly, separate from the steering column. This results

in the need for a test harness EL-47564 (fig.

19) for certain diagnostic procedures, to determine if the PSCM

is or is not the cause of the malfunction.

If you are faced with a DTC C0545 (steering shaft torque sensor) or

a DTC C0460 (steering wheel position sensor), you will need to use the

PSCM test harness when using either of the diagnostic tables. Refer

to the appropriate section of SI for details.

Follow this path: > build vehicle > Steering > Power Steering

System > Diagnostic Information and Procedures > DTC.

To perform the diagnosis, disconnect the torque/position sensor harness

connector from the PSCM (fig 20). Connect

PSCM the test harness. Then, using a 3 amp fused jumper wire, perform

the tests listed in the SI procedure, while observing the results on

your Tech 2.

- Thanks to Scott Bower |

figure

19 |

figure 20 |

| return

to Table of Contents |

|

| Exterior

Lamp Condensation |

Moisture

inside exterior lamps continues to be a concern. Bulletin 01-08-42-001A,

released in November, defines the causes, and provides guidelines for

determining the difference between condensation and a lamp with a water

leak.

Refer to the bulletin for details. Here are some of the highlights.

Condensation -- Condensation (fog) inside the lamp

housing occurs after a period of high humidity, which is an atmospheric

condition. The condensation should clear when the vehicle is parked

in a dry environment or when driven with the lights on. If condensation

occurs, replacing the lamp assembly may not correct the condition.

Leak -- Drops of various sizes collecting on the inside

of the lens after being exposed to rain or a car wash indicate a leak.

Water accumulated from a leak won’t clear if the vehicle is parked

in a dry environment, or when driven with the lights on. Water accumulation

in the lamp assembly indicates a need for service.

-

Thanks to Gary McAdam |

|

|

|

return

to Table of Contents |

|

| Fuel

Line Quick Connectors |

Two new style fuel line quick connects are in use.

The TI Group Global Quick Connector is used on C/K trucks, S/T trucks,

Malibu Sedan, Cadillac XLR and the 2004.5 and 2005 Chevrolet Corvette.

The Legris QC is used on Aztek, Rendezvous, Venture, Montana and Silhouette.

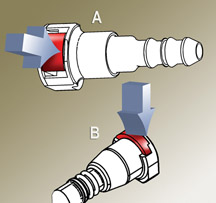

Release

Both Types -- To release the quick connect, push on the retainer using

hand pressure only. Do not attempt to remove it. (fig.

21)

A - TI type

B - Legris type

Do not use sharp or pointed objects to put pressure on the connector

retainer. Using a tool may fracture the retainer, making it less effective

at keeping the connector assembled. Also, attempts to remove the retainer

with the line inserted will result in retainer breakage.

TIP: If the connector

does not release with hand pressure, thoroughly clean it and blow out

grit and dirt with compressed air.

Repair

TI Group Global -- If the retainer is broken, it is

not necessary to replace the entire fuel line and attached component

to repair it. Three sizes of replacement retainers are available (fig.

22).

5/16

po |

21992748 |

3/8

po |

22717568 |

5/8

p0 |

21992746 |

Legris

-- Replacement parts are not available for the retainer.

- Thanks to Dave MacGillis |

figure

21 |

| |

figure 22 |

|

return

to Table of Contents |

|

| No

Crank, No Start |

If

the owner of a 2004 LeSabre or Park Avenue/Ultra built before December

19, 2003 experiences a no crank, no start condition, check the negative

battery cable torque at the engine block. The negative battery cable

may be loose or not torqued to specification (fig.

23). The ground location (G101) may not be drilled or tapped

deep enough into the engine block to allow the bolt to achieve the recommended

torque.

To correct this concern, install a shorter bolt or add two star washers

to reduce the height of the bolt.

- Thanks to Bill Metoyer

original

bolt |

12556062 |

shorter

bolt |

11517862 |

|

figure

23 |

|

return

to Table of Contents |

|

| Quality

Service Experience “How-To” |

Customers

who take delivery of a new vehicle during November and December are

eligible to receive a J.D. Power Initial Quality Survey 90 days later.

Because the surveys won't reach the customer until February through

April, the customer may have the opportunity to return to the dealership

for service before receiving their survey. The customer's service experience

can positively, or negatively, affect their perception of vehicle quality,

so the service department team has the opportunity to influence J.D.

Power scores.

It's essential that the customer be provided with an outstanding service

experience that exceeds their expectations. This includes:

Providing hassle-free service -- Make it easy for customers

to do business with you. Do you offer extended service hours? Are you

open on Saturdays?

Fixing vehicles right the first time -- Use

technical service bulletins and Service Information (SI) to identify

the correct repair. Pay special attention to the Field Product Reminder

- Car and Truck Fix it Right the First Time Issues, Parts Restriction

Information and Bulletin Summary bulletin, which is published once a

month.

Helping customers understand how vehicle features and controls

work -- Handle these issues right on the service drive

by using the Getting to Know Your Vehicle guides. Are your service advisors

trained on new product features, so they can answer customers' questions?

Making each service visit a "non-event" by exceeding customer

expectations -- An outstanding service experience may

more than compensate for the original repair issue. You want your customers

to leave your service department feeling completely satisfied.

Following-up with customers 2 to 3 days after service

-- Make sure customers are completely satisfied and understand the repairs

that were performed.

Dealer personnel are the last to touch the vehicle and to interact with

the customer before they receive a J.D. Power survey, the final link

in the quality chain.

- Thanks to Diana Sancya |

|

|

| return

to Table of Contents |

|

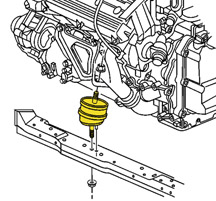

| DeVille

Engine Mount Replacement |

On

the 2000-04 Cadillac DeVille, modifications to the front engine mount

have resulted in the following changes:

- Front engine mount serviceable as a separate part, without bracket (fig.

24)

- Revision of replacement procedure. In SI, refer to Engine Mount Replacement

- Front in Engine Mechanical, or document 447931 (MY 2000) or 714354 (MY

2001-04).

- Revision of labor time

Refer to bulletin 03-06-01-029 for complete procedure and details.

-

Thanks to Bill Denton |

figure

24 |

|

return

to Table of Contents |

|

2004

Cavalier Accessory Power Outlets |

Many

Cavaliers were susceptible to blowing the cigar lighter fuse when certain

power accessory plugs were used in the outlet. For production, Engineering

has switched from a cigar lighter housing to an Accessory Power Outlet

(APO) on the instrument panel.

Cigar lighters and APOs use different electrical connectors. During

the time while the electrial harness was being redesigned, Engineering

created a hybrid APO. It consists of the body of a standard APO and

the connector base of a cigar lighter housing (fig.

25).

A Standard cigar lighter base

B Standard APO body

C Hybrid APO

10,500 Cavaliers were built with the hybrid APO (between VIN breakpoints

1G1JC52F947205493 and 232627). After the end breakpoint, the I/P wire

harness will be using a universal connector that allows either the APO

or the cigar lighter housing to be used.

TIP: They hybrid

part will not be available to service. Use only the cigar lighter housing

to replace the hybrid..

-

Thanks to Bill Denton |

figure

25 |

| return

to Table of Contents |

|

| Tail

Lamp Circuit Board |

Bulletin

03-08-42-006A presents information about the circuit board used in tail

lamps of 2002-04 TrailBlazer, Envoy and Bravada, and 2004 Ranier (fig.

26).

A new circuit board is available for repair if diagnosis leads to a

failed tail lamp bulb. If the lamp is loose, or the board is failed,

install a new circuit board on both sides.

TIP: The preferred

bulb is now supplied by Sylvania. Previously, the bulb may have been

provided by various suppliers.

-

Thanks to Bill Denton |

|

figure

26 |

| return

to Table of Contents |

|

| SSR Correction |

An

article on page 4 of the December 2003 TechLink contained outdated information

about the Chevrolet SSR. The corrected information is shown in bold.

Remote Keyless Entry

The Tech 2 must be used for this procedure. When “building”

the vehicle, specify 2003 or 2004 SSR. Then follow SI

procedures to complete the process.

-

Thanks to Bill Denton |

| |

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time (new issues in bold)

Car Issues – Fix It Right The First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2000-2004 |

Cavalier/Sunfire

- Grinding noise when clutch pedal fully depressed. |

Replace

clutch hydraulic line |

Don’t

replace Clutch/Bearing |

03-07-31-005

Dated 10/30/03 |

1997-2004 |

Grand

Am/Alero/Malibu – Brake pulsation |

Turn

rotor and use brake align procedure |

Don’t

replace rotors for pulsation |

00-05-23-002

01-05-23-001 Know How 15040.01B |

2003 |

DeVille

– No Crank/No Start |

Inspect

base of UBEC to ensure wire connectors fully seated, not loose |

Don’t

replace PCM |

03-06-03-009 |

2004 |

Grand

Prix -- Steering, suspension or cradle click noise. |

Re-torque

right steering gear mount |

Don’t

replace steering gear |

03-02-32-048

Dated 10/28/03 |

2000-2004 |

Buick

Century and Regal

-- CJ3 Manual Dual Zone HVAC fan/mode control knob failures |

Fan

and mode knobs are serviceable |

Don’t

replace CJ3 HVAC control head for failed knob |

VSSM

BB –12/15/03

Dealer VME 12/15/03

Dealer Bulletin Requested |

2000-2004 |

IXLR,

Impala/Monte Carlo, Grand Prix -- Headlamp Replacement for Condensation

in Lamp |

Normal

condition when limited to fog or fine mist appearance in high

humidity conditions |

Don’t

replace headlamp assembly when no water droplets are evident or

condensation covers less than 50% of lens |

01-08-42-001A

11/4/03

Sept 2002 TechLink |

2003-2004 |

CTS

– Variable Effort Steering (VES) “Service Steering

Message” DTC C1241 or C0450 |

Replace

VES solenoid only |

Don’t

replace entire steering gear |

03-02-36-001 |

2003 |

All

cars with 4T40/45E, 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM

Solenoid |

Don’t

replace transmission or valve body assembly |

02-07-30-039B

(Part #’s in bulletin have been superceded) |

2002-2004 |

All

cars with 4T40/45E and 4T65E -- DTC P0716, P0717 and other misc

codes |

Disconnect,

inspect, and reconnect transaxle wiring harness at transaxle |

Don’t

replace input speed sensor |

02-07-30-022B

(10/03)

Sept 2003 Techlink

12/03 IDL |

200-2004 |

NorthStar

Crank Sensors -- during limited parts availability period. |

Replace

only sensor that is diagnosised as faulty |

Don’t replace both sensors for insurance |

Dealer

VME Sent 10/03 and 12/03 |

|

| return

to Table of Contents |

|

|

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2002-2004 |

Fullsize and Midsize Pickups and Utilities – Transfer Case |

Use

Labor Operation K9993 whenever transfer case issue cannot be duplicated

or resolved after diagnostic efforts. |

Don’t

use Labor Operation K9992 (for manual trans) or Labor Operation

K9995 (for automatic trans) |

Service

VME

VSSM20030117 |

1999-2003 |

Fullsize Pickups – Rear Leaf Spring Slap Noise |

Replace

inserts and rubber washers |

Don’t

replace leaf spring |

03-03-09-002 |

2002-2004 |

TrailBlazer, Envoy, Bravada, Rainier with HomeLink Universal Transmitter

– Programming Diagnosis |

Use

J-41540 – GM Integrated HomeLink Tester (essential tool).

Follow SI and refer to customers to their Owner’s Manual. |

Don’t

replace HomeLink Transceiver without validating internal fault

recognized by J-41540 |

01-08-97-001B |

2002-2003 |

TrailBlazer,

Envoy, Bravada – Squeak/Rub/Scrub Type Noise in Steering

Column |

Lubricate

and remove material, per bulletin |

Don’t

replace upper or lower intermediate shaft |

02-02-35-006A |

2002-2004 |

TrailBlazer, Envoy, Envoy XL, Bravada, Rainier – Tail Lamp

Socket Circuit Board |

Replace

both tail lamp circuit boards |

Don’t

replace complete tail lamp assembly |

Service

VME, 9/22/03

03-08-42-006A |

2003-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed |

Don’t

replace complete mirror assembly |

03-08-64-028 |

2003 |

Fullsize

Pickups and Utilities – Transfer Case Service Light/New

Venture Gear Transfer Case |

Verify

that encoder motor is primary cause. Replace encoder motor sensor

and reprogram TCCM |

Don’t

replace module, encoder motor or transfer case for DTCs C0327,

P0836, P0500 |

03-04-21-001B |

2003 |

Fullsize

Pickups – 6.6L Diesel Engine ECM |

Follow

SI and bulletins for proper diagnostics for P0181. Refer to the

Owner’s Manual (block heater and front cover) |

Don’t

replace ECM (DTCs P0540 and P0181) unless diagnostics confirm

need to replace |

02-06-04-048,

03-06-04-021, 02-06-04-058 |

2002-2004 |

TrailBlazer,

TrailBlazer EXT – Wavy Front Fascia |

Repair

fascia with Dual Lock |

Don’t

replace front fascia |

02-08-62-004 |

2002-2004 |

TrailBlazer,

Envoy, Bravada – Mirror Erratic Return |

Replace

mirror actuator and reprogram module |

Don’t

replace outside mirror assembly |

02-08-64-008

02-08-64-021 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for March |

| |

|

| Know-How

Broadcasts for March |

| |

|

NOTE

TIME CHANGE |

| 10280.03D

Emerging Issues |

March

11,

2004 |

9:00

AM, 12:30 PM,

3:00 PM

Eastern Time |

| 10280.15D

Envoy XUV Water Management |

March

25,

2004 |

9:00

AM, 12:30 PM,

3:00 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

figure 12

figure 12

Car Issues – Fix It Right The First Time (new issues in bold)

Car Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)