Table

of Contents – November 2002 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

EVAP

System Operation

2000-02

Chevrolet Prizm

2003 Pontiac Vibe |

For over three decades,

vehicles have been equipped with EVAP systems. The purpose of the EVAP

system has always been to collect evaporated gasoline (for instance

during fill-up, while parked, and continuously while driving) and to

burn the vapors during normal engine operation. This is a major factor

in the reduction of unburned hydrocarbon emissions.

From the beginning, two things have remained constant. The vapors are

collected in a canister containing activated charcoal granules. And

manifold vacuum is used to draw the vapors into the engine. Everything

else about the system has been refined, modified and improved to more

effectively collect vapors, and to more precisely control when the vapors

are drawn off and burned. And the specific details of operation also

vary from one vehicle platform to another.

Today, the EVAP system is controlled by the PCM. And to meet OBD II

requirements, the latest systems are largely self-diagnostic, and able

to detect leaks as small as 0.020 inch (0.51 mm).

The EVAP system on the 2000-02 Chevrolet Prizm and the 2003 Pontiac

Vibe (fig. 1) performs the same tasks and

meets the same requirements as all other GM EVAP systems, but the control

principles are somewhat different. This is explained in detail in the

appropriate section of SI. As with all parts of SI, these sections are

revised on a continuing basis. And an upcoming Service Manual update

bulletin will itemize the latest revisions to SI.

Components

The Prizm/Vibe EVAP system consists of a vapor canister and three PCM-controlled

solenoid valves. (This is one solenoid more than most EVAP systems use.)

A fuel tank pressure sensor is used for diagnostics.

The vapor canister contains granules of carbon, which absorb gasoline

vapors on contact. When air is drawn through the granules, the carbon

gives up the vapors.

TIP: The canister

in this system is unique in that it consists of two halves, or chambers.

The chamber connected to the fuel tank is the vapor side of the canister,

and the chamber connected to the air cleaner is the air supply side.

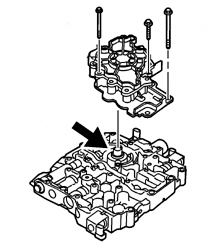

The Purge Solenoid valve is normally closed (no flow), and opens (flow)

upon command from the PCM (fig. 2). This

valve controls the application of manifold vacuum to purge the EVAP

system.

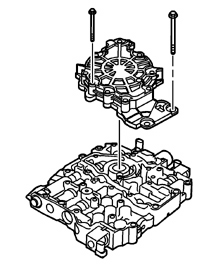

The Vent Solenoid valve is normally open (flow), and closes (no flow)

upon command from the PCM (fig. 3). This

valve allows air from the air cleaner to enter the EVAP system.

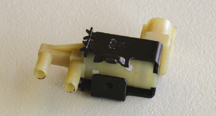

The Pressure Switching Solenoid valve, located between the two chambers

of the canister, is normally closed (no flow) (fig.

4). When necessary, it is opened (flow) by the PCM. When the

valve is open, the vapor space in the fuel tank is connected to the

canister.

Two additional valves are attached to the canister. They are operated

by spring-loaded check balls and control flow into and out of the canister.

The Evap Valve is on the vapor chamber side of the canister and the

Atmospheric Valve is on the air chamber side.

The Fuel Tank Pressure Sensor is located on the top of the fuel tank

(Vibe) or on the vapor canister (Prizm) (fig.

5).

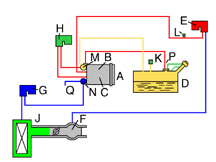

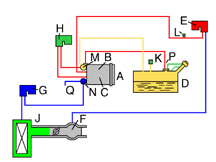

EVAP System Components (fig.

6)

A Canister

B Vapor Chamber

C Air Chamber

D Fuel Tank

E Purge Solenoid

F Manifold Vacuum

G Vent Solenoid

H Pressure Switching Solenoid

J Air Cleaner

K Fuel Tank Pressure Sensor

L EVAP Service Port

M Evap Valve

N Atmospheric Valve

P Fuel Tank Vent Valve

Vapor Canister Fitting Identification (fig.

7)

A From Vent Solenoid

B From Fuel Tank

C From Purge Solenoid

D To Switching Solenoid (2)

E From Fuel Tank (for refueling)

F To Drain Hose

Operation

During shutdown, the valves assume their normal, relaxed positions.

Parked Shutdown (Cooldown) -- Both the purge valve

and switching valve are closed and the vent valve is open. Under this

condition, as vapors form in the fuel tank, they are routed to the canister.

The calibration of the drain port passage check ball in the atmospheric

valve is set at 5.5 in. H2O, and above that pressure, air is allowed

to pass through the drain hose to atmosphere. On most other systems,

this air is allowed to pass through the vent solenoid to atmosphere.

Normal Operation After Ambient Air (Cold) Start --

When engine coolant temperature reaches 74° C (165° F), the

purge valve opens, applying manifold vacuum to the vapor chamber of

the canister. Because the vent valve is already open, manifold vacuum

draws air through the canister. This draws vapor into the engine to

be burned. The switching valve remains closed.

As the fuel in the tank is heated by the nearby exhaust system, fuel

evaporates and pressure within the tank increases.

TIP: This is

an important fact to understand. During normal operation of the system,

when the purge valve is turned on, and evacuation occurs, the pressure

in the fuel tank does not drop. In fact, it may even increase. This

does not indicate a problem during diagnosis.

After the vehicle reaches normal operating temperature, and other conditions

are met, the PCM runs a series of EVAP self-diagnostic tests. The purpose

of these tests is to identify whether each of the solenoid valves operates

as commanded, and also to determine if there are any leaks in the system.

Refer to the accompanying illustration as you read about the self-test

processes.

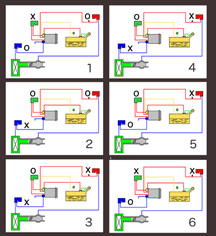

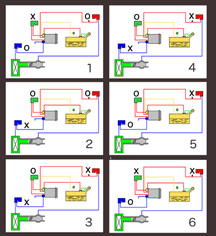

Valve Positions Indicated by X = Closed, O = Open (fig.

8)

1. Normal Operation, During Purge

2. Large Leak Test, Vacuum Increase

3. Large Leak Test, Vacuum Decay

4. Small Leak Test

5. Final Test, Vent Solenoid

6. Final Test, Pressure Switching Solenoid

1. Normal Operation, During Purge -- Before these tests

start, the vent valve is open, the switching valve is closed, and the

purge valve is open.

2. Large Leak Test, Vacuum Increase -- First, the vent

valve closes and the switching valve opens. The purge valve remains

open. This causes vacuum to increase in the entire system. Vacuum is

detected by the pressure sensor in the fuel tank. If the vacuum does

not increase, or increases beyond the specified limit, P0440, P0441,

and P0446 codes will set.

TIP: Because

more than one code will set, it’s recommended that you begin diagnosis

with the code set in Freeze Frame Failure Record.

3. Large Leak Test, Vacuum Decay -- The purge valve

is now closed, trapping vacuum in the EVAP system. Now, the pressure

sensor watches to see if, or how much, the vacuum decreases. A rapid

decrease in vacuum indicates a large leak. This will cause a code P0440

to set. This could indicate a leaky filler cap, a loose fitting, or

other large leak.

4. Small Leak Test -- If the system passes the large

leak test, the pressure sensor continues to monitor the trapped vacuum.

A slight vacuum decrease indicates a small leak. The EVAP system must

be able to identify a leak as small as 0.5 mm (0.020 inch). If a small

leak is detected, a code P0442 will set.

5. Final Test, Vent Solenoid -- Next, the system starts

to open the vent valve, admitting air into the system once again. Vacuum

should drop rapidly, indicating that the vent solenoid is working.

6. Final Test, Pressure Switching Solenoid -- Finally,

the switching valve is closed. The indicated drop in vacuum is now not

as rapid, because the pressure sensor in the tank is isolated from the

rest of the system. This indicates that the switching valve is working.

After the test is completed, the solenoid valves return to the normal

purge mode.

Once the system passes this final test, the EVAP system is declared

OK, and the necessary “PASSED” flag sets in the PCM.

If the system fails any step of the self-test, diagnostic codes will

set. SI contains the necessary steps to locate the cause(s) of the code(s).

Diagnostic Tips

IMPORTANT: Perform

the necessary diagnostic steps before replacing any components.

If you find it necessary to use the J-41413-200 EVAP Tester (the “smoke

machine”), you will need to plug the canister drain hose. Use

plug J-41413-301 for this purpose. If you do not, smoke will blow from

the opening. The check ball in the atmospheric valve is calibrated for

5.5 in. H2O, while the EVAP tester pressurizes the system to about 7-13

in. H2O.

TIP: One known

place to check for leaks using the “smoke machine” was covered

in the October 2002 TechLink. This involves the corrugated plastic vapor

line between the top of the fuel tank and the vapor canister (fig.

9). It is possible that the O-ring seals used in this line are

not functioning properly, or that the vapor line is not fully connected.

Remember, when the system is purging, with the purge valve open, pressure

in the fuel tank does not drop as it does in other systems, and actually

may increase. This is normal.

The Tech 2 contains several Service Bay tests, to expedite the diagnostic

process.

The EVAP Purge/Seal Function Test allows you to simulate

the leak portion of the test.

TIP: This test

applies only to the Pontiac Vibe.

The test is performed with the engine running. At first the Tech 2 controls

all three solenoid valves to see if it is possible to apply vacuum to

the entire system, then it seals the system to see if it will hold vacuum.

This checks valve operation and also checks for leaks.

The Check Mode is most often used while driving the

vehicle to duplicate the customer concern.

TIP: This test

applies both to Prizm and Vibe.

TIP: It’s

important to capture and save any DTC or Freeze Frame information on

the Tech 2 before entering the Check Mode. All DTC and Freeze Frame

information is cleared when Check Mode is entered.

Using Check Mode temporarily makes the EVAP system much more sensitive

to problems, so diagnostics will run quicker. It also temporarily turns

all B codes into A codes, so the MIL will illuminate right away if a

condition occurs.

- Thanks to Harry Cleaver, Frank Clark and Jeff Strausser |

figure

1 |

figure

2 |

figure

3 |

figure

4 |

figure

5 |

figure

6 |

figure

7 |

figure

8 |

| |

| |

|

figure 9 |

| |

| return

to Table of Contents |

| |

| Service

Administrative

Messages on SI

|

http://service.gm.com

is fast becoming the one-stop-shopping place for Service

Information.

The following are now available to you in SI:

- Service manuals

- 2003 Owners Manuals

- Bulletins

- Service Administrative Messages (US)

- Campaigns

- Preliminary Information

- Service VMEs (US)

Here’s a little more detail on the latest addition, Service Administrative

Messages.

Whenever GM sends out a Service Administrative Message over GM ACCESS,

it will also be put on SI. You will no longer have to wait for the message

to be relayed to you through your dealership’s communication system.

You will have direct access to it through SI.

There are several ways to access the Service Administrative Messages.

If you know the number

-- simply use the SI Number Search feature. You must type VSS followed

by the Service Administrative Message number.

If you have already “built”

the vehicle -- select Service Manuals/Bulletins, then

use the keyword search. This will present you with a list of all documents

in SI that use the keyword, pertaining to the specified vehicle. The

Service Administrative Messages will be at the bottom of the list.

You also have another option if you have already “built”

the vehicle -- select Service Manuals/Bulletins, then select Bulletins

by Category (fig. 10), then select Service

Administrative Message (fig. 11). This

will present you a list of all Service Administrative Messages pertaining

to the specified vehicle.

Updates

The Service Administrative Messages will be updated following the standard

SI update schedule:

- update weekly on Internet

- update bi-weekly on broadcast

- update on CD whenever issued.

- Thanks to Bob Savo, Lisa Scott and Mark

Stesney |

figure

10 |

figure

11 |

| return

to Table of Contents |

|

| TechLink

Website Renovated |

During

the last month, we’ve renovated the TechLink website. You can still

find it at http://service.gm.com, fourth link.

In addition to a new look, you’ll also find some new easy-to-use

features.

First, the opening page (fig. 12) allows

you to view everything in any of four languages: Spanish, German, French,

and of course English. You can return to this page at any time to quickly

select a different language.

On most Internet service providers, you will notice that the new website

downloads much quicker than before. For you techies, it’s because

we’re using simple HTML format, so you won’t need Acrobat

Reader to view it.

Navigation is simple, and mostly intuitive. And all four languages work

exactly the same way. All the control buttons are grouped at the top of

the page. At present, several buttons are reserved for upcoming features.

You will notice that the current month’s issue of TechLink now appears

as a single, scrollable document. You can reach any article by clicking

on its title in the table of contents (fig. 13),

or simply scroll to it. Illustrations are shown in the left hand margin

and are keyed to colored references in the text. You can enlarge any illustration

simply by clicking on it.

And some good news for those who like to print articles for later reference.

Simply drag to highlight whatever you want to print, then press the print

button on your browser. Be sure to click on Selection. You can quickly

print just one article, or the whole issue.

Finally, we’ve retained the archive of every TechLink published

since January 2000. These are being presented in the format in which they

first appeared, which means that some issues will still require Acrobat

Reader..

- Thanks to Mark Stesney |

figure

12 |

figure

13 |

| return

to Table of Contents |

|

Know-How Broadcasts

for December

|

| |

|

| Know-How

Broadcasts for December |

Emerging

Issues |

December

12 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

Technology

Close-Up |

December

19 |

9:00

AM, 12:30 PM,

3:30 PM

Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

| Water

in AIR System |

Some

1999 - 2001 Jimmy, Blazer, and Bravada vehicles with the L35 4.3 L engine

may experience a repeat DTC P0410 with evidence of water in the AIR

pump. If there is evidence of water in the AIR pump, the pump must be

replaced.

If the pump has been previously replaced, verify that the inlet and

exhaust hoses are connected correctly before performing any additional

diagnosis. Figure 14 shows the correct

hose connection. Repeat failures have occurred because of these hoses

being switched.

TIP: The inlet

port on the pump is marked IN. As the hoses lie unconnected, it is very

possible to assume that the reverse hose connection is correct.

If the hoses are connected correctly or this is the first repair of

this concern on the vehicle, the source of the water could be either

from the exhaust or the inlet side of the pump. To determine if the

water originated from the exhaust side, follow the SI diagnosis for

P0410 (Document ID 554347).

TIP: When you

are at the step for testing the vacuum solenoid for proper operation,

be sure to command the pump off and verify that the vacuum goes to zero.

If not, the cause may be a stuck-open vacuum solenoid. Replace as necessary.

If you do not find an issue with the exhaust side of the system, water

may be getting into the AIR system through the inlet hose and/or the

pump itself. To prevent this, cut the existing inlet hose near the bend

and attach a 2 foot (.6 m) length of heater hose, using a coupling (fig.

15).

TIP: For 1999

and early 2000 vehicles you will need 5/8-inch (15.9 mm) heater hose

and coupling. For late 2000 and early 2001 you will need a 3/4-inch

(19 mm) heater hose and coupling.

Route the hose along the right side of the engine compartment, ending

at the evaporator core housing. Cut the hose at a 45° angle, with

the angle pointing downward. This is a dry area, and it prevents kinking

of the inlet hose, which can cause a restriction.

The exhaust check valves are also a source of water entry into the AIR

pump. This can be diagnosed by inspection of the water found in the

AIR pump. If the water has a yellow tint and has an exhaust odor, replace

both check valves. Replacement of the shut-off valve is also recommended,

due to the caustic nature of the exhaust water, which can cause failure

of the diaphragm.

To insure no water enters the pump at the pump itself, add silicone

sealer to the grommet at the wire harness leading into the pump.

-

Thanks to Marty Case and Frank Tornambe

AIR

System Operation

The secondary

air injection (AIR) system helps reduce exhaust emissions at startup

by forcing fresh, filtered air into the exhaust stream to accelerate

catalyst operation.

The vehicle control module (VCM) provides a ground for the AIR

pump relay, which energizes the AIR pump and AIR solenoid. The

AIR solenoid applies engine vacuum to the shut-off valve, allowing

it to open. With the pump running, pressurized air flows from

the pump, through the shut-off valve, through a check valve on

each bank, and into the exhaust stream.

The control module monitors the pre-catalyst HO2S, and if insufficient

flow is detected, a P0410 DTC will set. Insufficient flow may

result from water in the system, as described above. |

|

figure

14 |

figure

15 |

| return

to Table of Contents |

|

| Typical

Power Accessory Port

or Cigarette Lighter Removal |

This

procedure may be used to remove a cigarette lighter or accessory port

if the standard method in SI does not work.

To review, here’s the standard method.

Remove the power accessory port fuse. Then remove the power accessory

port socket by placing one side of the T portion of J-42059 Cigarette

Lighter Socket Remover into the tab window. Angle the other side into

the opposite tab window. Pull the power accessory port socket straight

out.

If the standard method fails to remove the socket, use the following alternate

method.

Insert a small grinding tool with a cutoff wheel into the socket (fig.

16). Remove the plastic latches in the 3 mm (0.11 in.) square windows.

With the tabs removed, use J-42059 as directed above to remove the socket.

Remove J-42059 from the power accessory port socket. Then, disconnect

the electrical connector from the power accessory port.

And finally, use your index finger to pull out the power accessory port

retainer.

- Thanks to Scott Burns |

figure

16 |

| return

to Table of Contents |

|

| Park

Brake Spring Kits |

Park

brake spring kits are available for rear disc brakes to eliminate the

need to order park brake shoe kits to service broken retainers.

88936340 for 97-2002 Classic S/T pickup and utility trucks.

88935962 for 1999-2003 2500 and 3500 C/K trucks, G vans and Hummers.

TIP: Clips will

soon be available for 1500 C/K utility and pickup trucks.

- Thanks to Dan Oden |

| return

to Table of Contents |

|

| Vibe

A/C Lack of Cooling |

On

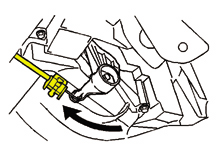

the Pontiac Vibe, the A/C temperature control is cable operated (fig.

17). In the case of a customer concern of insufficient cooling,

check and adjust the cable. The procedure is located in SI, document 841682.

Check this adjustment before replacing the compressor.

- Thanks to Jeff Strausser |

figure

17 |

| return

to Table of Contents |

|

| |

Owners

of 1999-2002 Chevrolet Blazers, S-10 Crew Cabs, GMC Jimmys, Sonoma Crew

Cabs and 1999-2001 Oldsmobile Bravadas may comment that their vehicle

will not start after sitting for 24 hours. Customers may also comment

on a number of other symptoms:

- open cruise control fuse

- blower motor runs intermittently

- battery drain

- headlamps remain on

- headlights dim very slightly for a moment while driving at night

- endgate glass release inoperative

Chafed wires under the driver and passenger seats may cause these conditions

(fig. 18).These wires carry battery voltage.

If the wires are damaged, it can lead to open fuses, or circuit breakers,

and/or battery discharge. On base vehicles, passenger seat wires are located

under the carpet.

To correct these conditions, repair damaged wires and replace any fuses

or open circuit breakers.

- Thanks to Christopher Lee |

figure

18 |

| return

to Table of Contents |

|

| Door

Switch Module Service |

Use

care when replacing a door lock and side window switch module on 2003

Chevrolet and GMC full size pickup or utility.

To avoid damaging the trim panel, it’s necessary to remove a screw

that retains the switch module to the trim panel.

This is covered in SI documents 849812 and 849813.

- Thanks to Steve Arendt and Greg Mousseau |

| return

to Table of Contents |

|

| 1999-2001

Cadillac Catera Transmission Control Module (TCM) DTCs P0601 and P0602 |

When

diagnosing DTCs P0601 or P0602 set in the TCM, do not attempt to program

the TCM. The TCM is not programmable and new replacement TCMs do not

require programming. After replacing a TCM, clear all DTCs, using the

Clear Eng/Trans DTC Info function on the scan tool. After replacing

the TCM, if a DTC P0602 sets in the engine control module (ECM), clear

all DTCs using the Clear Eng/Trans DTC Info function on the scan tool.

If the DTC resets, update the ECM programming with the latest calibration

available. The service manual information database has been updated

to address this concern in SI.

- Thanks to Michael G. Van Houten |

| return

to Table of Contents |

|

| Folding

Mirror Will Not Lock in Outboard Position |

The

electrically operated folding mirrors on 2003 C/K trucks are normally

folded in or out using the mirror control switch, when the mirror selection

rocker switch is positioned at the mid-point.

You may encounter an electrically folding mirror that will not lock into

the outboard position.

These mirrors are placed in the inboard position at the assembly plant.

If the mirror is manually moved outboard, it will not lock. It must be

moved electrically.

TIP: Be sure the

pre-delivery technician is aware of this procedure. Folding the mirror

outboard manually during PDI can lead to improper mirror operation.

If this condition occurs, move the mirror back inboard manually, and then

electrically position it outboard.

Your customers can encounter the same situation if they manually move

the mirrors.

- Thanks to Tom Mannering |

| return

to Table of Contents |

|

| Vibe

Key Cutting Information |

To

duplicate a Pontiac Vibe key, use key blank p/n 88972631 and one of

the key cutters in the accompanying chart. These key cutters are available

from GM Dealer Equipment at 1.800.468.6657

- Thanks to Jeff Strausser

| Supplier |

Function |

Part

Number |

Description |

| Ilco |

Hand Operated

Code Cutting

* Accessory Kit |

74-MK1-P26

74-MK1-TO-AE-01 |

Exacta Cutter

& Case

Kit - Pontiac VIBE |

| Ilco |

Machine Duplicating

|

74-045-110VAC

|

Heavy Duty

Duplicator |

| Ilco |

Machine Duplicating

and Code Cutting |

74-029A-GM

74-029A-TOY2 |

Combo Key Duplicator

& Key Code Cutter Kit - Pontiac VIBE |

| Ilco |

Computerized

Duplicating and Code Cutting |

74-ULTRACODE

|

Ultracode Code

Cutter & Duplicator |

| Curtis |

Computerized

Duplicating and Code Cutting |

425-9100021 |

Curtis PC+ |

Available

through GM Dealer Equipment

1-800-GM-TOOLS (1-800-468-6657)

* (Numerous Exacta Kits available for all GM products) |

|

|

|

| return

to Table of Contents |

|

| REMINDER

New Vehicle Prep -- Corvette Magnetic Selective Ride Control |

Magnetic

Selective Ride Control (RPO F55) is available on 2003 Corvettes. When

the ignition is turned off, the dampers offer very little damping. So,

plastic stuffers are inserted in the dampers for shipping from the factory

(Techlink, June 2002).

The stuffers must be removed during new

vehicle prep. Failure to do so will result in customer

dissatisfaction with the vehicle’s ride quality. Refer to bulletin

02-03-11-002 for complete details.

You can recognize the presence of Ride Control three ways:

- Ride Control button on console

- Corrugated dust boots on dampers

- Yellow tabs protruding from dust boots

To remove the stuffers, lift the vehicle to allow the wheels to hang

free. Reach from below, behind the tire. Compress the dust boot and

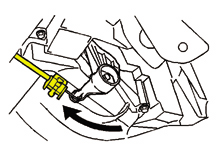

pull the yellow tab to remove the stuffer (fig.

19).

TIP: There is a stuffer on each damper, front and rear.

After removing the stuffer, be sure to pull the dust boot down to cover

the upper end of the damper tube (fig. 20).

- Thanks to Brad Thacher

|

figure

19 |

figure

20 |

| return

to Table of Contents |

|

| Search

Tip for Locating Product Information (PI) Documents on SI |

Since

June 17, 2002, it has been possible for you to search for PI documents

on SI. However, some people are experiencing difficulties.

Here are some tips.

After entering SI, you must click on the blue line that says click

here to enter a Vehicle Identification Number (VIN).

Next, input the vehicle’s VIN in the space provided. Be sure to

include all 17 characters. Then click on Submit.

Next, choose Service Manual/Bulletins.

When the next screen comes up, you will see a keyword search box. Do

not type anything in this box. The keyword search is not available for

PI documents. Instead, look at the list at the bottom of the screen.

Locate the line that says Preliminary

Information and click on it (fig.

21).

You will now see a list of all PI documents that pertain to the VIN

you input. You can then select any document for viewing (fig.

22).

- Thanks to GM Technical Assistance |

figure

21 |

figure

22 |

| return

to Table of Contents |

|

| 4T65E

Automatic Transmission

Pump |

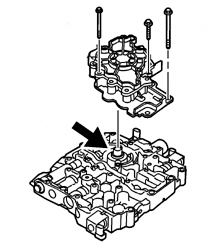

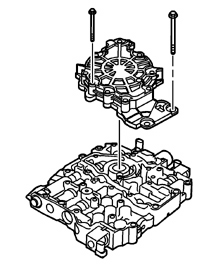

When

servicing the 4T65E automatic transmission, you may encounter two parts-compatibility

issues. These involve the valve body and transmission oil pump.

Starting July 15, 2002 (Julian date 196) all 2002 and 2003 4T65E automatic

transmissions have been built with a three-piece oil pump. The service

valve body is specific to the pump design.

The two-piece oil pump design has the oil pump rotor support in the valve

body (fig. 23). The first-design oil pump

part number 24221299.

The three-piece oil pump design has the oil pump rotor support in the

oil pump (fig. 24). The second-design oil

pump part number 24225894.

Part number questions for the valve body should be directed to Partech.

2002 and 2003 4T65E automatic transmissions built before July 15, 2002

(Julian date 196) could have been built with a first- or second-design

oil pump.

The two-piece oil pump design and valve body and three-piece oil pump

design and valve body are NOT interchangeable, because the pressure regulation

and calibration are different.

- Thanks to GM Technical Assistance |

|

figure

23

|

|

figure

24 |

| return

to Table of Contents |

|

| Bulletins

- October, 2002

This review

of service bulletins released through mid-October lists the bulletin

number, superseded bulletin number (if applicable), subject and models. |

00

– General Information

02-00-89-016; Policy Reminder on New and/or Remanufactured GM Service

Replacement Parts During Warranty Period; 2003 and Prior GM Passenger

Cars and LD Trucks, Hummer H2

01 – HVAC

02-01-39-005; HVAC System Inoperative for a Drive Cycle, Poor HVAC System

Performance in High Ambient Temperatures (Update HVAC Control Module

Software); 2002-03 Chevrolet TrailBlazer, EXT, GMC Envoy, XL, Oldsmobile

Bravada

03 – Suspension

01-03-10-010A; replaces 01-03-10-010; Inspection of Tire and Wheel Size

Prior to Diagnosis of Transmission Shifts, Poor Performance, Speedometer,

Cruise Control Concerns; 2001-02 Chevrolet, GMC Sierra with Duramax

Diesel Engine and Allison Transmission

02-03-09-002A; replaces 02-03-09-002; Intermittent Boom, Rumbling Noise

and/or Disturbance Heard in Passenger Compartment While Driving at Highway

Speeds (Replace Rear Coil Springs); 2002-03 Chevrolet TrailBlazer, GMC

Envoy with Rear Coil Springs

04 – Driveline Axle

02-04-95-001; Revised Differential Overhaul (11.5 Inch Axle) Procedure;

2001-02 Chevrolet Silverado, GMC Sierra Pickup Models

05 – Brakes

02-05-22-004A; replaces 02-05-22-004; Trailer Brakes Applied when Headlights/Park

Lamps are On, Brake Controller Illumination (Modify Brake Controller

Wiring Harness); 2002-03 Cadillac Escalade, EXT, Chevrolet Avalanche,

2001-03 Chevrolet Silverado, Suburban, Tahoe, GMC Sierra, Yukon, XL,

2003 Hummer H2

02-05-26-001; Rear Parking Brake Shoe Retaining Spring Clip Service

Kit for Drum-in-Hat (DIH) Equipped Vehicles; Specified 1998-2003 vehicles

06 – Engine/Propulsion System

01-06-04-018A; replaces 01-06-04-018; Intermittent Malfunction Indicator

Lamp (MIL) and PCM DTC P1404 (Recalibrate PCM); 2001 Buick Century,

Chevrolet Impala, Malibu, Monte Carlo, Venture, Oldsmobile Alero, Silhouette,

Pontiac Aztek, Grand Am, Grand Prix, Montana with 3.1L or 3.4L Engine

(VINs J, E -- RPOs LG8, LA1)

02-06-01-023A; replaces 02-06-01-023; Oil Leak at Oil Cooler to Engine

Block Mating Surface (Replace O-rings, Apply Sealant); 2001-03 Trucks

with 6.6L Duramax Diesel Engine (VIN 1 -- RPO LB7)

02-06-01-029; Needle Bearings Found in Oil Pan (Replace Rocker Arms);

Specified vehicles 1998-2003 with 4.8L, 5.3L, 5.7L or 6.0L V8 Engine

(VINs V, T, G, S, U -- RPOs LR4, LM7, LS1, LS6, LQ4, LQ9)

02-06-02-008; New Engine Coolant Fill Procedure; 2003 Chevrolet Express,

GMC Savana with 4.8L, 5.3L or 6.0L Gen III V8 Engine (VINs V, T, U --

RPOs LR4, LM7, LQ4)

02-06-04-046; Service Engine Soon Light On Intermittently and DTC P1441

Stored (Reprogram the PCM); 2002 Chevrolet Cavalier, Pontiac Grand Am

with 2.2L Engine (VIN 4 -- RPO LN2)

02-06-04-047; Revised Eelctronic Ignition (EI) System Diagnosis; 2002

Chevrolet TrailBlazer, GMC Envoy, Oldsmobile Bravada with 4.2L Engine

(VIN S -- RPO LL8)

02-06-04-048; Revised DTC P0540; 2001-02 Chevrolet Silverado, GMC Sierra

Pickup Models with 6.6L Engine (VIN 1 -- RPO LB7)

02-06-04-049; Revised DTC P0201 -- P0208; 2001-02 Chevrolet Silverado,

GMC Sierra Pickup Models with 6.6L Engine (VIN 1 -- RPO LB7)

07 – Transmission/Transaxle

99-07-30-016A; replaces 99-07-30-016; Diagnostic Information for Intermittent

Transmission Downshift, Slip, Busy/Cycling TCC or Noisy Cooling Fan;

2003 and Prior LD Trucks, Hummer H2 with Automatic Transmission

02-07-30-029A; replaces 02-07-30-029; New Powertrain Quality Cener for

Engine and Transmission Assembly Replacement; 2003 and Prior Passenger

Cars and LD Trucks, Hummer H3

02-07-30-032; Allison Transmission Control Module Fast Learn Procedure

Update Required After Transmission Repairs; 2002-03 Chevrolet Silverado,

GMC Sierra with Allison 1000 Series Automatic Transmission

08 – Body and Accessories

01-08-46-008A; replaces 01-08-46-008; Information on Upgrading Factory

Installed ONStar Generation 2.0 Equipped Vehicles to Generation 2.6;

Specified 2000-01 Vehicles with Factory Installed OnStar

02-08-49-007; Center Console Lid Hard to Open or Close (Lubricate Center

Console Lid Latch); 1999-2003 Chevrolet Silverado, Suburban, Tahoe,

GMC Sierra, Yukon, XL with Split Front Seats (RPO AE7)

02-08-49-008; Latch Replacement -- Instrument Panel (IP Compartment)

Procedure; 2000-03 Chevrolet Malibu

02-08-64-020; Passenger Door Outside Rearview Mirror Vibration (Install

New Reinforcement Bracket); Specified 1997-2001 MD Tilt Cab Models

09 – Restraints

02-09-40-003; Passenger Seat Shoulder Belt Too Tight or Cinches Up (Replace

Passenger Seat Belt Retractor Assembly); 2002 Chevrolet TrailBlazer,

EXT, GMC Envoy, XL, Oldsmobile Bravada

02-09-40-004; Front Seat Belt Buckles May Interfere with Door Panels

(Relocate New Buttons on Webbing); 2000-02 Chevrolet Monte Carlo

02-09-41-002; Air Bag Lamp On, Passenger Air Bag Indicator Always Reads

OFF, DTC B0092 Set (Repair Passenger Presence System PPS Sensor Harness);

2003 Cadillac Escalade, EXT, Chevrolet Avalanche, Silverado, Suburban,

Tahoe, GMC Sierra, Yukon, XL with Sensor Indicator Inflatable Restraint

Front Passenger/Child Presence Detector (RPO ALO) |

| return

to Table of Contents |

|

|

| |

|

|

|

| |

|

|

|

| |

|

|

|

|