Table

of Contents – May 2003 |

| |

|

|

|

| |

|

|

|

| |

|

|

|

|

|

|

Note:

Clicking on any picture or illustration will open a larger version

of that art.

|

|

GM

Oil Life System Revisited |

How often should

engine oil be changed?

- 3,000 miles (5000 km)

- 5,000 miles (8000 km)

- 7,500 miles (12000 km)

- 10,000 miles (16000 km)

Actually, all of these are correct, depending on operating conditions. Oil life is affected by many factors other than just miles driven.

The type of driving, temperature, and engine load all play a part.

That’s why GM has developed the GM Oil Life System, an electronic

watchdog that keeps track of all these variables and notifies the driver

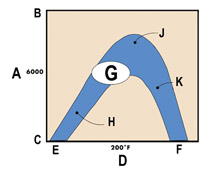

when it’s time to change oil. (fig. 1) We first told you about

the GM Oil Life System in the March 2000 TechLink. Since then, the

system has become standard equipment on nearly all GM products.

Briefly, the Oil Life System is programmed with a certain number of

engine revolutions. As the engine runs, this number is reduced until

it reaches zero, and the Oil Life light or message comes on. But there’s

more. Operating the engine under low or high temperatures, and under

high load conditions subtracts (penalizes) extra revolutions, so the

light comes on sooner.

Changing engine oil according to actual need rather than an inflexible

schedule provides several benefits.

First is simpified determination about when to change oil. No more

decisions about “normal” conditions vs. “severe” conditions.

Second is reduced operating costs for GM’s customers, who now

have to change oil only when it’s needed. Third is minimizing

the amount of used oil that must be disposed of. And fourth, engines

will always be running with sufficiently fresh oil, for long life.

These benefits will be realized only if engine oil is actually changed

as indicated by the GM Oil Life System.

Some customers “get it” when it’s explained to them.

Others may be reluctant to deviate from traditional oil change interval

charts. So, part of the responsibility falls on retail service people

to help get the message out.

TIP: To help you do this, an IDL broadcast is being prepared. Consult

the GM Training Program Guide and Schedule for “Understanding

the GM Oil Life System” (PPS03.P1D).

There’s More

Traditionally, the vehicle maintenance schedule has been based on miles

or time, while the oil change interval is now based on the GM Oil Life

System. This could result in customers having to bring their vehicles

in for an oil change when the light comes on, only to find that the

vehicle is due in a month for scheduled maintenance.

That’s all changing. In the accompanying article “Simplified

Maintenance Schedules”, you’ll learn how maintenance intervals

are now being tied into the oil change intervals indicated by the Oil

Life System.

-

Thanks to Jerry Garfield and Chuck Burns |

figure

1 |

|

|

|

|

|

|

| How to Search

on the TechLink Website |

You

can search the TechLink archives, in a roundabout sort of way. Go

to www.google.com and select the advanced search option.

In the blue box, type in the key word(s) you want to search. You can

limit the search four different ways, depending on which box(es) you

type in.

Then in the next section of the form, on the file format line, select

ONLY and select Adobe Acrobat PDF.

On the domain line, select ONLY, and then type http://service.gm.com

in the box provided.

Click on the grey Google Search button. This will display a list of every

issue of TechLink containing the specified key words. From this, choose

the one that describes what you’re looking for.

SHORTCUT TIP: If you want to avoid the form page, you can just type the

search request in the input box on the main Google page. You must type

your keyword(s) followed by this string exactly as shown. Spaces and

punctuation are critical.

keyword site:http://service.gm.com filetype:pdf

This will find exactly the same items as the first method.

-

Thanks to Mike Janke, Grand Prize Chevrolet Oldsmobile |

| |

|

|

Starter

Cranks After Key is Released

|

Refer

to bulletin 03-06-03-001. These are the highlights.

Owners of some 2003 Silverado and Sierra pickups or full-size utilities

with the 5.3L Engine (VIN Z -- RPO L59) may comment that the engine starter

continues to run after the key is released.

This is a normal condition and no repairs should be attempted for this

condition.

On these vehicles, the starter relay is controlled by the PCM, with input

from the key switch. After 0.4 seconds of cranking, a timer is activated

in the PCM. Once this happens, even though the key is released, the PCM

will continue to crank the starter until the engine starts or a no-start

time limit is reached.

The fuel pump module may take several seconds to build fuel pressure,

particularly after sitting overnight. The automatic crank feature ensures

sufficient crank time even if the customer releases the ignition switch

prematurely. |

|

|

| return

to Table of Contents |

| |

| Power

Door Lock and Window Switch |

Owners

of some 2001 - 03 Chevrolet Trackers may comment that the door locks

and/or power windows are inoperative.

The wires may become pinched or chafed by the door check link assembly.

Service Bulletin 03-08-64-002, issued January, 2003 provides wire repair

procedures. In addition, refer to SI document ID 162420 and reroute the

wires for sufficient clearance.

-

Thanks to Bill Denton

|

| |

| return

to Table of Contents |

|

| Reorganization

Changes Coming to SI |

The

following subsections of the service manual will move from Body and

Accessories to General Information starting with 2004 SI, as well

as the paper service manual.

- Squeaks and Rattles

- Air / Wind Noise

- Waterleaks

More information will follow in a later issue of TechLink.

-

Thanks to Jerry Bednarchik |

| return

to Table of Contents |

|

| Know-How

Broadcasts for June |

| |

|

| Know-How

Broadcasts for June |

|

Emerging

Issues

|

June

12, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

|

10270.18D

-- 2004 Cadillac New Model Features

|

June

26, 2003

|

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time

|

| -

Thanks to Tracy Timmerman |

|

|

| |

|

| Oil

Life System Reset Procedures -- Cars |

Many

GM cars and trucks are equipped with an oil life system which determines

when an oil change is required. After the oil has been changed,

it’s

necessary to reset the system.

Procedures for resetting 2001 through 2004 passenger cars are published

here. Trucks will be published next month.

The information for this article is the same as you will find in the

applicable owner or service manual.

To find this information in SI 2000:

Select the vehicle

Select category General Information

Select category Maintenance and Lubrication

Select category Maintenance and then GM Oil Life System-Resetting.

TIP: You may be able to use the Search function using the words Oil Life

System Resetting.

TIP: You can find copies of charts for earlier models on the TechLink

website on the Internet at http://service.gm.com. Look for the February

and March 2000 issues.

2001 - 04 Seville

2001 - 04 DeVille

1. Turn the ignition to ON but with the engine off.

2. Display the Oil Life message by pressing the Info button.

3. Press and hold the Reset button until the display shows 100% Engine

Oil Life. This resets the oil life index.

2001 - 02 Eldorado

1. Turn the ignition to Run but with the engine off.

2. Display the OIL LIFE LEFT message by repeatedly pressing the SKIP

INFO button.

3. Press the NO INFO RESET button until the display show 100% Engine

Oil Life. This resets the oil life index.

2003 - 04 CTS

Base Audio System

1. Press the up or down arrow on the INFO button located to the right

of the DIC display to access the DIC menu.

2. Once XXX% ENGINE OIL LIFE menu item is highlighted, press and hold

the CLR button.

3. The percentage will return to 100, and the oil life indicator will

be reset.

4. Repeat the steps if the percentage does not return to 100.

Navigation System

1. Turn the system on by pressing the PWR/VOL knob once. The PWR/VOL

knob is located to the lower left of the DIC display.

2. Press the INFO button located to the left of the display to access

the Vehicle Info menu.

3. Turn the TUNE/SEL knob located to the lower right of the display until

Engine Oil Life is highlighted. Press the knob once to select it.

4. Once XXX% Engine Oil Life is displayed, press the multi-function button

next to the Reset prompt in the upper right corner of the display.

5. The percentage will return to 100, and the oil life indicator will

be reset.

6. Repeat the steps if the percentage does not return to 100.

2004 SRX

Base Audio System

Press the CLR button on the right of the DIC display to acknowledge the

Change Engine Oil message. This will clear the message from the display

and reset it. To reset the oil life indicator, use the following steps.

1. Press the up or down arrow on the INFO button located to the right

of the DIC display to access the DIC menu.

2. Once XXX% ENGINE OIL LIFE menu item is highlighted, press and hold

the CLR button. The percentage will return to 100, and the oil life indicator

will be reset.

3. Turn the key to OFF.

If the Change Engine Oil message comes back when you start the vehicle,

or the percentage does not return to 100, the engine oil life system

has not reset. Repeat the procedure.

Navigation System

Press the display button to acknowledge the Change Engine Oil message.

This will clear the message from the display and reset it. To reset the

oil life indicator, use the following steps.

1. Turn the ignition to ON with the engine running.

2. Turn the system on by pressing the PWR/VOL knob located to the lower

left of the DIC display.

3. Press and hold the vehicle information display button located in the

upper right of the screen for 3 seconds to enter the vehicle information

menu.

4. Use the scroll up or down display keys to select Engine Oil Life.

5. Press and hold the RESET button on the display. The percentage will

return to 100, and the oil life indicator will be reset. Repeat the steps

if the percentage does not return to 100.

6. Press the RETURN button on the display to return to the main page.

7. Turn the key OFF.

If the Change Engine Oil message comes back when you start the vehicle,

the engine oil life system has not reset. Repeat the procedure.

2004 XLR

1. Press the up or down arrow to scroll the DIC to show OIL LIFE.

2. Once the XXX% ENGINE OIL LIFE menu item is highlighted, press and

hold the RESET button until the percentage shows 100%. Repeat the steps

if the percentage does not return to 100.

3. Turn the key to OFF.

If the Change Oil Now message comes back when you start the vehicle,

the engine oil life system has not reset. Repeat the procedure.

2001 - 04 Impala

2002 - 04 Monte Carlo

Using the Radio

1. Turn the ignition to ACC or ON, with the radio off.

2. Press and hold the TUNE DISP button on the radio for at least five

seconds until SETTINGS is displayed.

3. Press the SEEK PTYPE up or down arrow to scroll through the main menu.

4. Scroll until OIL LIFE appears on the display.

5. Press the 1 PREV or 2 NEXT button to enter the submenu. RESET will

be displayed.

6. Press the TUNE DISP button to reset. A chime will be heard to verify

the new setting and DONE will be displayed for one second.

7. Once the message has been reset, scroll until EXIT appears on the

display.

8. Press the TUNE DISP button to exit programming. A chime will be heard

to verify the exit.

Using the Accelerator Pedal

1. Turn the ignition to ON, with the engine off.

2. Fully press and release the accelerator pedal three times within five

seconds.

3. If the CHANGE ENGINE OIL message flashes, the system is reset. However,

if it stays on, it did not reset. You’ll need to repeat the procedure.

2001 - 02 Intrigue

1. Turn the ignition to ON, with the engine off.

2. Fully press and release the accelerator pedal three times within five

seconds.

3. If the CHANGE OIL light flashes, the system is resetting.

4. Turn the key to OFF after the light has finished flashing, then start

the vehicle.

5. If the CHANGE OIL light comes back on, the engine oil life system

did not reset. Repeat the procedure.

2001 - 03 Grand Prix w/o Trip Computer

2001 - 04 Regal w/o DIC

2004 GTO

1. Turn the ignition to RUN, with the engine off.

2. Fully press and release the accelerator pedal three times within five

seconds.

3. If the CHANGE OIL SOON light flashes, the system is resetting.

4. Turn the key to OFF after the light has finished flashing, then start

the vehicle.

5. If the CHANGE OIL SOON light comes back on, the engine oil life

system did not reset. Repeat the procedure.

2001 - 03 Grand Prix w/ Trip Computer

1. Press the MODE button until the light appears lit next to OIL

LIFE.

2. Press and hold the RESET button for three seconds. The oil life

percentage should change to 100%.

2001 - 03 Aurora

1. With the ignition on, press the SELECT right arrow button on the

DIC to OIL so the OIL LIFE percentage is displayed.

2. Press RESET and hold for five seconds. OIL LIFE XXX% will appear

and then when the button is released OIL LIFE 100% will be displayed.

2001 - 04 Bonneville

1. Display OIL LIFE on the DIC.

2. Press and hold the RESET button for more than five seconds. The

oil life will change to 100%.

2001 - 04 LeSabre

2001 - 04 Park Avenue

1. Display OIL LIFE INDEX on the DIC.

2. Press and hold the RESET button on the DIC for more than five

seconds. The oil life will change to 100%.

2001 - 04 Regal with DIC

1. Put the oil life display on the DIC.

2. Press the DIC RESET button for five seconds.

2001 - 04 Corvette

1. Turn the ignition to ON, with the engine off.

2. Press the TRIP button so the OIL LIFE percentage is displayed.

3. Press RESET and hold for two seconds. OIL LIFE REMAIN 100% will

appear.

2001 - 02 Camaro

2001 - 02 Firebird

1. Turn the ignition to RUN but with the engine off.

2. Push the Trip/Oil Reset button located on the instrument panel

for 12 seconds. The Oil Change light will start to flash to confirm

that

the system is reset. The reset is completed when the Oil Change light

goes out.

2001 - 04 Grand Am

2001 - 04 Alero

1. Turn the ignition to ON.

2. Push the RESET button located in the driver’s side instrument

panel fuse block. The CHANGE OIL light will start to flash.

3. Press and hold the RESET button again. The reset is complete when

you hear the chimes sound and the CHANGE OIL light goes out.

2004 Grand Prix

1. Press the options button on the DIC until ENGINE OIL MONITOR appears

on the DIC screen.

2. Presss the set/reset button to reset the system.

The next screen indicates that the engine oil monitor has been reset.

If the vehicle is equipped with the trip computer DIC, when the gage

button is pressed and the OIL LIFE REMAINING mode appears, it should

read 100 % OIL LIFE REMAINING.

3. Turn the key OFF.

If the Change Oil Soon message comes back when you start the vehicle,

the engine oil life system has not reset. Repeat the procedure.

2004 Malibu

1. Display OIL LIFE RESET on the DIC.

2. Press and hold the ENTER button for at least one second. An ACKNOWLEDGED

display message will appear for three seconds or until the next button

is pressed. This will tell you the system has been reset.

3. Turn the key OFF.

If the Change Oil Soon message comes back when you start the vehicle,

the engine oil life system has not reset. Repeat the procedure.

2002-04 Saturn L and Vue

1. Remove the cover of the underhood fuse block (UHFB), which is

located under the hood.

2. With the ignition key in RUN but the engine off, press the red

OIL RESET button and hold for 5 seconds.

3. If the CHANGE OIL SOON light is flashing, the system is reset.

The light will flash for up to 30 seconds or until the ignition is

turned

off.

4. If the light comes on again and stays on for 30 seconds at the

next ignition cycle, it did not reset. Reset the system again.

2003-04 Saturn Ion

1. Press and release the trip/reset button until the OIL LIFE message

is displayed.

2. Press and hold the trip/reset button until a chime sounds five

times and RESET is displayed in the message center. When the system

is reset,

the odometer will again be displayed in the message center.

3. Turn the key OFF.

If the CHG OIL message comes back on when you start the vehicle,

the system has not reset. Repeat the procedure.

- Thanks to Jerry Garfield

|

| return

to Table of Contents |

|

| Simplified

Maintenance Schedules Coming |

New

and simplified maintenance schedules are coming for 2004.

Historically, maintenance schedules have been regarded as complicated,

extensive, and in some cases confusing to customers.

In fact, there have been two separate schedules from which a choice must

be made. The short trip/city schedule was defined by a list of conditions,

including trips below 5 miles (8 km), extensive idling, and others. This

schedule called for performing certain operations such as oil changes

at fairly low intervals.

A long trip/highway schedule was defined simply as only if none of the

short trip definitions applied. And the service intervals were longer.

In addition, these schedules called for performing various operations

according to mileage and/or time.

And, maintenance schedules required literally dozens of pages to describe

fully in the owner’s manual.

All of this is changing on those vehicles equipped with the GM Oil Life

System.

First and foremost, oil changes are now done according to the GM Oil

Life System, which is explained in an accompanying article, “GM

Oil Life System Revisited.”

Equally important, all other maintenance items are being keyed to the

oil change intervals. Refer to individual vehicle maintenance schedules

for specific requirements.

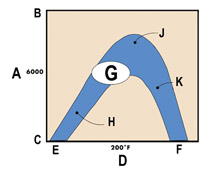

Refer to (fig. 2), How Driving Style Affects Oil Life.

A - Mileage Between Oil Changes

B - Long Trip

C - Short Trip

D - Engine Temperature

E - Cold

F - Hot

G - Typical Driver

H - Trips Less Than 2 Miles (3.2 km)

J - Highway Driving

K - Trailer Towing

Scheduled Maintenance

When the CHANGE ENGINE OIL light or message comes on, it means that service

is required on the vehicle. It should be serviced as soon as possible

within the next 600 miles (1000 km). It is possible that, under the best

conditions, the engine oil life system may not indicate that vehicle

service is necessary for over a year. However, engine oil and filter

must be changed at least once per year, and at this time the system must

be reset.

NOTICE: The owner should check oil regularly and keep it at the proper

level. Failure to keep the oil at the proper level can cause damage to

the engine not covered by warranty.

TIP: If the engine oil life system is accidentally reset, the vehicle

must be serviced within 3000 miles (5000 km) since the last service.

Reset the oil life system when the oil is changed.

Required services are described by the terms Maintenance I and Maintenance

II. (fig. 3) Generally, the first service should be Maintenance I, the

second should be Maintenance II, and alternated between I and II thereafter.

In some cases, Maintenance II may be required more often.

Maintenance I -- Use Maintenance I if the CHANGE ENGINE OIL light comes

on within 10 months since the vehicle was purchased or Maintenance II

was performed.

Maintenance II -- Use Maintenance II if the previous service performed

was Maintenance I. Always use Maintenance II whenever the light comes

on 10 months or more since the last service, or if the light has not

come on at all for 1 year.

Fig. 3 Typical Maintenance Schedules

Service |

Maintenance I |

Maintenance II |

| Change engine

oil and filter. Reset oil life system. |

X |

X |

| Lubricate

chassis components. |

X |

X |

| Visually check

for any leaks or damage. |

X |

X |

| Inspect engine

air cleaner filter change indicator. If necessary, replace filter. |

X |

X |

| Rotate tires

and check inflation pressures and wear. |

X |

X |

| Inspect brake

system. (a) |

X |

X |

| Check engine

coolant and windshield washer fluid levels and add as needed. |

X |

X |

| Perform any

needed additional services. |

X |

X |

| Inspect suspension

and steering components. (b) |

- |

X |

| Inspect engine

cooling system. (c) |

- |

X |

| Inspect wiper

blades. (d) |

- |

X |

| Inspect restraint

system components. (e) |

- |

X |

| Lubricate

body components. (f) |

- |

X |

| Check transmission

fluid level and add fluid as needed. |

- |

X |

Additional Required Services

Refer to the Typical Additional Required Services table. (fig. 4)

These services should be performed at the first maintenance service

(I or II) after the indicated miles (kilometers) shown for each item.

This table is a typical example. See the individual vehicle maintenance

schedule for specifics.

" Mileage intervals and services vary with

model line."

Fig.

4 Typical Additional Required Services

Service |

25,000

(41,500) |

50,000

(83,000) |

75,000

(125,000) |

100,000

(166,000) |

125,000

(207,500) |

150,000

(240,000) |

| Inspect fuel

system for damage or leaks. |

X |

X |

X |

X |

X |

X |

| Inspect exhaust

system for loose or damaged components. |

X |

X |

X |

X |

X |

X |

| Change automatic

transmission fluid and filter (severe service). (h) |

- |

X |

- |

- |

- |

- |

| Change automatic

transmission fluid and filter (normal service). |

- |

- |

- |

X |

- |

- |

| Change transfer

case fluid. |

- |

X |

- |

X |

- |

X |

| Replace spark

plugs and inspect spark plug wires. |

- |

- |

- |

X |

- |

- |

| Inspect positive

crankcase ventilation (PCV) valve. |

- |

- |

- |

X |

- |

- |

| Engine cooling

system service (or every 5 years, whichever occurs first). (i) |

- |

- |

- |

- |

- |

X |

Maintenance Footnotes

Maintenance footnotes may vary between vehicles. The following apply

to the typical schedules above, and have been condensed. They are

presented here only as an example. See individual vehicle maintenance

schedules for details.

a. Visually inspect brake components.

b. Visually inspect front and rear suspension and steering, CV joints,

boots and axle seals.

c. Visually inspect hoses.

d. Visually inspect wiper blades.

e. Check operation of seat belt system parts.

f. Lubricate locks, hinges, latches, seat hardware.

g. Add fluids as needed.

h. Change automatic transmission fluid if dictated by operating conditions.

i. Drain, flush and refill cooling system.

Owner Checks and Services

The owner is instructed to perform certain checks and services at specified

intervals, with the assistance of their GM Goodwrench dealer if desired.

These typically include:

- Engine oil level check

- Engine coolant level check

- Tire inflation check

- Starter switch check

- Automatic transmission shift lock control system check

- Ignition transmision lock check

- Parking brake and automatic transmission park (P) mechanism check

- Underbody flushing service

-

Thanks to Jerry Garfield and Chuck Burns

|

| |

figure

2

|

|

|

|

|

| return

to Table of Contents |

|

| Tracker

Windshield Replacement |

Owners

of some 2002 - 03 Chevrolet Trackers may comment that the windshield

has a crack in the lower left hand or right hand corner.

This condition may be caused by excessive sealant that can create an

uneven surface for the windshield to adhere to and may cause a stress

crack.

Service Bulletin 03-08-48-001, issued January, 2003 provides windshield

replacement procedures.

TIP: Do not use the dura-lock tabs that may be present.

- Thanks to Bill Denton |

|

|

| return

to Table of Contents |

|

| A

New Kind of Oxygen Sensor |

Some Background

The "conventional" O2 sensor in use since 1978 can tell the

engine control system only that the exhaust is either too rich or too

lean. It’s called a switching sensor because it makes a sharp

voltage transition when the air/fuel mixture varies a tiny amount

either side

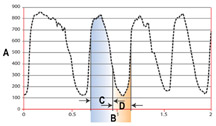

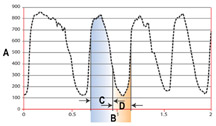

of ideal (14.7:1 for a gasoline engine). (fig. 5)

Refer to figure 5, Typical Switching-Style O2 Sensor Signal.

A. O2 Voltage (mV)

B. Time (s)

C. Rich-Lean

D. Lean-Rich

The engine controller responds to a rich signal from the O2 sensor by

leaning the mixture, and responds to a lean signal by richening the mixture.

Even more precise fuel control would be possible if the O2 sensor could

detect the exact deviation of the exhaust stream, lean or rich. The new

wide-range air/fuel sensor can do this.

Wide-Range Air-Fuel Sensor (WRAF)

The wide-range air-fuel sensor, or WRAF sensor, discussed in this article

will be used in the 4.6L LH2 engine in the 2004 Cadillac XLR and SRX.

This sensor may also be referred to as a lambda sensor or wide-band sensor.

The WRAF sensor has been used in the past on select models of GM vehicles

with the 3.0L L81 engine, first in the 1999-2001 Cadillac Catera, then

in the 2000-2004 Saturn LS.

TIP: Throughout service information, the wide-range air-fuel sensor is

referred to using the standard terminology of heated oxygen sensor or

HO2S; in this article we will refer to it as the WRAF sensor.

Advantages of the WRAF

A typical V6 engine operating at 2500 rpm will produce approximately

62 cylinder pulses per second per cylinder bank. Refer to the graph in

figure 5, which displays the voltage of a switching-style oxygen sensor.

During one rich-to-lean and lean-to-rich transition of the oxygen sensor

signal (1/2 second), there will be approximately 30 cylinder pulses.

Each cycle or switch is the average air-fuel ratio of several cylinders.

With a switching-style sensor, the engine controller will merely continue

to adjust fuel trim, rich or lean, until it sees a signal swing in the

opposite direction. The process then reverses and continues transitioning

rich-to-lean and lean-to-rich. This explains the constant cycling

or switching of the switching-style sensor.

So, the first advantage of the WRAF sensor is that it can detect the

exact deviation from 14.7:1, rich or lean, and allow the engine controller

to precisely adjust the air-fuel ratio to the desired amount.

TIP: Ideal combustion occurs with an air-fuel ratio of 14.7:1, also referred

to a stoichiometric.

Most switching-style oxygen sensors operate within a range of 0 to 1000

millivolts, and as a result will not provide an accurate reading when

the air-fuel ratio exceeds approximately 14.6:1 when rich or 14.8:1 when

lean.

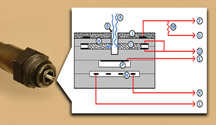

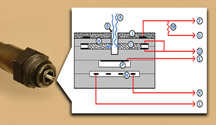

The WRAF sensor (fig. 6) can provide an accurate signal when the air-fuel

ratio is as lean as 16:1 or as rich as 11:1, allowing the engine controller

to continuously adjust fuel trim throughout this wide range of air-fuel

ratios. So, a second advantage of the WRAF sensor is its ability to provide

an accurate signal while operating in an air-fuel ratio, or lambda state,

other than stoichiometric .

Refer to figure 6, WRAF Sensor.

A. Trimming Resistor

B. Resistor Cover

C. Sensor

WRAF Wiring and Circuits

Refer to figure 7, WRAF Sensor Cutaway.

The WRAF sensor has six wires (circuits), divided among three functions.

Reference Voltage -- The engine controller provides a fixed signal voltage

to the WRAF sensor on two circuits. These circuits are called the reference

voltage circuit (D) and the low reference circuit (E) from the reference

air duct (P).

Pump Current -- There are two circuits called the input pump current (F) and

output pump current (G). They provide an electromotive force needed for the movement

of oxygen ions inside the sensor.

Heater (N) -- As with a switching-style sensor, there are heater voltage supply

(L) and heater low control (K) circuits. They are similar in operation to most

switching-style sensors.

Each sensor contains a trimming resistor (M) that is integral to the sensor connector.

This trimming resistor is used during sensor manufacturing to calibrate each

sensor to the desired performance specifications.

Operation

Here is what happens as exhaust flows past the sensor. Refer to the WRAF sensor

cutaway (fig. 7):

1. As the exhaust stream (A) passes the WRAF sensor, a sample of the exhaust

gases enters the exhaust gas sample tube (B) and moves through the diffusion

gap (C).

2. When the air-fuel ratio of the sampled exhaust gas changes, there is a corresponding

change to the voltage potential between the reference voltage circuit (D) and

the low reference circuit (E).

3. When the voltage on these circuits changes, the engine controller changes

the amount of voltage on the input pump current circuit (F) and the output pump

current circuit (G).

4. As the voltage on the input and output pump current circuits changes, oxygen

ions move into or out of the pumping cell (H) through the porous layer (J). This

brings the voltage potential between the reference voltage and low reference

circuits back to a desired value.

5. By monitoring the required voltage and current level change on the input pump

current and output pump current circuits, the engine controller can determine

what the air-fuel ratio is at that moment.

6. The engine controller can then determine exactly how much the air-fuel ratio

needs to be adjusted to maintain the desired voltage potential and thus the desired

air-fuel ratio.

The WRAF sensor is able to determine the exact amount of air-fuel ratio change

required for the upcoming cylinder pulses. This is different from a switching-style

sensor, which has a much larger estimating error of the air-fuel ratio change.

On a low level, there is closed-loop operation between the engine controller

and the WRAF sensor pumping circuits, low reference circuit, and reference voltage

circuit.

On a high level, there is closed-loop operation between the exhaust sampling

of the WRAF sensor and total fuel trim adjustment. The latter is similar to the

most traditional closed-loop fuel systems.

How to Interpret WRAF Sensor Data on the Tech 2

TIP: Even though the engine controller and the WRAF sensor use various voltage

levels during operation, the signal value displayed on the Tech 2 is a lambda

value, NOT a voltage value.

The variable name “lambda” refers to the deviation above or below

stoichiometric, or 14.7:1 air-fuel ratio. A lambda value of 1.000 is equivalent

to a perfect stoichiometric ratio of 14.7:1. Depending on vehicle platform,

the lambda value can be as low as 0.750 or as high as 3.999. A low lambda

value represents

a rich exhaust sample, and a high lambda value represents a lean exhaust

sample.

The lambda value can be used to calculate the exact air-fuel ratio.

For example, a lambda value of 1.025 on the scan tool indicates that the system

is operating lean. To find out exactly how lean, multiply 1.025 by 14.7. This

gives the result of approximately 15.07:1. Conversely, a lambda value of 0.975

indicates the system is operating rich. Multiply 0.975 x 14.7 = 14.33:1. This

gives you an idea of how the controller is able to determine the exact desired

air-fuel ratio.

The Meaning of Extreme Lambda Values

How can a lambda value of 0.750 or 3.999 be meaningful? Multiply a lambda value

of 3.999 x 14.7 = 58.79:1. This is clearly not an air-fuel ratio that any engine

could operate under during cruise or acceleration.

Extreme lambda values are a result of the limits of the controller hardware and

software. When a vehicle enters a fuel cut-off state during deceleration, the

lambda value may move to a very high number (infinity) because the controller

software and hardware are operating the pumping circuits at their maximum correction

state to offset the extremely lean air-fuel ratio that is occurring. The controller

software will not display infinity but will instead display a large number. Depending

on the controller manufacturer, these maximum limits may be as low as 0.750 during

a very rich condition, or as high as 3.999 during a very lean condition.

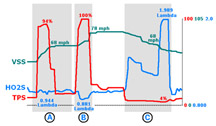

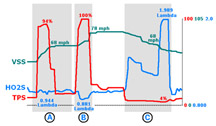

Typical WRAF Sensor Lambda Values (fig. 8)

Acceleration and Cruise -- The lambda value stays fairly flat, close to 1.000,

during the moderate to heavy acceleration and during cruise (A).

This is because the sensor and the engine controller are in their own closed-loop

operation and

the lambda value only “drifts” above or below 1.000 as the engine

controller makes its fuel trim adjustments. This closed-loop operation between

the engine controller and the WRAF sensor is an instantaneous reaction to

voltage deviations between the reference voltage circuit and low reference

circuit

and the resulting oxygen ion exchange via the pumping circuits.

Power Enrichment -- The lambda value moves lower when power enrichment is active

(B).

Deceleration -- During deceleration, the lambda value moves to 1.989. This is

because the engine controller has commanded a deceleration fuel cut-off state

and, as a result, the exhaust stream is extremely lean (C). Notice how the engine

controller will regulate the closing of the throttle; the throttle plate must

be less than five percent open before the lambda value will finally move to 1.989.

On this particular vehicle, 1.989 is the limiting value of the hardware and software.

Diagnosing a WRAF Sensor

Here are a few points to remember when diagnosing a WRAF sensor:

- With the sensor disconnected and the ignition on, the voltage level measured

on the input pump current circuit or the output pump current circuit, on the

engine harness side, is very low and should be measured using the DMM millivolts

scaling.

- In addition to the input and output pump current circuits, with the sensor

disconnected and the ignition on, there will be a voltage present on the reference

voltage circuit, low reference circuit, and possibly the heater low control circuit.

The applicable DTC tables, when necessary, will provide the exact voltage values.

Of course, there will be battery voltage present on the heater ignition voltage

supply circuit.

- The voltage that may be present on the heater low control circuit is a diagnostic

voltage produced by the engine controller. This voltage is used by the engine

controller to discriminate between a heater circuit open, short to ground, or

short to voltage condition. Depending on platform, the diagnostic voltage may

or may not be present.

- Remember this when performing voltage measurements on the engine harness side.

When a circuit fault is present, it may cause voltage level changes on the input

pump current, output pump current, reference voltage or low reference circuits.

So, you must not assume that because the voltage of the first circuit you measured

is not within the correct range it is the problem circuit!

- As with any heated oxygen sensor, no circuit repairs should be attempted to

the sensor harness.

-

Thanks to Jim Hanna

|

figure

5

|

figure

6

|

figure 7

|

figure

8

|

| return

to Table of Contents

|

|

Bulletins – April,

2003

This review of service bulletins released through mid-April lists the

bulletin number, superseded bulletin number (if applicable), subject

and models. |

Program

Bulletin

03011; Remote Keyless Entry System Inoperative; Specified 2003 Cadillac,

Chevrolet, GMC Pickups and Utilities; Hummer H2

Recall Bulletin

03-008; Driver Air Bag Inflator; 2003 Buick Rendezvous, Cadillac DeVille,

Chevrolet Venture, Impala, Monte Carlo, TrailBlazer, EXT, GMC Envoy,

XL, Pontiac Montana

00 – General Information

03-00-91-001; Vibration Analysis Worksheet; 2003 and Prior Passenger

Cars and Trucks, Hummer H2

01 – HVAC

03-01-39-001; Rear HVAC Blower Control Knob May Fall Off (Install New

Design Knob); 1998-2001 Cadillac Seville

03 – Suspension

01-03-08-002A; replaces 01-03-08-002; Front Suspension Clunk/Rattle Noise

Diagnosis; 1998-2003 Chevrolet Malibu, Oldsmobile Cutlass, Alero, Pontiac

Grand Am

03-03-07-001; Revised Wheel Alignment Specifications; 2003 Chevrolet

Silverado GMC Sierra 1500

04 – Driveline Axle

02-04-21-002A; replaces 02-04-21-002; Service 4WD Indicator Illuminated,

DTC B2725 Set, Transfer Case Selector Switch in One Position -- Indicator

Lamp Indicates Another Range is Selected (Replace Transfer Case Shift

Control Switch); 2002-03 Chevrolet TrailBlazer, EXT, GMC Envoy, XL, with

4-Wheel Drive

02-04-21-005A; replaces 02-04-21-005; Slips in 4-Wheel Drive, Noise,

Vibration, Leaks, Hot Odor (Diagnose and Repair Front Differential and/or

Transfer Case; Specified 1998-2003 Pickups and Utilities with Autotrak

Transfer Case (RPO NP8) (Selector Pad on Instrument Panel Must Have Auto

4WD, 4HI, 4LO, and 2HI Selections)

02-04-21-008A; replaces 02-04-21-008; Shudder, Rocking Motion, Binding,

Feels Like Vehicle is Stuck in 4WD (Crow Hop) when Turning at Low Speeds

(Replace Transfer Case Encode Sensor and Reprogram TCCM); 2002-03 Chevrolet

TrailBlazer, GMC Envoy, Oldsmobile Bravada

03-04-17-002; Whine Noise From Rear Axle (Diagnose and Replace Rear Propeller

Shaft with New Tuned Torsional Damper Rear Prop Shaft); 2002-03 Chevrolet

TrailBlazer, GMC Envoy, Oldsmobile Bravada with 4.10 Ratio Rear Axle

(Standard Short Wheelbase ) (RPO GT5)

03-04-17-003; Vibration/Noise from Auto/Manual Shifter During Drive/Gear

Shifts (Replace Front Prop Shaft to Transmission Flange Retaining Bolts);

2003 Cadillac CTS

03-04-17-004; Revised Prop Shaft Replacement Procedure; 2003 Cadillac

CTS

03-04-18-001; Availability of New Front Drive Axle Nut; 1997-2003 Chevrolet

Malibu, Oldsmobile Alero, Pontiac Grand Am

03-04-19-001; Use of Synthetic Front Axle Lubricant for 4WD Vehicles

Sold in Cold Weather Climates; Specified 2002-03 Chevrolet and GMC Pickups

and Utilities with 4WD and 9.25-inch Front Axle Assembly

03-04-19-002; Squeak, Squeal or Whistle Noise from Front Axle (Replace

Intermediate Axle Seal and/or Differential Carrier Seal); 2002-03 Chevrolet

TrailBlazer, GMC Envoy with 4WD, Oldsmobile Bravada AWD

03-04-21-001; 4WD Light, 4WD Inoperative, DTCs C0327, P0836, P5000 (Permanent

Fix Not Available At This Time); 2003 Chevrolet and GMC Pickup and Utility

with NP1 (NVG 263EAU), NP8 (NVG 246EAU) Transfer Case

06 – Engine/Propulsion System

01-06-04-002A; replaces 01-06-04-002; CEL Concern -- DTC P0101 Set (Reprogram

PCM); 2000 Cadillac DeVille, Eldorado, Seville with 4.6L Engine (VINs

9, Y -- RPOs L37, LD8)

03-06-01-005; Revised Crankshaft Rear Oil Seal Replacement, Crankshaft

Rear Oil Seal Installation and Special Tools; 2003 Cadillac DeVille,

Seville, Oldsmobile Aurora

03-06-01-006; Powertrain Qualilty Center for Performance Parts Engine

Replacements; 2003 and Prior Passenger Cars and LD Trucks, Hummer H2

03-06-01-008; Crankshaft Rear Oil Seal Leaks During Extreme Cold Weather

Operation (Modify Oil Separator); 2002-03 Chevrolet and GMC C/K, C4500/5500

with 6.6L Duramax Diesel Engine (VIN 1 -- RPO LB7)

03-06-03-003; AC Delco Replacement Battery Warranty Procedures; 2003

and Prior Passenger Cars and Trucks, Hummer H2

03-06-04-014; Oil Present Around Turbo Area, Oil Level Low, Oil Pressure

Gauge May Drop (Inspect/Replace Turbo Oi Feed Pipe Assembly); 1999-2002

Chevrolet and GMC MD Tilt Cab Models with 6HK1T Diesel Engine (VIN 3

-- RPO LG4)

03-06-04-015; Revised Engine Cranks but Does Not Run Diagnostic; 2002-03

Chevrolet Silverado, Suburban, GMC Sierra with 5.3L Engine (VIN Z --

RPO L59)

07 – Transmission/Transaxle

02-07-30-051A; replaces 02-07-30-051; Transmission Shifting In and Out

of 4th and 5th Gear (Hunting) When Pulling/Carrying a Load, Unable to

Manually Select 4th Gear (Install 5th Gear Inhibit Switch); 2001-02 Chevrolet

and GMC HD2500/HD3500 with 6.6L Diesel or 8.1L Gas Engine (VINs 1, G

-- RPOs LB7, L18) and Allison Auto Trans (RPO M74)

03-07-30-004; Introduction of New AISIN Transmission Quality Center;

2001-03 Chevrolet and GMC MD Tilt Cab Models with 4HE1-TC Diesel Engine

and AISIN Auto Trans

03-07-30-005; SES Indicator Illuminated; Transmission Slips, Engine Flare,

Delayed 2-3 Shifts, Shifts Missing, No Shift, DTC P0730, P0756, P0757

(Replace Accumulator Assembly/Service Transmission); Specified 2002 Chevrolet

and GMC Pickups and Utilities with 4L80E (MT1) or 4L85E (MN8) Auto Trans

08 – Body and Accessories

01-08-50-014A; replaces 01-08-50-014; Driver’ Seat Back Material

Pulling Away from Side Impact Air Bag Module Bezel (Replace Side Impact

Air Bag Bezel/Retainer); 2001-03 Chevrolet Monte Carlo

02-08-44-020B; replaces 02-08-44-020A; No Audio Out of Speakers at Times

(Reprogram Radio and/or Replace Amplifier); 2003 Cadillac, Chevrolet,

GMC Pickups and Utilities, Hummer H2

03-08-44-005; Poor Radio Reception or Radio Static/Increased Interference

with Rear Window Defogger On or Some Window Defogger Grids May Be Inoperative

(Diagnose and Repair Rear Window Defogger Heating Grid); 1997-2003 Buick

Century, Regal, Chevrolet Impala, Monte Carlo, Oldsmobile Intrigue

03-08-44-006; Revised Entertainment Information for Class 2 Radios; 2002

Chevrolet Blazer, S-10, GMC Jimmy, Sonoma

03-08-50-005; Front Heated Seat Inoperative/Cold (Replace/Install Seat

Heat Element); 1997-2002 Cadillac DeVille, Seville, Eldorado with RPO

KA1

03-08-50-006; Uncomfortable Front Seat Cushions (Reposition Cushion Trim

Cover); 2002 Pontiac Bonneville

03-08-52-001B; replaces 03-08-52-001A; Remote Keyless Entry System Inoperative

(Reprogram Passenger Door Module); Specified 2003 Cadillac, Chevrolet

and GMC Pickups and Utilities, Hummer H2

03-08-59-001; Ratle Noise from Front Center of Dash Area (Reroute/Insulate

Accelerator Cable); 2002-03 Chevrolet Cavalier, Pontiac Sunfire with

2.2L Engine (VIN F -- RPO L61)

03-08-98-001; Bubbles in Paint Around Perimeter of Roof (Replace Roof);

1999-2002 Chevrolet Camaro, Pontiac Firebird

03-08-110-002; Sun Visors May Not Stay in Extended Position (Replace

Sun Visors and Retainers); 1997-2003 Buick Century, Regal

03-08-131-001; Power Take-Off Description of Operation and Programming;

2003 Chevrolet Kodiak, GMC Topkick with PTO

09 – Restraints

02-09-40-005A; replaces 02-09-40-005; Availability of Rear Seat Shoulder

Belt Comfort Guides; 2003 Buick Century, Regal, Pontiac Grand Prix, Cadillac

Escalade, EXT; Chevrolet Avalanche, Silverado, Suburban, Tahoe, TrailBlazer

EXT, GMC Envoy, Sierra, Yukon, XL

03-09-40-001; Squeak Type Nose Coming from Inside Front Seat When Seat

Belt is Moved (Fix Not Yet Available); 2003 Cadillac CTS

|

| return

to Table of Contents |

|