|

|

Note: Clicking

on any picture or illustration will open a larger version of that art.

|

|

Removing

Transseal Protective Film |

Numerous

GM vehicles, including the Cadillac XLR and Chevrolet Corvette, are

delivered to the dealership with Transseal® protective film on most

horizontal surfaces (fig.1). Bulletin 03-08-51-001

has been released to provide instructions for removing this film.

Transseal

film is installed early in the manufacturing process and protects the

vehicle surfaces during assembly as well as during shipment and storage

(fig. 2).

TIP: For continued

protection, leave the film on the vehicle until it’s prepped for

delivery to the customer (up to 6 months) (fig.

3).

For satisfactory removal, follow the instructions in the bulletin completely

and carefully. Here are some of the important highlights. See the bulletin

for details.

The film releases easily from the paint at an ambient temperature between

60°F and 85°F (16°C and 29°C). If the vehicle has been

parked in the sun, place it in the shade and allow the painted surfaces

to cool to this temperature. The film may tear into small pieces if

you attempt to remove it without allowing it to cool.

TIP: For extreme

conditions (film has been on a long time, is dirty or is difficult to

remove by hand), the bulletin suggests soaking the film with water,

then applying Murphy Oil Soap or equivalent with a woolen mitt

(fig. 4). Washing is particularly important when the film is

contaminated by railroad dust or other grit (fig.

5). Gritty film can flop over and contact the painted surfaces,

causing scratches.

The film must be thoroughly wetted with cool water. Never use hot water.

Use a standard tap water from a garden hose, or a pressure washer within

a range of 1000-2200 psi (6900-15000 kPa).

When wetted, the film’s appearance turns from clear to milky,

indicating that the release agents have been activated and the film

can be removed.

Perhaps the most effective method of removing the film is to peel a

corner back to break the seal (fig 6),

allow water to penetrate under the film (fig.

7), then peel with one hand while directing the water with the

other (fig. 8).

Small particles of film that remain on the surface can be removed by

applyling GM OptiKleen concentrate (do not dilute). Apply the concentrate

with a clean, soft cloth to dissolve the Transseal particles.

After the film is removed, if a haze remains on the surface, simply

wash the vehicle with soap and water to provide a polished luster.

TIP: The manufacturer

offers assistance at 1.800.307.7218 (US) or 972.286.7890 (Canada).

- Thanks to Len Tillard and George Grogan |

|

figure

1 |

figure 2 |

figure

3 |

figure

4 |

figure

5 |

figure

6 |

figure

7 |

figure

8 |

| return

to Table of Contents |

|

|

| TechLink

Distribution |

Beginning with this issue, the quantity of TechLink

newsletters being sent to dealers is being changed. You will receive

either 3, 5 or 10 copies, depending on dealership size (US only).

Effective immediately, only dealers will receive TechLink. Internal

distribution within GM has ceased. Back issues will no longer be stocked

and cannot be ordered from the DealerWorld online store.

You are encouraged to begin using the TechLink website. This can be

located at http://service.gm.com.

In the Archives, you will find a PDF of each past issue of TechLink,

from October 1999 to the present issue. These PDFs can be used to make

additional b/w or color copies on your printer.

TIP: Each TechLink

is posted to the website the second week of the month of issue.

- Mark Stesney, publisher |

|

| |

|

|

Including Codes with Warranty Claims |

Various

module-based systems in vehicles are capable of providing a great deal

of diagnostic information in the form of diagnostic trouble codes (DTC).

You are requested to pass along as much of this information as possible.

TIP: See the May 2005 issue of TechLink for an

explanation of how to navigate the diagnostic information in SI.

Technicians -- Record the following on the repair order:

- technician observations

- customer comments

- diagnostic codes (B = body, C = chassis, P = powertrain, U = communication).

See the GM Service Policies and Procedures Manual, article 1.6.2.

Warranty Claims Administrator -- Enter the same information

in the comment section on the warranty claim for submission.

See the GM Claims Processing Manual, Section 4.2.g.

This information is continually analyzed by GM Engineering. This process

provides engineers with accurate, detailed information on a more timely

basis. The idea is to identify and resolve potential product concerns

as early as possible.

If you will provide applicable diagnostic codes, your observations,

and customer comments on every vehicle you repair, Engineering can begin

to better understand the root cause of the condition. |

|

return to Table of Contents |

|

| Top

Tier Gasoline Availability |

As

mentioned in the August 2004 TechLink, GM participated in developing

a Top Tier Detergent Gasoline standard, which exceeds the detergency

standards imposed by the EPA (applies to the United States only).

TIP: A running list of comforming gasoline brands

will appear in the Reference Guide section of the TechLink website at

http://service.gm.com.

Here’s a list of gasoline brands that meet Top Tier standards

as of August 15, 2004.

Chevron

Chevron has markets in 29 states in the West, Southwest and South.

QuikTrip

QuikTrip (not to be confused with Kwik Trip) operates convenience stores

and travel centers in:

Tulsa, OK

Springfield, MO

Kansas City, MO and Kansas City, KS

Wichita, KS

Des Moines, IA

Omaha, NE

St. Louis, MO and St. Louis, IL

Atlanta, GA

Dallas-Ft. Worth, TX

Phoenix, AZ

Bartlesville, OK

Miami, OK

Vinita, OK

Columbia, MO

-

Thanks to Jay Dankovich |

| |

| return

to Table of Contents |

|

| BCM

Setup |

IMPORTANT: This

information applies only to the 2004-05 Chevrolet Malibu and 2005 Pontiac

G6.

When you are setting up a new BCM using the Tech 2, a screen will ask

you:

Do you want to set up a new BCM?

If you answer YES, the screen will read:

Controller

is locked.

Select ENTER to continue . . .

IMPORTANT:

When you see the “Controller is locked” screen, do not assume

that this means you are unable to change options, and press EXIT. If

you do this, and then replace the BCM, this is an unnecessary replacement

of an otherwise good BCM.

You must press ENTER to continue. The screen will read:

Would you

like to Configure Options Only

Answer YES to proceed.

- Thanks to Steve Apking |

|

|

| return

to Table of Contents |

|

| Idle

Flare or Decel Stall |

This

condition may affect 2002-04 vehicles with 4 cylinder 2.2L engine

(VIN F - RPO L61) (Chevrolet Malibu, Cavalier, and Classic, Oldsmobile

Alero, Pontiac Grand Am and Sunfire).

Some owners may comment about an engine idle flare when the clutch is

depressed. Also, some owners may comment about a low speed engine decel

stall when coming to a stop.

The flare is caused by the vehicle entering stall-saver mode when the

clutch is depressed. The low speed engine decel stall is produced by

an interaction between the engine control software and the IAC motor.

Reprogram the PCM with the latest calibration available. The new calibration

was released beginning with TIS satellite data update version 6.0 for

2004 available June 2004. As always make sure your Tech 2 is updated

with the latest software version.

-

Thanks to Steve Oakley |

| |

| |

| |

|

return

to Table of Contents |

|

| CTS

Transmission Oil Cooler Line Fitting Service |

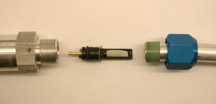

The following information applies to the 2003 through present Cadillac

CTS vehicles with automatic transmissions.

Radiators on these vehicles have two non-serviceable transmission oil

cooler (TOC) fittings that mount the in-tank cooler to the plastic radiator

end tank. These fittings are also are non-removable. A protective wall

is placed around the fitting to prevent wrench access

(fig. 9).

A threadlocking compound is used to retain the fittings to the in-tank

cooler. Any attempt to remove these fittings will damage the threads

on the in-tank cooler and damage the seal between the in-tank cooler

and the plastic radiator end tank. This can result in a coolant or transmission

oil leak and possible vehicle damage.

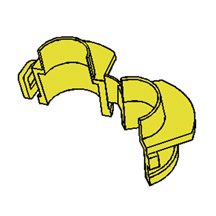

Proper removal of the TOC line requires the use of J-44827

(fig. 10) to properly disengage the TOC line from the fitting.

Refer to SI for the service procedure for correctly disconnecting and

re-connecting the TOC lines from the fittings (fig.

11).

-

Thanks to Chris Semanisin |

figure

9 |

figure

10 |

figure

11 |

|

return

to Table of Contents |

|

| Carbon

Canisters |

Carbon

canisters, on automobiles since 1970, have changed in external appearance

and size (fig. 12). But inside they all

perform the same function -- storing fuel vapors (hydrocarbons) that

would otherwise pollute the atmosphere. Vapors come from the fuel tank

(and the float bowl of a carburetor, if so equipped).

The outer plastic housing of the canister contains one or more chambers

of activated carbon pellets. The special properties of this material

allow the carbon canister to do its job.

Carbon Pellets

Carbon results when wood is heated to about 1,000° F without oxygen.

Volatile organic compounds in the wood are driven off, leaving behind

the carbon (charcoal) and the minerals (ash).

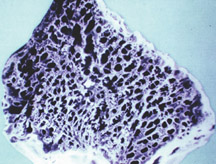

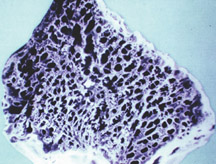

Activated carbon is treated with oxygen to open up millions of tiny

pores between the carbon atoms (fig. 13).

This material has a surface area so large that one gram may have the

surface of two to five football fields!

Activated carbon is widely used to adsorb odors or substances from liquids

or gases. The adsorbed substance is attached by chemical attraction

much like a sponge soaking up water. Fuel vapors migrate into all the

little pores in the carbon, attach themselves, and are trapped.

When the carbon adsorbs fuel vapor, an exothermic (creates heat) reaction

occurs. During a re-fueling event, the canister may have an internal

temperature of 212° F. The external temperature is closer to 150°

F, due to airflow through the canister.

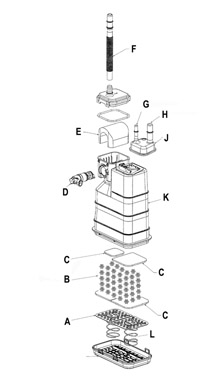

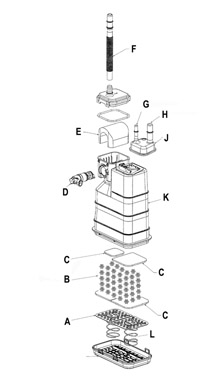

Components

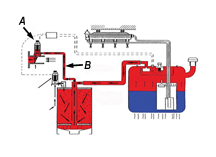

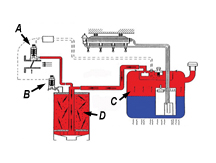

The accompanying diagram (fig. 14) represents

a typical carbon canister. The activated carbon (B) is packed tightly

into the body (K) of the canister using screens (C). A spring-loaded

(L) volume compensator plate (A) continually pushes up against the screens

that hold the carbon in place.

Leaving the carbon loose would decrease effectiveness by allowing too

much air space between the particles and would allow the carbon to move

around and pulverize.

The vent to atmosphere (F) is controlled by a solenoid (D) that is normally

open. In this diagram, the vent solenoid is integral with the canister.

A replaceable filter (E) keeps dust from intruding into the canister

and reducing its effectiveness. The liquid trap (J) consists of a cover

and a series of molded ramps that prevent liquid fuel from entering

the canister from the fuel tank vapor tube (H). Finally, vapor is drawn

from the canister by engine vacuum through the vapor purge tube (G).

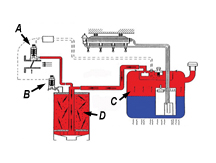

Evaporative Emission System

The carbon canister is part of the Evaporative Emissions System.

In the vapor storage mode (fig.

15), fuel vapors from the fuel tank travel through plumbing to

the canister. The amount of vapor created depends on:

- ambient air temperature

- Reid Vapor Pressure of fuel

- heat from road surface and exhaust system

- heated return fuel

During this mode, the Canister Purge Solenoid (A) is closed (unenergized)

and the Vent Solenoid (B) of the canister is open (unenergized) to the

atmosphere. Fuel vapor (C) is adsorbed by the activated carbon in the

canister (D). Any air displaced from the canister by the vapor is pushed

out the vent. Fuel vapors will not “leak” out of the vent

to any great extent due to the attraction of the vapor to the carbon.

During operation of the vehicle, the control module (PCM, VCM, etc.)

commands a purge mode (fig. 16),

in which the Purge Solenoid (A) is pulse-width-modulated, similar to

a fuel injector. The vapors are pulled by engine vacuum (B) out of the

carbon and fuel tank into the intake manifold. This resembles squeezing

water out of a sponge for re-use. The vapors are removed from the carbon’s

tiny pores, preparing it for more storage.

Things That Can Go Wrong With a Carbon Canister

Vapor system-related codes to know:

P0440 |

Evap

Emission (EVAP) System |

P0442 |

Small

leak detected |

P0446 |

System

performance |

P0455 |

Large

leak detected |

P0496 |

Flow

during non-purge |

P1441 |

Flow

during non-purge |

TIP:

Some code numbers have changed recently. P0440 became P0455. And P1441

became P0496.

Carbon canister loose in brackets – The canister bouncing

around breaks up the carbon and turns it into dust that can at times

be found in the purge solenoid. This may not set a code unless enough

carbon dust restricts the flow in the Evap system, or prevents the purge

solenoid from operating properly.

Damage incurred by foreign objects striking the canister and breaking

the canister body – This will cause major leakage during

evap testing, possibly causing a P0442 or P0455 and of course venting

vapors to the atmosphere.

Water in the canister – Water can be pulled in through

the vent solenoid if the solenoid or its vent tube are exposed to water

(such as the bed drain on a C/K pickup, Bulletin 00-06-04-024). Water

inhibits the carbon’s ability to adsorb vapor. Water tends to

stay in the carbon for a period of time even with purging. This has

a high potential of setting a P0446.

Fuel saturation – Overfilling of the fuel tank forces

fuel into the canister. Liquid fuel inhibits the carbon’s ability

to adsorb and may cause a restriction in the system, causing a P0446.

Dust and dirt contamination – Almost always pulled in

through the vent solenoid. Initially this causes a flow problem and

eventually inhibits the carbon’s ability to adsorb. A filter is

usually used in the vent path of the carbon canister to trap contamination

before it gets to the canister. The filter may be located in the canister

under a cover or remotely mounted at the end of the vent (air) tube.

It’s always located before the vent solenoid. Check SI for the

location of the filter. When a P0446 code is set, this filter and the

entire vent path should be checked for restrictions.

Insect infestation – Due to the heat generated during

adsorption, the canister becomes attractive to insects (fig.

17). Generally they nest in the vent tube of the vent solenoid

and can cause a restriction resulting in a P0446. Always check the entire

length of vent tubing for foreign material if a code P0446 is set, and

clean as necessary.

- Thanks to Randy Pearl and Paul Reed |

figure

12 |

figure

13 |

figure

14 |

figure

15 |

figure

16 |

figure

17 |

| |

| |

| |

| return

to Table of Contents |

|

| Cab

Rattle Noise |

Owners

of some 2001-05 Chevrolet Silverados and GMC Sierras may comment of

a rattle type noise coming from the rear of the cab during body twist

maneuvers or over bumps. This noise may be coming from the dealer-installed

GM Tubular Assist Bars (Nerf Bars). Several cases have been reported

were the gasket between the Tubular Assist Bar and the body mounting

bracket were distorted and the Assist Bar had cut through the gasket,

making metal-to-metal contact with the body bracket. The gasket can

be distorted or cut by over-tightening the body bolts during installation

of the Assist Bars.

To correct this concern, replace the Assist Bar gaskets, which are included

in hardware kit 88961680 (brackets, bolts, and washers). Be careful

when installing the body bolts. Apply blue Loctite and tighten the bolts

to 91 Nm (65 lbs. ft.).

DO NOT use an air impact wrench.

- Thanks to Tom Clapham |

|

| return

to Table of Contents |

|

| Instrument

Panel Itch or Ticking Noise |

Owners of some LeSabres may encounter a creak or tick noise in the instrument

cluster area while driving over bumps. This noise is due to the mispositioned

felt strip on the top pad between the I/P and the cluster. The felt

strip is usually too far forward, toward the windshield.

To correct this condition, reposition the felt strip toward the driver

(fig. 18).

- Thanks to Bill Metoyer |

figure

18 |

|

return

to Table of Contents |

|

| Cobalt

Door Upper Front Trim Panel |

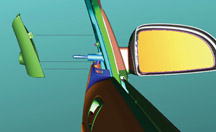

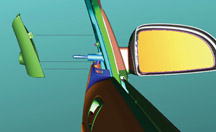

On the 2005 Cobalt, the method for attaching the Side Door Upper Front

Trim Panel (“shark fin”) depends on the trim level.

On base models with manual outside rearview mirror, the extension is

removable by pulling the trim piece straight back from the door; it

is held in place by clips (fig. 19).

On uplevel models with power outside rearview mirror, the extension

is heat-staked to the door trim panel. There is no provision for removal.

Attempting to do so will result in damage to the door trim panel.

-

Thanks to Ed Kay |

|

figure

19 |

|

return

to Table of Contents |

|

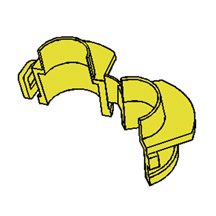

| Duramax

Diesel Injector Tips |

Attention

to detail is important when working with Duramax diesel injectors. Perform

a visual inspection of the fuel line connections and the area around

the injector for corrosion and contamination before removal.

Follow the removal and installation procedures in SI, ensuring that

all areas are clean and free of dirt and contaminants before installing.

Before installing the injector, move aside any wires or other obstacles

that may interfere with installation.

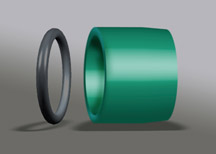

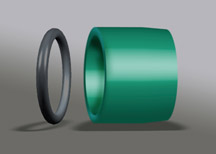

Be sure the high-pressure copper seal (A) is attached to the bottom

of the injector (fig. 20). If the seal

is damaged, it could cause a compression leak, leading to a running

condition and high imbalance rates.

Be sure the rubber O-ring (B) is seated in the mid-barrel groove on

the injector. The rubber O-ring prevents water and contaminants from

getting between the injector and the engine.

Be sure the injector and hold-down bracket are seated and in the proper

position, and the attaching bolt is torqued to the appropriate specification.

- Thanks to Art Seymour |

| |

figure

20 |

|

return

to Table of Contents |

|

| Inline

A/C Filter |

Service

Technicians Voice Concerns – GM Listens and Delivers

It’s common A/C service knowledge that, when a compressor fails,

contaminants are carried throughout the system. Thorough refrigerant

flushing is time-consuming and does not assure complete 100% removal.

Although some thermal expansion valves (TXVs) have their own screens,

they don’t have the surface area to contain compressor failure

debris. So, for years, a service in-line filter has been recommended

to prevent TXV plugging.

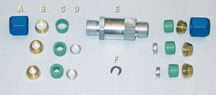

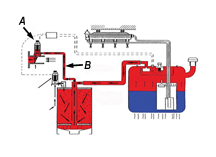

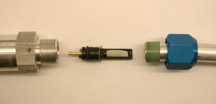

The original GM service filter (fig. 21)

effectively contained contaminant material. But, this part had several

installation shortcomings that technicians readily pointed out. These

included:

- Installation leak sensitivity -- any deviation from approved procedure

could result in

leaks.

- Installation labor -- required double installation to ensure no leaks.

- Capacity limitation -- certain compressors and systems would benefit

from additional contaminant capacity.

- Numerous models -- the parts department never seemed to have the right

unit in stock.

Realizing these shortcomings existed, GM worked with the original supplier

to redesign the filter to address all of the technicians’ concerns.

The resulting filter

(fig. 22) provides a larger capacity, universal

application, and enhanced reliability in the real-world field environment.

In late 2003, ACDelco released the redesigned filter 15-10413 (GM p/n

89016656).

A Nut

B Ferrule

C Seal

D Tube Adaptor

E Filter Body

F Orifice Retainer Clip

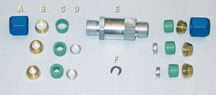

What’s different about this new service filter?

Provides a simplified, robust, leak-free installation.

The original filter design incorporated an O-ring to seal around the

A/C tube OD. Successful installation required a smooth round surface.

Technicians pointed out the obvious field reality:

- Tubes are not all perfectly round (fig. 23)

- Tube finish has surface imperfections (fig.

24)

- Installing the filter collar twice to assure proper seating is inefficient

and time-consuming.

The redesigned filter replaces the single O-ring with a robust tapered

sealing sleeve (fig. 25). The seal provides

10 times the sealing area and greatly increases the seal’s ability

to overcome tube irregularities. The addition of slots (fig.

26) on the brass ferrule permits the ferrule to seat correctly

on the first installation and increases compression on the seal.

Increased debris containment

The redesigned filter incorporates a new screen within a new body. This

not only shortens the overall filter length but also increases the capacity

three-fold, while reducing restrictions to pressure and flow.

Universal application and ability to cover new systems

The old filter had four part numbers to accommodate two tube sizes,

with a variation of each to incorporate an 0.072-inch orifice. The new

unit is universal and fits the 5/16-inch, 3/8-inch and 1/2-inch tube

sizes common to TXV systems.

In addition, the universal unit permits reworking an existing orifice

(regardless of size -- 0.072-inch, 0.062-inch, 0.052-inch, etc.) and

incorporating it into the filter (fig. 27).

This greatly simplifies inventory and increases flexibility.

TIP: Because

of the interchangeable fittings, the filter can be used to join different

tubing sizes. It can also be used as a splice to repair a damaged tube

or to replace a damaged thread.

Overall, the new filter provides the insurance technician have been

requesting to reduce comebacks on compressor replacements -- especially

on vehicles with rear A/C systems.

- Thanks to Jim Resutek |

|

figure

21 |

figure

22 |

figure

23 |

figure

24 |

figure

25 |

figure

26 |

figure

27 |

| return

to Table of Contents |

|

| Technical

Assistance Information |

This

information applies to US dealers only and is effective as of September

13, 2004.

GM Technical Assistance Center (GMTAC) would like to be able to resolve

your concern during the first phone call. Bulletin 01-00-89-011B explains

the procedures that are now in place to help this happen.

The bulletin contains a copy of the GM TAC form, which you are required

to fill out before placing a TAC phone call. In filling out the form,

you are required to obtain specified information. A few of them are

emphasized here. See the bulletin and the form for complete details.

1. You are required to follow Strategy Based Diagnostics and include

your findings on the form.

2. You are required to provide the SI document number of the technical

issue you’re working on.

3. You are required to have the dealer code, VIN, and RO number.

Having these steps completed before you call will allow the consultant

to spend time researching the issue rather than giving out service information

that’s already available at your dealership.

TIP: When you

call TAC, a recorded message will remind you of these requirements before

you’re connected to a consultant.

TIP: SI is now

being updated every 24 hours, so the latest PI and bulletin information

is available at your dealership. And remember, a VIN is no longer required

to access PI information on SI.

The GM TAC form also contains space for you to close the TAC case when

it has been resolved. This information is important in helping TAC update

the database with the latest information, which will be useful to help

future callers with the same condition.

And finally, there’s a space for you to provide feedback on the

survey portion fo the form, regarding the assistance you received. TAC

will use this information to make continuous quality improvements.

- Thanks to Sean Garrison |

|

| return

to Table of Contents |

|

| M74

Allison LCT1000 PTO Gear Applications |

Some

2004-05 Chevrolet and GMC pickup trucks equipped with Allison LCT1000

transmissions do not have PTO (power take-off) gears installed on the

rotating housing. Instead, they have a tone ring for the turbine speed

sensor that is not able to drive a PTO.

2001-04 |

6.6

LB7 (VIN code 1) |

PTO

gear |

2001-05 |

8.1

L18 (VIN code G) |

PTO

gear |

2004-05 |

6.6

LLY (VIN code 2) pickup |

no

PTO gear |

2004-05 |

6.6

LLY (VIN code 2) chassis cab |

PTO

gear |

If a customer desires

to use a PTO on a pickup truck equipped with a LLY 6.6 engine, it will

be necessary to install a rotating housing that has a PTO gear installed

on it, p/n 29540518.

TIP: This procedure

is not covered under warranty and is at the customer's expense.

-

Thanks to Rusty A. Sampsel |

| return

to Table of Contents |

|

| Changes

To Personalization And Memory Recall |

Starting

in 2005, the mid-size Chevrolet, GMC and Buick SUVs will have a change

in personalization operation. The key fob will no longer recall seat position,

mirror position, radio presets, HVAC settings and/or DIC personalization

settings for each driver.

Vehicles equipped with memory seats RPO AAB will recall seat and mirror

positions only for driver 1 and 2. To activate the memory recall feature,

each driver will need to program the seat and mirror settings to one of

the memory positions.

The driver must select driver 1 or 2 when entering the vehicle so the

seats and mirrors can recall to the programmed position. No other personalization

features will follow the driver 1 or 2 button.

Also, the DIC will no longer display driver 1 or 2. This is a engineering

change and no repairs should be attempted.

- Thanks to Dino Poulos |

|

|

|

return

to Table of Contents |

|

| Steering

Will Not Lock |

Owners

of some 2004-05 Chevrolet Colorado and GMC Canyon vehicles may comment

that the steering will not lock when the key is removed from the ignition.

This is a normal condition. The Colorado and Canyon never had this feature.

The owner’s manual and service information were published incorrectly.

They are both currently in review and will be updated with the correct

information. Do not perform any repairs for this concern.

-

Thanks to Dino Poulos |

|

|

| return

to Table of Contents |

|

| Seatbelt

Retractor |

Owners

of some 2004 Chevrolet Corvettes may state that the driver or passenger

seatbelt will not extend from the seatbelt retractor.

If a resolution can't be found through normal diagnosis, replace the

affected seatbelt and install a new bolt (p/n 15017724) and new washer

(p/n10257765) and discard the original bolt and washer. The larger diameter

washer distributes the clamping load evenly on the lower seatbelt retractor.

-

Thanks to Paul Radzwilowicz |

| return

to Table of Contents |

|

| Tire

Scrub Noise On Low Speed Turns |

Owners

of some 1999-2005 Full Size Trucks and Utilities may experience tire

scrub noise on low speed turns (parking lot maneuvers). The steering

rod (centerlink) can be installed backwards on all trucks and utilities

with recirculating ball type steering that do not use a steering dampener.

To determine the correct installation of the steering rod, compare to

a like vehicle. In a correct installation, the steering rod should curve

to the rear, outboard of idler/pitman attachment holes and inboard of

the inner tie rods.

The idler and pitman attaching holes are tapered in only one direction.

With the steering rod installed incorrectly, the curved portion of the

rod between the idler/pitman holes and inner tie rods curves toward

the front of the vehicle. Remove and correctly reinstall the steering

rod (centerlink).

-

Thanks to Jim Will |

|

|

| return

to Table of Contents |

|

| Windshield

Upper Reveal Molding |

Some

2003-05 HUMMER H2s may have a less than perfect fit of the windshield

upper reveal molding which may contribute to wind noise in the windshield

area.

To replace the molding, you no longer have to order and replace a complete

windshield assembly. The molding, p/n 15060528, is now available through

Service Parts Operations. The labor operation is B7540 and pays straight

time. Refer to SI document number 800535 for replacement procedures.

-

Thanks to Paul Radzwilowicz |

|

|

| return

to Table of Contents |

|

Car Issues

– Fix It Right The First Time (new issues in bold) Car Issues

– Fix It Right The First Time (new issues in bold) |

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

1997-2005 |

Buick

Century, Regal – Broken

Armrest Lid Latch |

Replace

lid latch only. |

Don’t

replace console armrest lid (Regal) or front seat center storage

armrest (Century) when only latch is needed. |

03-08-49-018A |

2004-2005 |

Grand

Prix – Outside Rearview Mirrors |

Replace

mirror glass

or motor. |

Don’t

replace complete mirror assembly. |

04-08-64-009 |

2004 |

Grand

Prix – Steering, Suspension or Cradle Click Noise |

Re-torque

right steering gear mount. |

Don’t

replace steering gear or cradle. |

03-02-32-048 |

2000-2003 |

Century,

Regal, Lumina, Impala, Monte Carlo, Grand Prix, Intrigue with

3.8L L36 Engine – Coolant Leak |

Replace

upper intake manifold gasket only. |

Don’t

replace upper intake manifold assembly for coolant leak condition. |

03-06-01-016 |

2001-2004 |

Aztek,

Rendezvous (FWD), Venture/Montana/Silhouette – Pop and/or

Rattle in Exhaust Down Pipe |

Follow

procedure in bulletin using clamp p/n on down pipe to correct

rattle/buzz noise. |

Don’t

replace converter assembly for rattle/buzz noise without completing

instructions in bulletin. |

03-06-05-003 |

2000-2004 |

All

Cars with 4T40/4T45E and 4T65E – Light On/Various Transmission

Codes Stores |

Check

transmission 20-way connector for secure connection (disconnect

and reconnect). |

Don’t

replace transmission, TCC PWM, VSS, PCS or valve body. |

02-07-30-022B |

1998-2004 |

Seville

– Heated Seat Inoperative |

Replace

only needed heating element. |

Don’t

replace entire seat cover if heated seat element is inoperative. |

01-08-50-002C |

2000-2004 |

Cavalier/Sunfire/Alero/Grand

Am – Inoperative Sunroof Module |

Retime

module or replace only motor for inoperative complaints. |

Don’t

replace entire sunroof module assembly. |

03-08-67-009A |

2003-2004 |

Cavalier/Sunfire

– Air Conditioning Compressor Noisy |

Inspect

for ground out conditions that can cause A/C compressor noise

complaints. |

Don’t

replace A/C compressor for excessive noise complaint without inspecting

for ground outs. |

03-01-38-012 |

1999-2004 |

All

Cars and Trucks – Brake Warranty, Service and Procedures |

Issue

One: Refinish

brake rotor.

Issue Two: Measure

for LRO.

|

Issue One: Don’t replace brake rotors.

Issue Two: Don’t measure for LRO.

|

00-05-22-002D |

|

| return

to Table of Contents |

|

|

Truck

Issues – Fix It Right The First Time Truck

Issues – Fix It Right The First Time

|

Model

Year(s) |

Vehicle

Line(s) --

Condition |

Do

This |

Don’t

Do This |

Reference

Information / Bulletin |

2001-2003 |

Fullsize Pickups – Injector Replacement for High Flow Rates |

Use

Bulletin 04-06-04-007A for injectors with high fuel return rates.

Use Special Policy 04039 for 01-02 vehicles. |

Don’t

replace 8 injectors except for high fuel return rates. Other injector

failures are fix as failed. |

Special

Policy

04039 |

2004-2005 |

All Cars and Trucks – State-of-Charge Upon Delivery of New

Vehicle |

Check

the battery’s state-of-charge per revised PDI procedure. |

Don’t

remove and replace the battery. |

02-06-03-009A |

2003-

2005 |

Avalanche, Suburban, Tahoe, Silverado, Yukon/XL, Sierra, Escalade

– Snap/Popping Noise from

Front of Vehicle |

Slot

left side mounting holes on front crossmember

per bulletin. |

Don’t

replace crossmember. |

03-08-61-002B |

2002-2004 |

Fullsize

and Midsize Pickups and Utilities – Labor Operation Assignments

for Control Module Reprogramming |

When

submitting claims for reprogramming an electronic module, use

correct labor operation that reflects module being programmed. |

Do

not use K5364, which is for reprogramming transmission control

module (TCM), when reprogramming TCCM. |

02-04-21-006D

02-06-04-057D |

2002-2004 |

Fullsize and Midsize Pickups and Utilities – Sleepy New

Venture Gear Transfer Case Control Module |

Verify

sleepy module as primary cause, per bulletin. Reprogram TCCM with

latest software released 3/11/04. |

Don’t

replace encoder motor or transfer case. Replace module only if

C0550 DTC shows as current or in history. |

02-04-21-006D |

2002-2003 |

Chevrolet

Avalanche and Cadillac Escalade EXT – Cargo Covers and Cladding

Faded or Stained |

Thoroughly

clean, dry and treat the components with “Armor-dillo.” |

Don’t

replace cargo covers for this condition. |

04-08-111-001A

(July

2004)

|

| 2002-2004 |

All

Passenger Cars and Trucks – Air Conditioner Compressor Diagnosis |

Follow

SI and bulletin for diagnostic information before compressor replacement. |

Don’t

replace air conditioning compressor. |

01-01-38-013A

03-01-38-019

|

| 2002-2004

(models with HomeLink™ option) |

All

TrailBlazers, All Envoys, Bravada, Rainier with HomeLink Universal

Transmitter – Programming Diagnosis |

Use

J 41540 – GM Integrated HomeLink Tester. Follow SI and refer

customers to

Owner’s Manual. |

Don’t

replace the HomeLink Transceiver without validating internal fault

recognized by J 41540. |

01-08-97-001B |

| 2002-2004 |

All

TrailBlazers, Envoy, Envoy XL, Bravada – Squeak/Rub/Scrub

Type Noise in Steering Column |

Lubricate

and remove material, per bulletin. |

Don’t

replace the

upper or lower

intermediate shaft. |

02-02-35-006A

|

2001-2004 |

Fullsize

Pickups and Utilities – Servicing Wide Load Mirrors (RPO

DPF) |

Replace

individual

parts as needed. |

Don’t

replace the complete mirror assembly. |

03-08-64-028

|

|

| return

to Table of Contents |

|

|

| Know-How

Broadcasts for November |

| |

|

| Know-How

Broadcasts for November |

| November

11, 2004 |

10280.11D

Emerging Issues |

|

| November

18, 2004 |

10280.23D

To Be Announced |

9:00

AM, 12:30 PM,

3:00 PM Eastern Time |

| -

Thanks to Tracy Timmerman |

|

|

| return

to Table of Contents |

|

|

Car Issues

– Fix It Right The First Time (new issues in bold)

Car Issues

– Fix It Right The First Time (new issues in bold)

Truck

Issues – Fix It Right The First Time

Truck

Issues – Fix It Right The First Time