| |

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Navigating

the Upgrades in SI for 2005 |

First,

a Little History

GM on-board computer systems have come a long way since the Computer

Command Control (CCC) system first appeared in the early 1980s.

As time passed, additional modules were added to operate anti-lock brakes,

air bags, body control functions, HVAC, entertainment, and other functions.

Sophistication was multiplied when the modules were allowed to communicate

with each other using the Class 2 network, and more recently GMLAN.

The original CCC-era ECM was reprogrammed by removing the PROM “chip”

(programmable read-only memory) and plugging in a replacement. Many

of the current modules need to be programmed or set-up before use. Often,

this requires use of a scan tool and downloading data from the Techline

terminal.

Through all of this hardware evolution, the service manuals also evolved,

from paper manuals to the present web-based SI, and from having the

electronics isolated in their own service category to having them distributed

among the sub-systems they affect.

Moving Forward

Now, access to all control module integration information will be in

one central place in SI.

Beginning with the 2005 model year, the SI material for Vehicle Control

Systems is being considerably enhanced for each and every vehicle line.

We’ll focus on the Chevrolet Equinox because it is the first 2005

model available in SI. (fig. 1)

TIP: Even though

you may not work on Equinox vehicles, we suggest you follow along in

the Equinox sections of SI. As other 2005 vehicles are available in

SI, the reorganization information will apply to them as well.

TIP: SI will

contain more information than before, but because some service categories

are being moved and condensed, you may not find the information where

you expect to find it. Here are the details.

How the New Organization Works

For this example, begin by “building” the vehicle in SI.

In the category choices, you will see Vehicle Control Systems. This

should always be your starting point. The paths look like this (the

heading lists here have been abbreviated for simplicity):

| -

“Build” the vehicle |

| -

Select the Service Manual |

| -

Vehicle Control Systems |

| |

-

Vehicle DTC Information |

| |

|

-

Diagnostic Information and Procedures |

| |

|

|

-

Diagnostic Starting Point -- Vehicle |

| |

|

|

-

Diagnostic System Check -- Vehicle |

| |

|

|

-

Diagnostic Trouble Code (DTC) List -- Vehicle |

| |

|

|

-

Symptoms -- Vehicle |

| |

-

Computer/Integrating Systems |

| |

|

-

Diagnostic Information and Procedures |

| |

|

|

-

Diagnostic Starting Point |

| |

|

|

-

Scan Tool Information |

| |

|

|

-

DTCs and Symptoms for: |

| |

|

|

|

-

Body Control Systems |

| |

|

|

|

- RAP |

| |

|

|

|

- Data Link

Communications |

| |

|

|

-

Control Module References |

| |

|

|

-

Data Link References |

| |

|

-

Repair Instructions |

| |

-

Programming and Setup |

TIP:

There appear to be some redundancies in the above

list, such as Diagnostic Starting Point being listed two places. They’re

linked to the same place, so no matter where you start, you’ll

end up in the correct place.

In the following paragraphs, we’ll describe some of the highlights

of this new organization.

Computer/Integrating Systems

Let’s get this one covered right away. When you look for the Body

Control Systems, Data Link Communications, and Retained Accessory Power

information in Body, you’ll discover that these service categories

are no longer in the index.

Don’t panic. The details are still there; they’ve just been

moved to Computer/Integrating Systems in Vehicle Control Systems.

Focus on the Vehicle

Traditionally, you’ve begun diagnosing a system by performing

a Diagnostic System Check. Because systems are now thoroughly integrated

(interrelated), systems no longer operate independently of other systems.

Most everything is a part of a vehicle-wide network. Diagnostic System

Checks have been deleted from individual service categories. So, diagnosis

now starts with a Diagnostic Starting Point -- Vehicle

and is followed by the Diagnostic System Check -- Vehicle.

The Diagnostic Starting points will also remain in the various service

categories to guide you to the Diagnostic System Check --

Vehicle in the event that you don’t know where to

start.

TIP: The Vehicle

Diagnostic System Check looks specifically for vehicle-wide conditions

that can affect operation of more than one module, such as communication

problems and voltage problems.

If a DTC is set, you will be directed to the Diagnostic

Trouble Code (DTC) List -- Vehicle. This list contains

every DTC that can be set by any module on the vehicle. Simply scroll

the list to reach the desired DTC.

TIP: Because

the DTC list is quite long, you may wish to use the search function

to locate the desired DTC. Press Control F. Fill in what you want to

search for, specify matching parameters if necessary, and select which

direction to search. Click the Find Next button to begin your search.

The DTC list contains two important and useful features. First, it includes

a descriptor for each code. Second, it includes

a link to the diagnostic procedure needed

to determine why the DTC was set.

TIP: DTC lists

have been deleted from individual service categories.

DTC Descriptors

In addition to being on the DTC List -- Vehicle, the descriptor for

each DTC will be included in the facing page of its diagnostic table

document. The descriptor is a text description of what the DTC number

represents.

Control Module References

This heading, found under Computer/Integrating Systems is the heart

of the new organization. Click on this link and you will see a table

that includes every module that can be installed on the vehicle you’re

working on. For each module, you will find links to schematics, repair

instructions and programming and setup.

TIP: This table

includes every component that has “Control Module” in its

name, regardless of whether the component can be programmed, set-up

or configured. It also includes every other component that can be programmed,

set-up or configured, even though “Control Module” is not

a part of its name.

TIP: If you begin

your repair by following diagnostic steps, you will be brought to the

Control Module References table, if the diagnostic directs you to replace

or reprogram a control module.

Schematic Links -- Clicking on a link will take you

to the wiring schematic that includes the selected module. You may find

this information useful both in diagnosis and in repair.

Repair Instruction Links -- Clicking on a link will

take you to the appropriate document in SI for replacement instructions

for the selected module.

Programming and Setup Links -- Clicking on a link will

take you to the appropriate procedure for either programming or setting

up the selected module. If no programming or set-up is required, you

will be told this as well. You will not be left wondering.

Data Link References

Vehicles that have multiple data communication links include this feature.

This document details which control modules communicate on which data

links (i.e., Class 2, GMLAN, etc.) and link you to the appropriate diagnostic

for a communication problem for that control module.

Programming and Setup

The simplest way to describe the changes here is to say that access

to all the information you need to make the vehicle perform properly,

after a control module repair, is conveniently organized.

TIP: This section

was previously called Programming and contained only generic SPS programming

information.

TIP: You can

reach this section either by selecting it directly from Vehicle Control

Systems, or you can be led here from the Control Module References table.

Here, you’ll find instructions for programming or setting-up each

module that requires such a procedure.

TIP: Diagnostics

assume that you start with a vehicle that has the correct control modules

with the correct calibrations and configurations. A recent component

replacement or reprogramming event without the proper programming or

setup procedures may be the source of the concern with the vehicle.

-

Thanks to Kevin Fondaw and Andrew Fegan |

|

figure

1 |

|

|

| |

|

|

| return

to Table of Contents |

|

|

| Service

Information Discontinues Win 98 Support |

Late last year, GM Service and Parts Operations announced the Techline

end-of-life support policy for Windows 98 starting January 15, 2004

(see TechLink Dec. 2003). A minimum PC specification and browser information

were included as part of this communication. This change ensures optimal

performance for Techline applications.

Until now, the impact has been minimal. However, in May, a new set of

Service Information (SI) CDs will be shipped to all US dealers. Instructions

will indicate the compatible operating systems (Windows 2000 and XP

Professional) and the minimum PC hardware configuration.

During installation of the application, SI will detect the operating

system. If Windows 98 or ME are detected, SI will not load. Instead,

SI will advise the user that the operating system is incompatible.

Going forward, all releases of SI and LTG will be affected by this change

including the June 1, 2004 GM Labor Time Guide.

If you plan to upgrade your PC, please follow these tips:

TIP: Before upgrading

PC hardware or the operating system, review the Techline minimum PC

specification on http://service.gm.com.

TIP: It is recommended

to use a full operating system installation rather than an upgrade.

Use of an upgrade may affect proper functionality of SI.

TIP: Those who

wish to continue using Windows 98 (or ME) are encouraged to use the

SI web site.

Additional information can be found at http://service.gm.com

under the Techline tab.

-

Thanks to Lisa Scott |

|

|

|

|

New TIS/Tech 2 Programming Feature |

An

article in the October 2003 issue of TechLink explained a new Tech 2

feature implemented in Diagnostics. It permits you to go directly to

Request Information in the Special Function menu. You don’t have

to leave Diagnostics, you won’t have to “re-build”

the vehicle, and only the module you’re working on is commanded

to download information.

The feature described in October was the first of several steps being

taken to make your Tech 2 more efficient to use.

Now, another step is being taken, effective with satellite-broadcast

TIS application version 4.1, released March 22. This software version

must be installed for this feature to work. The Tech 2 should be updated

to the latest version, 24.001.

Once Request Information is performed on the new module you’ve

just installed, you will then have to connect your Tech 2 to TIS to

download the latest calibrations.

TIP: This new

feature is not dependent on module replacement; it will work on existing

modules as well.

Here’s the new feature. The only controller you will see in the

Supported Controller list in TIS is the one you are working on. You

will not have to look for it.

TIP: When you

reconnect the Tech 2 to the vehicle to program the module, you must

use the Service Programming System menu. As always, follow all cautions

through the programming process. Also remember to check for any Set

Up, Crank Learn, Adapt Learn ABS and other procedures necessary to complete

the programming process.

- Thanks to Mark Stesney |

|

|

| |

return to Table of Contents |

|

| TIS

Version Explanation |

You

may be wondering how to determine the version number for various parts

of TIS (Techline Information System). For instance, Blockpoint, Satellite

Data Release, Tech 2 version, and month of release.

TIP: This information

applies to all GM Dealers networked through GM ACCESS. Stand-alone users

rely on CDs and web access for updates.

To check these version numbers, open the TIS application and go to “Help

/ About TIS 2000” to locate the following list.

About TIS

2000

1. North American Operations 04.1

2. Satellite Update/Mise a jour 4.0

3. Tech 2 Version 24.001

4. TIS2000 - NAO DATA-CD GM DAT 03/2004

The 04.1 is your blockpoint or software application version

number. The 04 indicates the year of the broadcast, and the .1 indicates

the version within that year. Blockpoints are normally broadcast on

a quarterly basis and include items for service and sales applications

in your GM dealership. Service applications include TIS (Techline Information

Systems) and SI (Service Information).

2. Satellite updates are data related, are

also broadcast and vary from monthly to bi-weekly. The first digit usually

indicates the month (1 = Jan, 2 = Feb) and the second digit indicates

the version number. Odd-numbered data updates (1.0, 3.0, 5.0) are broadcast

every second month. These odd-numbered data updates include new VINs,

calibrations and, most important, updates for your Tech 2. Look for

updates for your Tech 2 when you see an odd number.

Even-numbered data updates (2.0, 4.0, 6.0) include VINs and calibrations.

Incremental updates (3.25, 3.5) usually include VINs and calibrations.

Occasionally, a special or interim Tech 2 update will be included.

3. It’s important to know your Tech 2 version.

As described above, the Tech 2 must be updated on a regular basis. Tech

2 updates include added vehicle coverage, new applications and functionality,

fixes when necessary, and much more. Knowing the version number is helpful

when troubleshooting an issue with TCSC (Techline Customer Support Center)

or engineering. Numbering usually re-starts with .001 each year. For

instance, 24.001 was the first Tech 2 version release for this year.

23.011 was an interim release this year to address some special issues.

4. The 03/2004 indicates the month this particular data was released.

Bottom line: To make the most of your Techline software, which includes

TIS and SI, be sure you are working with the most current update.

-

Thanks to Mark Stesney

|

| |

| |

| return

to Table of Contents |

|

| Rear

Cupholder Latch |

1999-2002 Chevrolet Avalanche, Silverado, Tahoe, Suburban, GMC, Sierra,

Yukon, Yukon XL and Cadillac Escalade, EXT equipped with a rear cupholder

in the center console may experience a broken cupholder latch. Do not

replace the middle console assembly. Order part number 88934982 Front

Floor Console Cupholder Latch in catalog group 16.650 and replace the

latch.

-

Thanks to Wesley Wood |

| |

| return

to Table of Contents |

|

| Sensing

and Diagnostic Module (SDM) Connector |

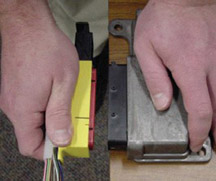

When

servicing an air bag (SIR) system, here’s how to remove and install

the SDM electrical connector without causing damage.

IMPORTANT

TIP: Observe

safety cautions in SI to avoid SIR deployment, personal injury,

or unnecessary SIR system repairs.

TIP: Disable

the SIR system. Refer to SIR Disabling and Enabling Zone in SIR.

TIP: Refer

to the appropriate section in SI for the complete procedure. This

may involve removing other vehicle components for access to the

sensing and diagnostic module (SDM). |

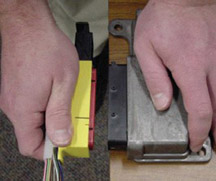

SDM Connector Removal

1. Pull out the red connector position assurance (CPA) from the SDM

connector.

2. Pull the slide retaining lock fully open from the SDM connector.

(fig. 2)

3. Grasp the SDM yellow connector by the connector housing. (fig.

3)

TIP: Do not grasp

slide retaining lock or wire bundle for removal.

4. Remove the SDM connector from the SDM while carefully maintaining

axial alignment.

TIP: Be careful

not to twist or rotate excessively when removing the connector, which

could cause damage.

SDM Connector Installation

The SDM must be installed to the vehicle according to SI procedures

before performing these steps.

TIP: Be careful

not to rotate the connector excessively when installing the connector

into position. Maintain proper alignment during the installation process.

1. Align and install the SDM connector onto the SDM.

2. Push the slide retaining lock fully closed to lock the SDM connector

onto the SDM.

TIP: If the slide

retaining lock is difficult to push, squeeze the center of the yellow

harness connector housing, to overcome a slight plastic interference

fit during the slide retaining lock assembly step.

3. Push in the red CPA into the SDM connector.

IMPORTANT

TIP: Refer

to the appropriate SIR section in SI for the complete procedure.

This may involve installing other vehicle components removed for

access to the sensing and diagnostic module (SDM).

TIP: Before

applying power to the SDM, make sure it is securely fastened, with

the arrow facing toward the front of the vehicle.

Enable the SIR system. Refer to SIR Disabling and Enabling Zone

in SIR.

The AIR BAG indicator may remain ON after the SDM has been replaced.

DTC B1001 may set, requiring the SDM part number to be set in multiple

modules. If the indicator remains ON after enabling the SIR system,

perform the diagnostic system check and follow the steps thoroughly

to ensure that the SDM is set properly. |

-

Thanks to Wesley Wood

|

figure 2 |

|

figure

3

|

| return

to Table of Contents |

|

| Do

Not Swap BCMs |

Although

most of us have done it occasionally, using parts from other vehicles

for test purposes has never been recommended. As vehicle systems become

more integrated, there are many instances where this practice is unacceptable.

In some cases installing parts from one vehicle into another will have

a negative effect not only on the test component(s) but on other components

in the vehicle. In some circumstances, this can lead to replacing components

that functioned perfectly before the test.

The following information applies to one specific instance -- the 2004

Colorado and Canyon pickups.

When diagnosing conditions in systems that involve the Body Control

Module (BCM), some technicians take a diagnostic shortcut by swapping

a known-good BCM into the vehicle being diagnosed.

IMPORTANT: DO

NOT swap the BCM from one vehicle to another for any reason.

First, this is not an acceptable procedure. Always follow the diagnostic

steps presented in SI.

Second, in the case of the Colorado/Canyon, swapping the BCM will cause

the following to occur:

- The radio will lock up.

- The Powertrain Control Module (PCM) will reset the Oil Life System

to 100.

- The PCM will set a P0315 (crank variation learn).

TIP: If a P0315

is set, you must run the crank variation relearn using the Tech 2 to

relearn the crank variation parameters.

The PCM will retain these conditions even if the original BCM is put

back into the vehicle. The radio will unlock, however.

IMPORTANT: DO

NOT swap the BCM from one vehicle to another for any reason.

-

Thanks to Devin Koski |

|

return

to Table of Contents |

|

| Parking

Brake Cable Noise |

This

information applies to Venture, Montana, and Silhouette models. During

2003, the rear parking brake cable retainer was repositioned to eliminate

rattle concerns. In some cases it may result in a metallic noise from

the left rear. This may be more pronounced on vehicles that do not have

electronic load leveler control, option G67. The parking brake cable

retainer is positioned directly above the rear trailing arm axle tie

rod and in some circumstances, contact may occur. If you encounter this

condition, install retainer part number 10408652. This park brake cable

retainer will avoid contact with the tie rod.

TIP: On vehicles

equipped with G67 load leveler, make sure the parking brake cable does

not rub on the position sensor or associated wiring. It may be necessary

to add conduit or tape to protect the wiring.

- Thanks to Tom Geist |

| |

| return

to Table of Contents |

|

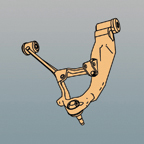

| Interchangeable

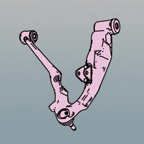

Control Arms |

Engineering has changed the design of the lower control arm used on

C/K HD trucks and the HUMMER H2.

The original A-shaped arms for the C/K HD were p/n 12475475/76 and 88982348/49

for the H2. The service arms for all vehicles are now the V-shaped arms.

The V-shaped arms are direct bolt-in replacements and require no special

treatment; they simply look different. The new V-shaped arms are p/n

15103878/79 for the C/K HD and 15103880/81 for the H2.

TIP: These are

the production as well as service part numbers and should not be mixed.

The bushing rate for the H2 arm is much firmer than that of the C/K

HD.

-

Thanks to Steve Love and Dan Stress

|

Service

V Arm |

C/K

|

15103878/79 |

| Service

V Arm |

HUMMER

H2 |

15103880/81 |

|

Original

Service

A Arm |

C/K |

12475475/76 |

| Original

Service

A Arm |

HUMMER

H2 |

88982348/49 |

|

|

|

|

return

to Table of Contents |

|

| XLR

HVAC After-blow |

A new software version for the HVAC module is available on the XLR to

update the functionality of the after-blow. The following procedure

allows you to offer this update to the customer.

TIP: After-blow permits

the HVAC blower to run for a pre-determined time period after the ignition

is turned off, to assist in drying the evaporator, to minimize odor.

Before programming, follow these steps to check the current software

status.

1. In Tech 2 Diagnostics, follow this path.

- 2004

- Passenger car

- Cadillac

- Y

- Vehicle Control Systems

- Computer/Integrating Systems

- ECU Identification Information

- HVAC

- Module Information 2

2. Observe the part numbers listed in Module Information 2. If the Software

Part Number displayed is 00BACD05 or the Calibration ID number displayed

is 00BACD06, perform steps 3, 4 and 5. If the Software Part Number displayed

is 00BAE5EA or the Calibration ID number displayed is 00BAE5EB, go directly

to step 5.

3. Go to TIS terminal and perform SPS calibration download procedure

for HVAC.

4. Go back to the vehicle and download new software into the vehicle.

5. Perform the Afterblow Enable Procedure in HVAC Systems-Automatic,

to enable after-blow on the HVAC module.

-

Thanks to Trish Zambo and Nolan Steinert |

|

|

|

return

to Table of Contents |

|

| Tire

Hoist Mechanism |

On

2003-04 C/K trucks, If the spare tire hoist has been fully raised without

a spare tire in place, the secondary latch mechanism may have become

engaged. If this has occurred, the hoist will not lower and the following

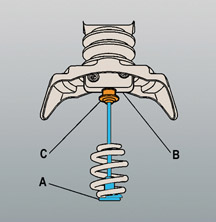

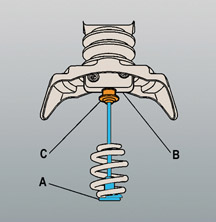

procedure will have to be performed. Refer to figure

6 for parts identification.

Turn the hoist shaft counterclockwise until approximately 15 cm (6 in)

of cable is exposed (A).

While holding the latch pin (B), fully depress the latch button (C)

and release the secondary latch from the hoist assembly. Some side-to-side

and/or up-and-down movement may be necessary to disengage the latch

mechanism.

Continue turning the hoist shaft counterclockwise to lower the hoist

the rest of the way.

- Thanks to Dan Oden |

figure

6 |

|

return

to Table of Contents |

|

| Quad-Band

Antenna |

A

new antenna will appear on the Cadillac SRX beginning this month (fig.7).

It has a plastic base and a stubby 3-inch (7.6 cm) mast. It is expected

that this antenna will see widespread use in future model years.

The antenna is called a quad-band because it incorporates four separate

antennas into one unit:

- XM radio

- OnStar GPS

- OnStar analog

- OnStar digital

Another similar unit, the tri-band, incorporates only the three OnStar

antennas.

TIP: This antenna

is not used for conventional AM/FM reception.

The quad-band antenna is installed to the vehicle’s roof much

like the typical XM antenna, although it has multiple cables.

TIP: Do NOT apply

paint or clear coat to the radio antenna. This will damage the function

of the antenna, causing poor reception or loss of reception of the XM

digital signal.

- Thanks to Jim Hughes |

figure

7 |

| return

to Table of Contents |

|

| Creak

Noise at Low Speed |

This

information pertains to 2004 Pontiac Bonneville, Buick LeSabre and Cadillac

DeVille.

Customers may comment about a creak noise that can be heard coming from

the rear end of the vehicle when driving at low speeds and making turns.

This noise can also be heard when performing parking-lot type manuvers.

The noise may be caused by the electronic level control sensor link

ball sockets (fig. 8). Clean and lubricate

the sockets with a non-water soluble type grease to eliminate the noise.

- Thanks to Bill Metoyer

GM

Vehicle Care Lubriplate |

89021668

(89021674 in Canada) |

GM

Vehicle Care Super Lube |

12346241

(10953474 in Canada) |

|

figure

8 |

| return

to Table of Contents |

|

| Odometer

Programming |

Starting

with model year 2004, odometer information for the Grand Prix is stored

in the Drivers Information Center (DIC) instead of the Instrument Panel

Cluster (IPC). When ordering a replacement DIC for a 2004 Grand Prix,

be sure you obtain the vehicle’s mileage and provide it to the

Electronic Service Center (ESC).

TIP: The odometer cannot be programmed into the DIC in the field. The

mileage must be programmed by the ESC before sending the DIC to the

dealer.

- Thanks to Steve Falko |

| return

to Table of Contents |

|

| Pictorial

Service Information, Part 2 |

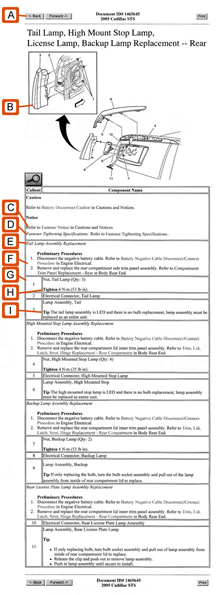

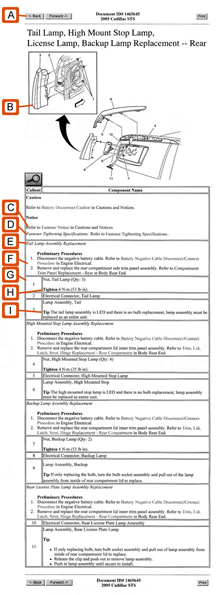

As

promised last month, here’s a sample of the new pictorial approach

being developed for SI.

A procedure printed from the SI website will typically run 2-3 pages,

considerably fewer than needed to print a procedure in the old format.

This example represents how Pictorial will look on the web version of

SI (fig. 9). Here are some highlights.

(A) Repair Title

(B) Illustration -- Disassembled view of the

components involved in the repair, shown in “vehicle context”

to indicate where they’re located. A callout number on each item

corresponds with a part in the procedure.

(C) Fastener Notice link -- Leads to standard

statement in Cautions and Notices

(D) Fastener Tightening Specifications link --

Leads to standard tightening statement

(E) Component Replacement

(F) Preliminary Procedures -- Steps that take

place before performing the repair. Lifing and Jacking is a good example.

(G) Callouts -- Each line in the repair table

contains information relevant to the numbered item shown in the illustration.

The item is named, noun first, using parts manual nomenclature.

The callouts may include supplemental information, such as:

(H) Tightening Specification

(I) Tip -- Insights and helps, as though being

shared by an experienced technician.

Caution, Notice

Special Tool Number

This new approach will be introduced this fall for the following vehicles:

- 2005 Cadillac STS

- 2005 Chevrolet Corvette

- 2005 Chevrolet Cobalt

- 2005 Mini Vans.

- Thanks to Bob Scherer |

figure

9 |

| return

to Table of Contents |

|

| Memory

Seat Modules |

This

information applies to 2004 C/K trucks with memory seat modules.

Modules are being replaced unnecessarily, perhaps due to misunderstanding

of proper operation. Here are some tips. This is a two-step process.

Enabling Using DIC

Seat memory is enabled using the DIC (Driver Information Center). When

the vehicle leaves the factory, the Seat Position Recall is set to the

OFF mode, which is the default. The Easy Exit Seat is also set to the

OFF mode, which is the default.

The Seat Position Recall moves the seat to the driver’s preferred

position according to which mode is enabled using the DIC:

OFF -- seat position is recalled when memory

button 1 or 2 is pressed.

KEY FOB -- seat position is recalled when the

key fob button is pressed

KEY IN -- seat position is recalled when when

the ignition key is installed.

When enabled, Easy Exit moves the seat rearward when the ignition key

is removed.

For the Seat Position Recall to function automatically, it’s necessary

to select either Key Fob or Key-In. For the Easy Exit Seat to function,

it’s necessary to select ON.

Setting Position in Memory

Setting the driver’s chosen seat position into memory is a separate

step. Adjust the seat to the desired position (also adjust mirrors, radio

presets, and other related functions if available), then press and hold

the Driver 1 button to store the information in memory. Repeat for Driver

2.

TIP: Observe if

the seat memories are operative before proceeding with diagnostic steps

for memory seat module replacement.

- Thanks to Paquita Bailey |

| |

| return

to Table of Contents |

|

| Power

Window Motor |

This

information from bulletin 04-08-64-003A applies to 1999-2004 full sized

trucks.

The power window motor assembly for the front doors can now be ordered

separate from the regulator. The motor and regulator assembly continues

to be available as well.

TIP: Use the

bolts included with the replacement motor. Discard the original attaching

parts.

-

Thanks to Steve Oakley |

| return

to Table of Contents |

|

| TAC

Corner |

GMDealerworld

is a fast way to access recently released recall information (fig.

10).

The following are the steps log onto GM Dealerworld and obtain recent

bulletin, campaign and GM Messenger messages:

1. Go to the web and type http://www.gmdealerworld.com/

2. Enter your User name and password.

TIP: You may

need to establish this at the dealership. The dealership has a Partner

Security Coordinator that can provide or reset passwords for Dealerworld.

3. From the home page you are able to select: Recall Information,GM

Messenger, GM VISS, Calibration ID and SI.

-

Thanks to GM Technical Assistance |

figure

10 |

| return

to Table of Contents |

|

| Problem

with Radio Setup |

After

installing a radio in a 2004 Buick Rendezvous or Pontiac Aztek, you

may receive Calibrate or Error message on the radio or possibly a DTC

after what appears to be a successful radio setup.

Use 2003 as the model year in the Tech 2 and you should not receive

an error message or DTC.

This Tech2 software problem is being investigated for a resolution using

2004 as the model year on the above listed vehicles.

-

Thanks to Phil Race |

| |

| return

to Table of Contents |

|

| OnStar

Steering Wheel Controls |

After

the radio is replaced in a 2003-04 CTS or 2004 SRX with a non-navigation

radio option, the customer may complain that the steering wheel controls

for the OnStar are inoperative. When the customer presses the SWC button

to initiate OnStar Personal Calling (OPC), the radio will display AUDIO

MUTE instead of PHONE and the OnStar ready prompt is not heard.

Using the Tech 2, go to the radio under spec

al functions, set options, optional modules, then select OnStar and

save options. It is necessary to cycle the ignition off and open the

door to disable RAP to save programming.

-

Thanks to Amy Sutherland |

| return

to Table of Contents |

|

| Loose

Crankshaft Reluctor |

This

information applies to 2001-2004 Chevrolet and GMC C/K and MD C 4/5

trucks equipped with the 6600 Duramax LB7 Diesel Engine with rough,

unstable, incorrect idle speed or stall.

After completing the published diagnostics for an engine stall or misfire

with no trouble found, and the data indicates intermittent high balance

rates on random cylinders, check for a loose crankshaft reluctor.

To inspect the crank reluctor, remove the right inner fender, crank

sensor, and crank sensor spacer. Use a blunt probe and try to move the

reluctor clockwise or counter clockwise. If the crankshaft reluctor

is found loose, repair by replacing the necessary parts and be sure

to include the alignment pins.

-

Thanks to Jack McVoy |

| return

to Table of Contents |

|

| DVD

Technical Assistance |

This

information applies to 2002-04 Pontiac Montana, Chevrolet Venture and

Oldsmobile Silhouette.

Any calls on 2002 or newer U/X Van DVD entertainment system (that involve

the part itself) should be referred to Model Electronics Technical Assistance

at 800.433.9657 (in Canada, ACDelco Superstore).

-

Thanks to Amy Sutherland |

| return

to Table of Contents |

|

| Fuel Sender

Assembly Replacement |

A

2004 Chevrolet Malibu with 3.5L LX9 engine may experience the following

driveability symptoms after a fuel sender assembly replacement.

- intermittent stall

- stalls after filling with fuel

- fuel odor, or

- EVAP canister saturated with fuel

Refer to SI Document I.D Number 1245199, Fuel Sender Assembly Replacement.

Verify that step number 2 of the installation procedure was performed

correctly: connect the ventilation harness inside the fuel tank to the

bottom of the modular fuel sender cover.

-

Thanks to Duane Raymond |

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time (new issues in bold)

Car Issues – Fix It Right The First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2001-2004 |

Aztek),

Rendezvous, Venture, Montana, Silhouette – Pop and/or Rattle

in Exhaust Down Pipe |

Follow

procedure in bulletin using clamp P/N on down pipe |

Don’t

replace converter assembly for rattle/buzz noise without completing

instructions in bulletin. |

03-06-05-003 |

2000-2003 |

LeSabre,

Park Avenue, Regal, Impala, Monte Carlo, Bonneville, Grand Prix

With 3.8L V6 Engine (RPO L36) – Loss of Coolant, Milky Colored

Oil |

Replace

upper intake manifold gasket only. |

Don’t

replace upper intake manifold assembly for coolant leak condition. |

03-06-01-016 |

2000-2004 |

All

Cars with 4T40/4T45E and 4T65E – Light On/Various Transmission

Codes Stores |

Check

transmission 20-way connector for secure connection (disconnect

and reconnect). |

Don’t

replace transmission, TCC PWM, VSS, PCS or valve body. |

02-07-30-022B |

1998-2004 |

Seville

– Heated Seat Inoperative |

Replace

only needed heating element. |

Don’t

replace entire seat cover if heated seat element is inoperative. |

01-08-50-002C |

2001-2004 |

Century/Regal

– Intermittent SES, ABS or TCS Lamp, No Crank/No Start,

Various I/P Cluster Intermittents, DTCs Set, Shifter Locked in

Park (BTSI Inoperative) |

Check

UBEC harness connectors for damage and replace damaged terminals. |

Don’t

replace UBEC, ignition switch, SDM, BCM, shifter assembly (Regal)

or intermittently inoperative clusters. |

03-08-45-004 |

2000-2004 |

Cavalier/Sunfire/Alero/Grand

Am – Inoperative Sunroof Module |

Retime

module or replace only motor for inoperative complaints. |

Don’t

replace entire sunroof module assembly. |

03-08-67-009A |

2003-2004 |

Cavalier/Sunfire

– Air Conditioning Compressor Noisy |

Inspect

for ground out conditions that can cause A/C compressor noise

complaints. |

Don’t

replace A/C compressor for excessive noise complaint without inspecting

for ground outs. |

03-01-38-012 |

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

Issue

One: Refinish brake rotor.

Issue Two: Measure for LRO |

Issue

One: Don’t replace brake rotors.

Issue Two: Don’t measure for LRO |

00-05-22-002C |

2003-2004 |

CTS

– Variable Effort Steering (VES) “Service Steering

Message,” DTC C1241 or C0450 |

Replace

only VES solenoid. |

Don’t

replace entire steering gear. |

03-02-36-001 |

2003 |

All

cars with 4T40/45E, 4T65E and 4T80E – Code P0742 |

Replace

TCC PWM Solenoid |

Don’t replace transmission, torque converter or valve body

assembly. |

02-07-30-039C |

|

| return

to Table of Contents |

|

|

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2002-2004 |

Fullsize and Midsize Pickups and Utilities – Sleepy New

Venture Gear Transfer Case Control Module |

Verify

sleepy module as primary cause, per bulletin. Reprogram TCCM with

latest software released 3/11/04. |

Don’t

replace encoder motor or transfer case. Replace module only if

C0550 DTC shows as current or history. |

02-04-21-006C |

2004 |

Fullsize Pickups – 6.6L LLY Diesel Engine Injectors |

04

LLY Duramax® fuel injector is on restriction. Contact TAC

before replacing injector. |

Do

not replace an LLY Duramax® injector before contacting TAC. |

GM

Messenger VSS20040067 |

2002-2004 |

Chevrolet Avalanche and Cadillac Escalade EXT – Cargo Covers

and Cladding Faded or Stained |

Thoroughly

clean, dry and treat components with “Armor-dillo.”

To order call 888.393.4722 or online at www.armor-dillo.net. |

Don’t

replace cargo covers for this condition. |

04-08-111-001 |

2002-2004 |

Fullsize

and Midsize Pickups and Utilities – Transfer Case CNND Labor

Operation |

Use

Labor Operation K9993 for transfer case issue on 4WD or AWD vehicle

cannot be duplicated or resolved after diagnostic efforts. |

Don’t

use Labor Operation K9992, which is for manual transmission concerns

or Labor Operation K9995, which is for automatic transmission

concerns. |

Service

VME

VSSM20030117 |

1999-2003 |

Fullsize Pickups – Rear Leaf Spring Slap Noise |

Replace

inserts and rubber washers. |

Don’t

replace leaf spring. |

03-03-09-002 |

1993-2004 |

All

Passenger Cars and Trucks – Air Conditioner Compressor Diagnosis |

Follow

SI and bulletin for diagnostic information before compressor replacement. |

Don’t

replace air conditioning compressor |

Service

VME, 10/31/03,

01-01-38-013A |

2002-2004

(models with HomeLink option) |

All

TrailBlazers, All Envoys, Bravada, Rainier with HomeLink Universal

Transmitter – Programming Diagnosis |

Use

J 41540 – GM Integrated HomeLink Tester. Follow SI and refer

customers to their Owner’s Manual. |

Don’t

replace HomeLink Transceiver without validating internal fault

recognized by J 41540 |

01-08-97-001B |

2002-2003 |

All

TrailBlazers, Envoy, Envoy XL, Bravada – Squeak/Rub/Scrub

Type Noise in Steering Column |

Lubricate

and remove material, per bulletin. |

Don’t

replace upper or lower intermediate shaft. |

02-02-35-006A |

2003-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual parts as needed. |

Don’t

replace the complete mirror assembly.

P/Ns: 15182964-65 |

03-08-64-028 |

2002-2004 |

All

TrailBlazers, All Envoys, Bravada, Rainier – Mirror Erratic

Return |

Replace

mirror actuator and reprogram module |

Don’t

replace outside mirror assembly |

02-08-64-008,

02-08-64-021,

03-08-64-033 |

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for June |

| |

|

| Know-How

Broadcasts for June |

| 10280.06D

Emerging Issues |

June

10, 2004 |

9:00

AM, 12:30 PM,

3:00 PM

Eastern Time |

| 10280.18D

New Model Features -- 2005 Pontiac, Buick and Chevrolet

Cars |

June

24, 2004 |

9:00

AM, 12:30 PM,

3:00 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

Car Issues – Fix It Right The First Time (new issues in bold)

Car Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)

Truck Issues – Fix It Right The First Time (new issues in bold)